Method for preparing pure-phase MXene by using plasma etching technology

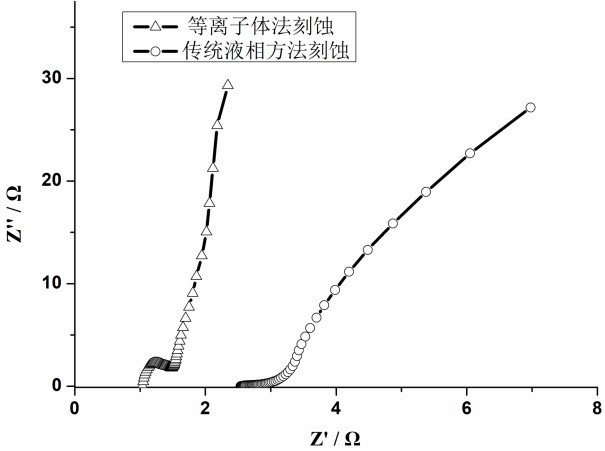

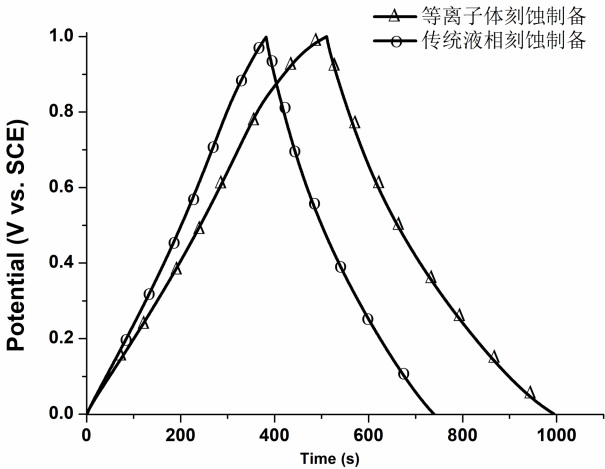

A plasma and plasma source technology, applied in the field of plasma etching technology to prepare pure phase MXene, can solve the problems of reducing MXene, unable to prepare pure phase, unable to obtain pure phase materials, etc., to maintain purity and maintain purity , Optimizing the effect of energy storage properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of method utilizing plasma etching technology to prepare pure phase MXene comprises the steps:

[0042] Step 1: The ratio of raw material powder is 2:2:1 by mass, weigh Mo powder, Ca powder and C powder respectively, totaling 30g, put them in the agate ball mill jar, and follow the mass ratio of powder: ball stone : Anhydrous ethanol ball milling medium = 1:4:1 Add ball stones and anhydrous ethanol ball milling medium, in the ball mill at a speed of 400 r / min, mix and mill for 4 hours, and the obtained uniform mixture is dried in a vacuum oven at 80°C 12h;

[0043] The second step: weigh 5g / part of the mixture obtained in the first step, place it in a stainless steel mold with a diameter of 20mm, pressurize 50MPa uniaxially, and cold press it into a cylindrical green body for use;

[0044] Step 3: Place the cylindrical green body obtained in the second step in a high-temperature tube furnace, enter a nitrogen protective atmosphere for pressureless sintering, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com