Patents

Literature

72results about How to "Efficient manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

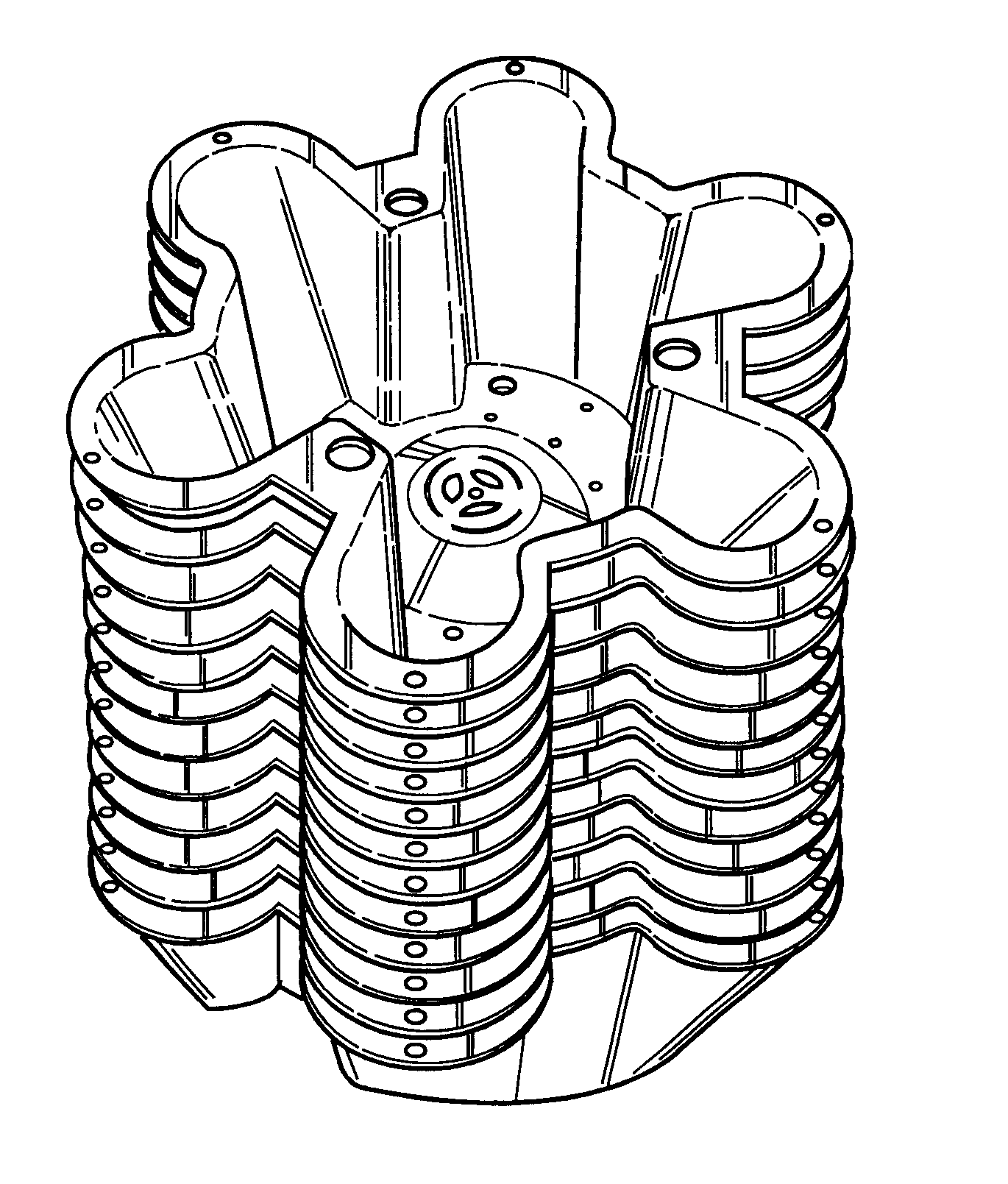

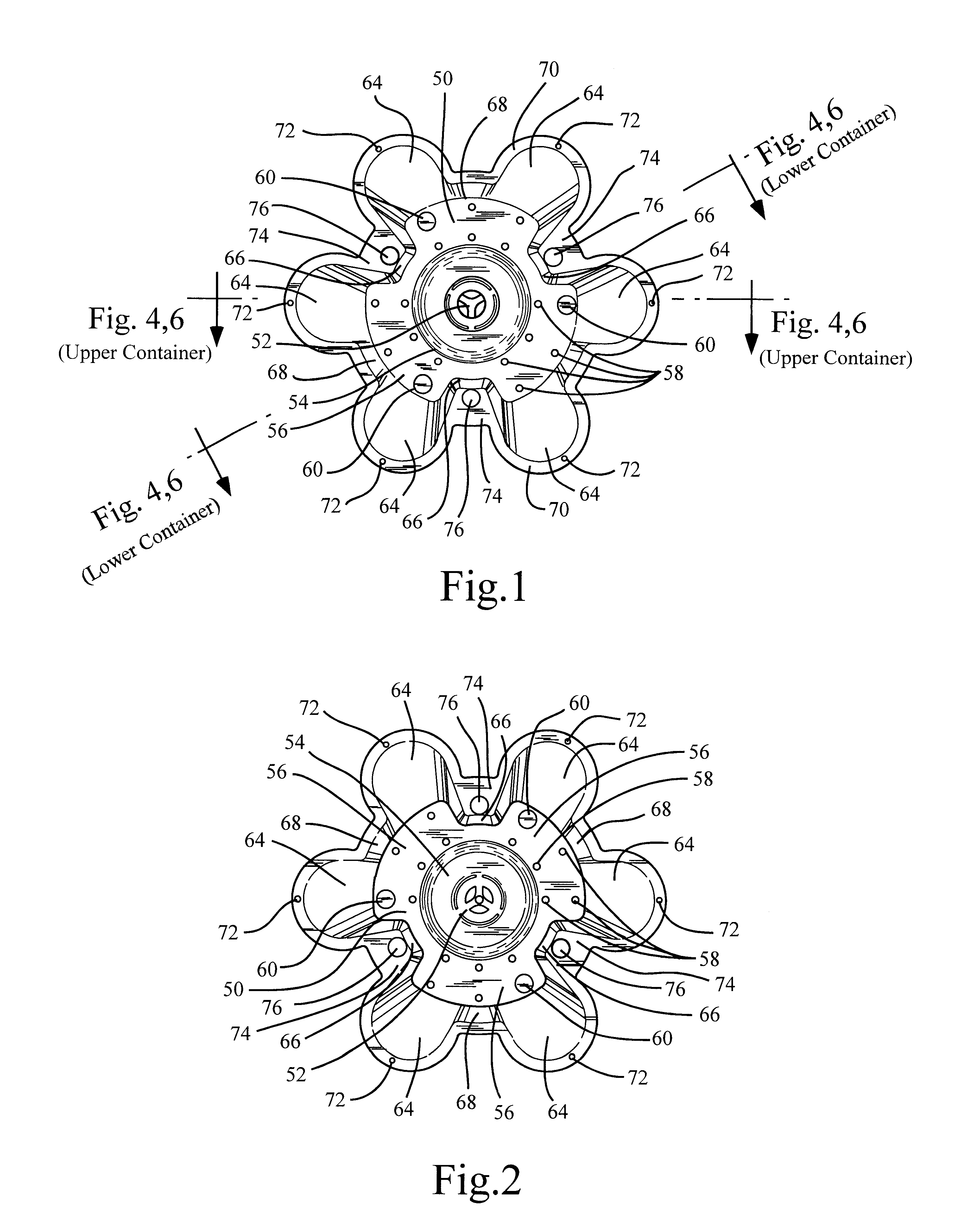

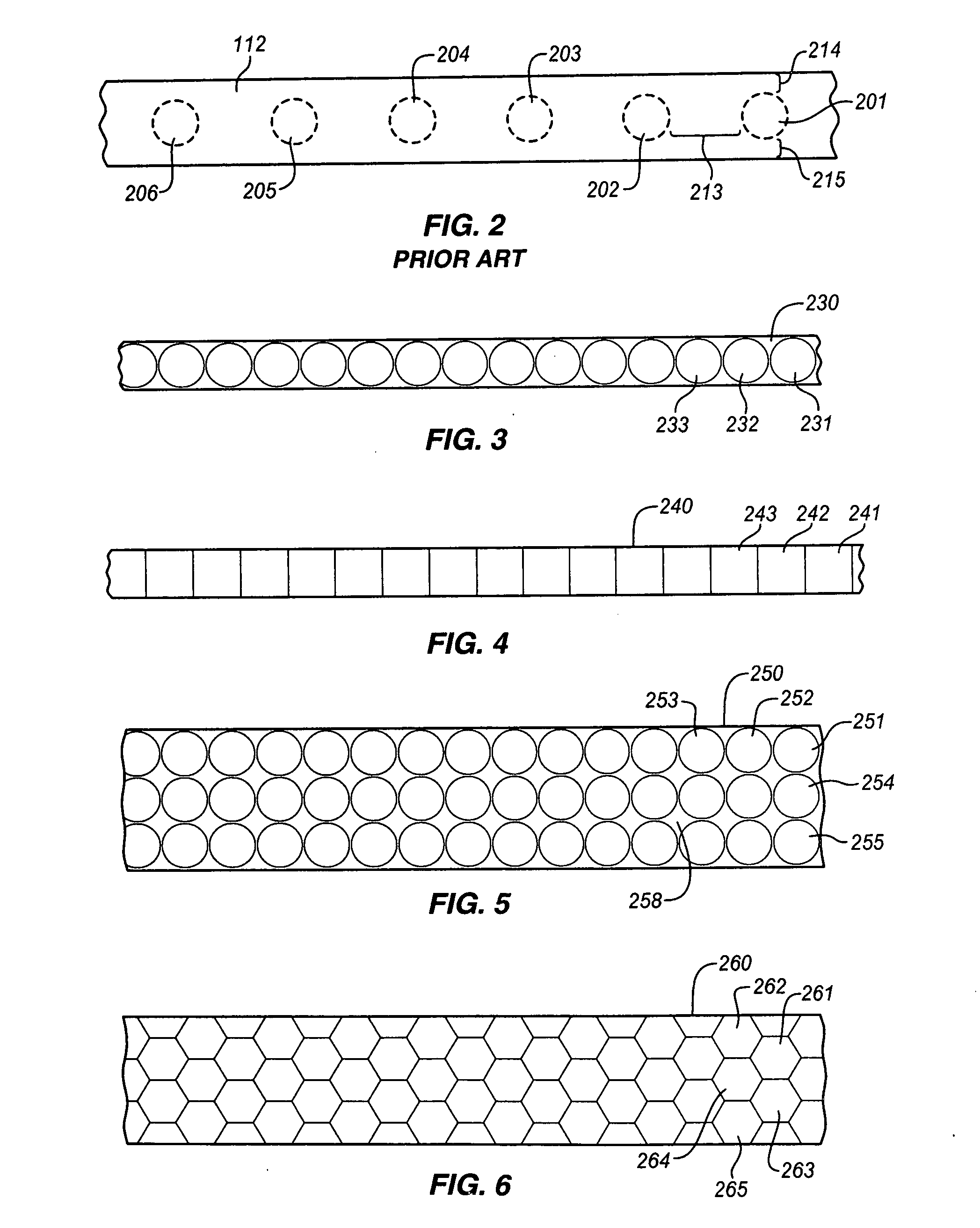

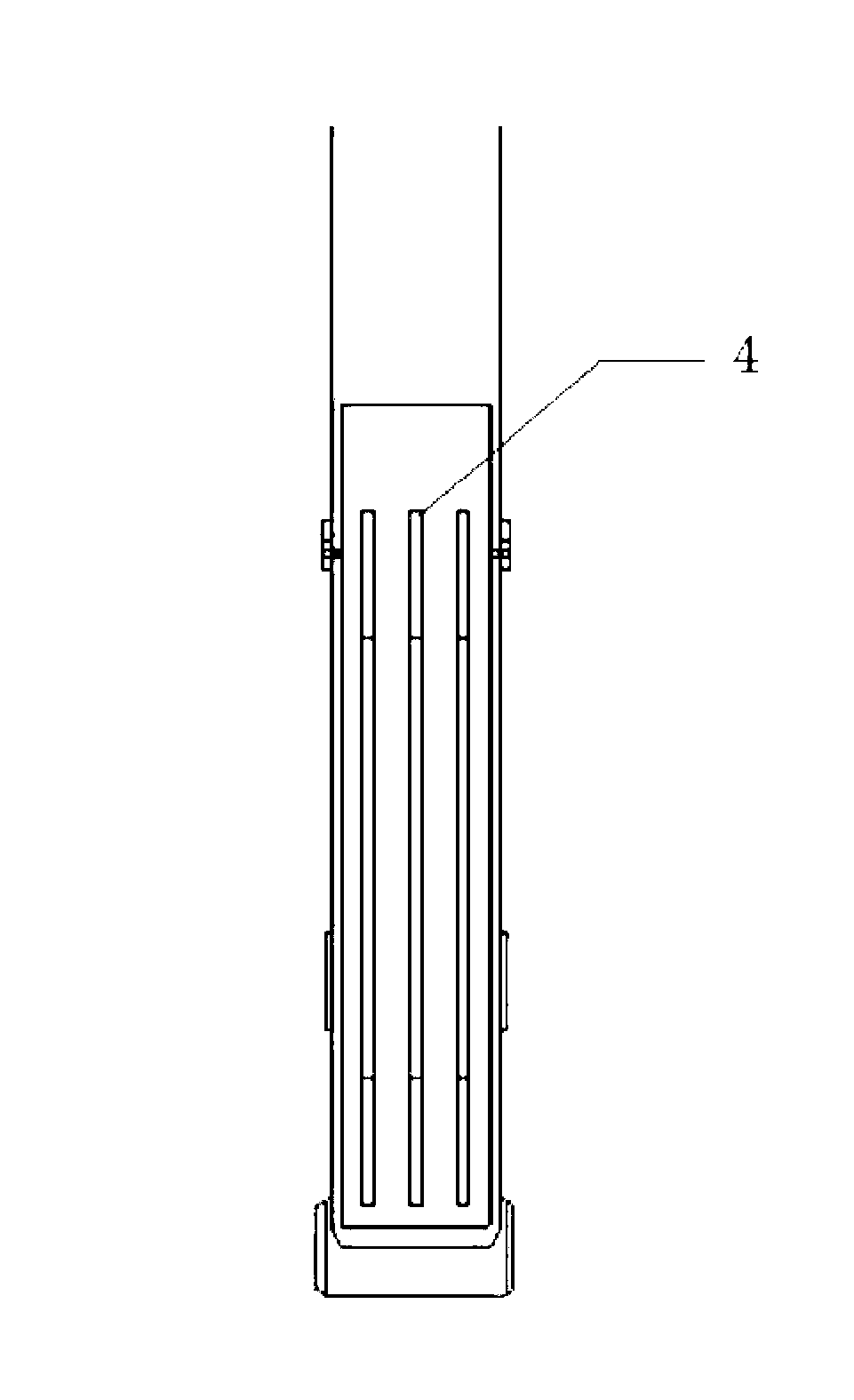

Intensive plant growing stacking container system

InactiveUS6612073B1Quickly and easily repeatedSmall sizeWatering devicesCultivating equipmentsEngineeringVertical array

A molded plant growing container system is easily stacked in a vertical array providing a self-supporting apparatus for intense horticulture. This apparatus increases crop yields over conventional growing methods. The containers nest within each other for ease of transport, are quickly and easily assembled, provide efficiency in installation and use of growing medium, increased numbers of plants in a given space, and are adaptable to a variety of irrigation methods.

