Warp sizing machine head

A locomotive and locomotive technology, applied in liquid/gas/vapor yarn/filament processing, textile material processing equipment configuration, etc., can solve the problems of complex locomotive structure, large space occupation, insufficient transmission force, etc. The effect of reducing the occupied space and improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings.

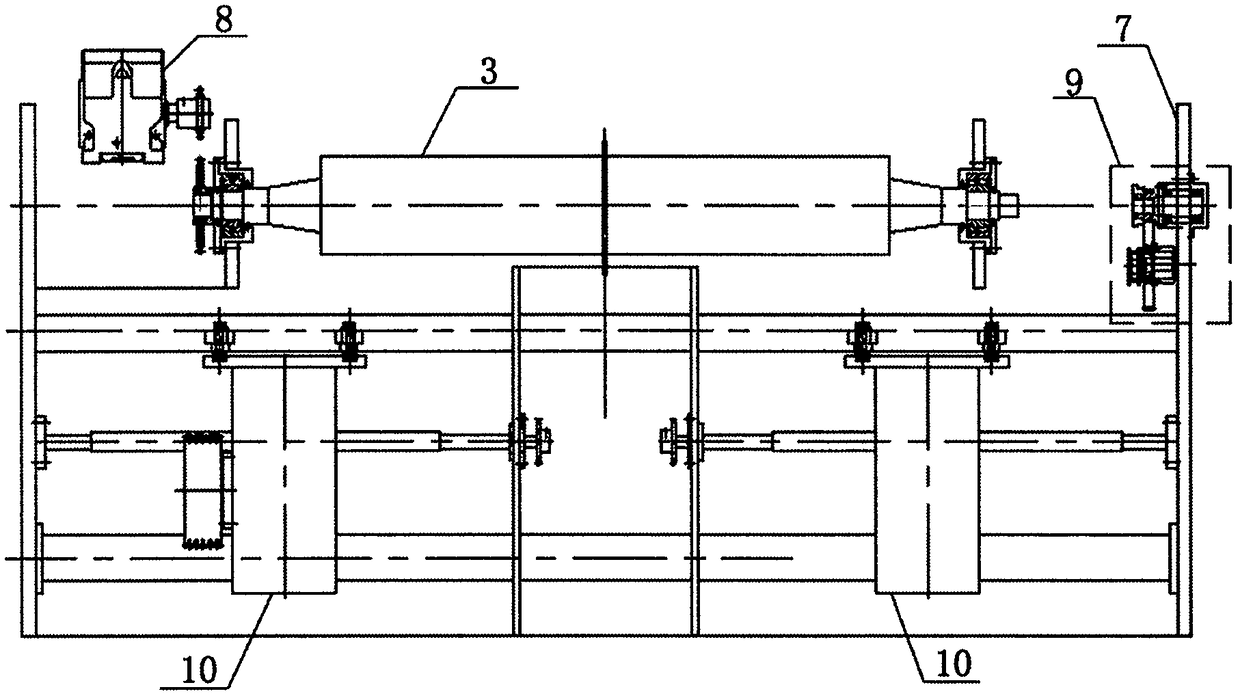

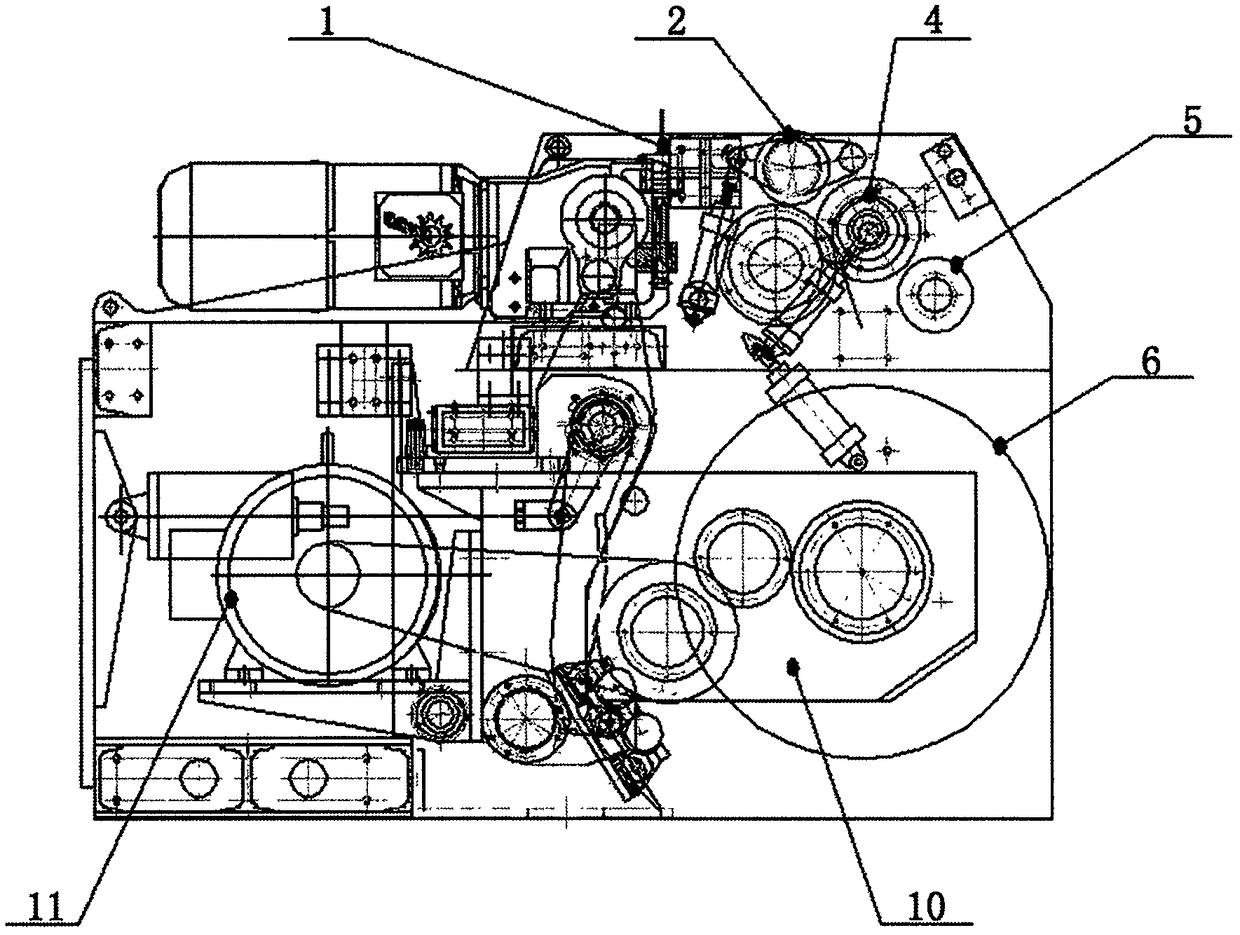

[0021] according to figure 1 with figure 2 The headstock of a sizing machine shown includes a telescopic reed 1, a length measuring roller 2, a traction roller 3, a tension roller 4, a guide roller 5 and a weaving shaft 6, a telescopic reed 1, a length measuring roller 2, and a traction roller 3. The tension roller 4 and the guide roller 5 are both arranged on the upper part between the large wall panels 7 on both sides of the vehicle head, and the weaving shaft 6 is located on the inner lower part between the large wall panels 7 on both sides. 3. In the large wallboard 7, it is connected with the reducer 8 and the motor for transmission, and a built-in reed swing mechanism 9 is arranged above the right large wallboard 7.

[0022] Above-mentioned traction roller 3 ends are 300mm to big wallboard 7 distances, and traction roller 3 roller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com