An opening and closing induction batch electrospinning device

An electrospinning, batch technology, applied in textile and papermaking, fiber processing, filament/thread forming, etc., can solve the problems of high starting voltage and low output, and achieve the advantages of low starting voltage, increasing batch, and increasing conveying speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

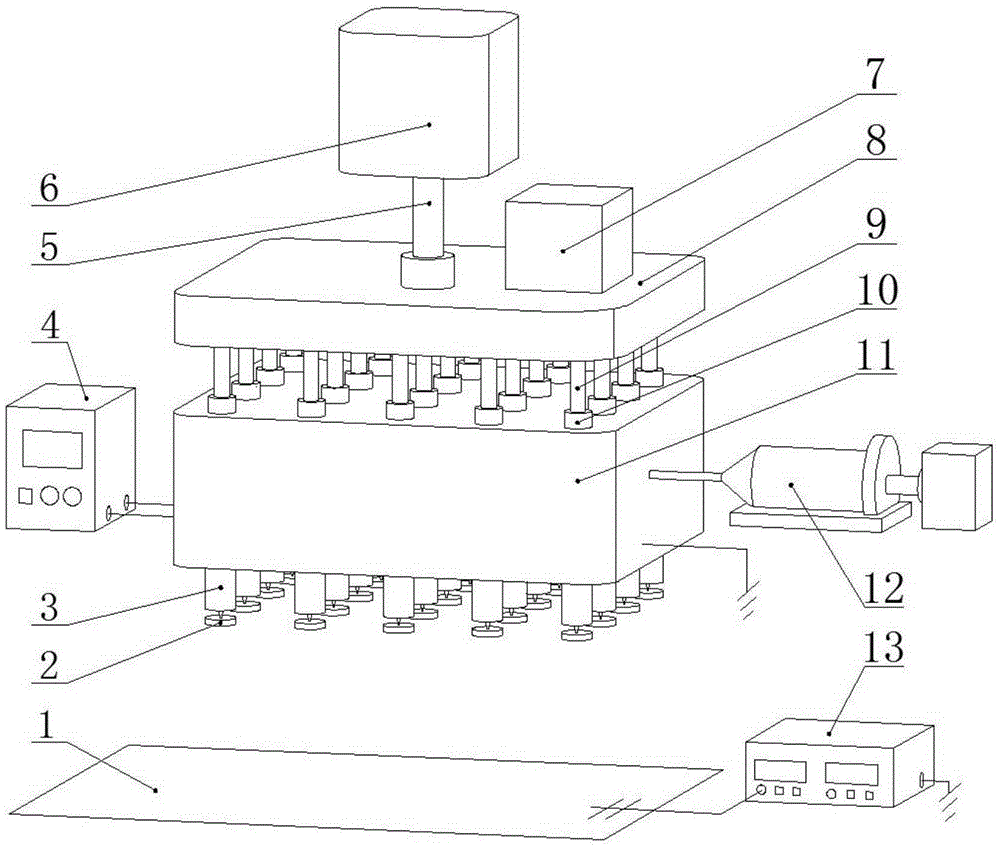

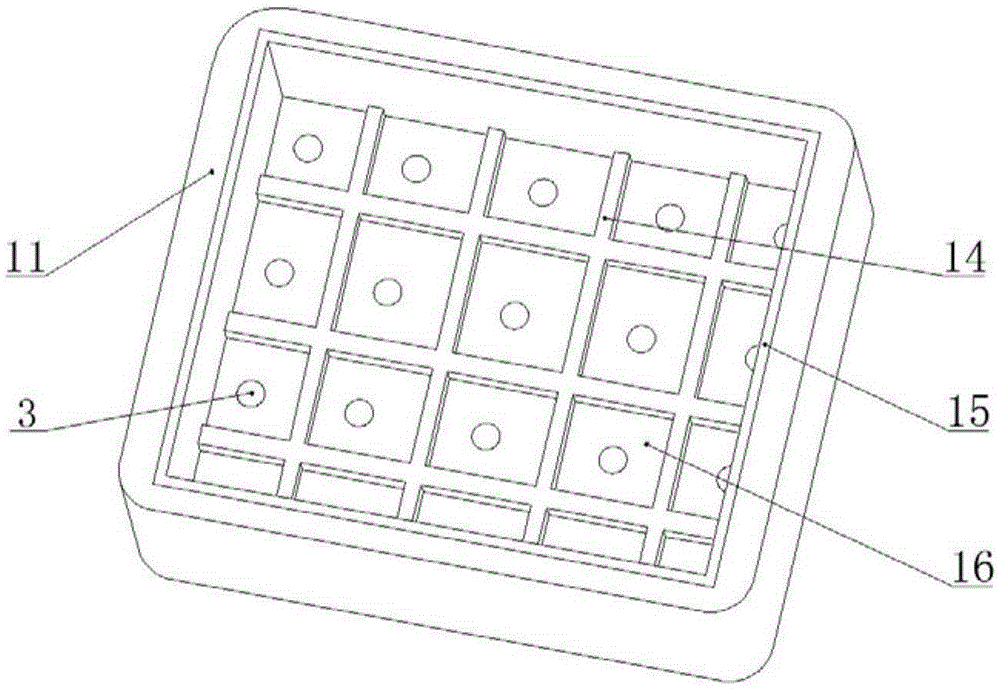

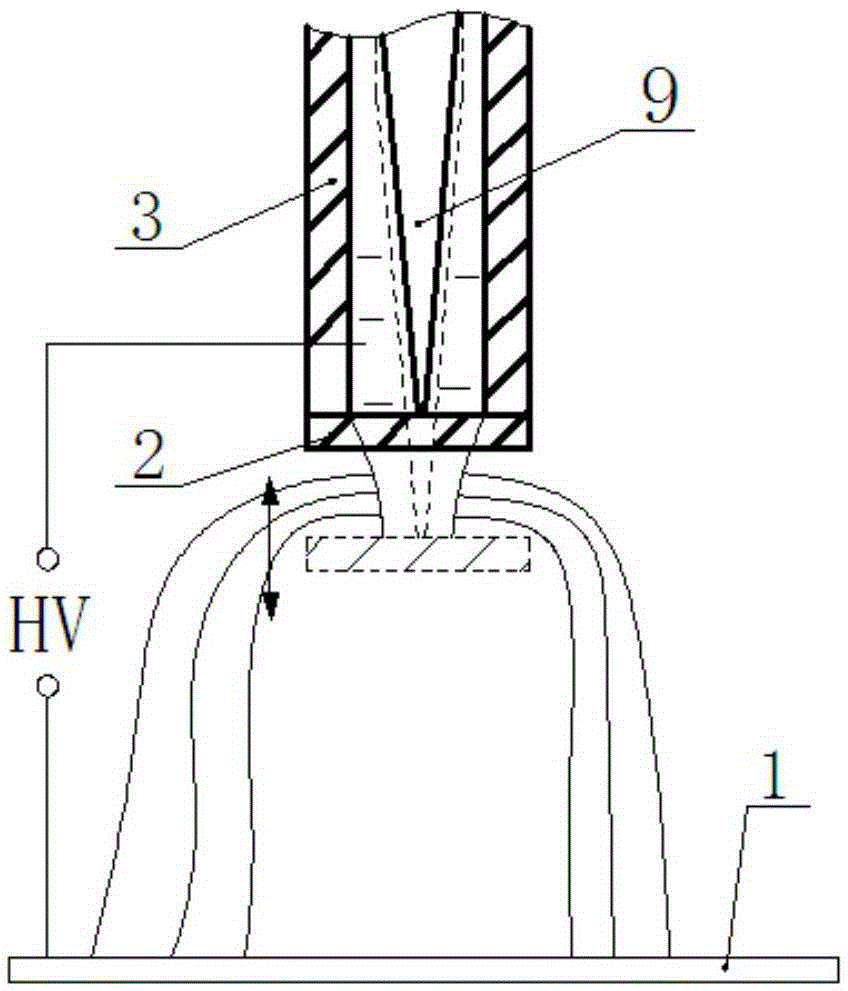

[0027] see Figure 1~3 , the present embodiment is provided with material storage box 11, liquid supply device 12, heating element (comprising inner wall heating layer 15 and inner bottom surface heating layer 16), temperature sensor (not shown), temperature control box 4, nozzle array 3, nozzle Cover 2, drive motor 7, multi-axis output box 8, vibration generator 6, conductive metal strip 14, collection device 1 and high-voltage power supply 13;

[0028] The material storage box 11 communicates with the liquid supply device 12, and the liquid supply device 12 feeds the spinning material to the material storage box 11 quantitatively and at a constant speed. The inner wall and the inner bottom surface of the material storage box 11 are laid with a heating layer (the inner wall heating layer 15 and the inner bottom surface heating layer 16), and the spinning material in the material storage box 11 is heated and kept warm. A temperature sensor (not shown in the figure) is arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com