Owner:MARKS & NOVA BALL MARKS TRUSTEES OR SUCCESSORTRUSTEE OF THE MARKS FAMILY TRUST UAD 5 13 05 ROBIN

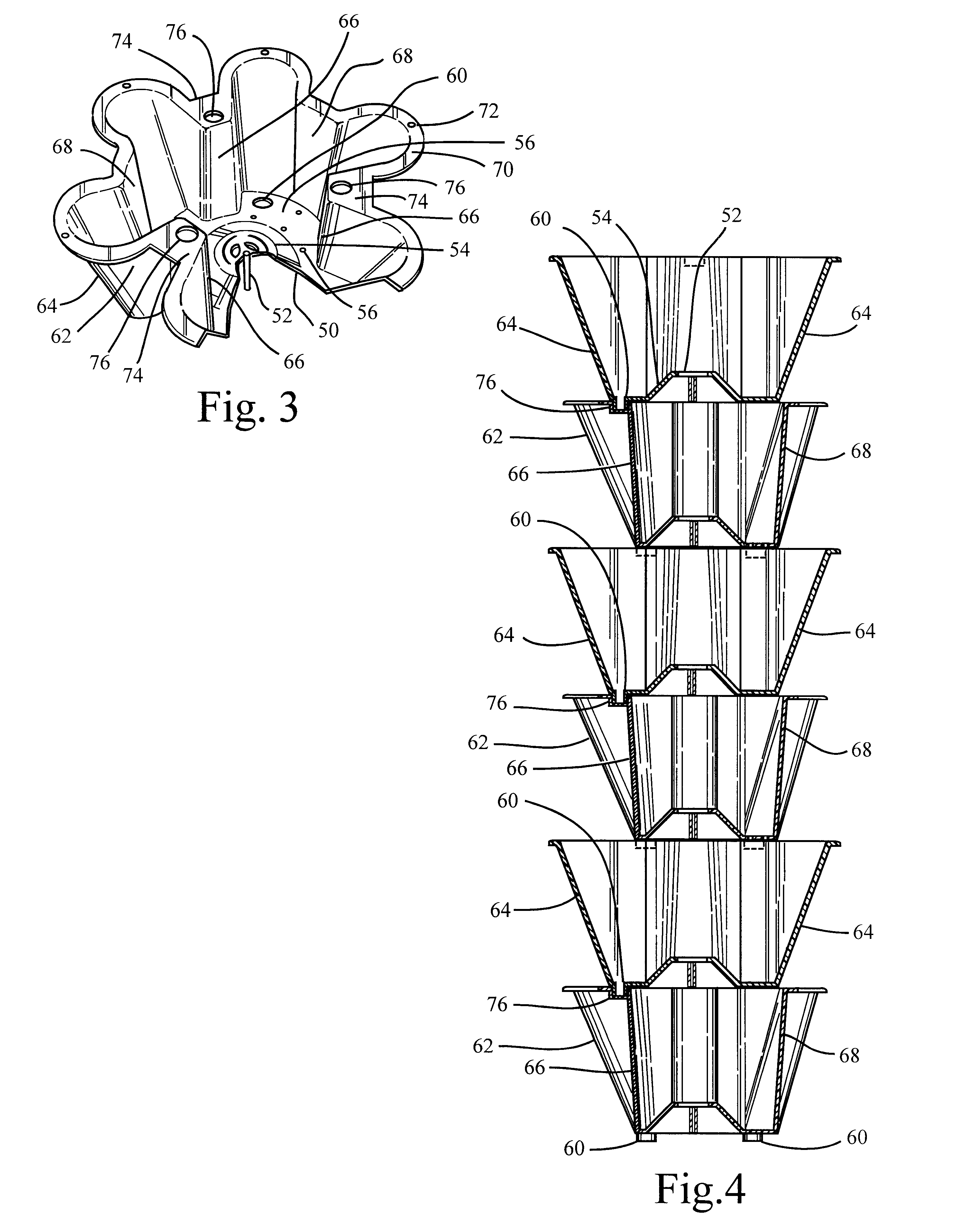

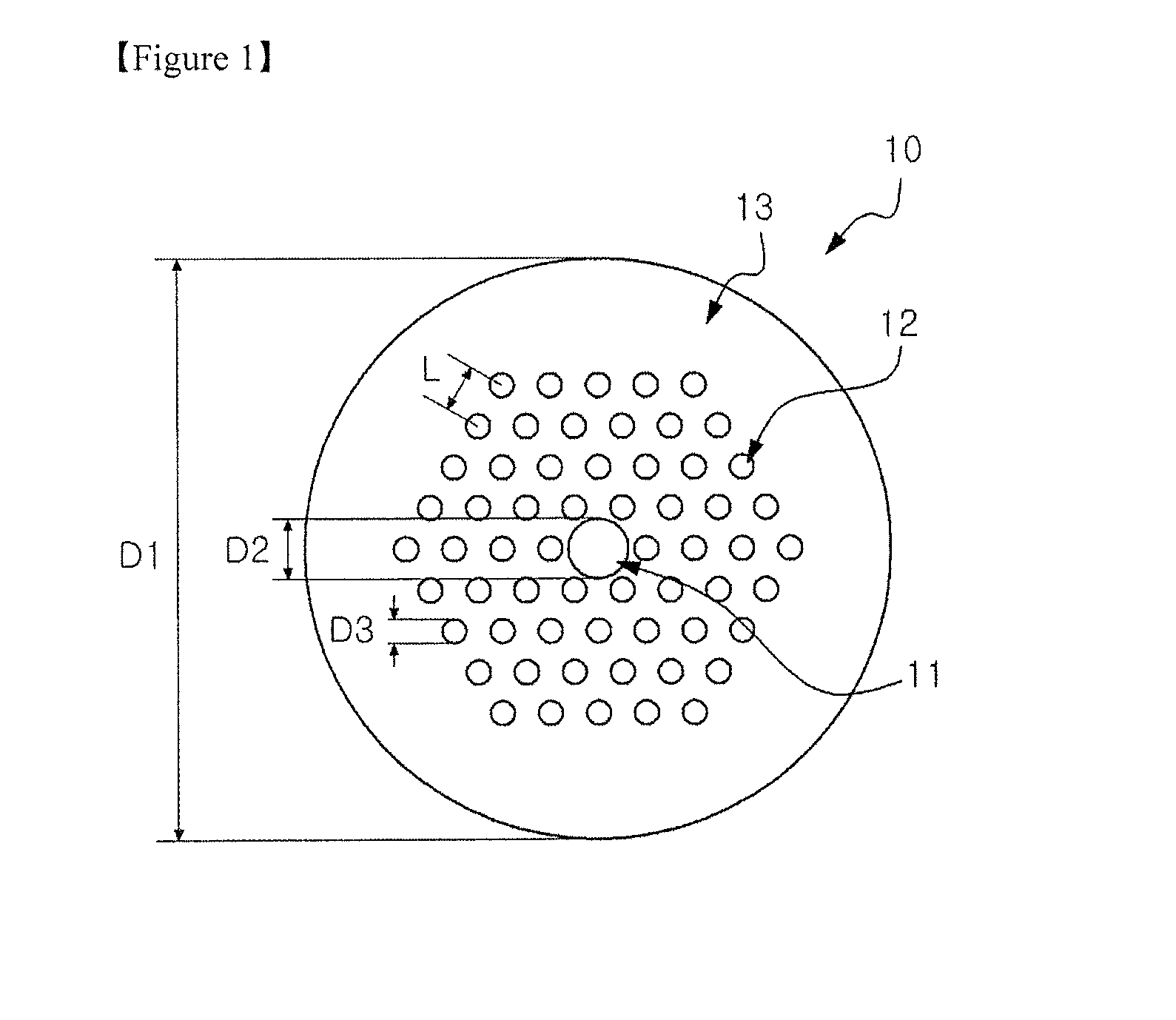

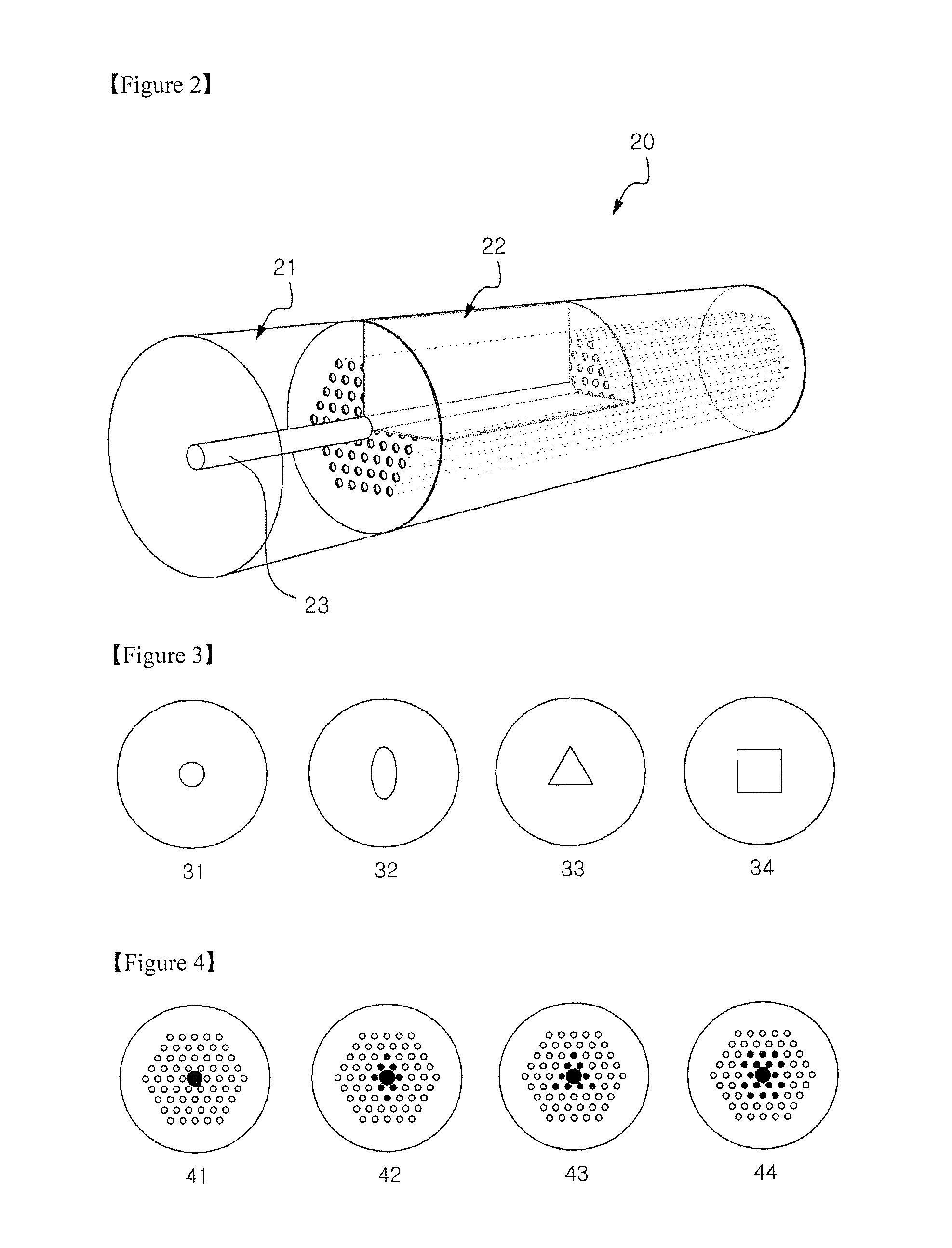

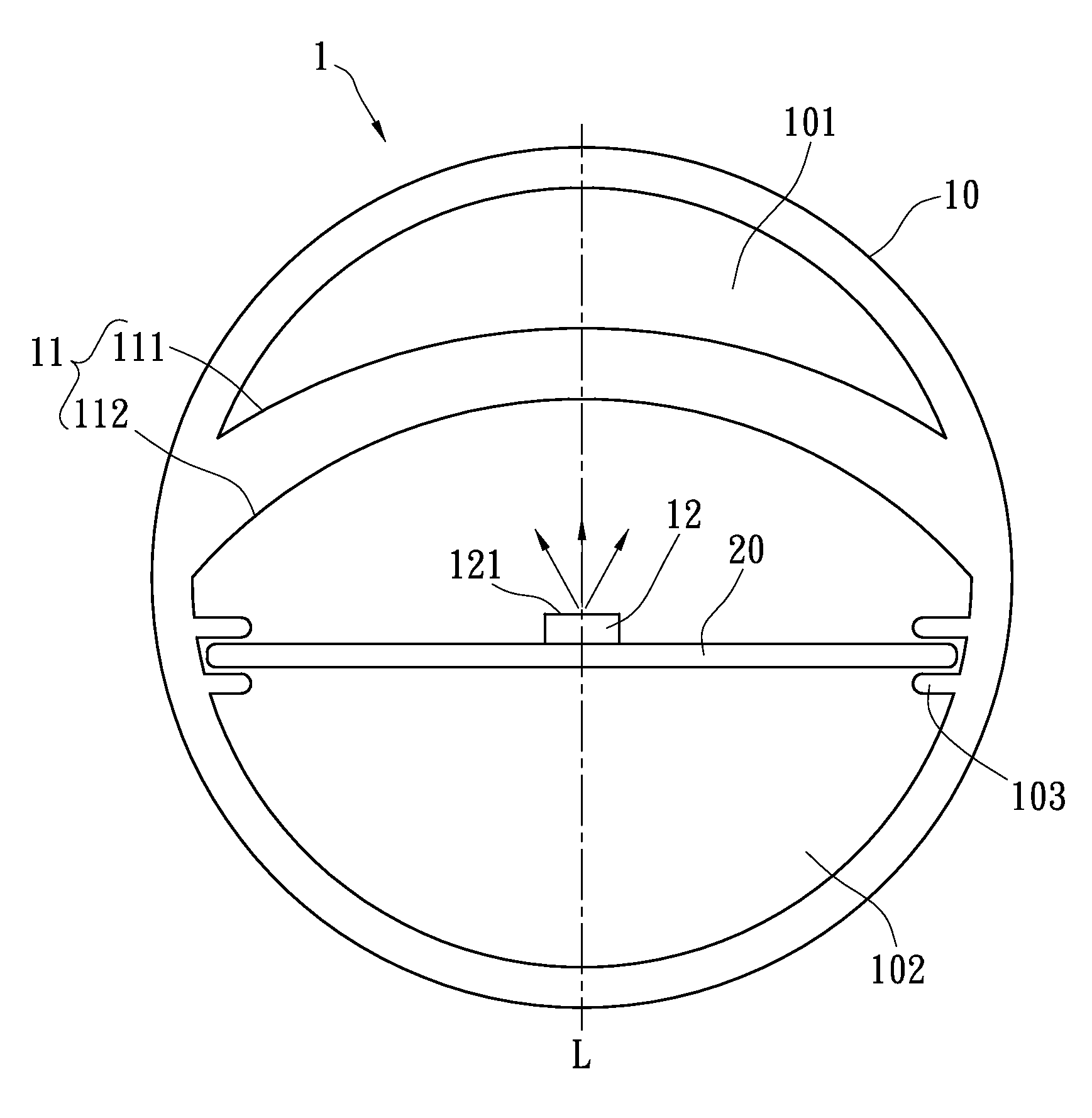

Hybrid photonic crystal fiber, and method for manufacturing same

InactiveUS20140178023A1Efficient manufacturing processKeep sizeGlass making apparatusCladded optical fibreUltra-widebandFluorescence

The present invention relates to a hybrid photonic crystal fiber, into the core of which a functional material is injected. The hybrid photonic crystal fiber of the present invention comprises: a central hole having a diameter of 4 to 15 μm extending in the longitudinal direction; an inner cladding also formed in the longitudinal direction outside the central hole, having a hexagonal arrangement of air holes, each of which has a diameter of 2 to 5 μm and a lattice constant of 4.5 to 7 μm; an annular outer cladding surrounding the outer surface of the inner cladding; and a core formed by filling a functional material in some of the air holes including the central hole. According to the present invention, changes in the state, i.e. the liquid, liquid-crystal, or biofluid states, of the functional material that fills the core that has a variety of shapes may enable the modulation of light intensity, wavelength, phase, and polarization, and thus enable various photonic networks to be produced. The hybrid photonic crystal fiber of the present invention may serve as various optical sensors capable of sensing changes in refractive index caused by external stresses such as temperature and pressure. The hybrid photonic crystal fiber of the present invention may be used as a light source for a fluorescent dye laser for a visible ray zone using fluorescent dye, or for an ultra-wideband laser of 700 nm or higher using high nonlinear liquid.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

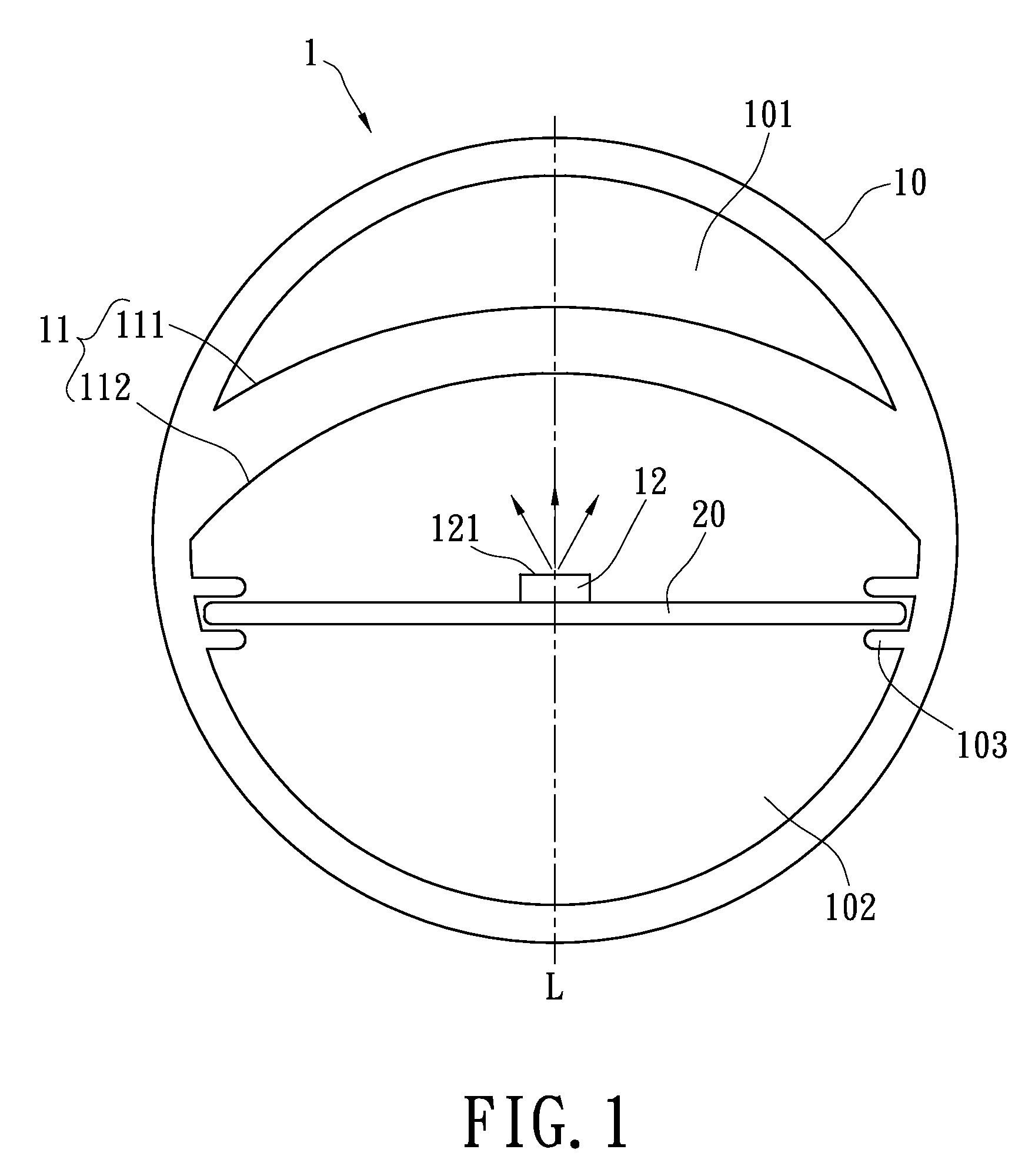

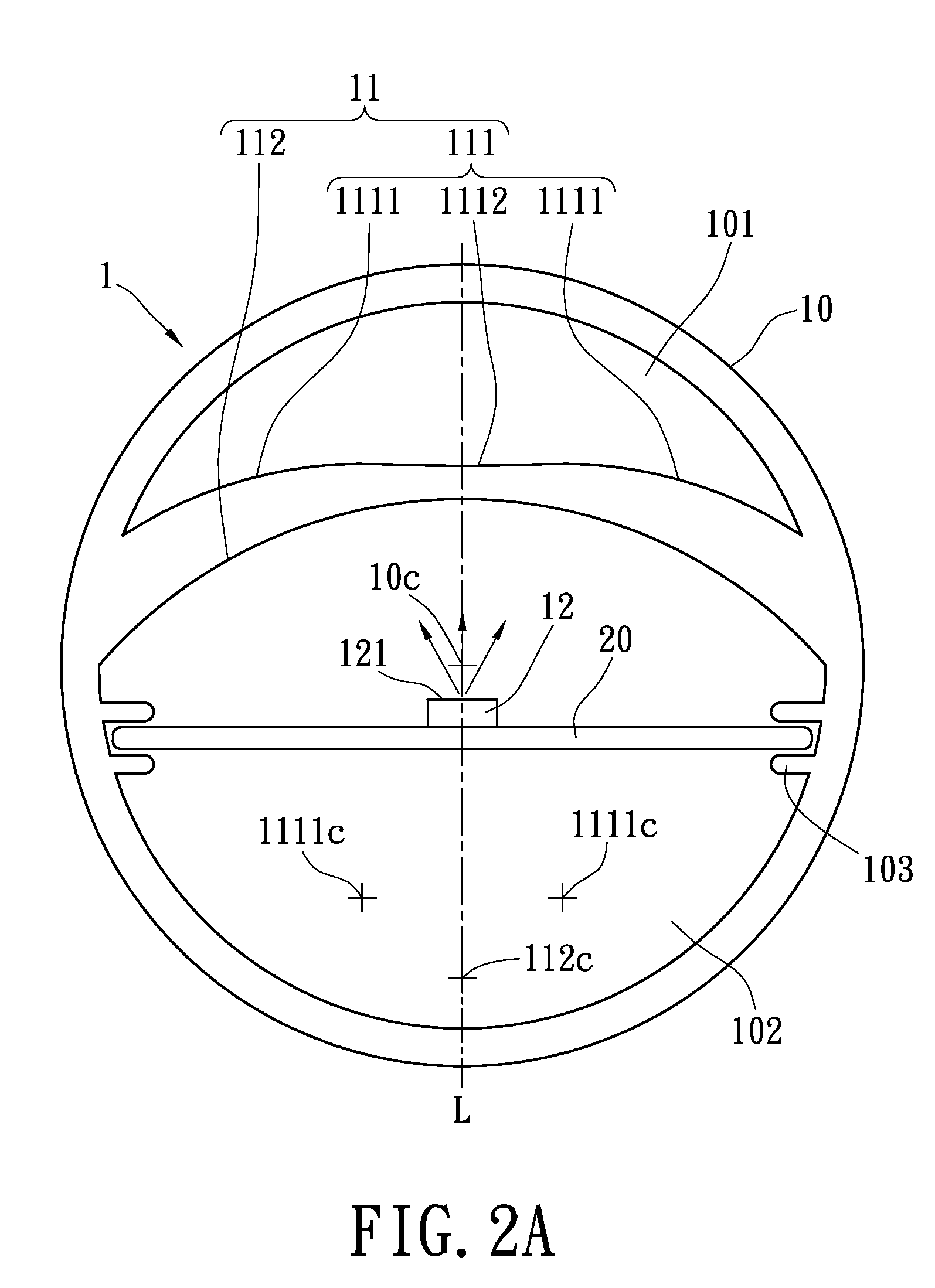

LED luminaire

InactiveUS20110292652A1Efficient manufacturing processIncrease viewing angleNon-electric lightingPoint-like light sourceEngineeringLED lamp

A LED luminaire includes a body portion having a lighting module and an optical structure formed integrally with the body portion. The optical structure is formed within the body portion and located in a light-projection direction of the lighting module. The optical structure substantially is a sheet-like structure with a first surface and a second surface. The first surface has at least two side portions with a first curvature, and the second surface has a second curvature. The first curvature is greater than the second curvature. Thereby, the view angle of the light is increased as the light generated from the lighting module passes through the optical structure.

Owner:LITE ON TECH CORP +1

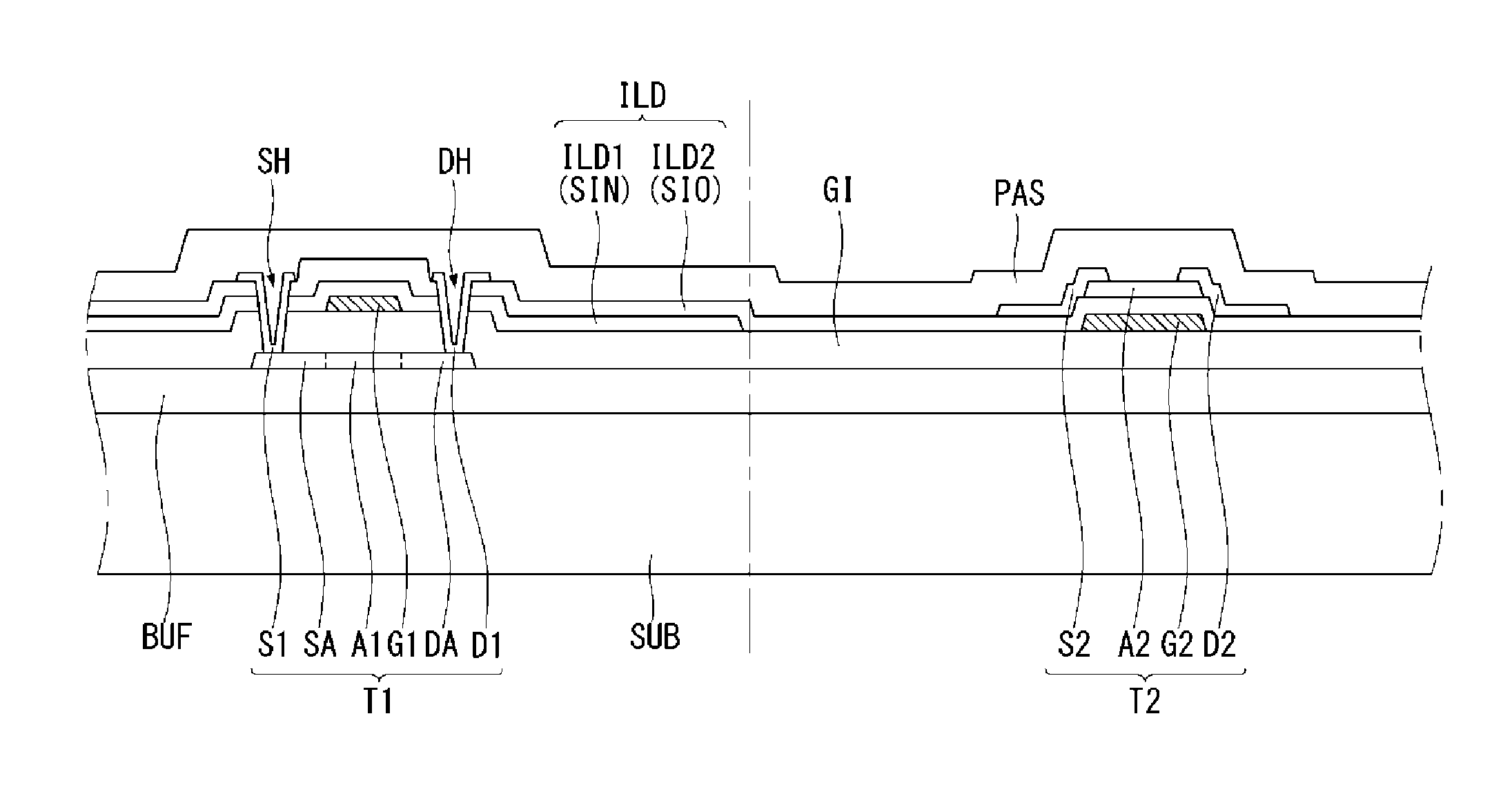

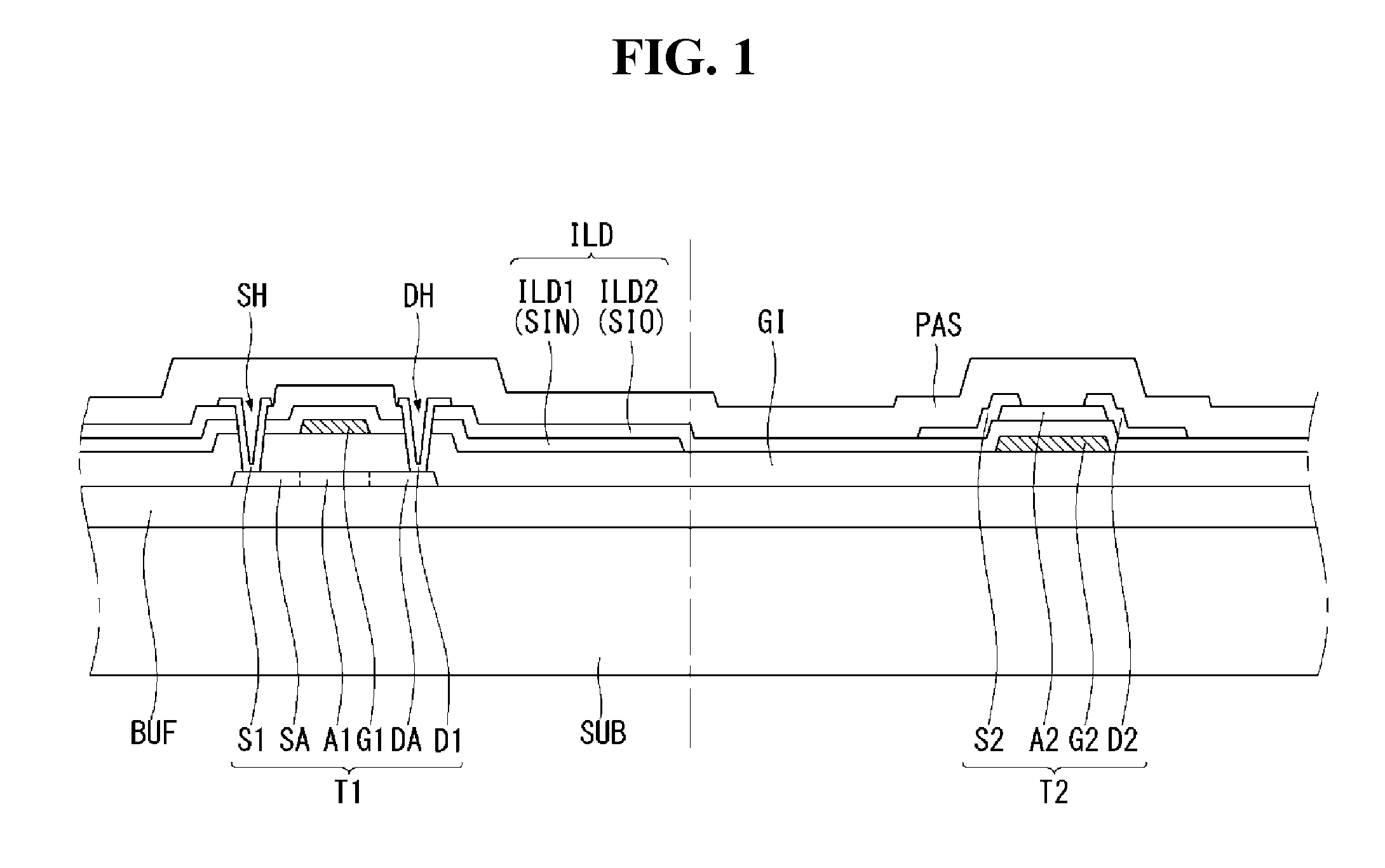

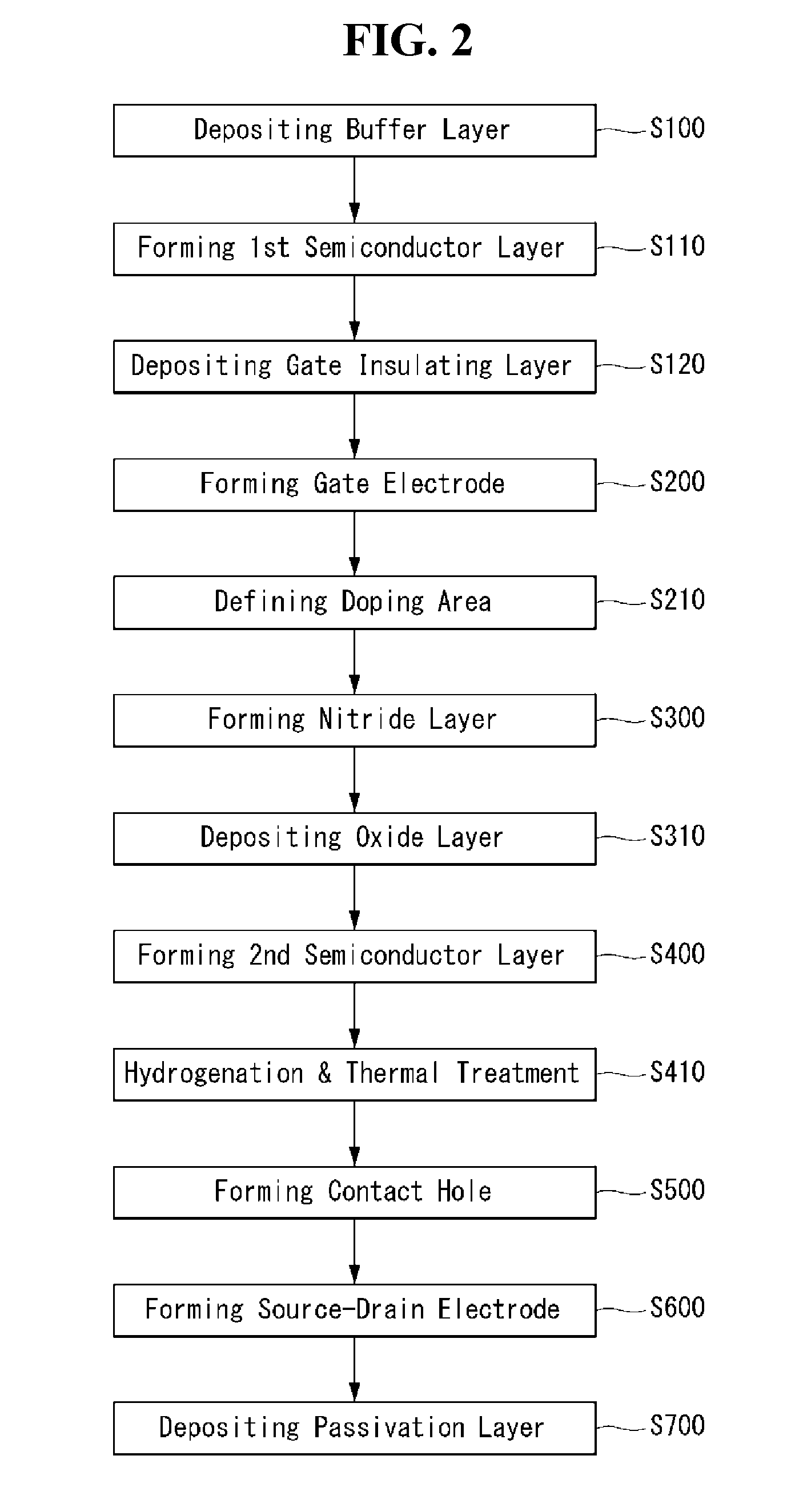

Thin film transistor substrate and display using the same

ActiveUS20150243685A1Efficient manufacturing processReduce numberTransistorSolid-state devicesOxide semiconductorDisplay device

Provided are a thin film transistor substrate and a display using the same. A thin film transistor substrate includes: a substrate, a first thin film transistor disposed at a first area of the substrate, the first thin film transistor including: a polycrystalline semiconductor layer, a first gate electrode on the polycrystalline semiconductor layer, a first source electrode, and a first drain electrode, a second thin film transistor disposed at a second area of the substrate, the second thin film transistor including: a second gate electrode, an oxide semiconductor layer on the second gate electrode, a second source electrode, and a second drain electrode, a nitride layer disposed on an area of the substrate, other than the second area, the nitride layer covering the first gate electrode, and an oxide layer disposed: over the first gate electrode and the second gate electrode, and under the oxide semiconductor layer.

