Electrochemical single cells for a battery and battery

An electrochemical, single-unit technology, applied in electrochemical generators, secondary batteries, battery cooling/heating, etc., can solve cost-intensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

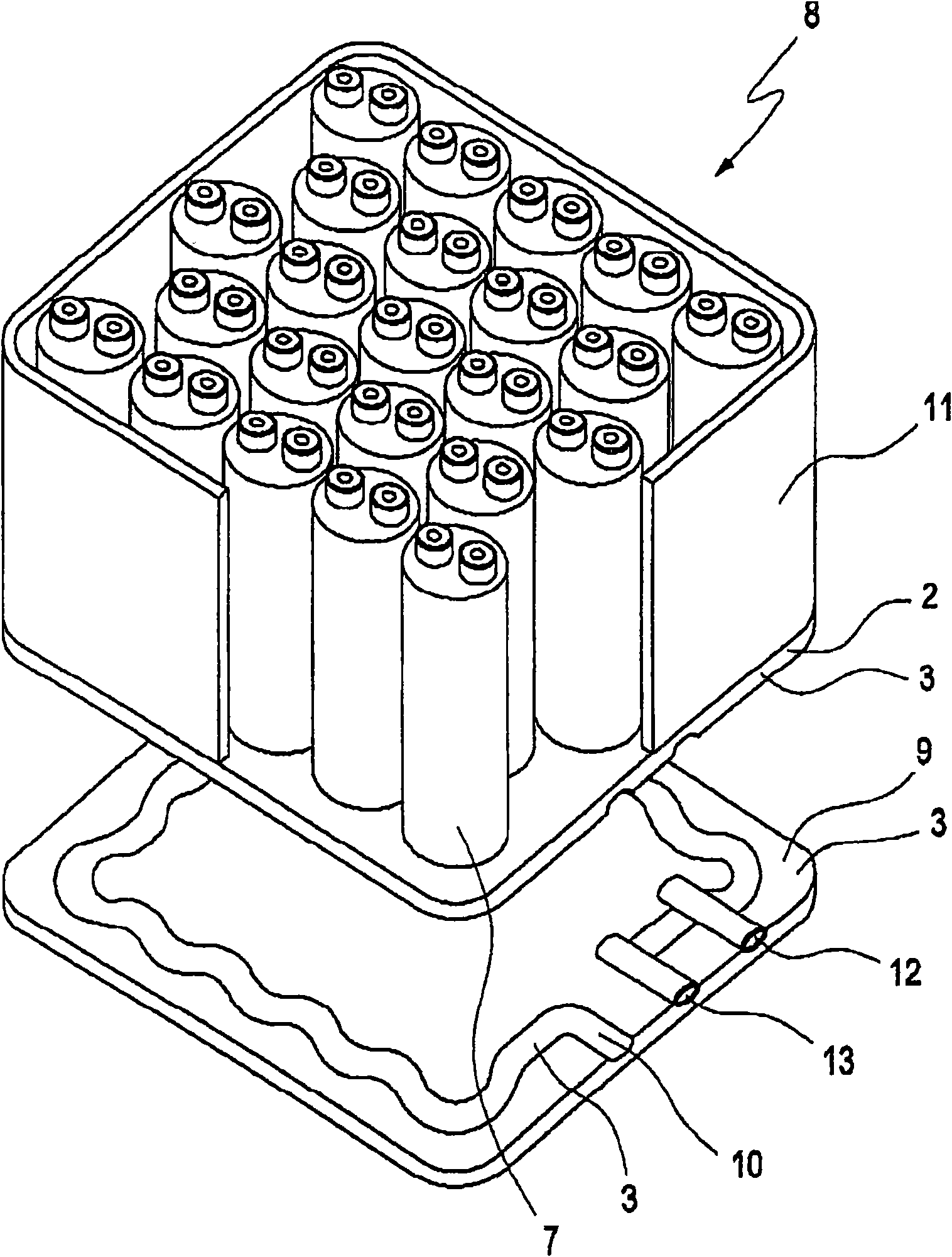

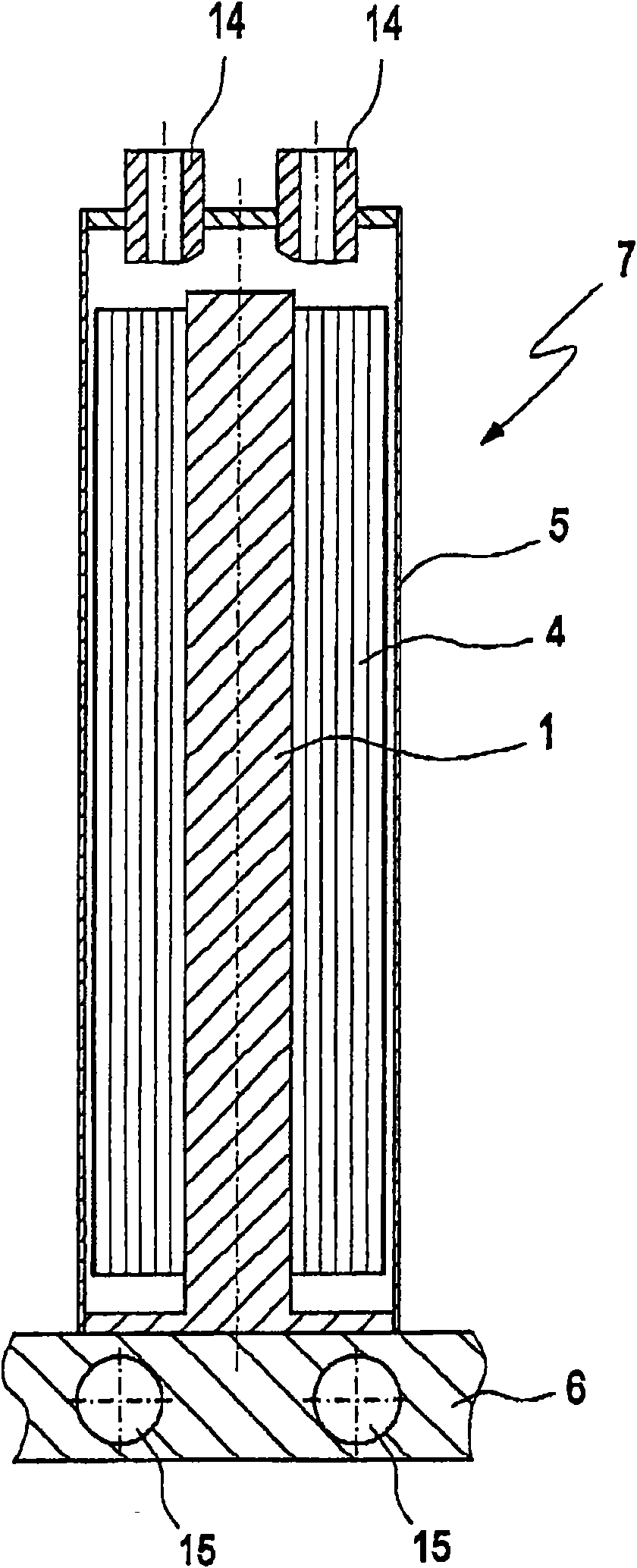

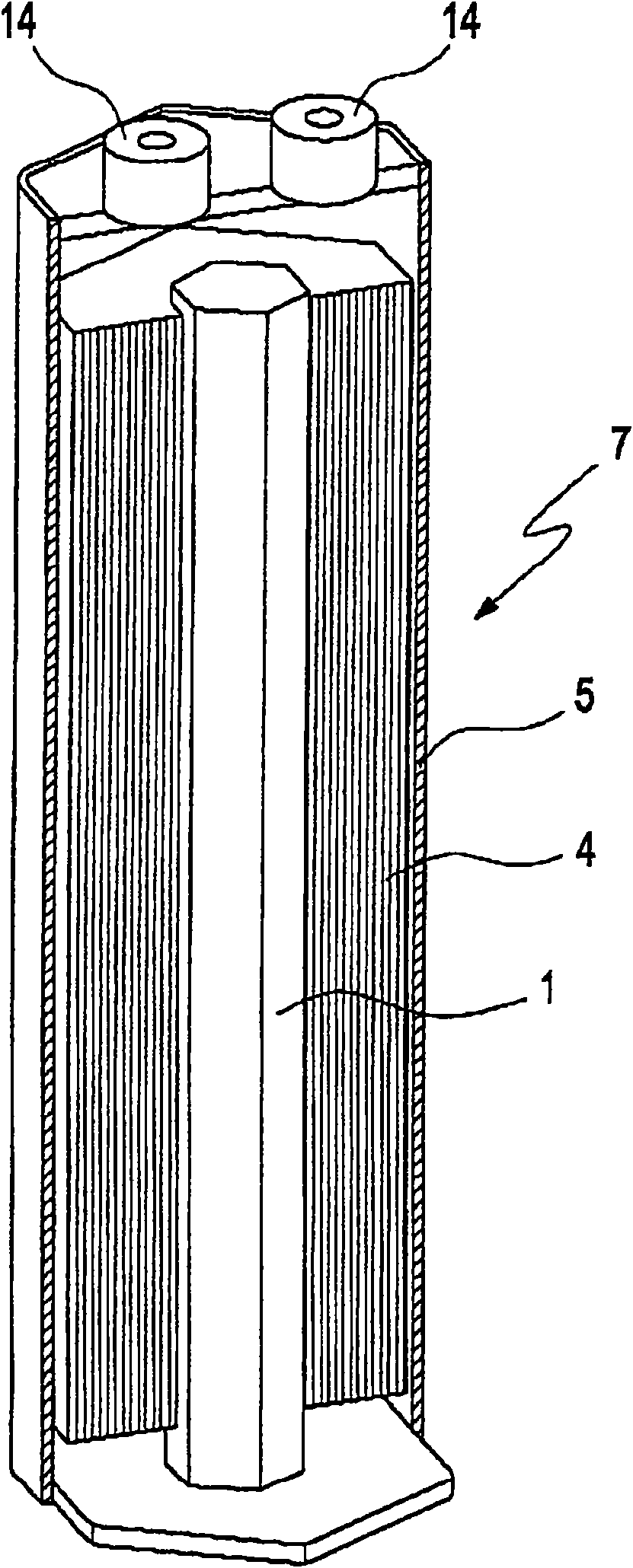

[0021] exist figure 1 A battery 8 is shown in , which also includes a plurality of cells 7 electrically connected to each other. The cells 7 are arranged in an in particular completely closed battery housing 11 . The single body 7 is arranged on a heat conducting unit 2 designed as a metal plate. The cells 7 are arranged on the heat conduction unit 2 with their longitudinal axes parallel to each other, wherein the heat conduction rod 1 of each cell 7 is thermally connected to the heat conduction unit 2 .

[0022] Together with the base plate 9 and the cooling coil 10 arranged between these two plates 2 , 9 , the heat conducting unit 2 forms a temperature control unit 3 for at least a part of the cells 7 of the battery 8 . With the temperature control unit 3 it is possible in a simple and cost-effective manner to advantageously influence the temperature in the cell 7 connected thermally to it.

[0023] Furthermore, in a suitable manner, the cooling coil 10 can additionally b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com