Method for mfg multilayer printed circuit board and composite foil for use therein

A multi-layer printing and composite sheet technology, which is applied in the manufacture of printed circuit precursors, printed circuits, printed circuits, etc., can solve problems such as inability to extend copper layers, small diameters, and low laser energy, and achieve less processing equipment and high productivity , The effective effect of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

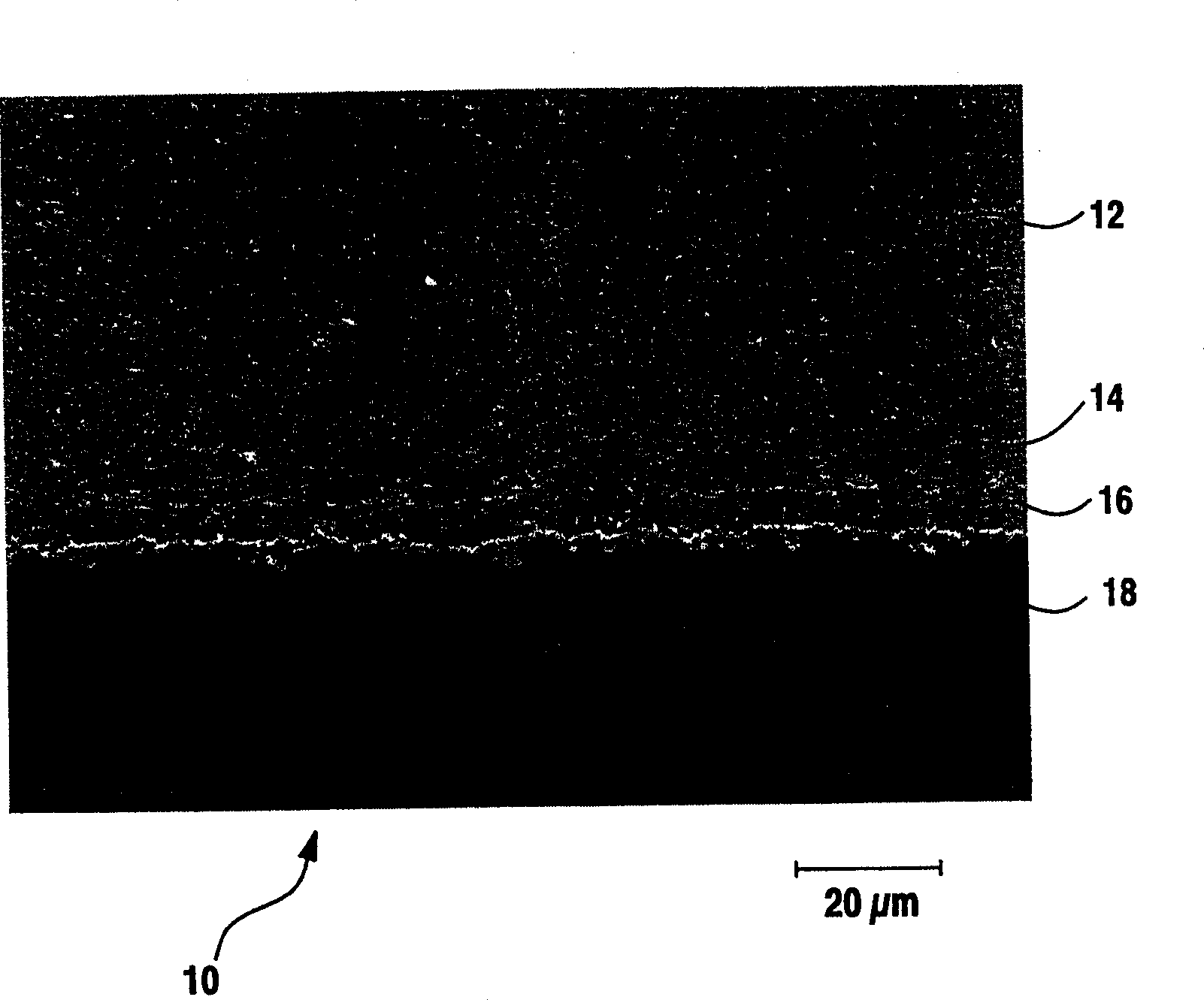

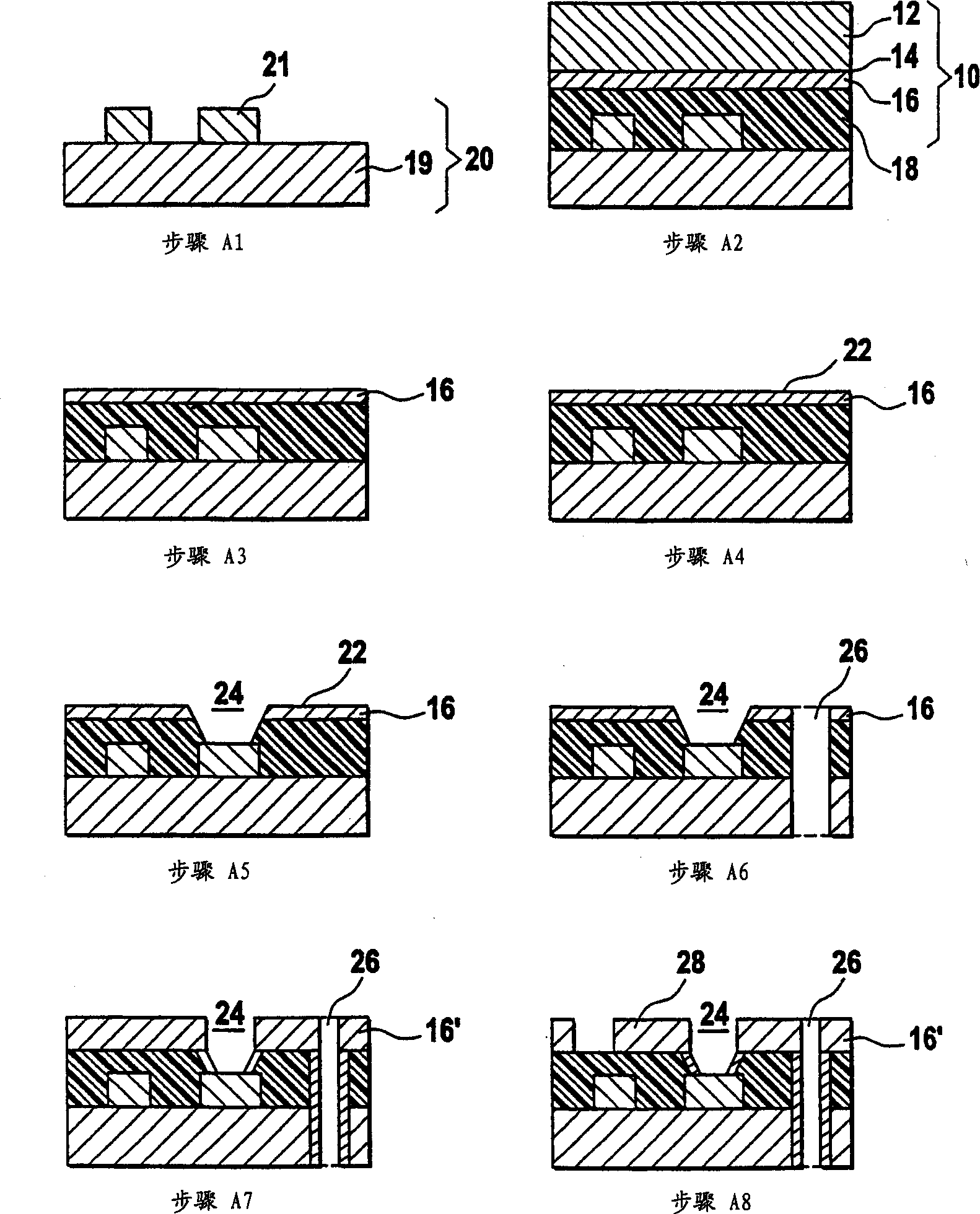

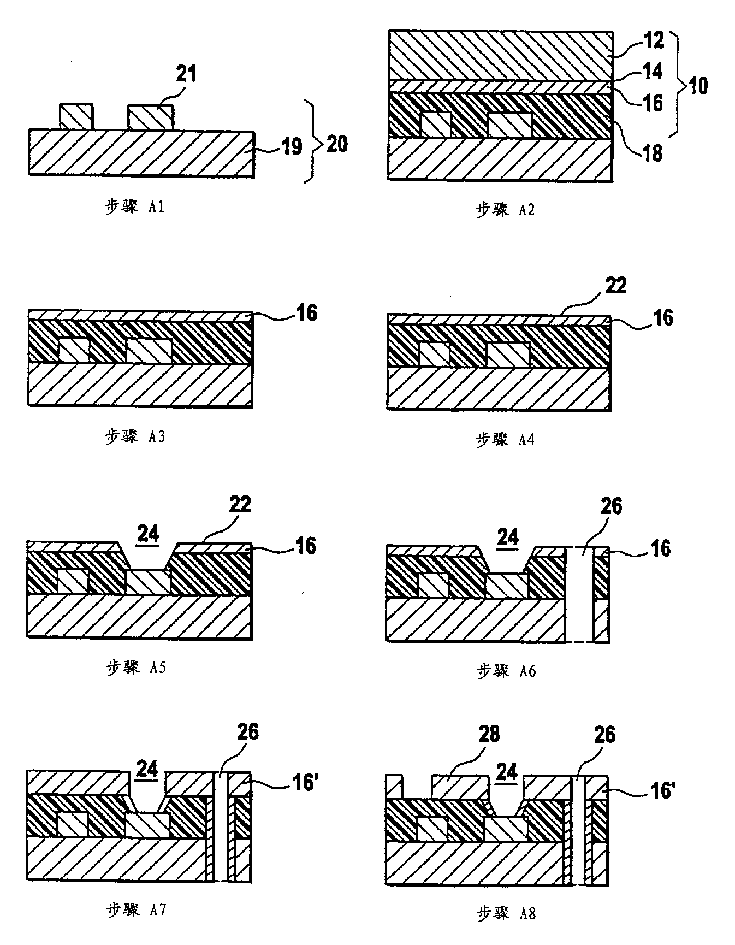

[0028] The present method uses a composite sheet 10, more specifically a resin-coated copper foil of a mounting carrier, to manufacture a multilayer PCB. figure 1 A scanning electron micrograph of such a composite sheet is shown, which will be laminated on a core plate. It consists of four distinct layers: carrier 12 ; release layer 14 ; working copper foil 16 ; and resin coating 18 . This composite sheet is the result of two consecutive manufacturing processes.

[0029] The first process is similar to that described in US3,998,601. First, a 70 μm thick slide 12 was fabricated by continuous electrodeposition from an acid-based electrolyte on a rotating titanium cylinder with a precisely designed surface. The surface topography of the barrel dictates and controls the initial copper layer deposited. The surface topography of the other side of the carrier layer - the rough side - is controlled by additives in the alkaline barrel electrolyte. In a further step, a release layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com