Owner:LG DISPLAY CO LTD

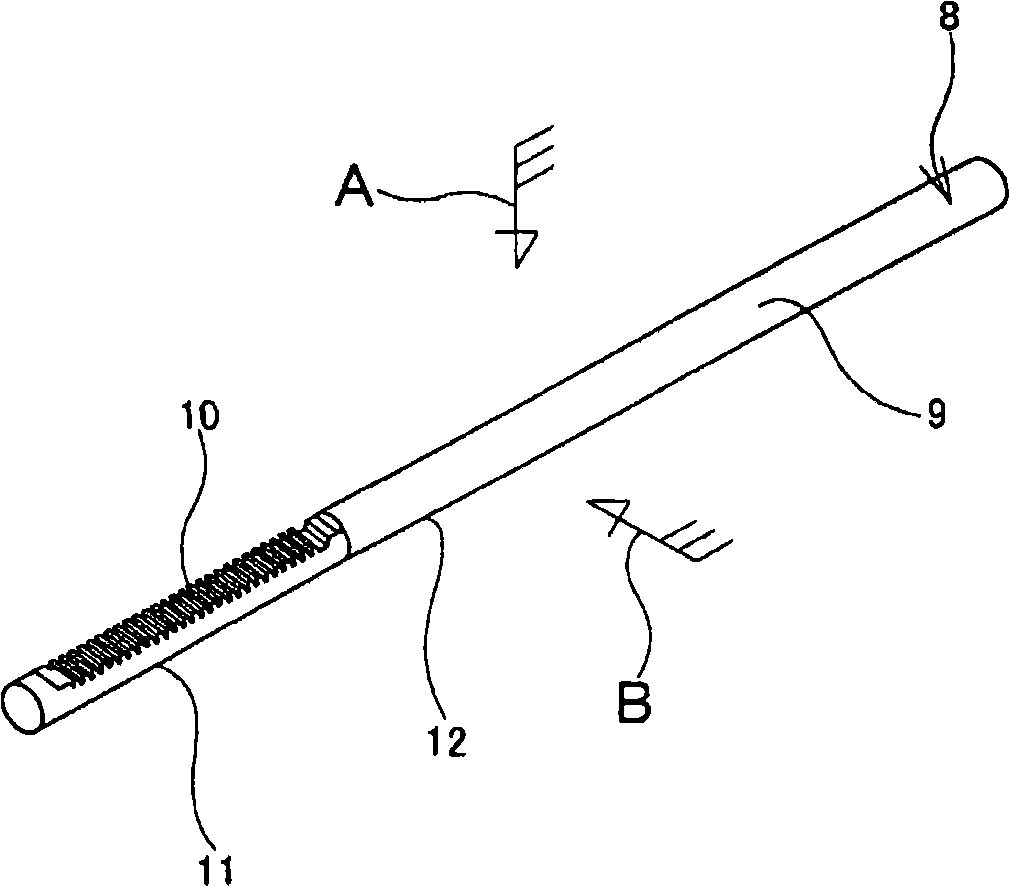

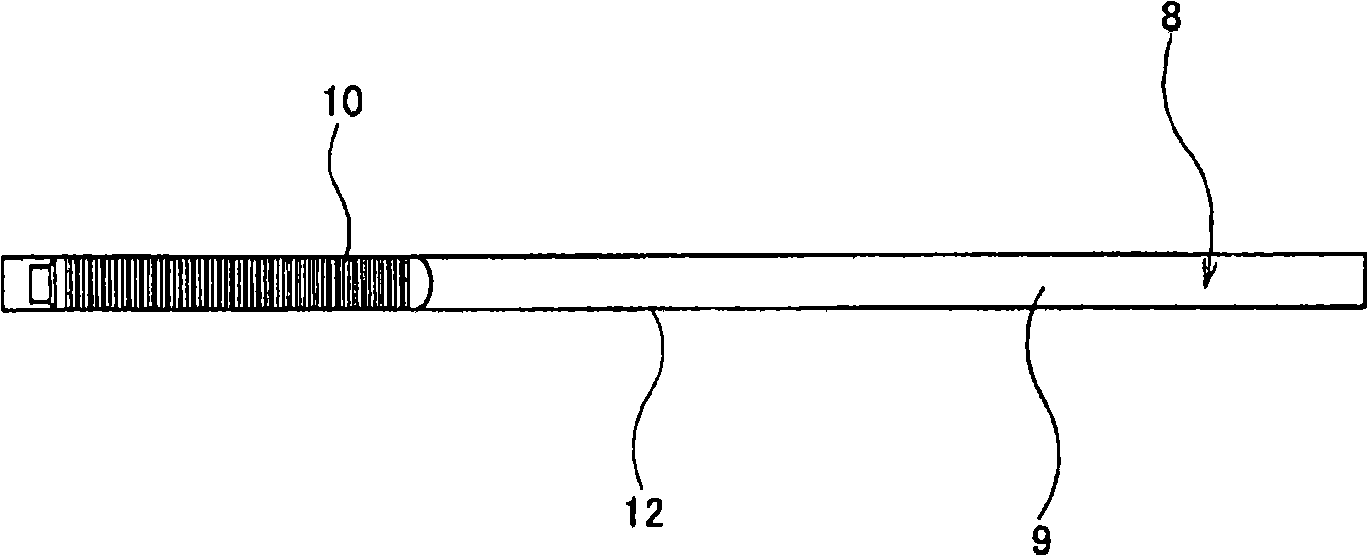

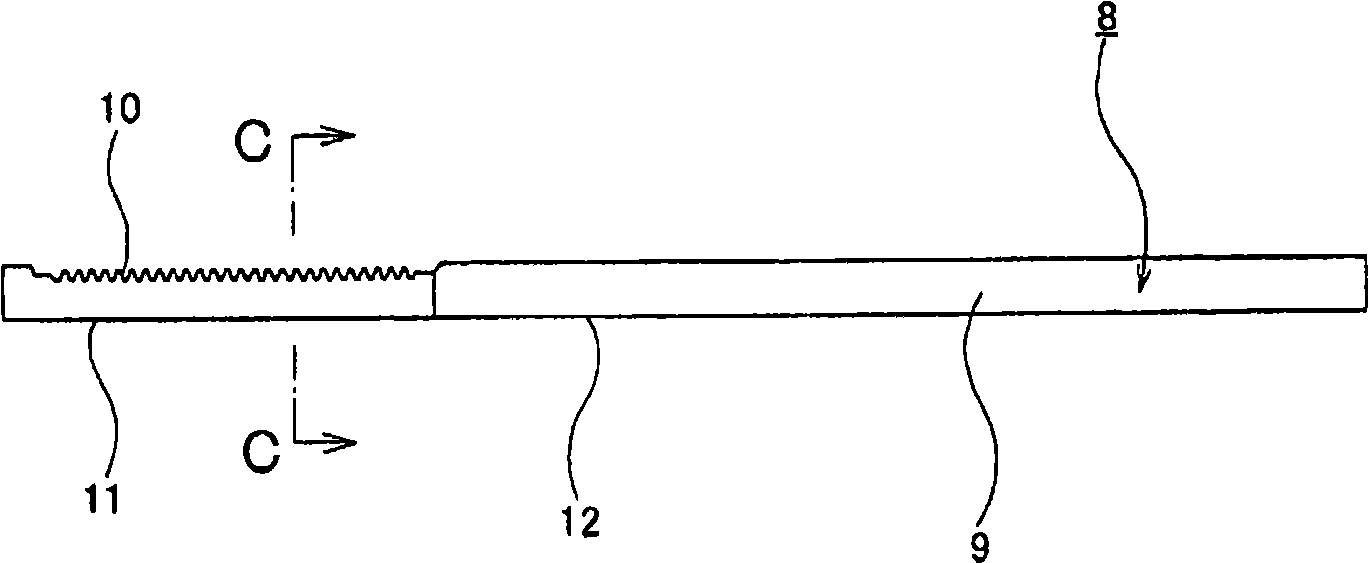

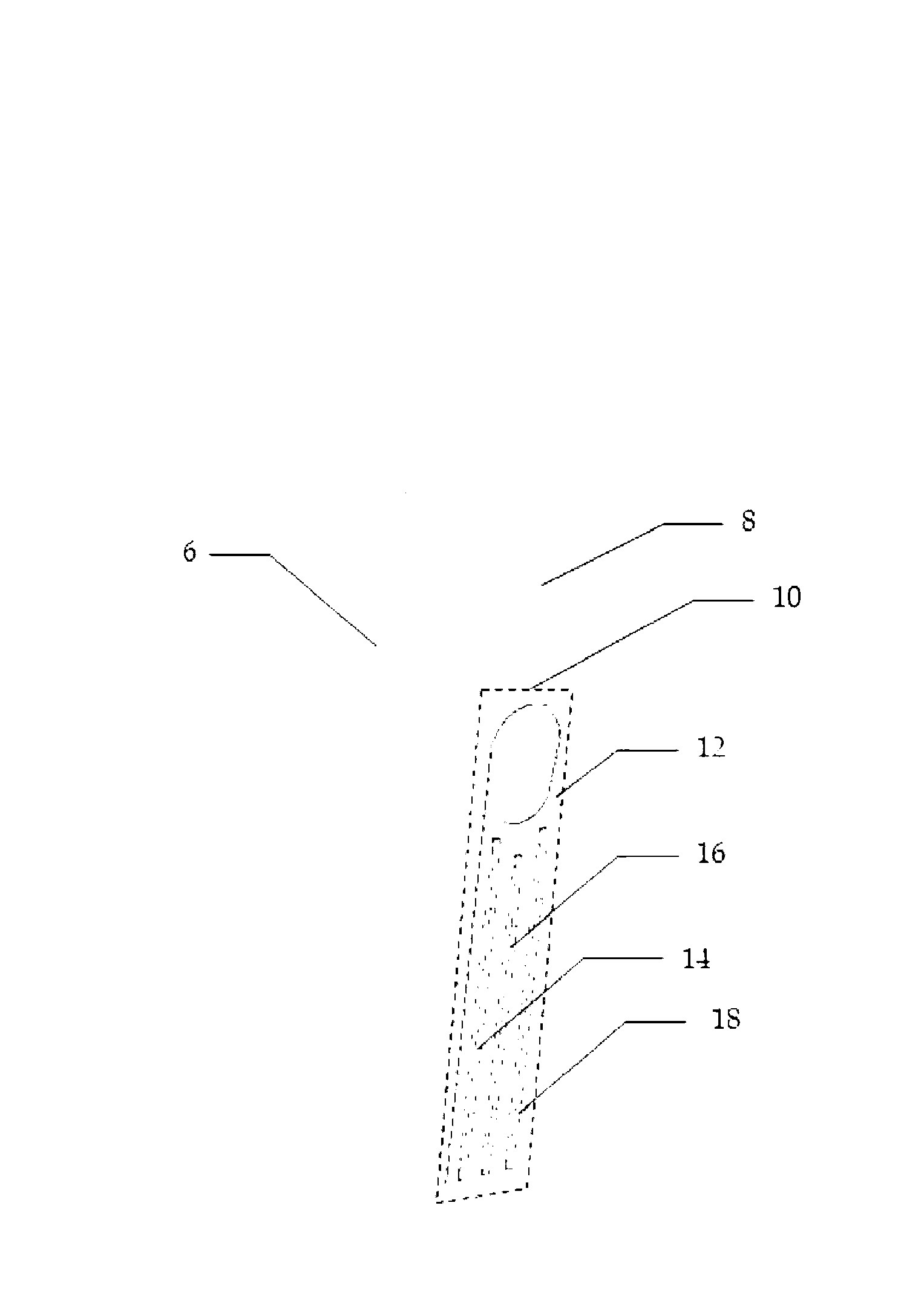

Rack and production method thereof

ActiveCN101547759AAvoid volumePrevent protrudingMetal-working apparatusPortable liftingEngineeringMechanical engineering

A light-weight structure capable of sufficiently ensuring any of the width size, strength and rigidity of a rack tooth (10), and a production method thereof. A rack tooth (10) is formed by plastic working on one side surface in the radial direction of a part in the axial direction of a sectionally circular rod unit (9). The radius of curvature of the section shape of a portion deviated in the circumferential direction from a rack-tooth (10) forming portion is set to be larger than the radius of curvature of the section shape of an outer circumferential surface of the remaining part in the axial direction of the rod unit (9). For this purpose, as shown by (A)->(B), the part in the axial direction and the remaining part in the circumferential direction are formed into a partially cylindrical surface portion (17) having a radius of curvature larger than that of the outer circumferential surface of a material (13) while a portion in the axial direction of the material (13) and a portion in the circumferential direction are being crushed, thereby defining an intermediate material (20).Then, as shown by (C)->(D), the above rack tooth (10) is formed at a portion in the axial direction ofthe intermediate material (20) and a portion in the circumferential direction. Finally, as shown by (E)->(F), it is subjected to sizing to complete a rack (8).

Owner:NSK LTD

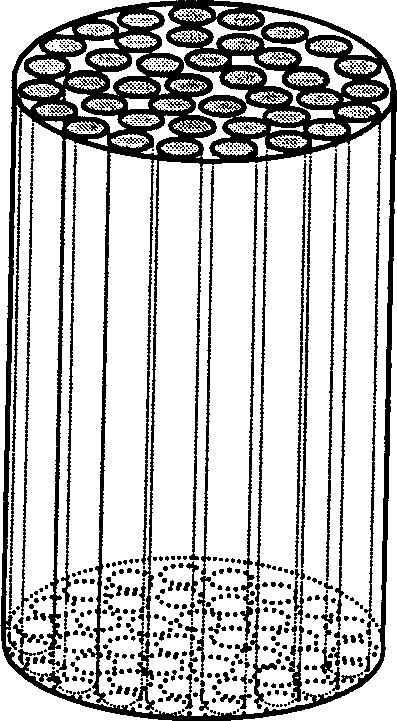

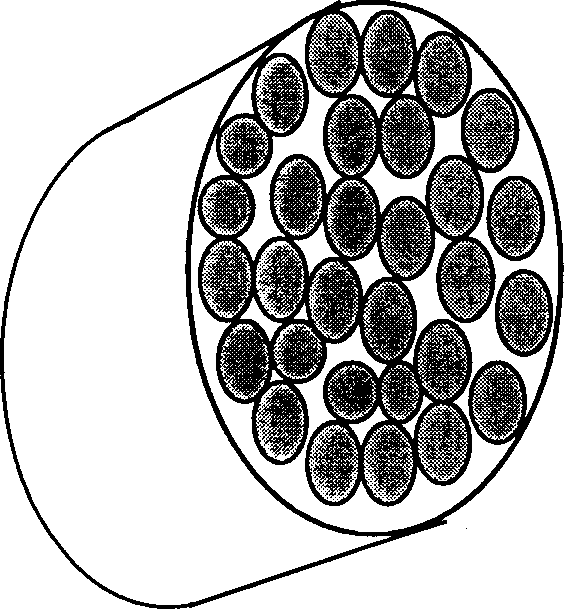

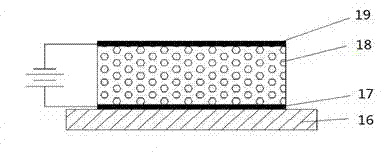

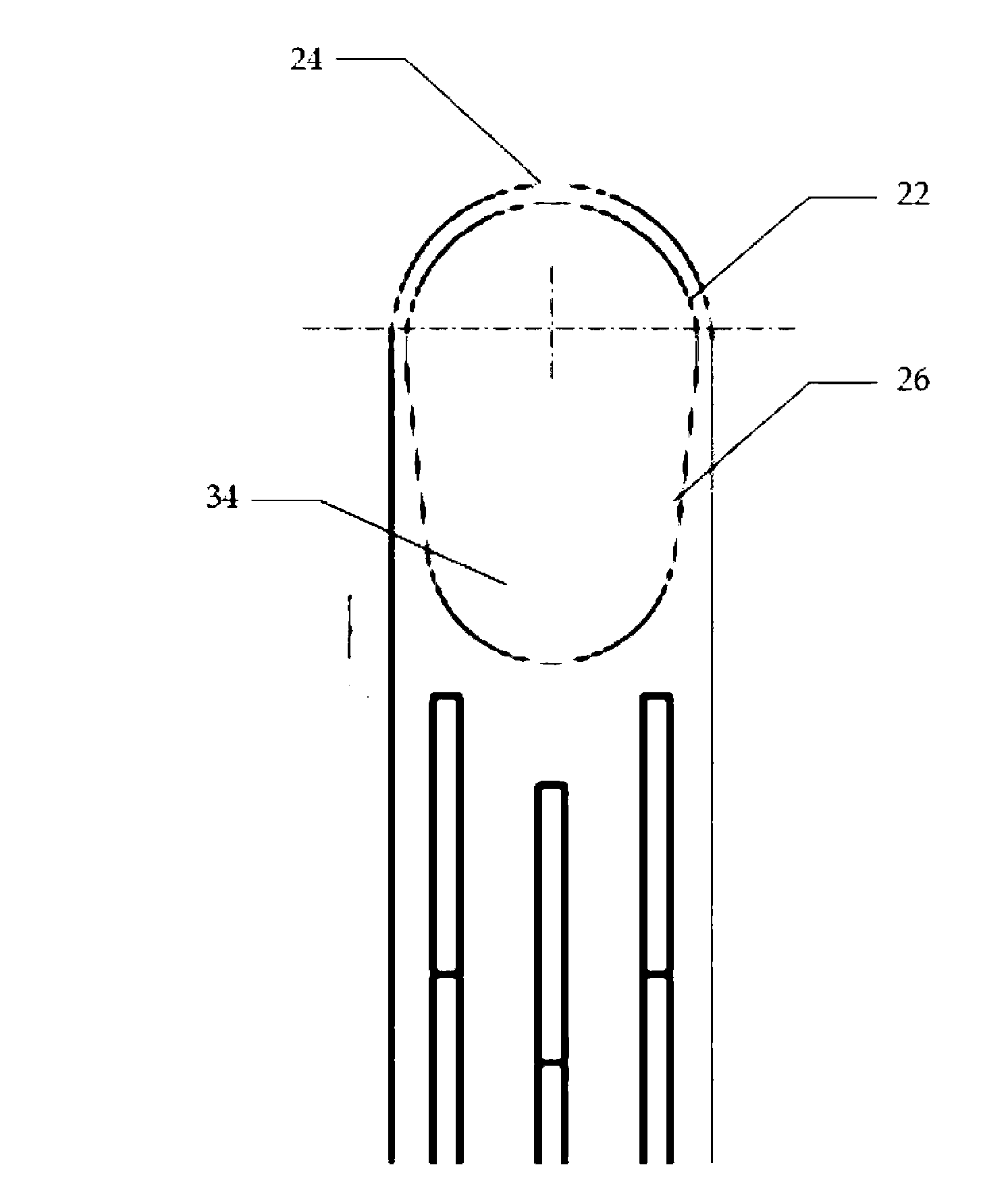

Preparation process of spinal cord and peripheral nerve repairing material

The new-type spinal cord and peripheral nerve repairing material possesses same-direction microtube type structure characteristics, and can be made into the forms of cylinder and rectangle according to the requirements. It has the following characteristics: 1. exteral surface of said material is full-closed structure, can effectively preventing internal fibre connective tissue from growing into; 2. the microtube diameter size of the material can be controlled in 30-200 micrometers, it is favorable for growth of nerve regenerative fibre; and 3. arrangement directions of microtubes are axial, and mutual parallel and uniform. it is favourable of directional extension of nerve regenerative fibre. It can be dirctly implanted for repairing spinal cord and peripheral nerve defect, also can be used as carrier of various cell implantation, can carry various nerve growth factors and nerve trunk cell, etc.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

