Ultrasonic machining tool with three groups of ultrasonic vibrators formed into conical structure and controlling method

An ultrasonic vibrator and ultrasonic machining technology, which is used in metal processing equipment, grinding machine parts, grinding automatic control devices, etc., can solve the problems of uneven processing residue and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The implementation and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

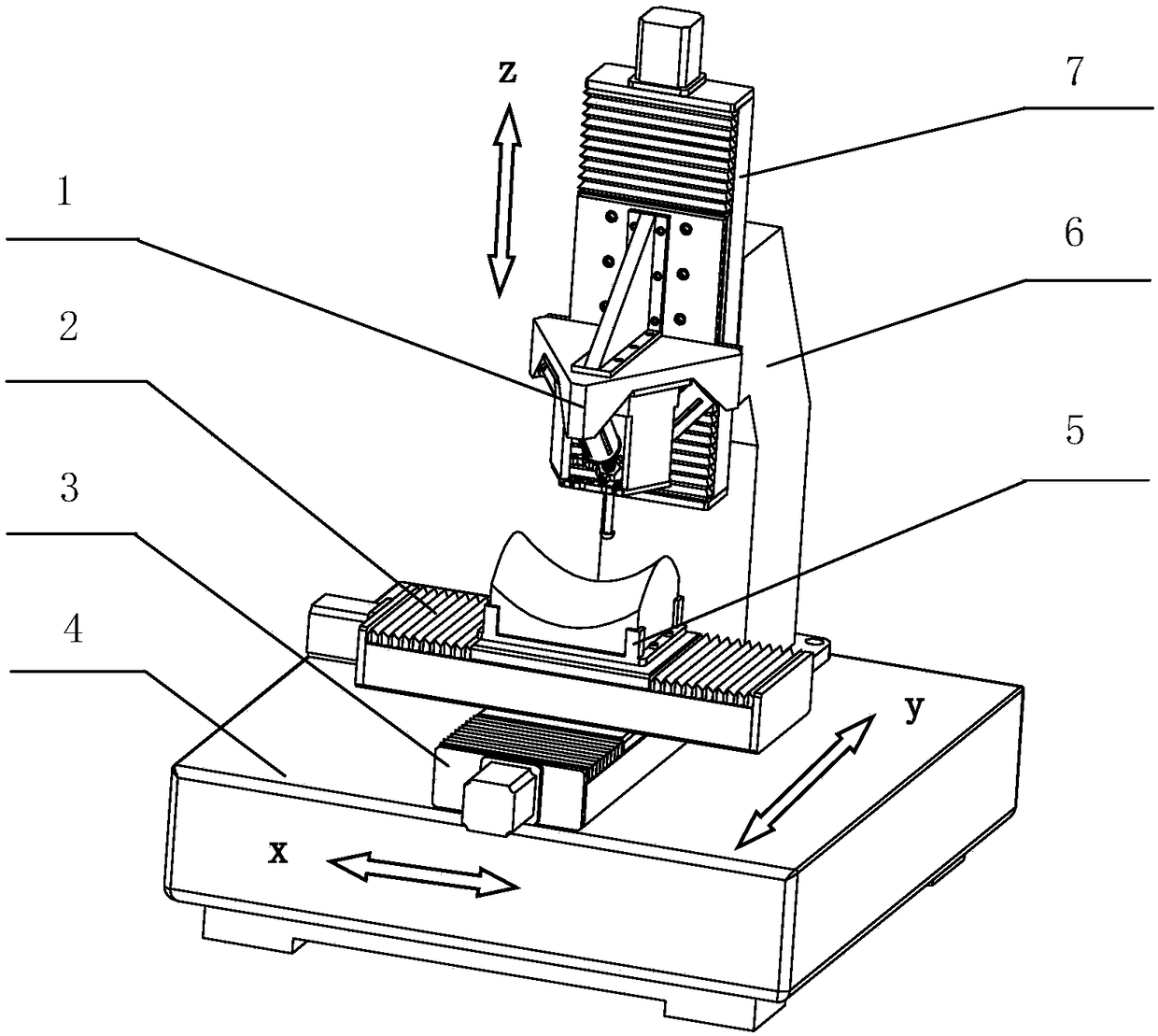

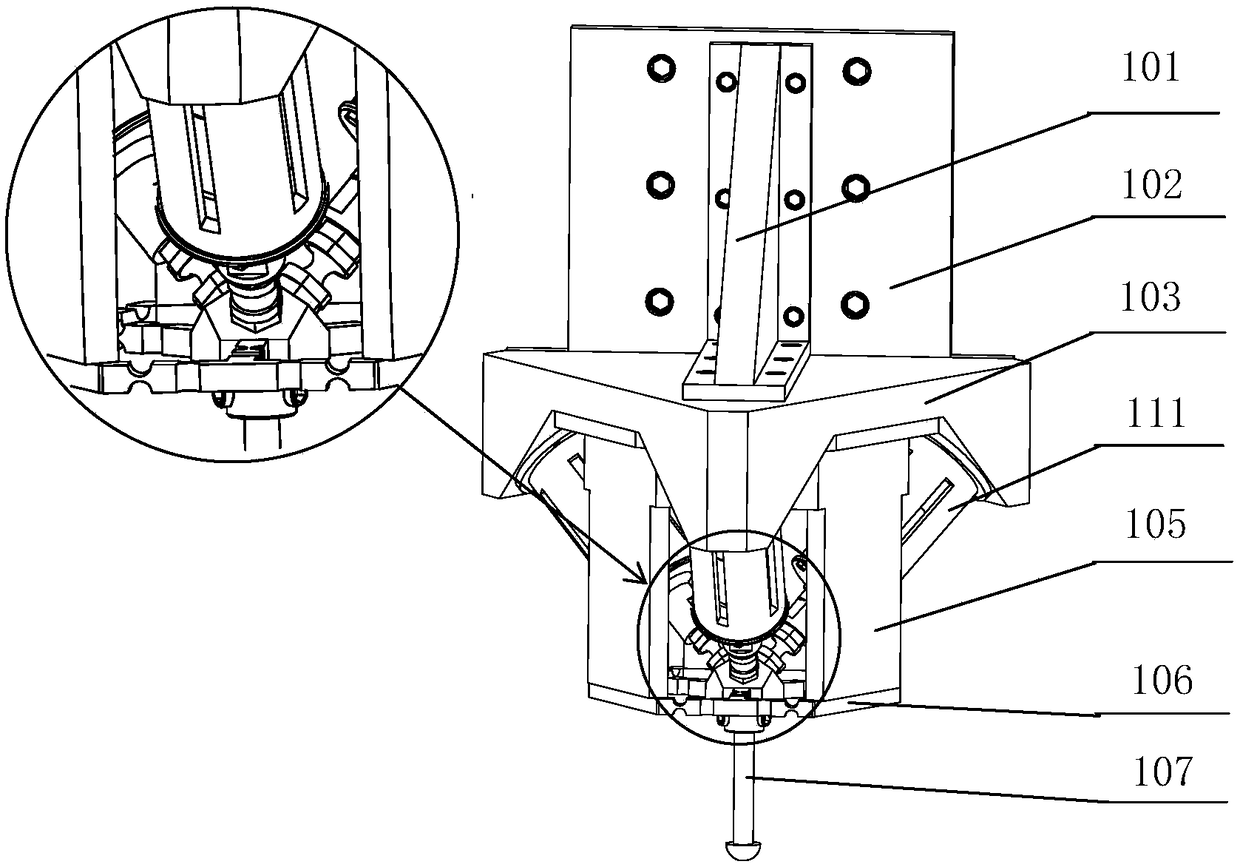

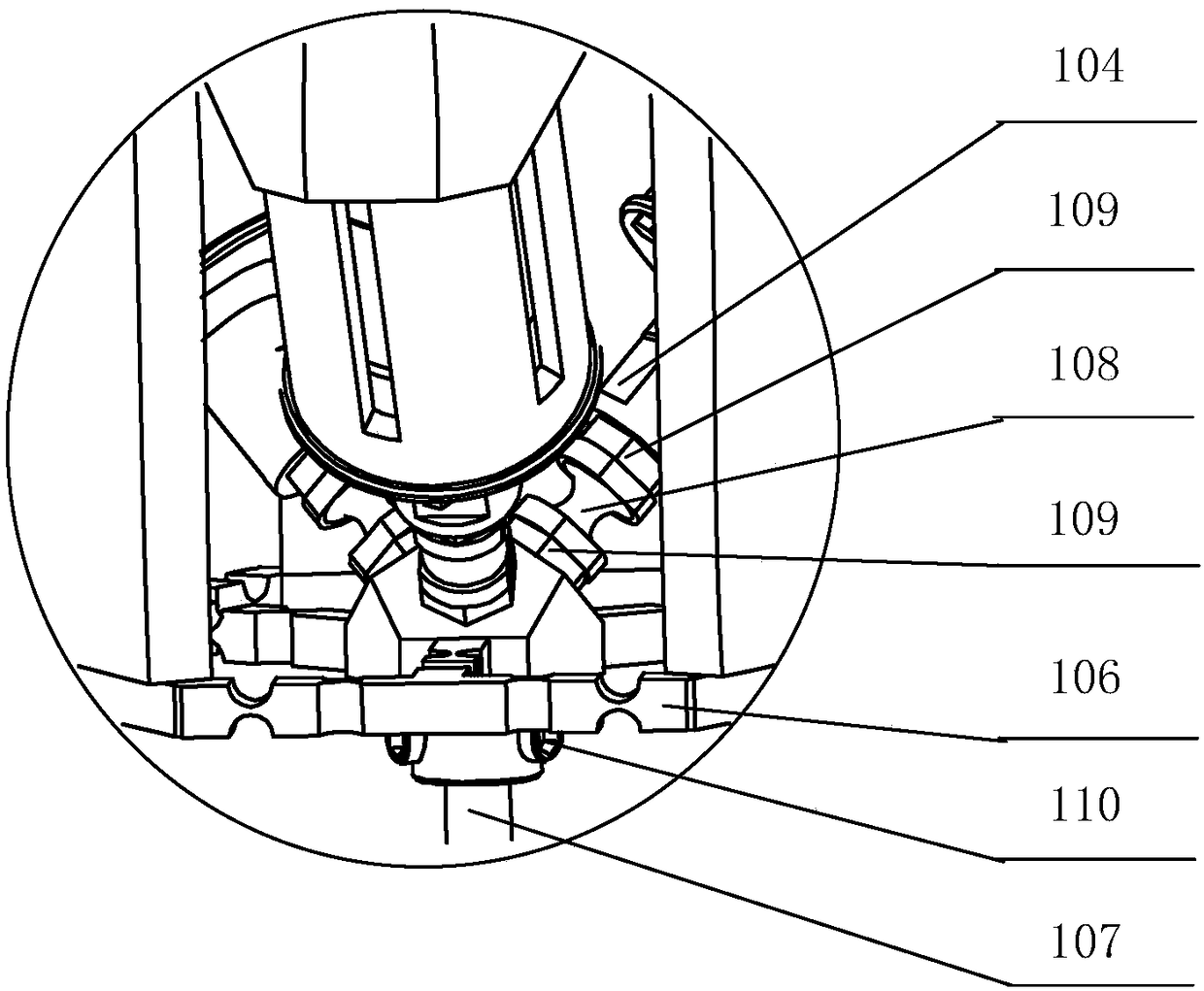

[0075] figure 1 It is a schematic diagram of the overall structure of the present invention, an ultrasonic machining machine tool with three groups of ultrasonic vibrators in a cone structure, including an ultrasonic tool system 1, a transverse guide rail 2, a longitudinal guide rail 3, a machine tool base 4, a workpiece fixture 5, and a vertical guide rail mounting arm 6 and the vertical guide rail 7, the longitudinal guide rail 3 is longitudinally fixedly installed in the middle position on the upper side of the machine base 4, the transverse guide rail 2 is laterally fixedly installed on the slide plate of the longitudinal guide rail 3, and the workpiece fixture 5 is fixedly installed on the slide plate of the transverse guide rail 2 Above, the vertical guide rail installation arm 6 is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com