A kind of silver-plated conductive aramid paper and preparation method thereof

A technology of aramid paper and Zhongyin, which is applied in papermaking, paper, physical treatment paper, etc., can solve the problems of low conductivity of conductive aramid fiber, unfavorable large-scale fine production, increased concentration of chemical reagents, etc., and achieve excellent washing resistance and Bending firmness, high electromagnetic shielding efficiency, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) A commercially available aramid paper substrate with a thickness of 0.18 mm was cut into a size of 5 cm×5 cm, soaked in a 50% ethanol solution, washed for 30 minutes, taken out and dried.

[0031] (2) The cleaned aramid paper substrate is subjected to normal temperature plasma treatment under the conditions that the nozzle height is 4 cm, the nozzle speed is 1 m / min, and the duty ratio is 80%.

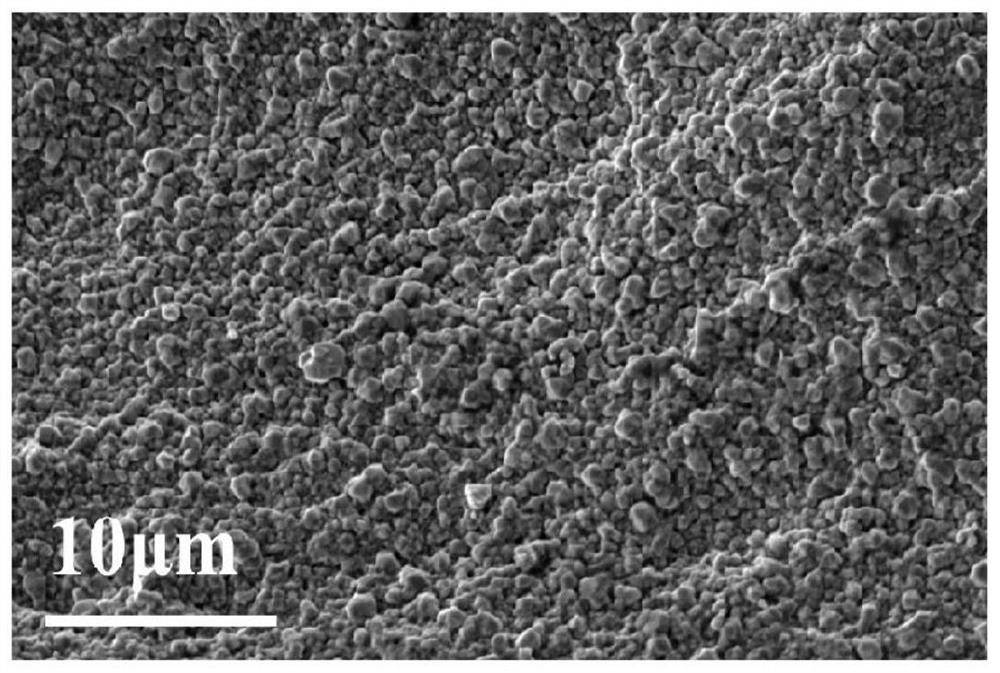

[0032] (3) Put the plasma-treated aramid paper substrate into the silver nitrate solution with a concentration of 20g / L prepared in advance, after soaking for 30min, slowly drop the glucose solution with a concentration of 30g / L into the silver nitrate solution In the solution, after the reaction was carried out for 24 hours, the aramid paper substrate was taken out, washed with deionized water for 3 times, and then vacuum-dried at a temperature of 60° C. for 24 hours to obtain silver-plated conductive aramid paper.

[0033] The electrical resistance of the conductive aramid...

Embodiment 2

[0036] (1) A commercially available aramid paper substrate with a thickness of 0.18 mm was cut into a size of 5 cm×5 cm, soaked in a 50% ethanol solution, washed for 30 minutes, taken out and dried.

[0037] (2) The cleaned aramid paper substrate is subjected to normal temperature plasma treatment under the conditions that the nozzle height is 5 cm, the nozzle speed is 1 m / min, and the duty ratio is 80%.

[0038] (3) Put the plasma-treated aramid paper substrate into the silver nitrate solution with a concentration of 15g / L prepared in advance, after soaking for 30min, slowly add the glucose solution with a concentration of 30g / L to the silver nitrate In the solution, after the reaction was carried out for 24 hours, the aramid paper was taken out, washed three times with deionized water, and then vacuum-dried at a temperature of 60° C. for 24 hours to obtain silver-plated conductive aramid paper.

[0039] The electrical resistance of the conductive aramid paper prepared in thi...

Embodiment 3

[0042] (1) Prepare a 50% ethanol solution, cut commercially purchased aramid paper with a thickness of 0.30 mm into a size of 5 cm × 5 cm, soak it in it, wash it for 60 minutes, take it out and dry it.

[0043] (2) The cleaned aramid paper is subjected to normal temperature plasma treatment under the conditions that the nozzle height is 2 cm, the nozzle speed is 1 m / min, and the duty ratio is 30%.

[0044] (3) Put the plasma-treated aramid paper into the silver nitrate solution with a concentration of 5g / L prepared in advance, and after soaking for 60min, slowly drop the glucose solution with a concentration of 10g / L into the silver nitrate solution In , after the reaction was carried out for 36 hours, the aramid paper was taken out, washed with deionized water for 3 times, and then vacuum-dried at a temperature of 60° C. for 24 hours to obtain silver-plated conductive aramid paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com