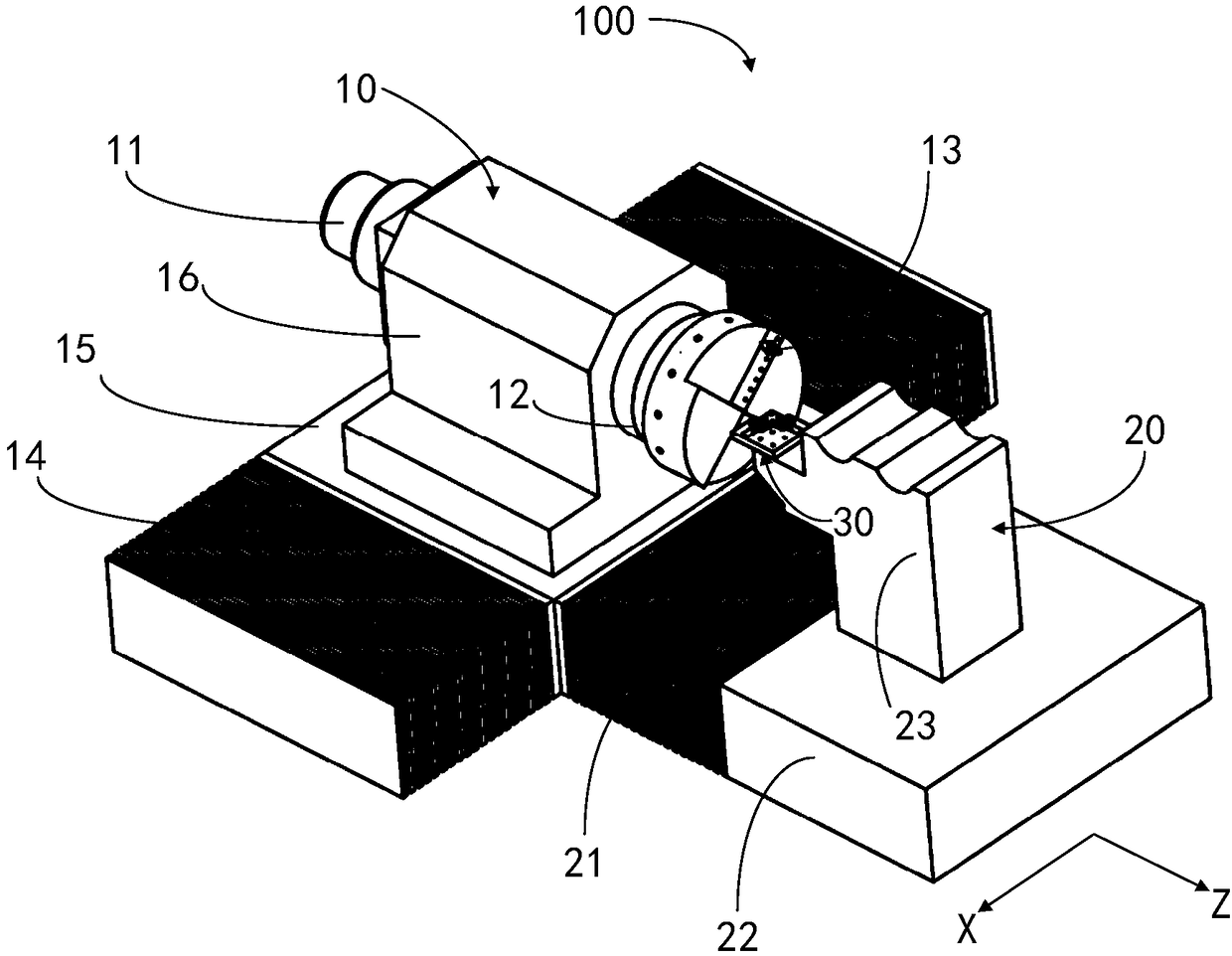

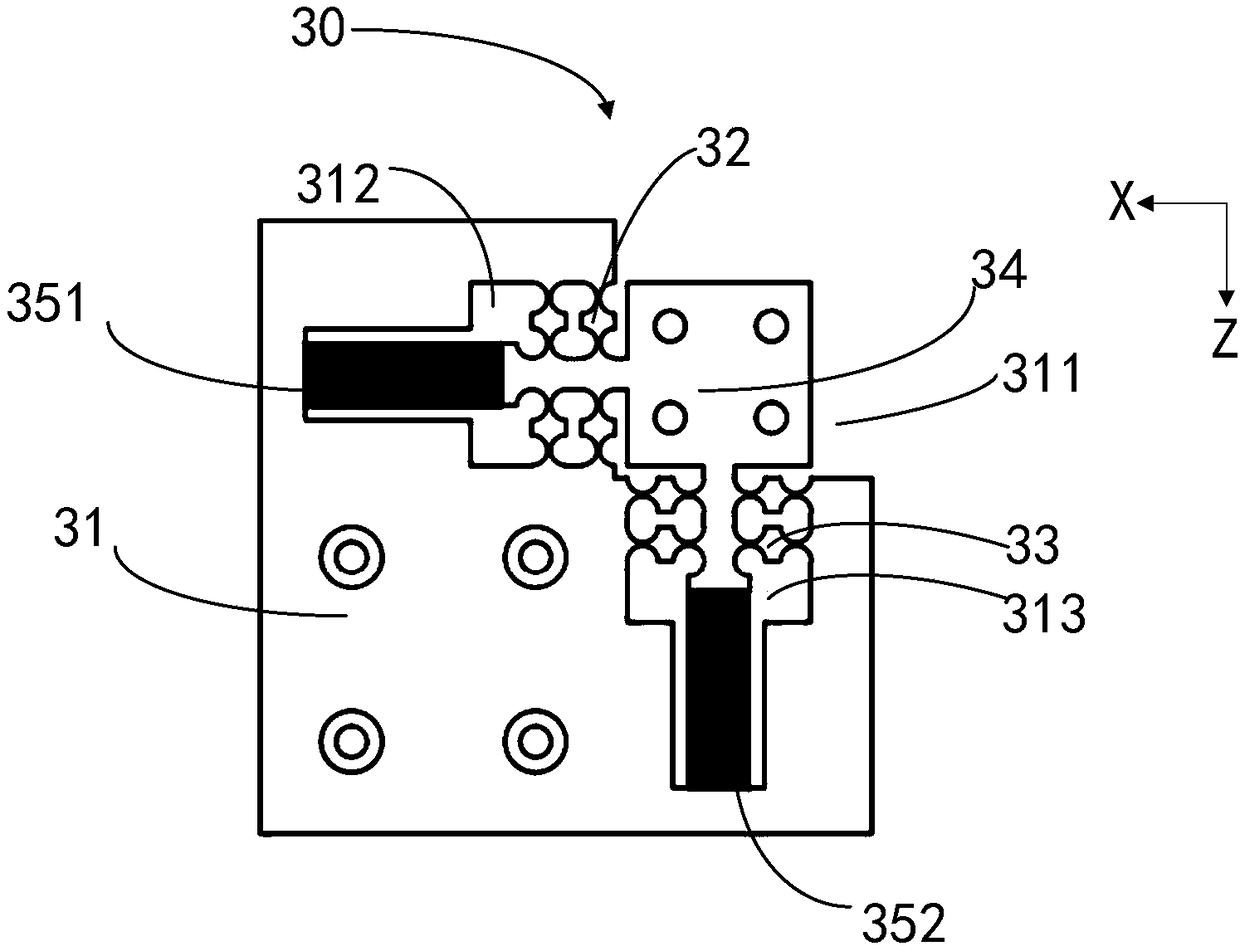

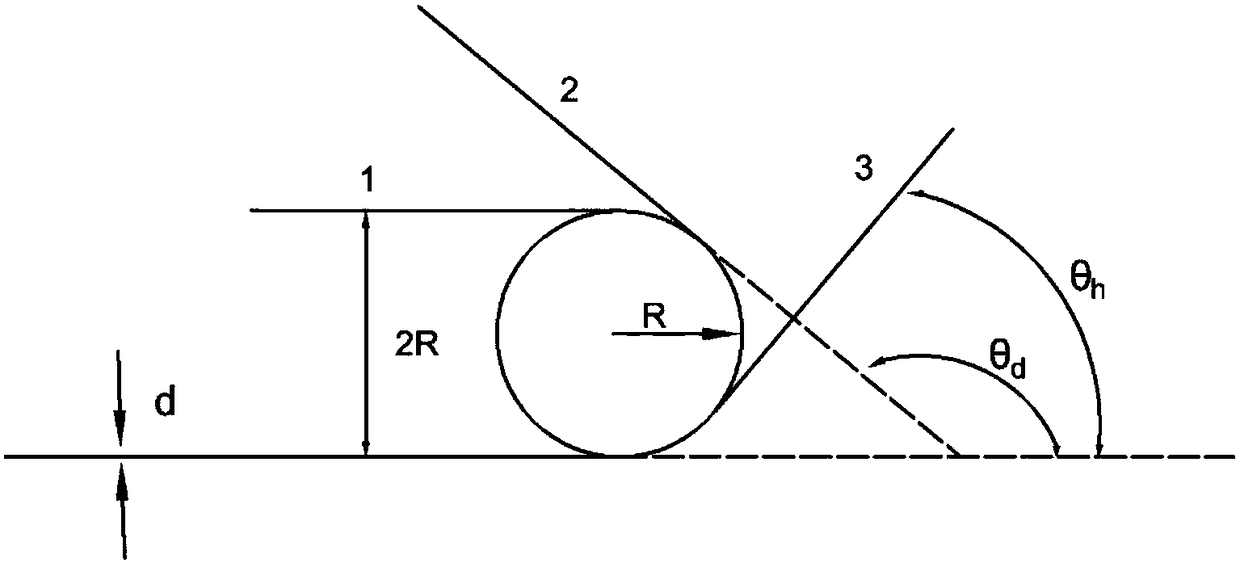

Micro-nano structure machining machine tool and micro-nano structure machining methods

ActiveCN108145179AEfficient manufacturing processMechanical vibrations separationTurning machinesMicro nanoEngineering

The invention provides a micro-nano structure machining machine tool comprising a tool apron, a work steady, and a vibration device; the tool apron can move in the X-axis direction of the machine tooland is provided with a rotating shaft with an axis perpendicular to the X-axis direction of the machine tool; a tool is arranged at the end portion of the rotating shaft; the work steady is arrangedrelative to the tool apron and can move in the Z-axis direction of the machine tool; the vibration device is fixed on the work steady and comprises a base station, a first flexible vibration body, a second flexible vibration body, a workpiece platform, and a first flexible vibration portion for driving the first flexible vibration body and the second flexible vibration body to vibrate; the first flexible vibration body is connected with the base station and the workpiece platform, and the vibration sensing direction of the first flexible vibration body is the X-axis direction of the machine tool; the second flexible vibration body is connected with the base station and the workpiece platform, and the vibration sensing direction of the second flexible vibration body is the Z-axis directionof the machine tool; the first flexible vibration body and the second flexible vibration body are separately located on two adjacent sides of the workpiece platform; and one side, not connected with the first flexible vibration body and the second flexible vibration body, of the workpiece platform is disposed opposite to the tool. The invention also provides two micro-nano structure machining methods.

Owner:SHENZHEN UNIV

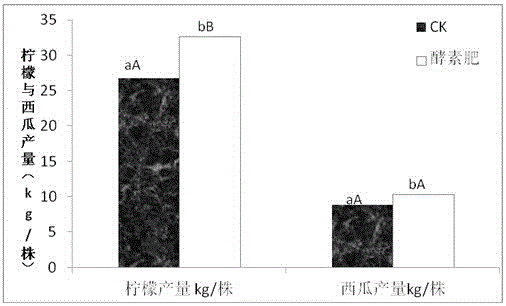

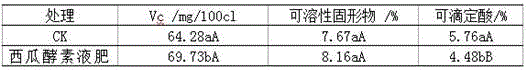

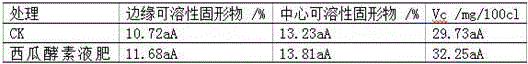

Watermelon enzyme liquid fertilizer and preparation method thereof

InactiveCN105801203APromote growthExpand the populationSuperphosphatesOrganic fertiliser preparationPlant rootsDisease damage

The invention provides a watermelon enzyme liquid fertilizer and a preparation method thereof, belonging to the technical field of bio-organic fertilizer preparation and utilization. The watermelon enzyme liquid fertilizer is prepared from the following components in percentage by mass: 45-68% of watermelon, 1-5% of lemon, 2.5-8% of grapefruit, 3.5-15% of tomato, 1-5% of pineapple, 0.3-1% of yeast, 0.5-3% of urea, 0.7-2% of potassium sulfate, 4-6.5% of calcium superphosphate, 0.15-0.5% of zinc sulfate, 0.1-0.5% of borax, 0.3-0.8% of brown sugar or molasses, 5.5-20% of fresh plant and 3-20% of water, wherein the total percentage of all components is 100%. The product is rich in multiple enzymes, vitamins, minerals, amino acids and trace elements; by adopting the product, the fruits and vegetables grow vigorously, the plant root system is well developed, the pest and disease damage is effectively reduced and prevented, the microbial population of soil is enlarged, the soil is improved, the yield and quality of fruits and vegetables are increased, and the product is economical and environment-friendly.

Owner:YUNNAN FUSHANLI FERTILIZER IND TECH CO LTD

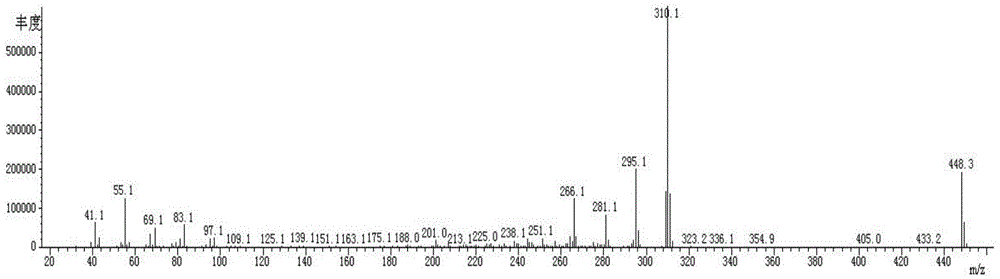

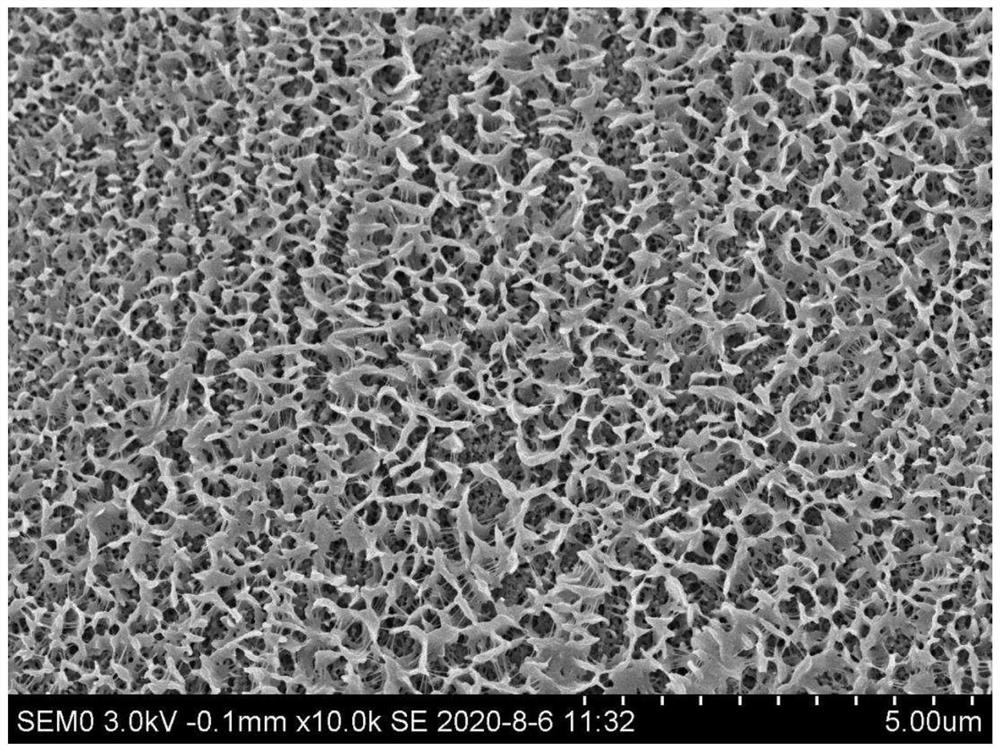

Gold-silver alloy nano porous metal material and preparation technology thereof

The invention relates to a gold-silver alloy nano porous metal material and a preparation technology thereof, and relates to the field of preparation of gold-silver alloy nano porous metal material. The gold-silver alloy nano porous metal material is mainly characterized by consisting of high-purity (greater than 99.990 / 0) gold and silver at a weight ratio of 1:(1.0-1.2); and the gold-silver alloy nano porous metal material is porous gold with a pore diameter of 15+ / -2nm and prepared by electrochemical corrosion. Through the invention, the gold-silver alloy nano porous gold with the pore diameter of 15+ / -2nm and uniform pores can be prepared, and the preparation technology is simple and effective.

Owner:SUZHOU GULI BIOTECH

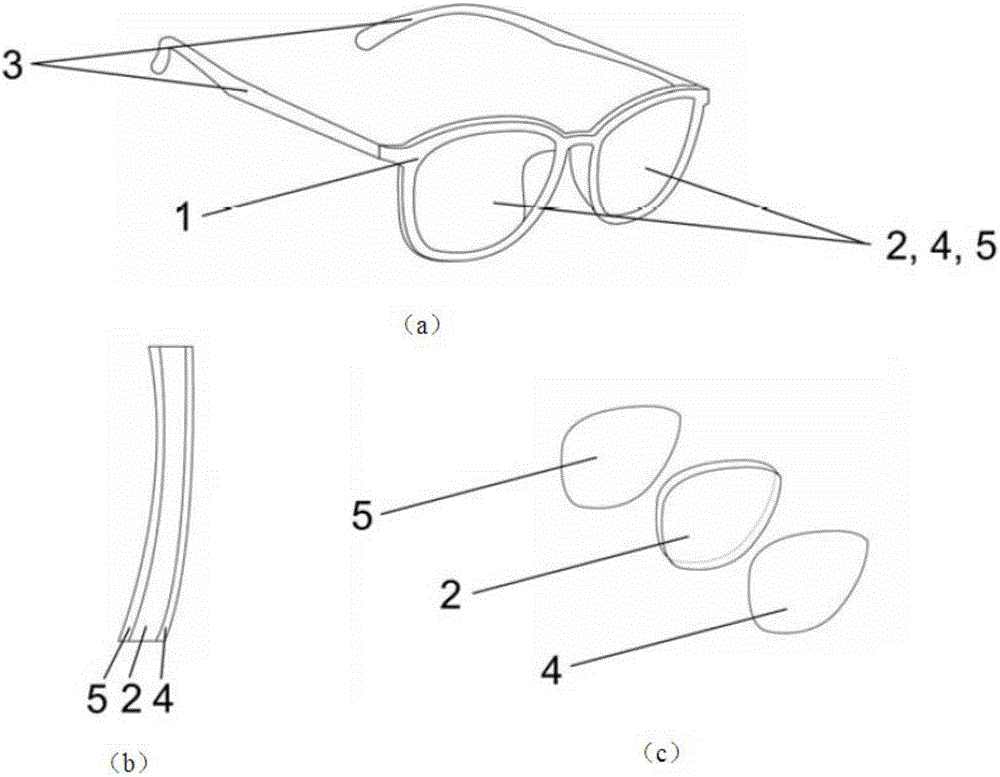

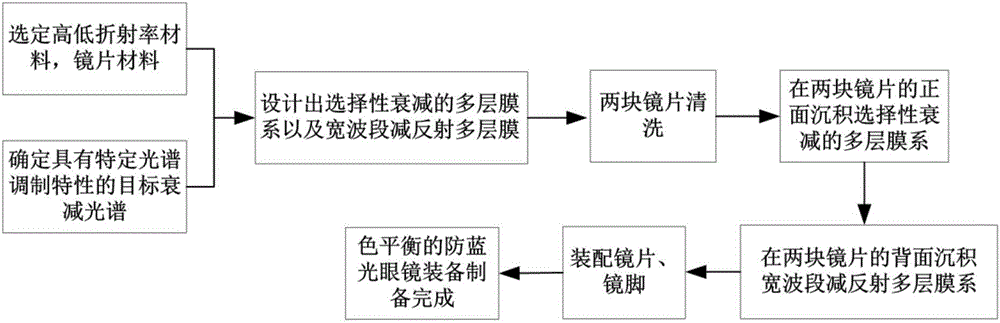

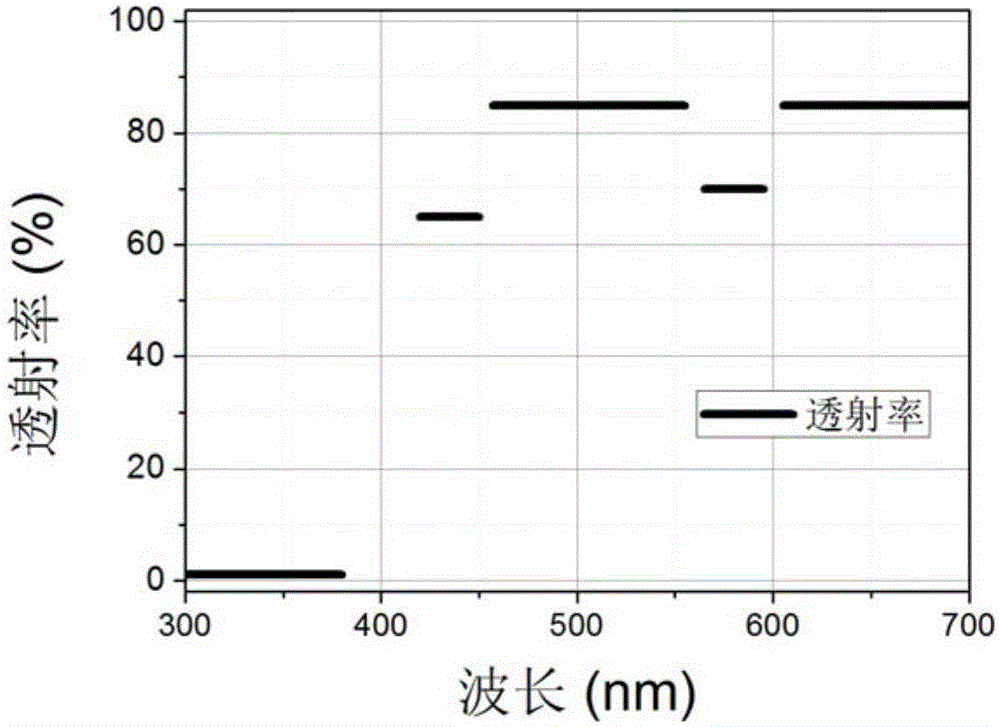

Color balance anti-blue-ray lens, glasses and equipment and manufacturing method thereof

ActiveCN106772744AAvoid harmGuaranteed indistortionOptical filtersOptical partsUltrasound attenuationHigh energy

The invention discloses a color balance anti-blue-ray lens, glasses and equipment and a manufacturing method thereof. An all-dielectric multilayer film pile with characteristics of two selective transmission attenuation band characteristics is deposited on the front side of a lens body; a wide-band anti-reflection multilayer film pile of the visible light band is deposited on the back side; the color balance anti-blue-ray lens meet the requirements that the transmission rate at the 420nm to 450nm band is lower than or equal to 65 percent; the transmission rate at the 565nm to 595nm band is lower than or equal to 70 percent; the transmission rate at the 460nm to 555nm band is higher than or equal to 85 percent; the transmission rate at the 605nm to 700 nm band is higher than or equal to 85 percent; the transmission rate at the 300nm to 380nm band is smaller than or equal to 1 percent; the color coordinate of the integral transmission spectrum is positioned in a range (0.333+ / -0.005, 0.333+ / -0.05). The proper high-low-refractive-index film layer design is selected, so that the transmission attenuation can be realized in the specific high-energy blue-ray band; the corresponding attenuation compensation can be performed in the color complementation band, so that the anti-blue-ray human eye protection without color balance distortion can be realized. The color balance anti-blue-ray lens, glasses and equipment and the manufacturing method have the advantages that the structure is compact; the manufacturing process is simple; the cost is low; the large-scale production is easy.

Owner:HANGZHOU DENGZHITA TECH CO LTD

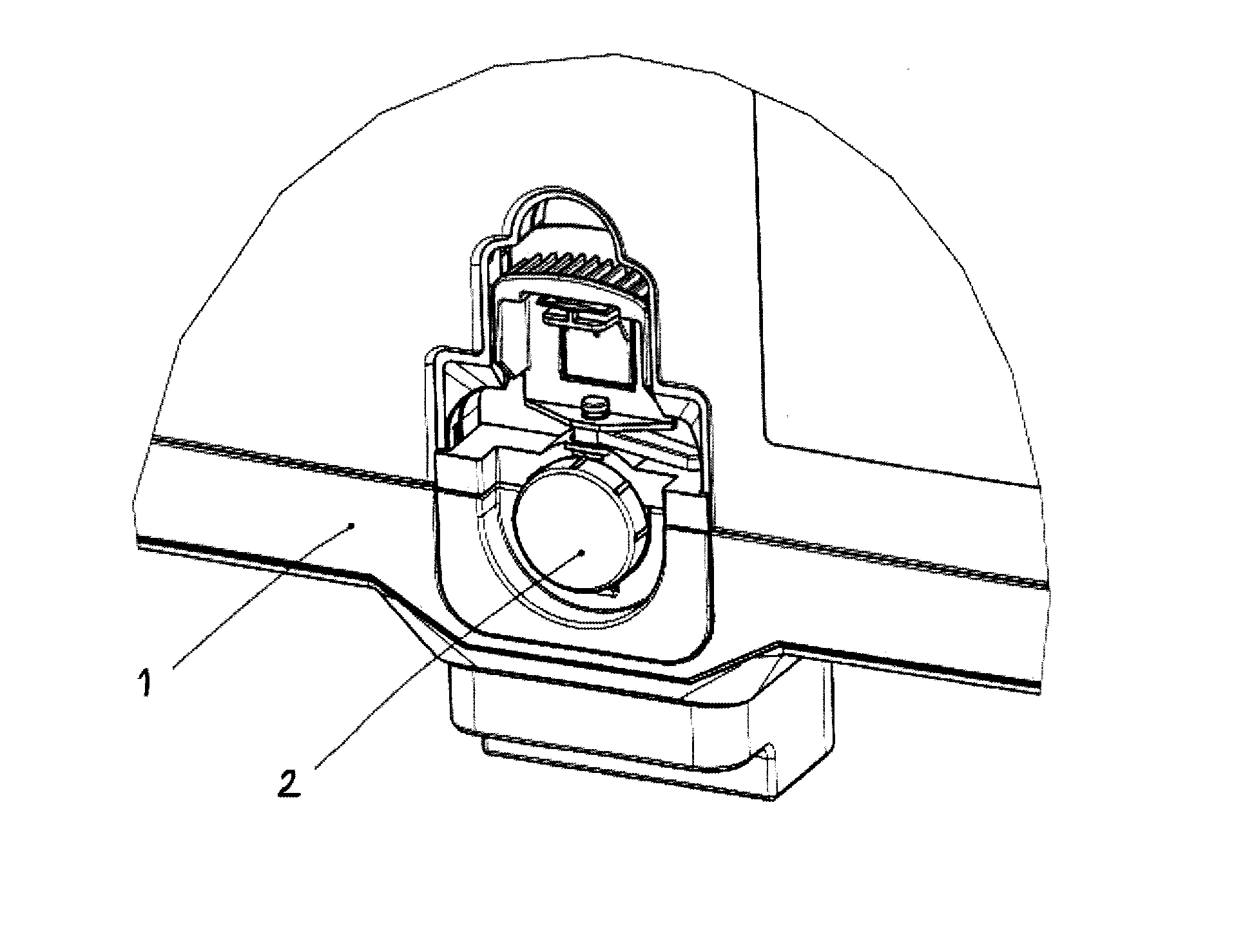

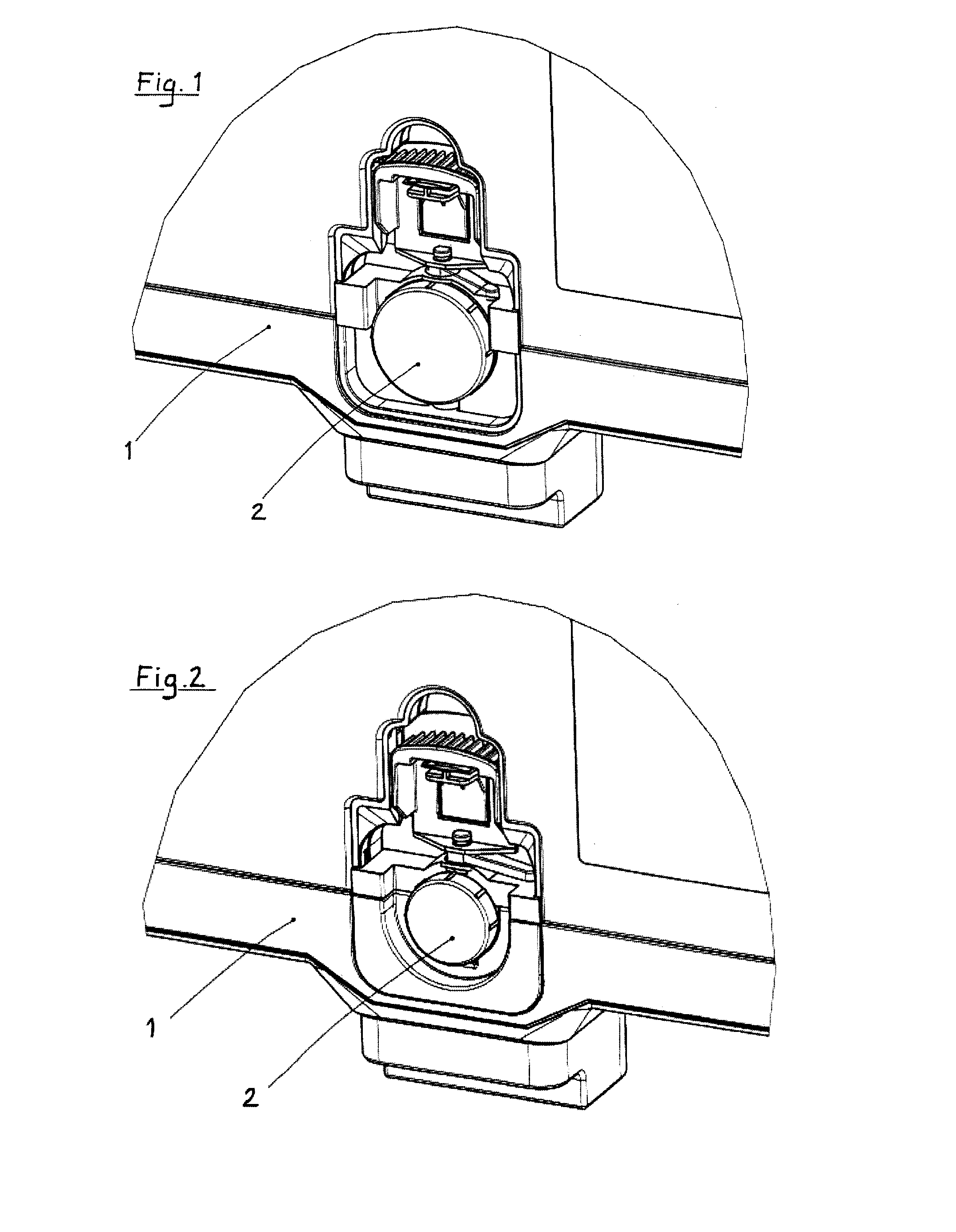

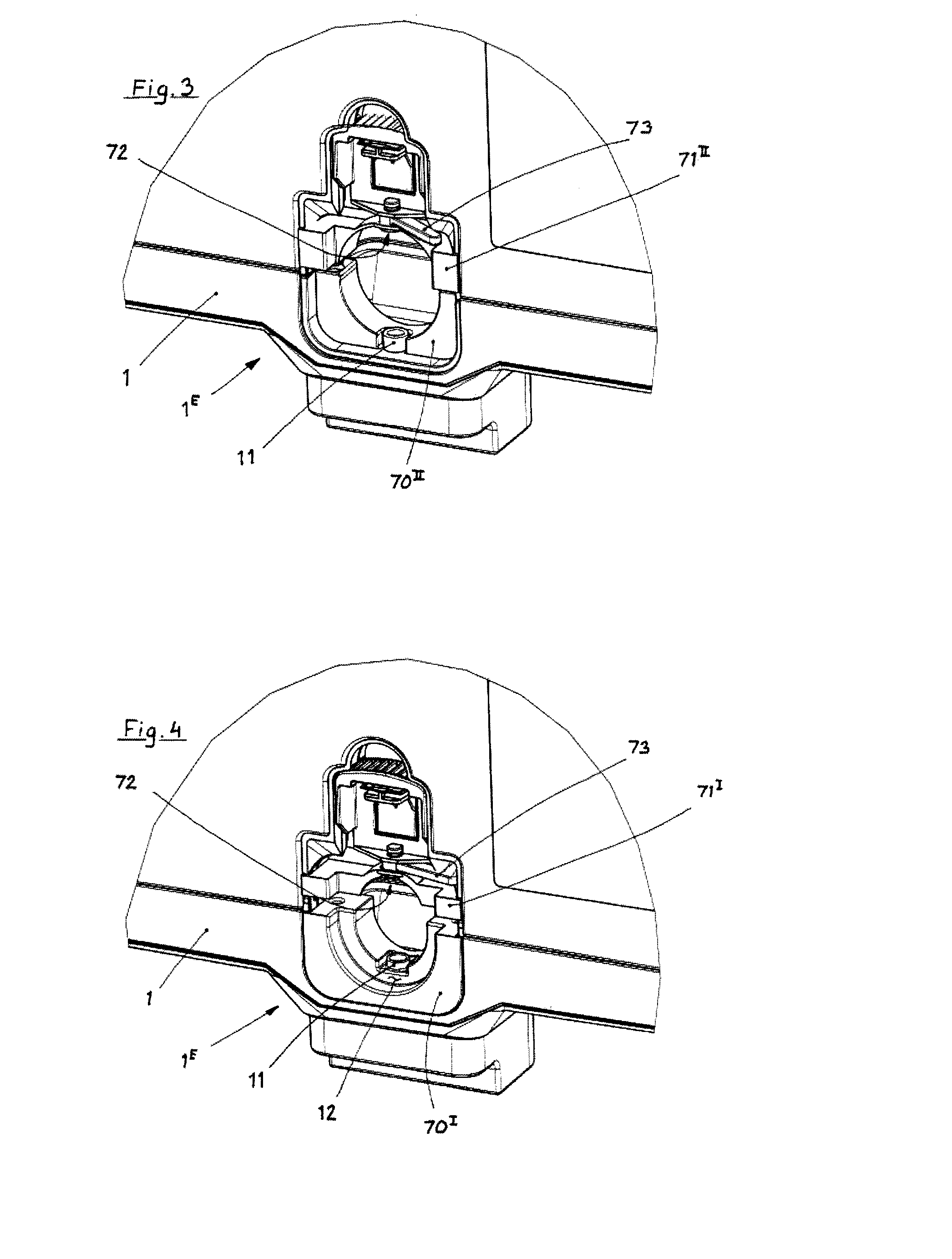

Valve assembly intended for use together with a pallet container and a liner

InactiveUS20140231689A1Efficient preparationImprove featuresClosuresLift valveBiomedical engineeringValve guide

A valve assembly (2) intended for use together with a pallet container (1) and a liner. The valve assembly (2) comprises a support member (6). The support member (6) is provided with a guiding hole (63) intended to interact with a lower valve guide member (11).

Owner:SCHOELLER ARCA SYST

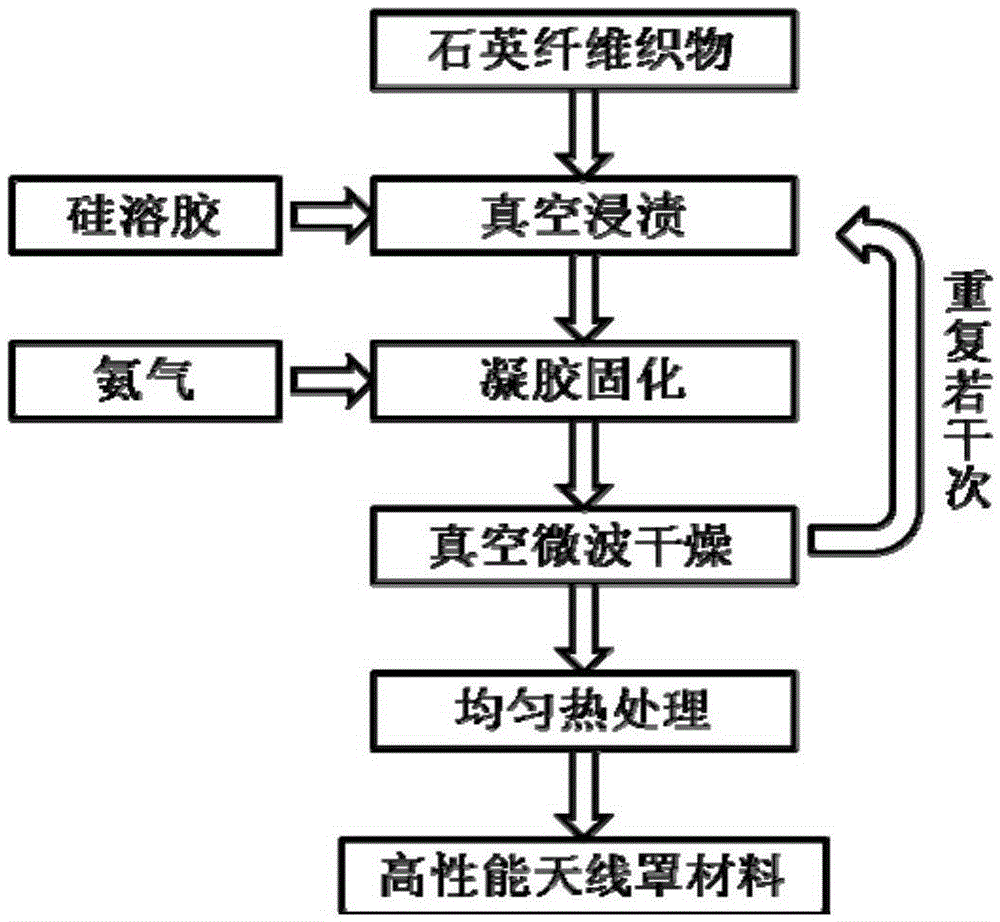

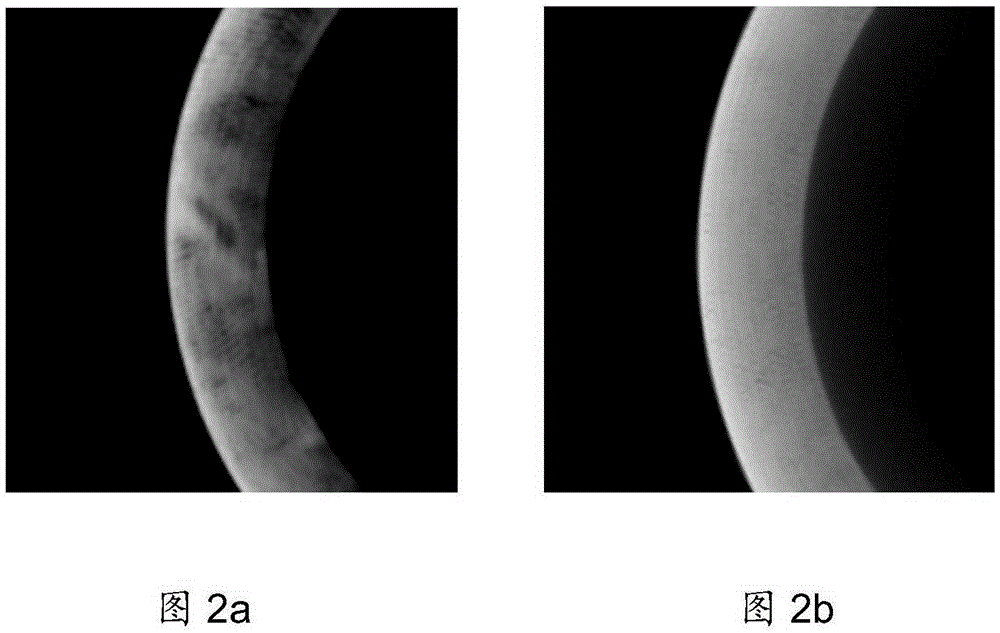

Uniform compaction method of silicon oxide based antenna housing composite

The invention relates to a uniform compaction method of a silicon oxide based antenna housing composite. According to the method, after fiber fabric is steeped, silicasol gel is changed into solid, so that overflow and loss of silicasol in subsequent procedures are avoided; quick drying is carried out by using a vacuum microwave drying technology subsequently; the above process is circulated for several times; finally, after uniform heat treatment, namely heating during rotation, the relatively compact composite with uniform density is obtained; the method significantly improves density uniformity of the material via a whole gel technology and a uniform heat treatment technology; the drying efficiency is improved via microwave drying based on the silicasol gel; time consumed by a drying procedure is shortened; and a material preparation period is shortened.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for assembling thermo-electric device through printed electronics manufacturing technology

InactiveCN102903840AHave diversitySimple methodThermoelectric device manufacture/treatmentScreen printingManufacturing technology

The invention discloses a method for assembling a thermo-electric device through a printed electronics manufacturing technology. The method comprises the steps as follows: directly preparing a thermo-electric size on a bottom electrode in a silk screen printing way; adding the prepared thermo-electric size into a marking press; marking and sintering a substrate to obtain films; drying; then printing or welding a layer of top electrode on the substrate; leading wires from the bottom electrode and the top electrode, so as to assemble to form a thermocouple; and connecting a plurality of thermocouples in series so as to form a thermo-electric device with a large area. By adopting the method, the thermo-electric device can be assembled on a rigid foundation; the thermo-electric device also can be assembled on a flexible base plate such as an aluminum sheet, so that options are diversified; the method is simple, convenient to implement, and low in cost; and compared with conventional preparation technology for thermo-electric devices, the method is high in production efficiency, and particularly suitable for mass production.

Owner:SHANGHAI UNIV

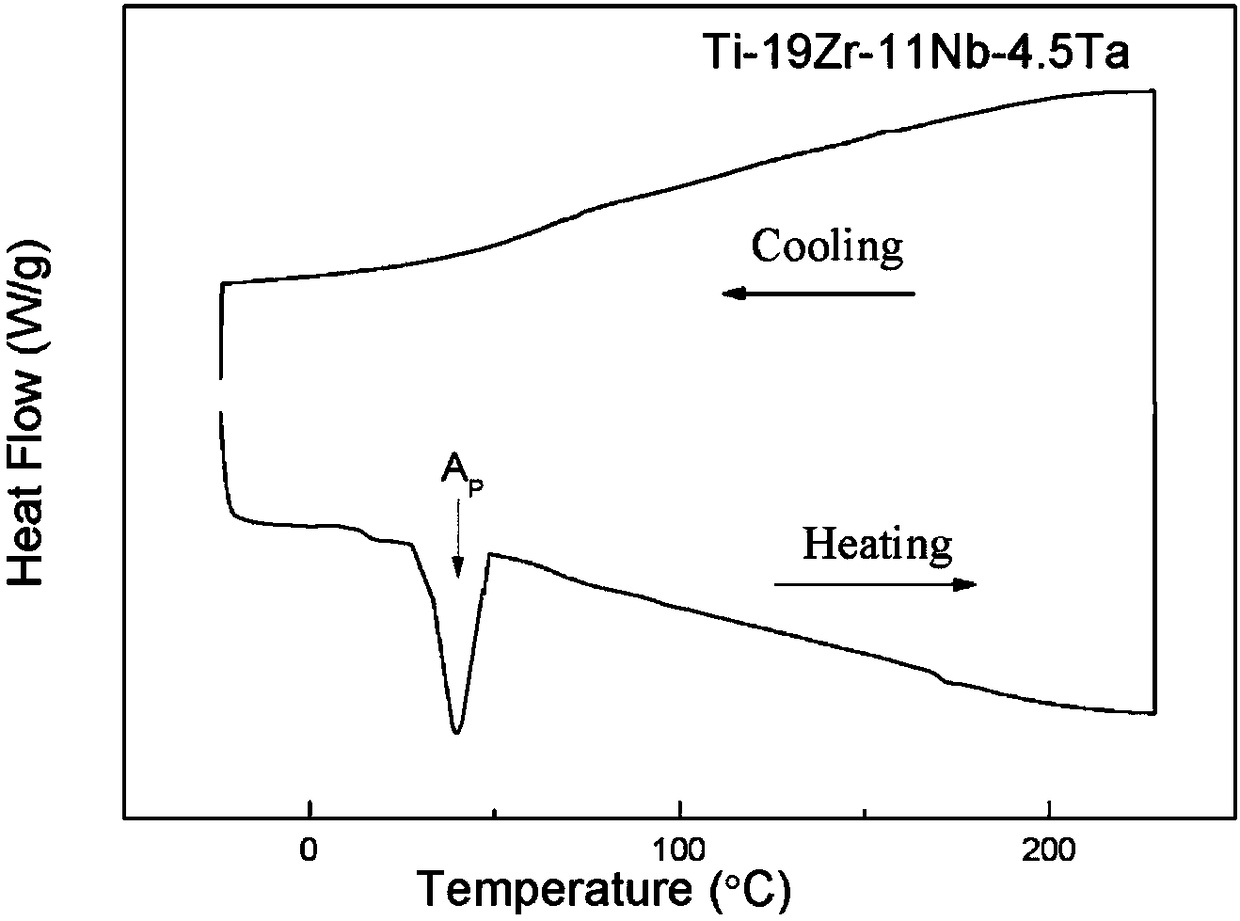

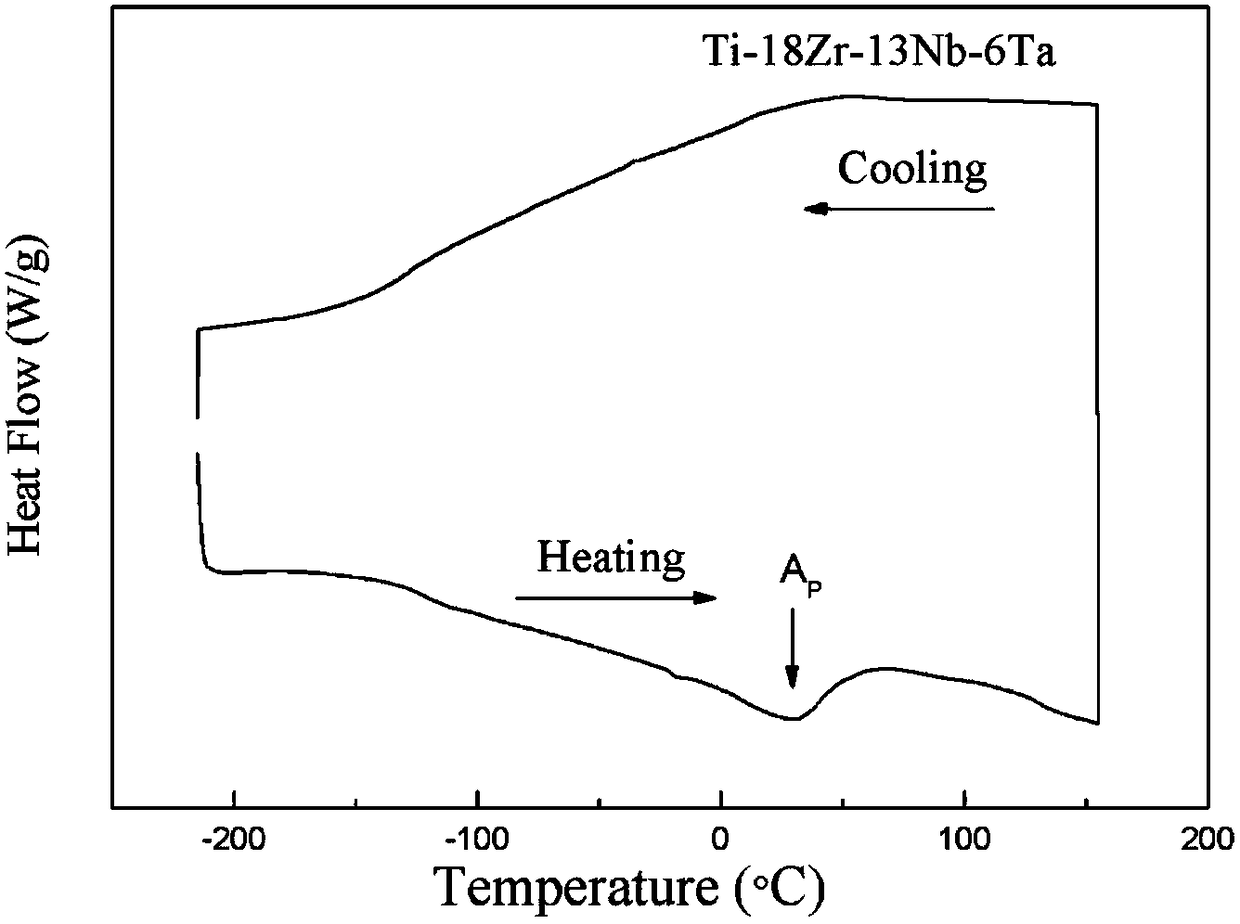

Low-phase-transformation-temperature titanium-zirconium-niobium-tantalum shape memory alloy, a preparation method and application thereof

The invention provides a novel titanium-zirconium-niobium-tantalum shape memory alloy with a low phase transformation temperature. Based on the total amount of 100 percent, the titanium-zirconium-niobium-tantalum shape memory alloy is prepared from the following components by atomic percent: 15 to 25 percent of zirconium, 11 to 15 percent of niobium, 4.5 to 10 percent of tantalum and the balance of titanium. The reverse martensitic phase transformation temperature is 0 to 45 DEG C, the maximum shape memory effect is 3.9 percent, and an alloy product with a great shape memory effect and good biocompatibility is obtained by certain thermomechanical treatment. According to the titanium-zirconium-niobium-tantalum shape memory alloy, a low-phase-transformation-temperature alloy material is provided to prepare a typical medical straddle nail product by use of an advanced machining technology for application to medical human body orthopaedic implantation, and preparation of connectors, vascular stents, straddle nails and various products in the field of human body implantation medical devices.

Owner:烟台浩忆生物科技有限公司

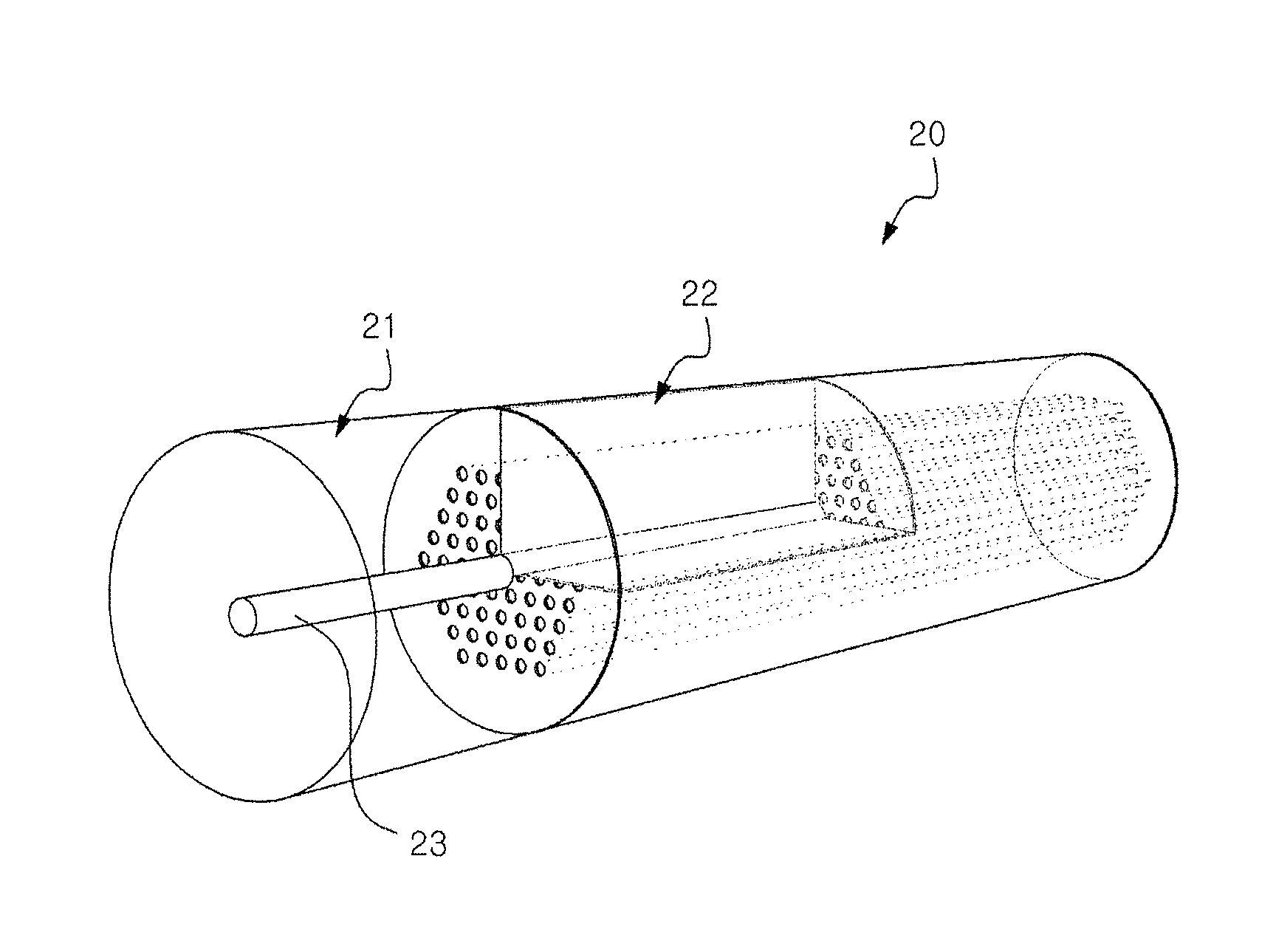

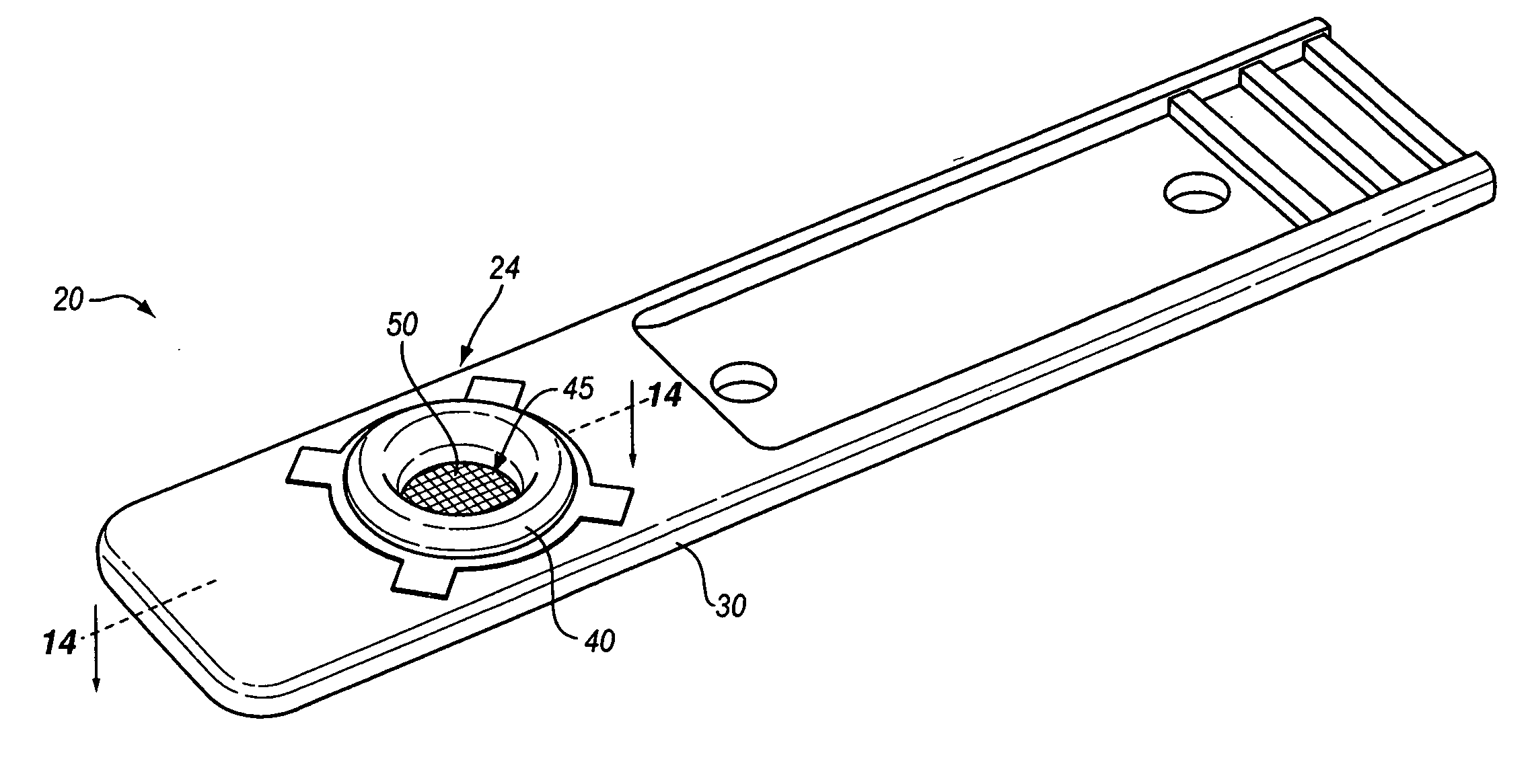

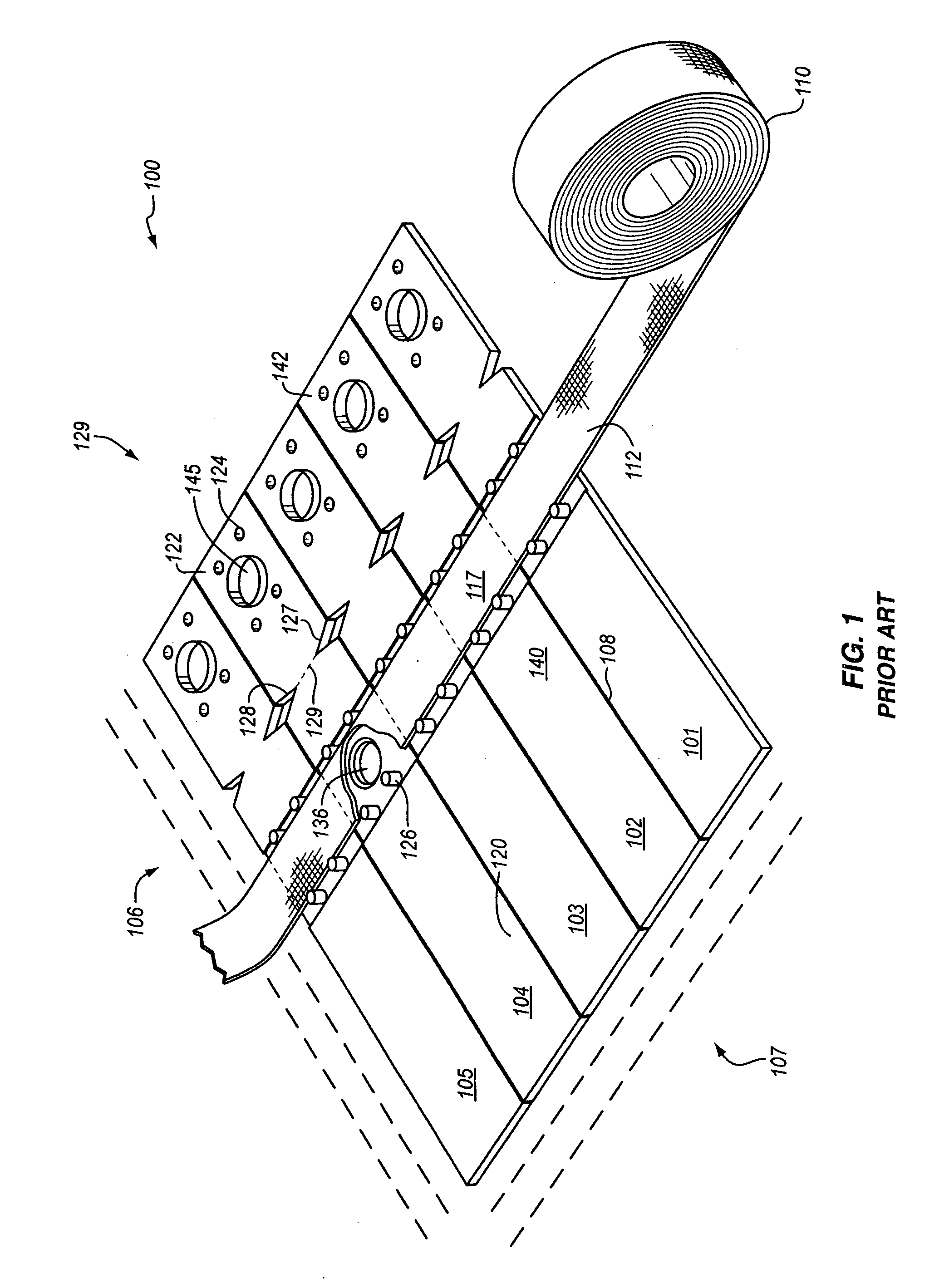

Apparatus and method of manufacturing bodily fluid test strip

InactiveUS20060062690A1Reduce wasteEfficient manufacturing processAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionEngineeringBody fluid

There is a dry test strip holder having a test port and a retainer defining a well about the test port, and a sheet of test strip material. A test element that is 50% or less greater than the size of the test port is cut from the sheet using a die and punch. The punch drives the test element through a channel in the die while the cone-shaped outer surface of the die spreads the retainer, allowing the test element to drop into the well. A cap is snapped over the retainer to capture the test element.

Owner:POLYMER TECH SYST

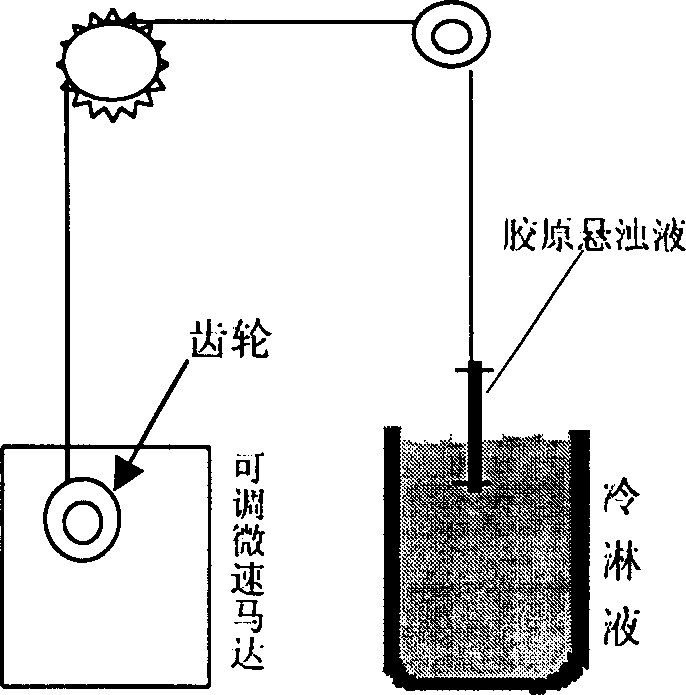

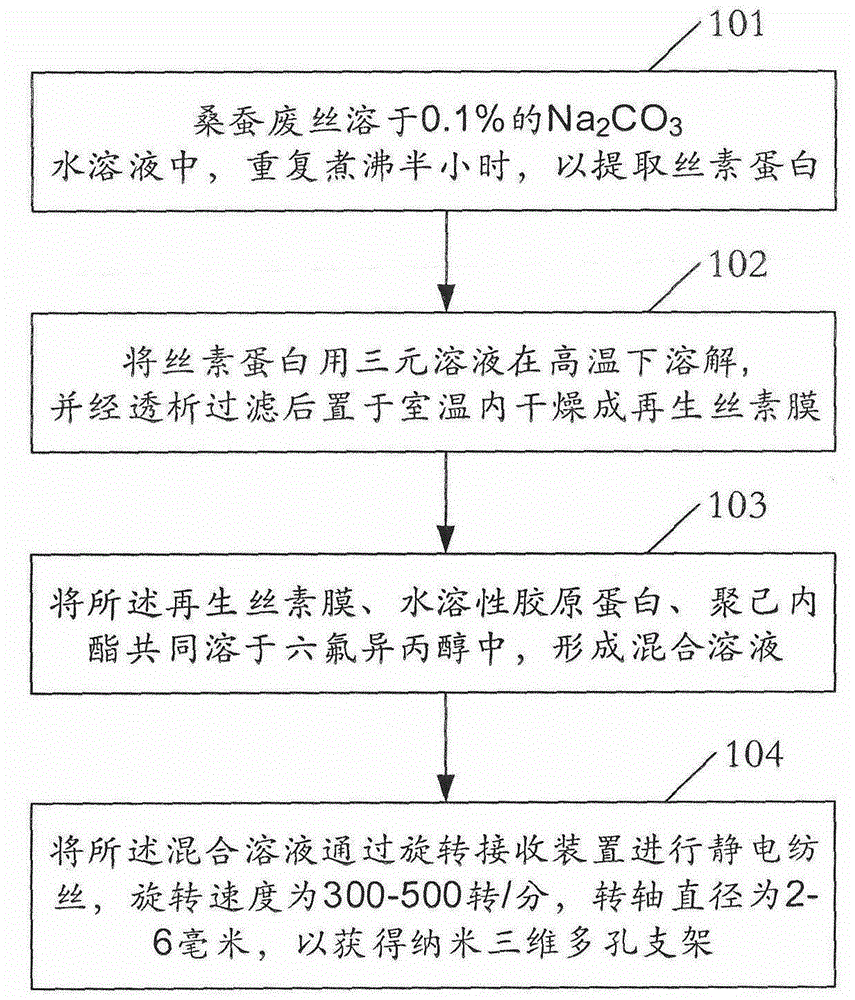

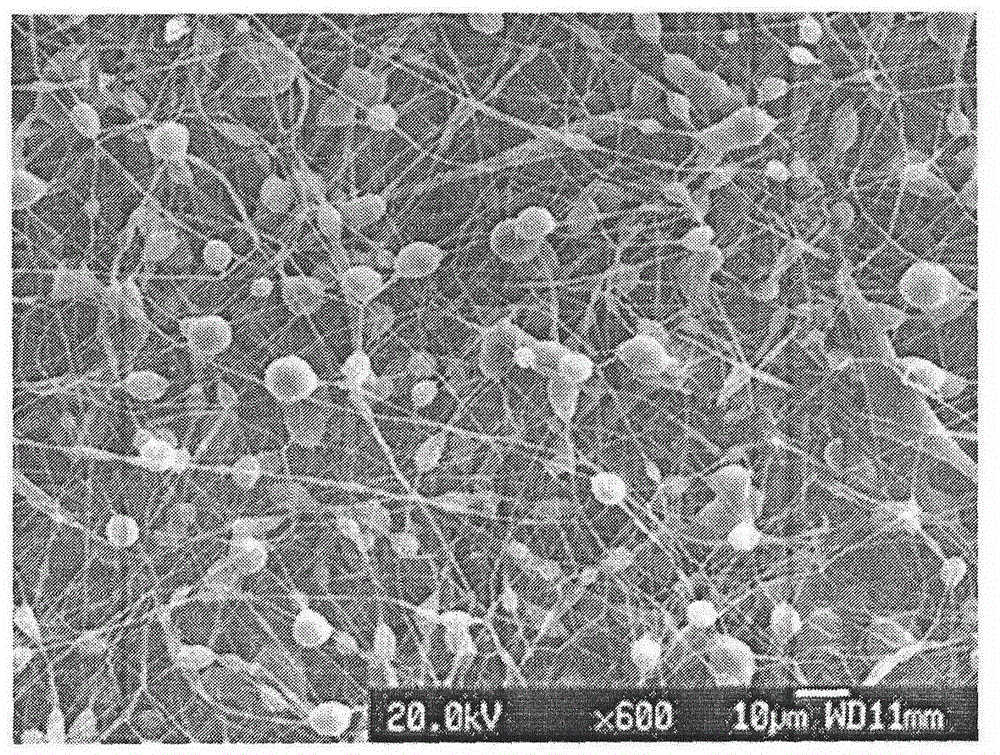

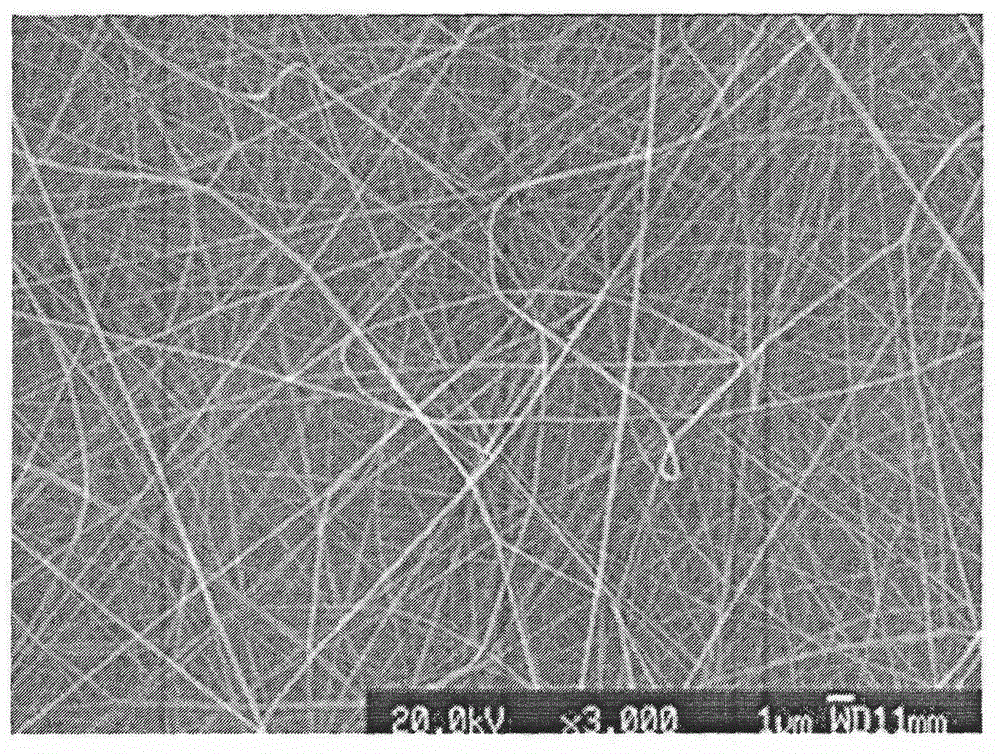

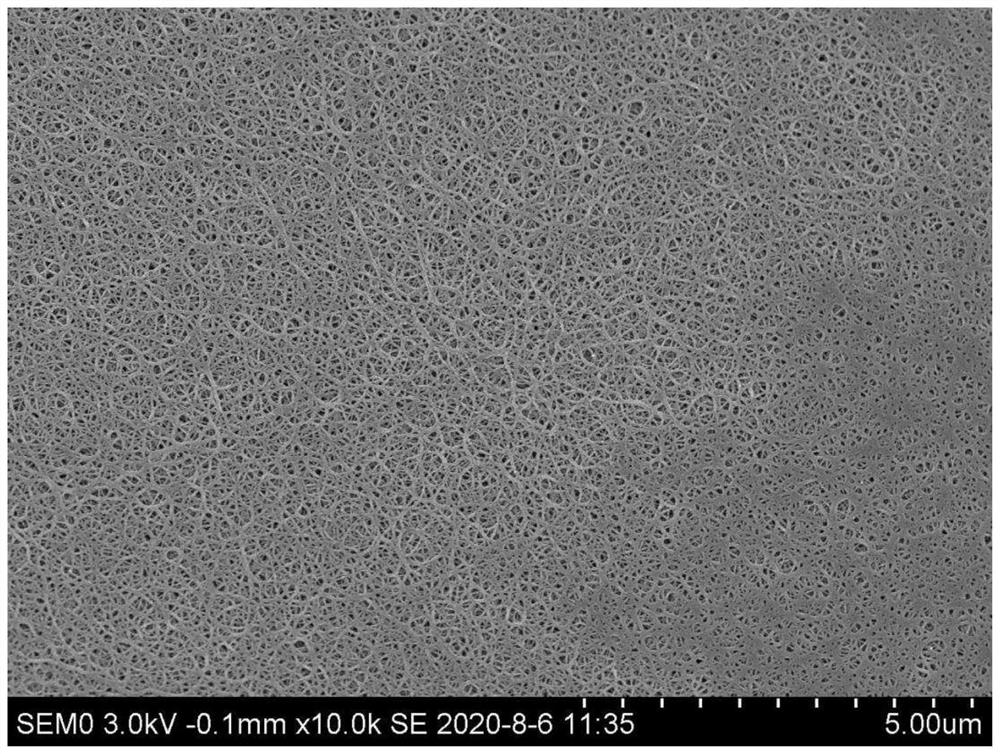

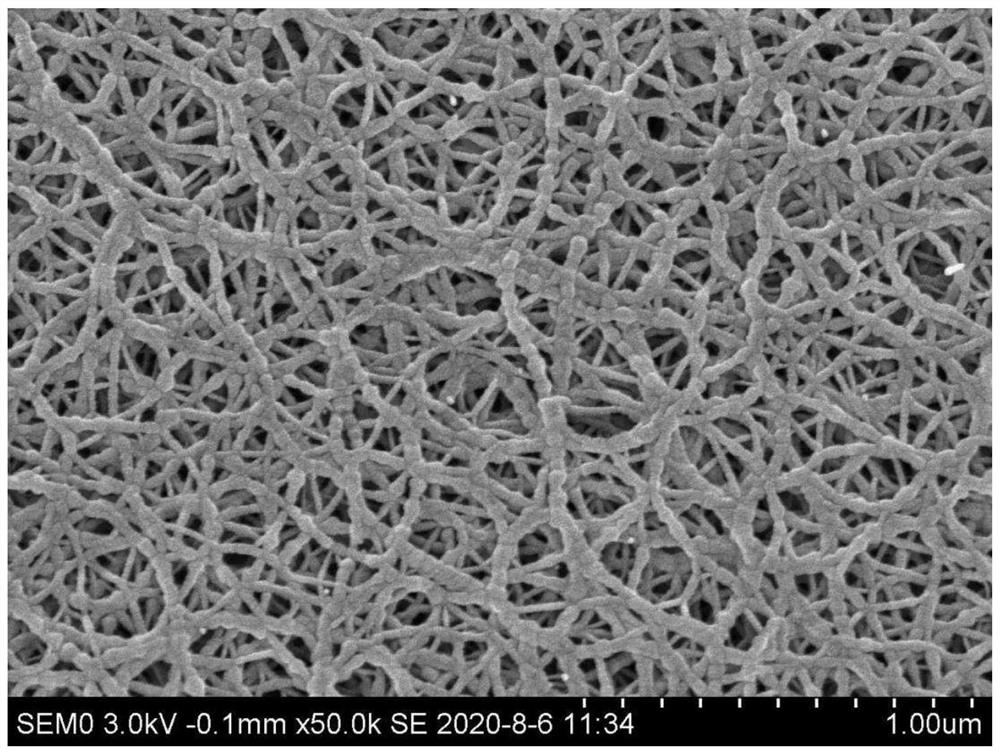

Polycaprolactone-collagen-fibroin nano three-dimensional porous stent and preparation method thereof

InactiveCN104874018AEasy to processEfficient manufacturing processFilament/thread formingConjugated cellulose/protein artificial filamentsUrethral stentsFresh Tissue

The invention relates to the field of the preparation of urethral stents, and discloses a polycaprolactone-collagen-fibroin nano three-dimensional porous stent and a preparation method thereof. The preparation method comprises the following steps of dissolving waste mulberry silk in a 0.1 percent of Na2CO3 aqueous solution, and repeatedly boiling for half an hour, so as to extract silk fibroin; dissolving the silk fibroin at a high temperature by using a ternary solution, dialyzing and filtering, and then putting at a room temperature for drying to form a regenerated silk fibroin membrane; dissolving the regenerated silk fibroin membrane, water-soluble collagen and polycaprolactone in hexafluoroisopropanol together, so as to form a mixed solution; carrying out electrostatic spinning on the mixed solution through a rotary receiving device, so as to obtain the nano three-dimensional porous stent, wherein a rotation speed is 300 to 500 revolutions per minute, and the diameter of a rotating shaft is 2 to 6 millimeters. The stent provided by the invention is convenient and efficient to process and manufacture, is convenient to apply, moreover, is convenient for adjusting various performances of a material, is stale in structure, and has certain mechanical strength to support the growth of a fresh tissue.

Owner:SHANGHAI TONGJI HOSPITAL

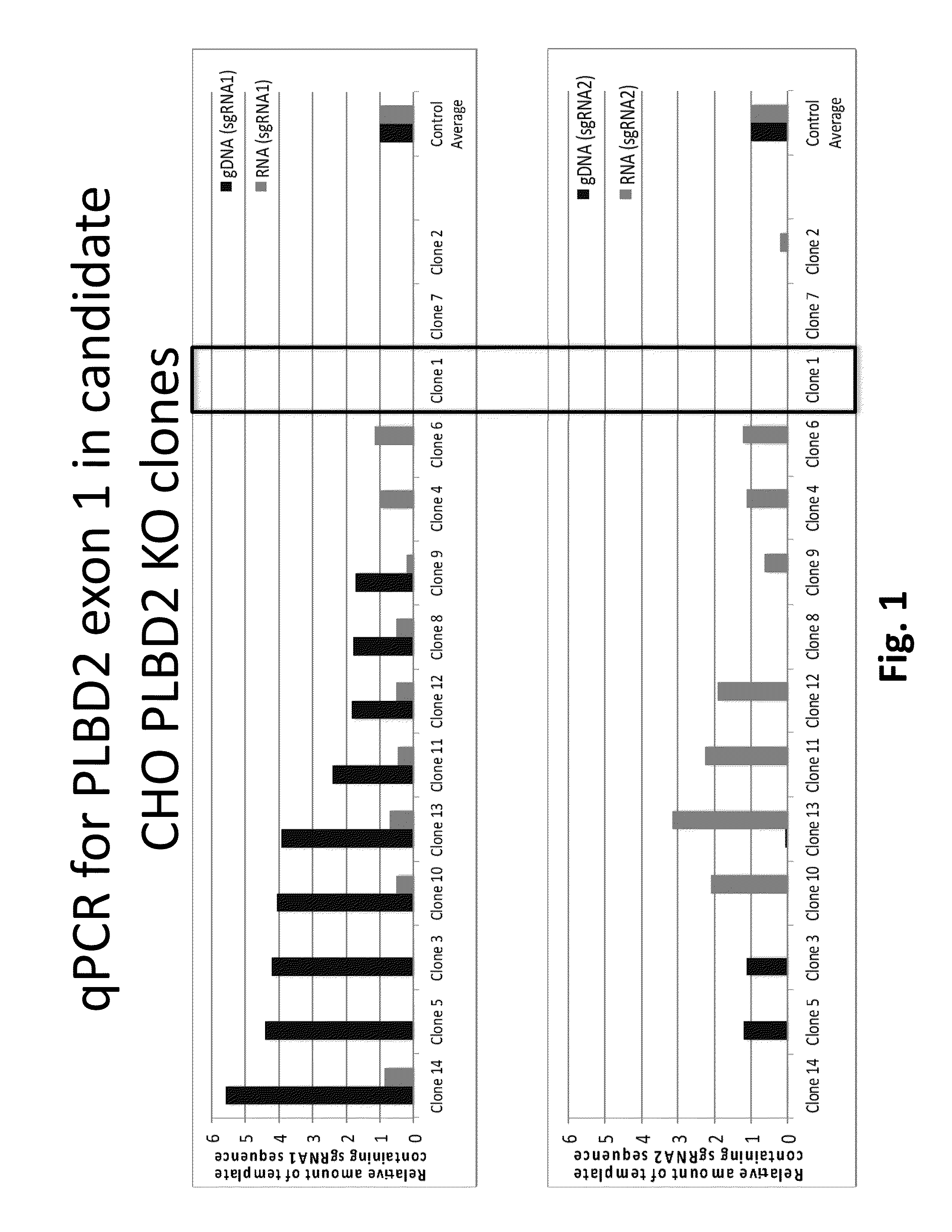

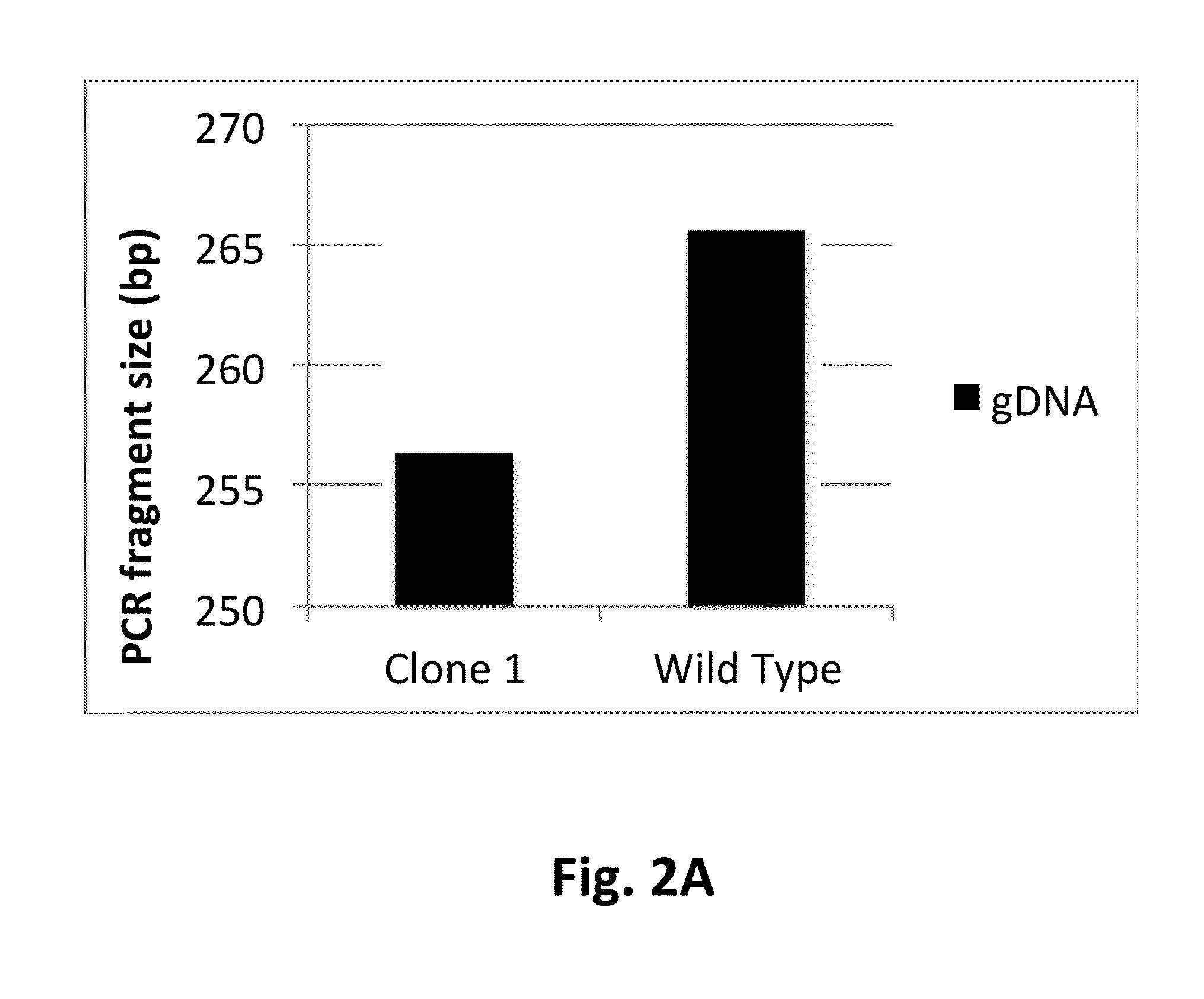

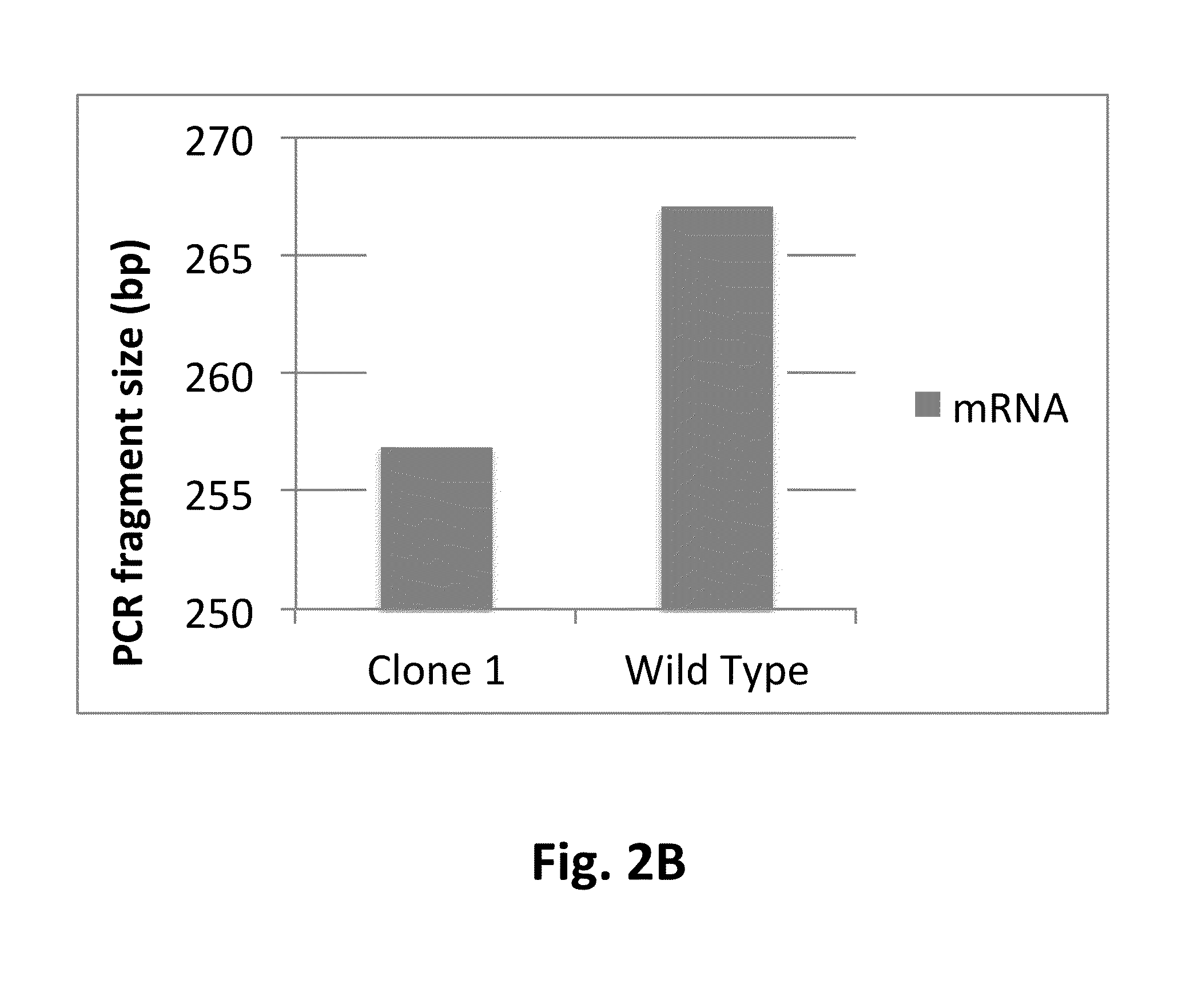

Host cell protein modification

InactiveUS20160251411A1Efficient manufacturing processEfficient preparationHydrolasesGenetically modified cellsMolecular biologyEukaryotic cell

Compositions and methods for engineered cell lines and expressions systems are provided that allow for expression of recombinant proteins in eukaryotic cells and their ease of isolation. Cell expression systems capable of expressing a protein of interest essentially free of a bound host cell protein are also provided.

Owner:REGENERON PHARM INC

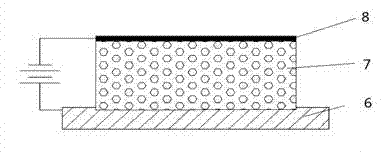

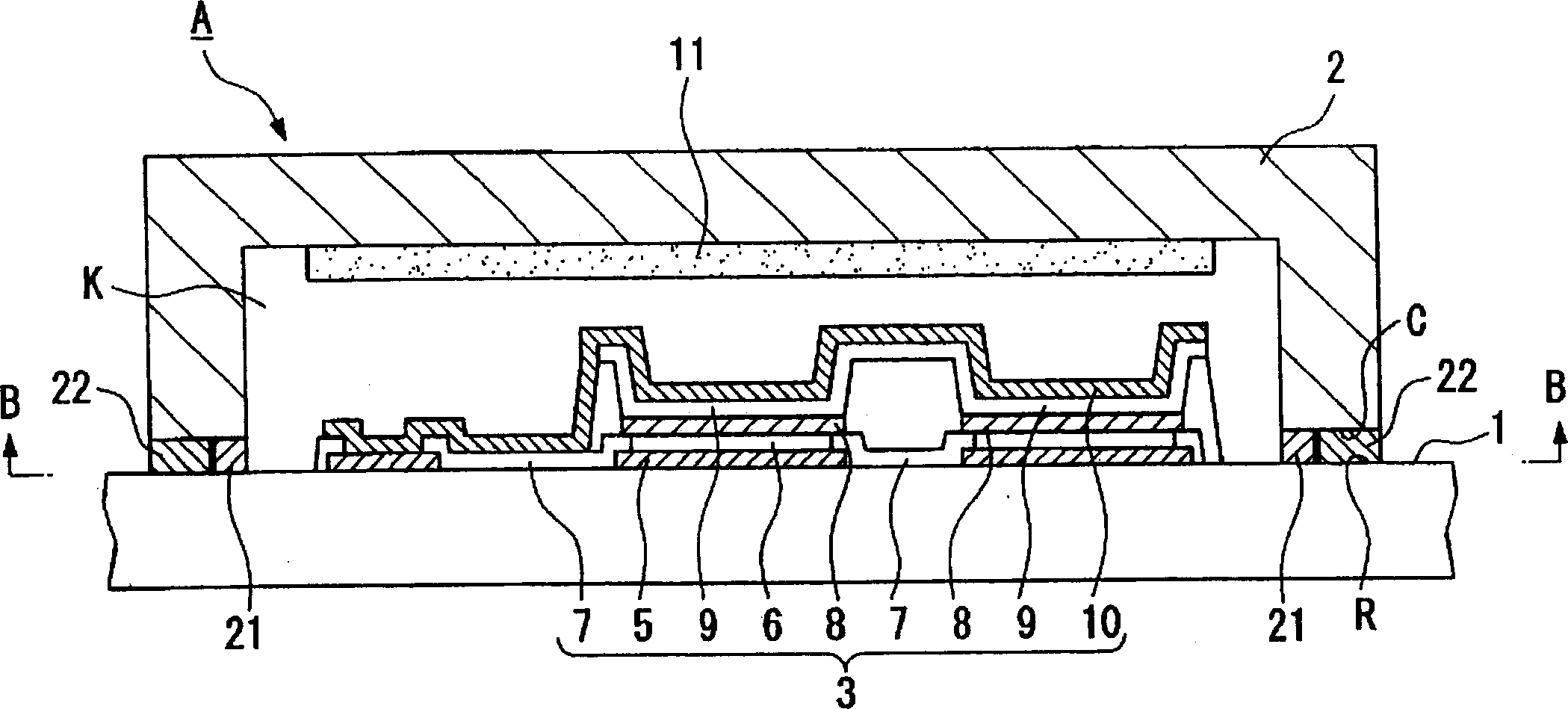

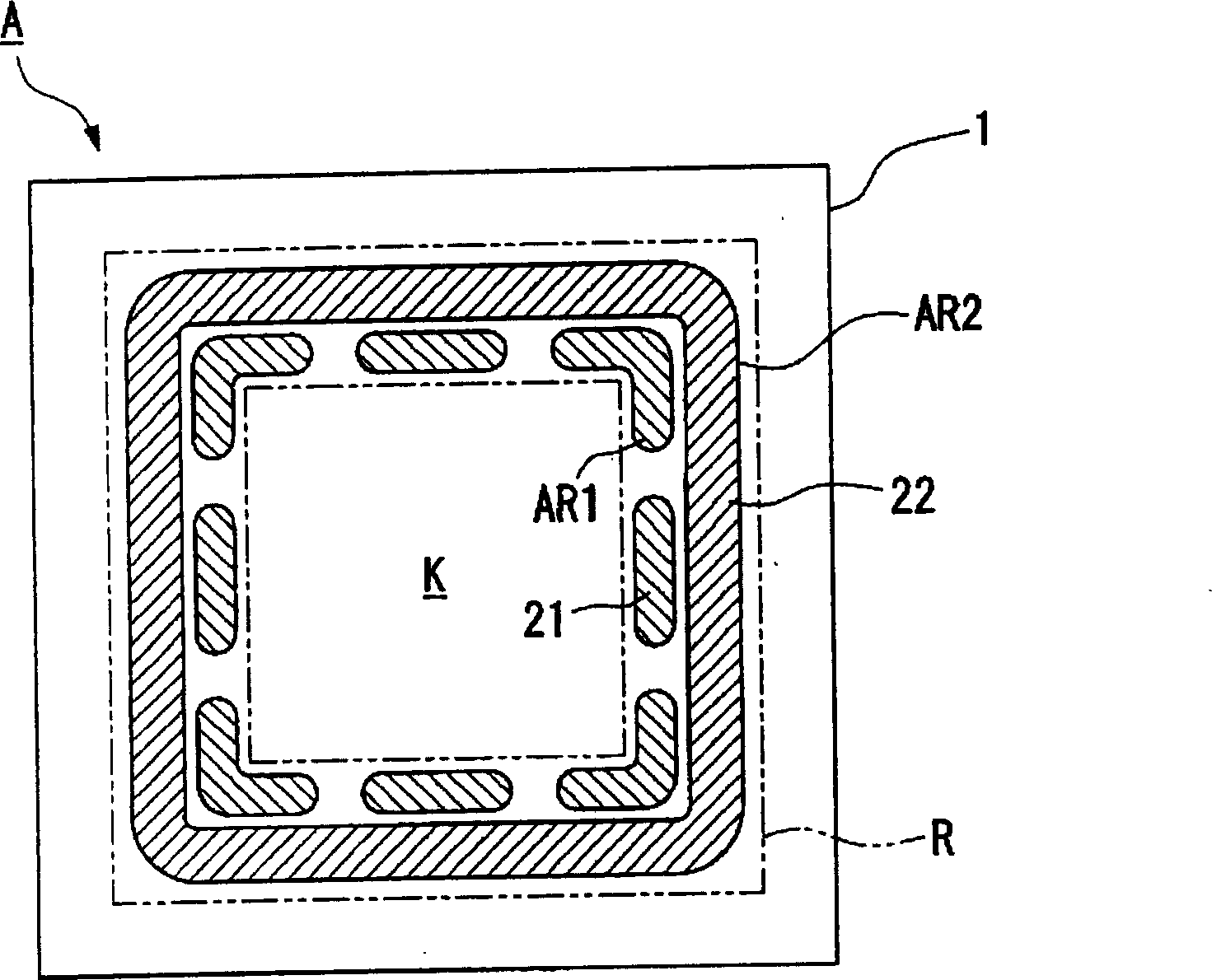

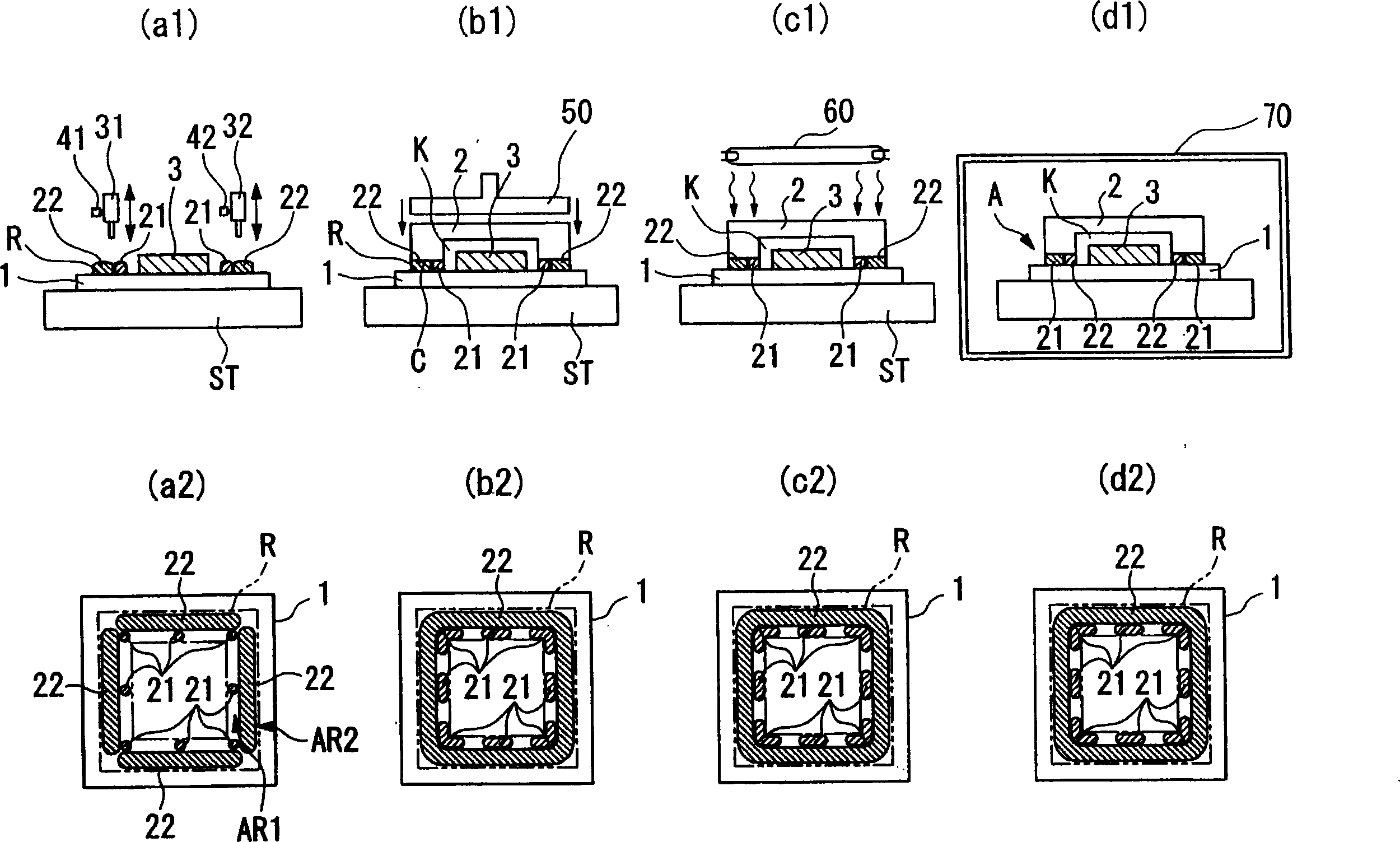

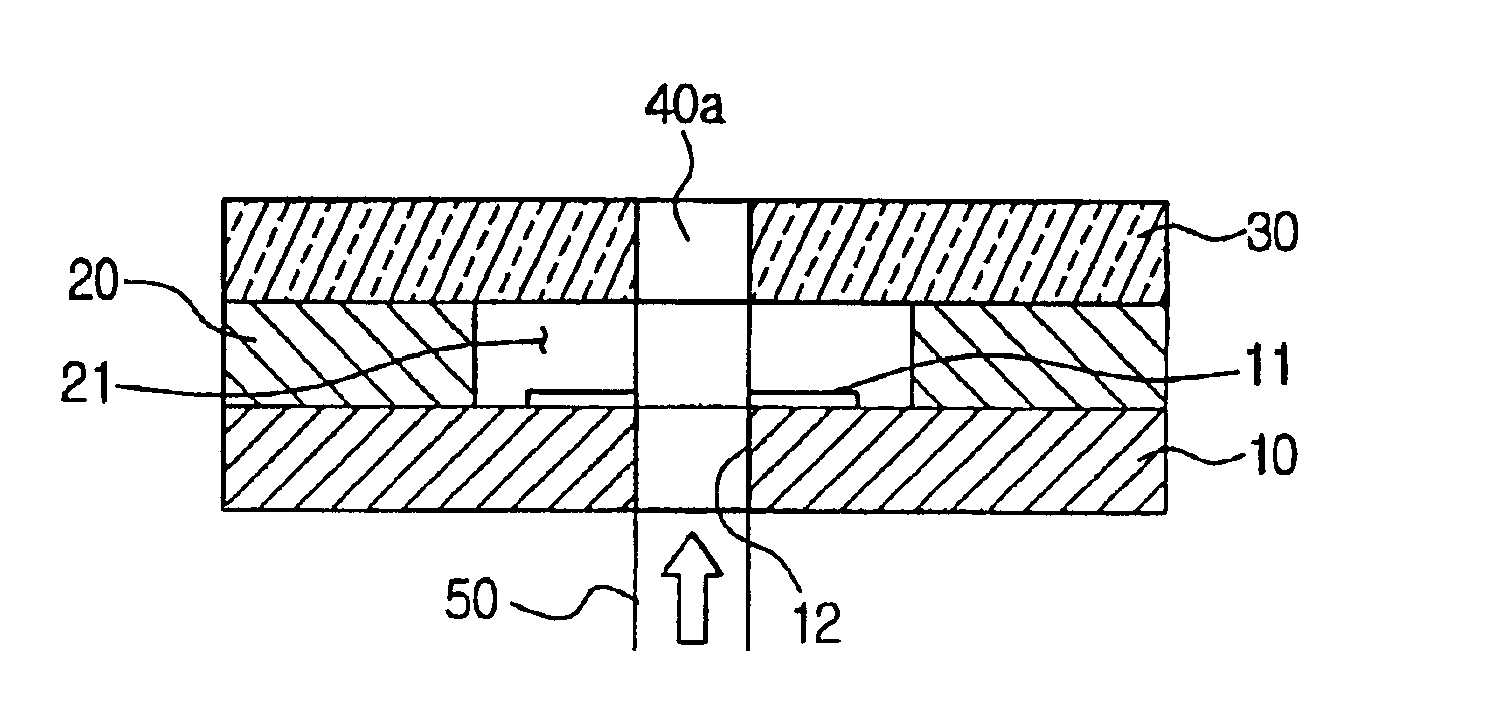

Electrooptical device and electronic appliances

InactiveCN1913193AReduce curing waiting timeEfficient manufacturing processElectroluminescent light sourcesSolid-state devicesAdhesiveEngineering

The present invention provides an electro-optical device including a light-emitting element disposed on a first member, including: a second member; and a filler filled in a surface of the first member on which the light-emitting element is formed and the a sealed space formed between the second components; and a discontinuously disposed adhesive disposed outside the portion where the light emitting element is formed, for bonding the first component and the second component.

Owner:SEIKO EPSON CORP

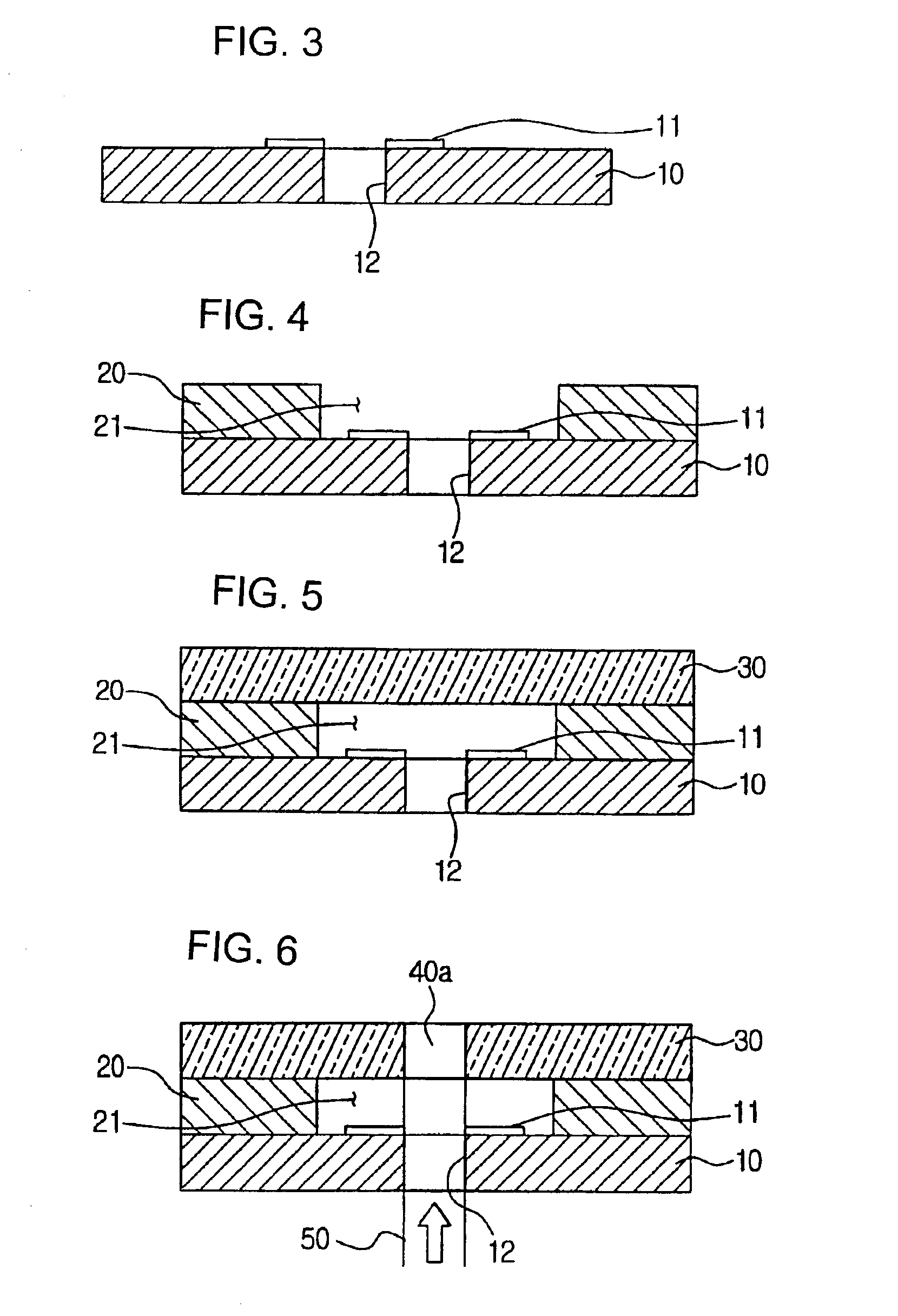

Method of manufacturing head of inkjet printer

InactiveUS6922892B2Improve discharge efficiencyEfficient manufacturing processError preventionWave amplification devicesSpray nozzleProduction rate

A method of manufacturing a head of an inkjet printer includes forming a heater on a substrate and also forming an ink feeding passage through the substrate in a vertical relation to a surface where the heater is formed, forming an ink chamber communicating with the ink feeding passage of the substrate; attaching the substrate to the nozzle plate, and forming a tapered nozzle in the nozzle plate, the tapered nozzle being narrower in diameter in an inside of the nozzle plate than an outside of the nozzle plate, by radiating a laser beam from inside toward the outside of the nozzle plate, wherein the substrate is used as a mask. Since the nozzle is formed by radiating the laser beam to the nozzle plate through the ink feeding passage of the substrate after attaching the nozzle plate to the substrate, the accuracy of the nozzle in form and position improves, and the nozzle of desirable structure of the improved ink discharge efficiency can be obtained by radiating the laser beam only once. Also, the manufacturing process becomes simpler, and due to improved manufacturing process, the productivity increases.

Owner:HEWLETT PACKARD DEV CO LP

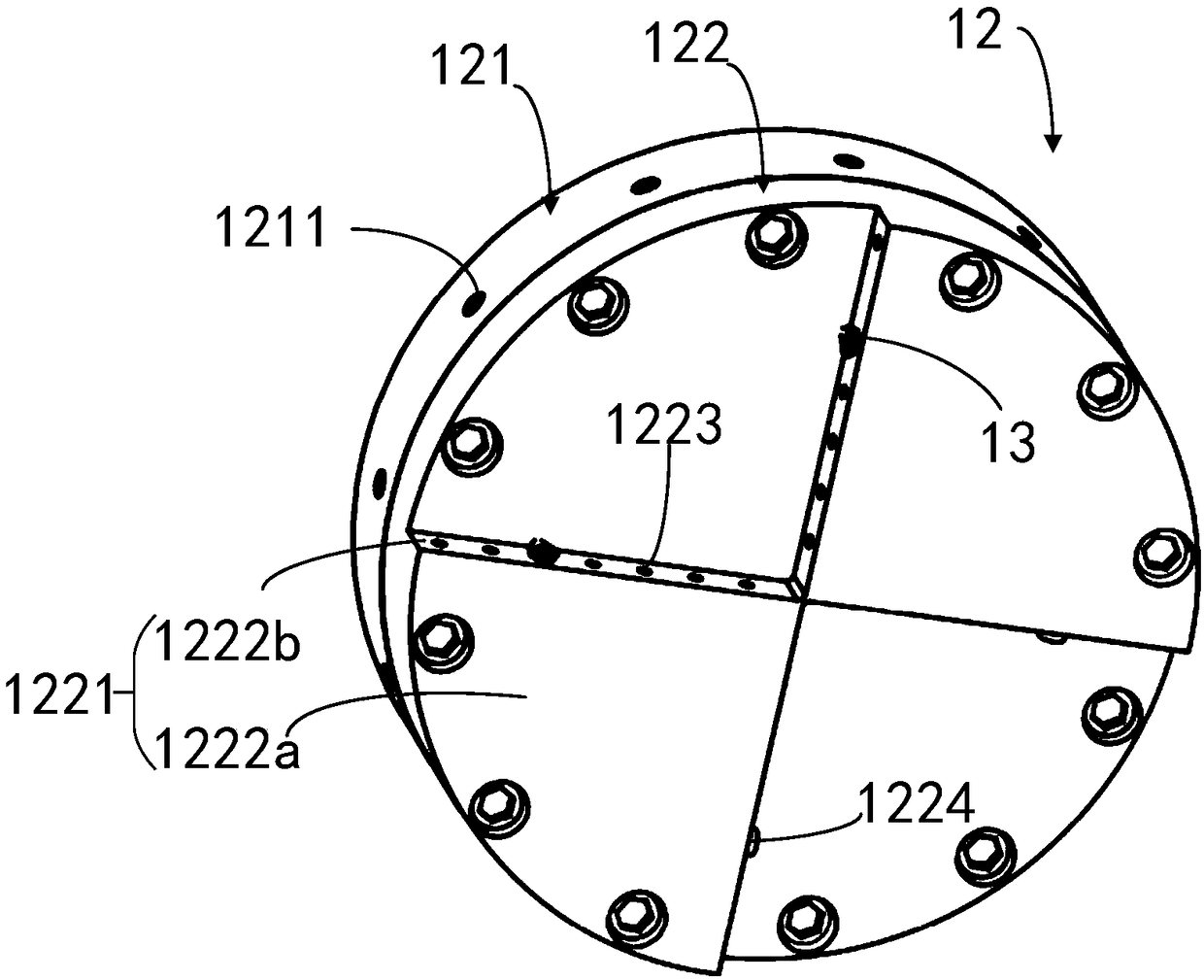

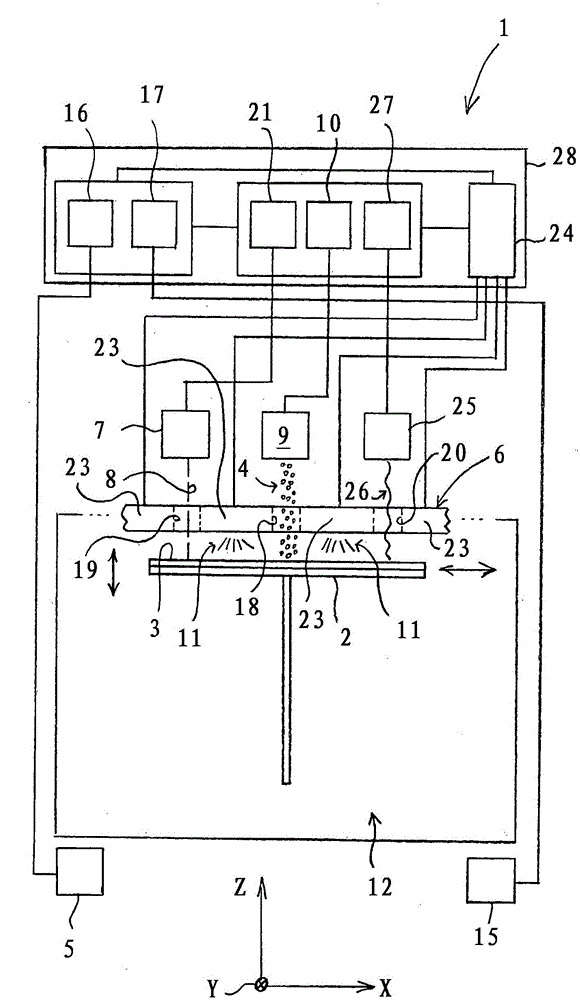

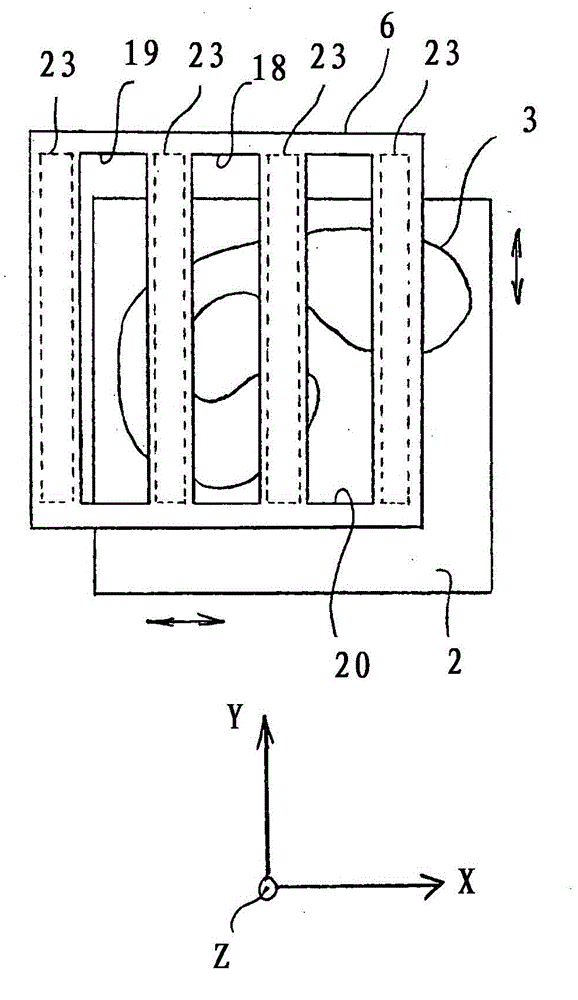

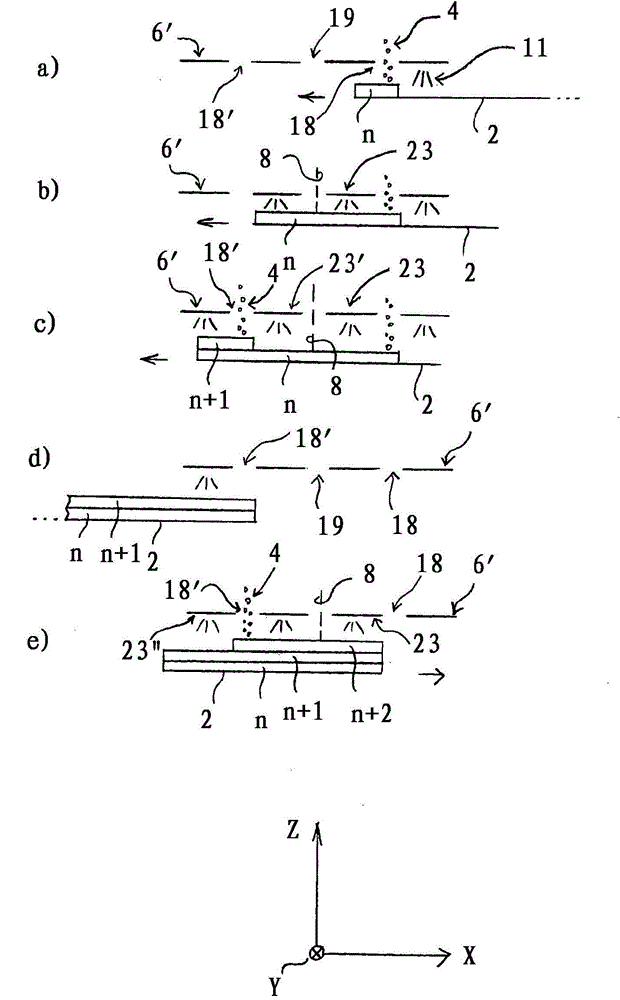

Apparatus for manufacturing three-dimensional objects

ActiveCN104416907AEfficient manufacturing processManufacturing heating elementsAuxillary shaping apparatusEngineeringRadiation

An apparatus and a method manufacture three-dimensional objects by selective solidification of a build material applied in layers. In order to improve the manufacturing process and in particular to optimize heat input, a heating element is provided that has at least two functional openings. One of the at least two functional openings serves as a material pass-through and another of the at least two functional openings serving simultaneously as a radiation pass-through.

Owner:FIT股份公司

A protection assembly for an off-road vehicle

InactiveCN103255803AReduce stiffnessReduce structural stiffnessMechanical machines/dredgersSuperstructure subunitsEngineering

The invention discloses a protection assembly for an off-road vehicle. The protection assembly comprises a protection board and a plurality of protection ribs. One end of at least one rib is lower than the same end of each of the other ribs and all the ribs are identical at the other end. Two ends of each rib are provided with inclined surfaces. The protection board is also provided with one or a plurality of profiles which comprises a constant part at the front end of the protection board and a variable part guided to the front end of the protection board. The protection assembly is arranged on a base board of a vehicle part in a manner that the width of the protection board is the same as the interval of side boards. The ribs can be welded or bound to the protection board which can be welded or bound to the base board of a protected part.

Owner:DEERE & CO

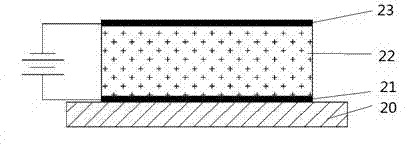

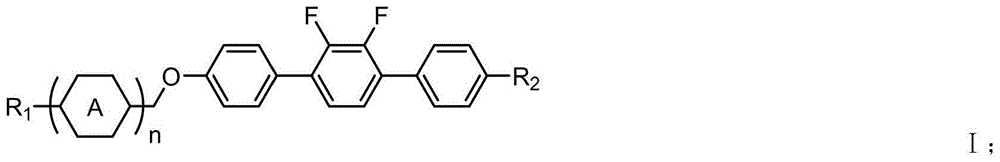

High-clearing-point and high-refractive-index anisotropic negative liquid crystal composition and application thereof

ActiveCN104974766AShorten the timeReduce intensityLiquid crystal compositionsNon-linear opticsCrystallographyDielectric anisotropy

The invention discloses a high-clearing-point and high-refractive-index anisotropic negative liquid crystal composition which includes one or more of compounds represented as the general formula I, one or more of compounds represented as the general formula II, one or more of compounds represented as the general formula III, one or more of compounds represented as the general formula IV and / or one or more of compounds represented as the general formula V. The liquid crystal composition is high in response speed, low in rotation viscosity, high in clearing point, high in optical-anisotropy and high in dielectric-anisotropy. A liquid crystal display device employing the liquid crystal composition is quick in response, is high in clearing point and is low in driving voltage, can achieve balance of all performances and is suitable for liquid crystal displayer in the modes of VA, IPS or ECB. In addition, the polymerization wave band of a liquid crystal medium containing the liquid crystal composition can be closed to a large wave band, so that the liquid crystal medium can be used for producing the display device with a long UV wavelength, thereby reducing or avoiding harmful and damaging effect due to a short UV light component. The liquid crystal composition can be widely used in liquid crystal displayers in the modes of PSA, PSVA or PNLC.

Owner:JIANGSU HECHENG DISPLAY TECHCO

Method for preparing copper-based catalyst carrier

ActiveCN104016342AIncrease productivityGood dispersionCatalyst carriersCarbon compoundsDispersityBULK ACTIVE INGREDIENT

The invention relates to a method for preparing a copper-based catalyst carrier. The method comprises the following steps: taking crushed plant-based raw materials, carbonizing the plant-based raw materials by use of mixed acid at 20-80 DEG C for 2-12 hours so as to obtain a carbonized material; washing the carbonized material with deionized water until the pH value is equal to 7, and activating to obtain the activated carbon; washing the activated carbon with 2mol / L hydrochloric acid until the pH value is equal to 7, placing in a drying oven and drying at 100-120 DEG C to obtain the final product. In the process for preparing the activated carbon disclosed by the invention, a mixed acid charring method is adopted, so that the reaction time is shortened, the production efficiency of an organic silicon monomer is improved, and the method has the advantages of water and energy conservation, reduced energy consumption, simple preparation process, convenience and effectiveness; the obtained carrier has excellent microscopic physical properties and the active ingredients of the catalyst prepared from the carrier have good dispersity and thus the hard agglomeration of the formed powder is avoided.

Owner:QINGDAO UNIV OF SCI & TECH +1

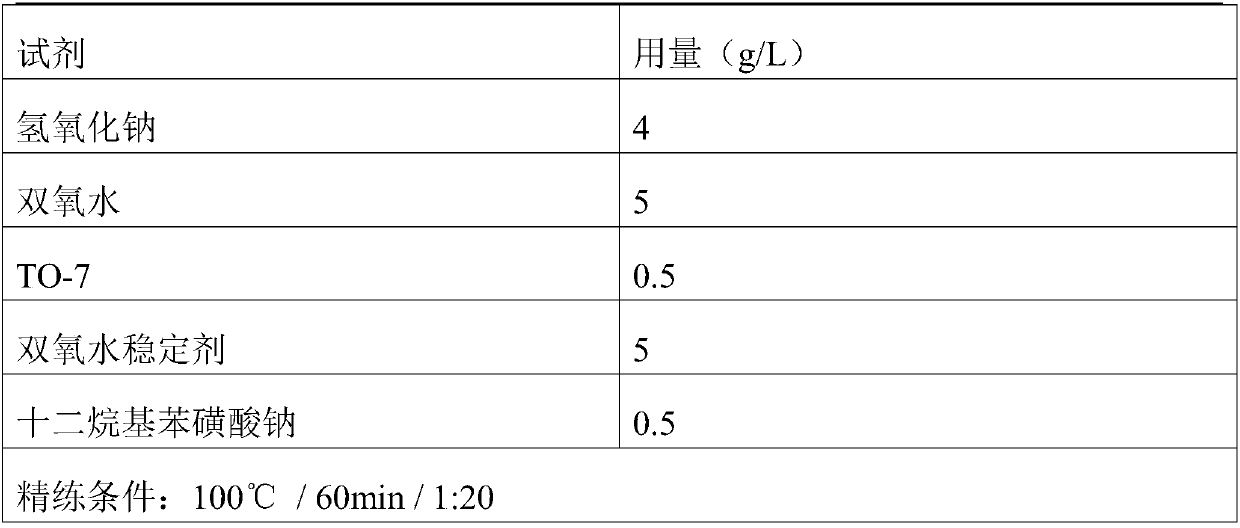

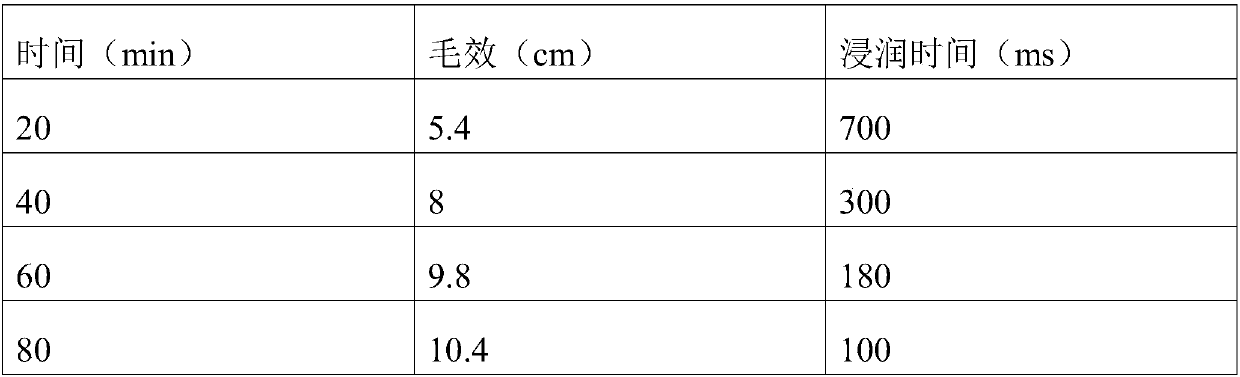

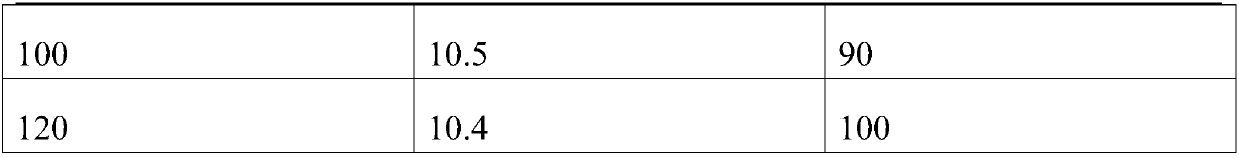

Dyeing pretreatment agent of cotton fabrics and treatment method

InactiveCN107740263ADifferent wettabilitySimple preparation processVegetal fibresAlcoholSurface-active agents

The invention provides a dyeing pretreatment agent of cotton fabrics. The dyeing pretreatment agent of cotton fabrics comprises sodium hydroxide, hydrogen peroxide, a hydrogen peroxide stabilizer, isomeric alcohol and a surface active agent. The dyeing pretreatment agent effectively solves the phenomenon that an activated dye easily cause dye non-uniformity due to high dyeing rate for cotton products in a silica-based non-aqueous medium. The cotton products with different wettability performances can be prepared by changing the using amounts of sodium hydroxide, hydrogen peroxide and the surface active agent and the factors such as pretreatment time and temperature; and the treatment agent preparation and treatment technology are simple and effective; and the treatment technology is greenand environmentally-friendly.

Owner:JIANGSU NEW REBA TECH CO LTD

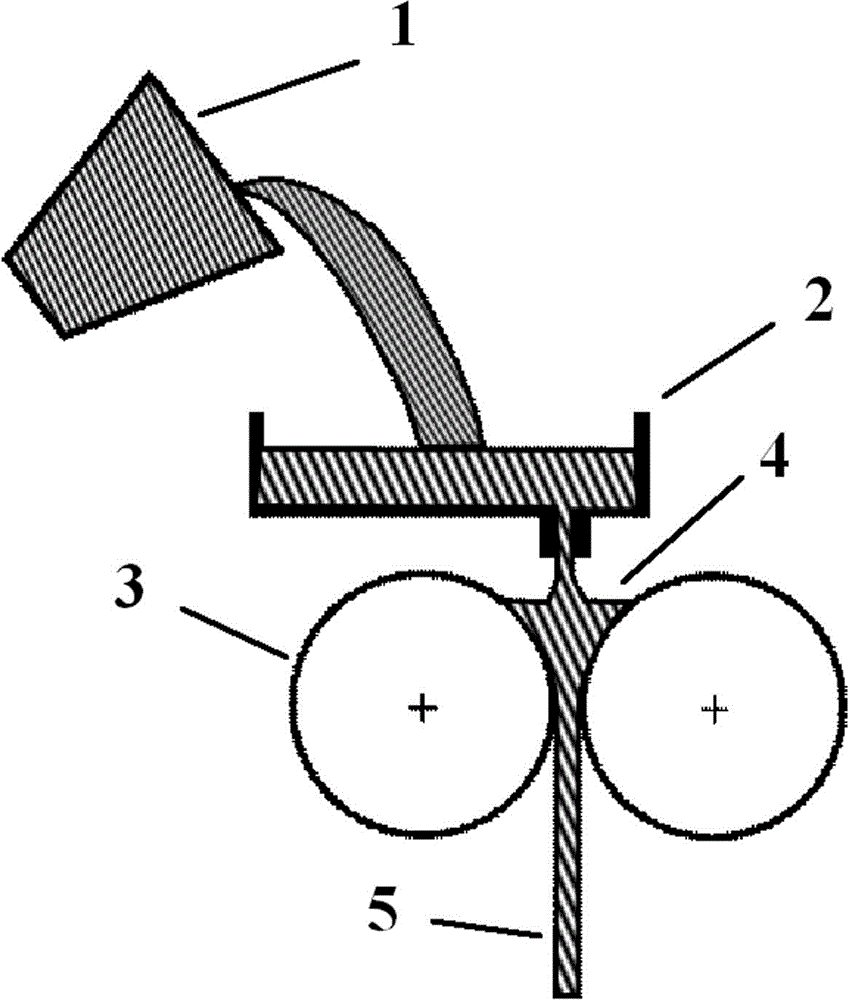

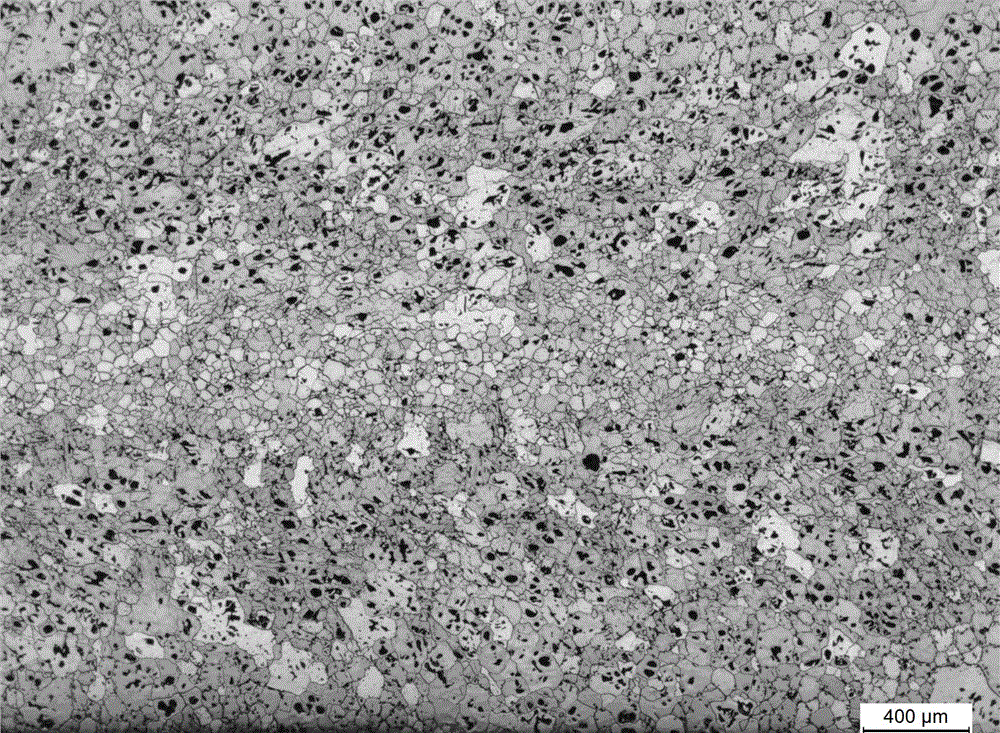

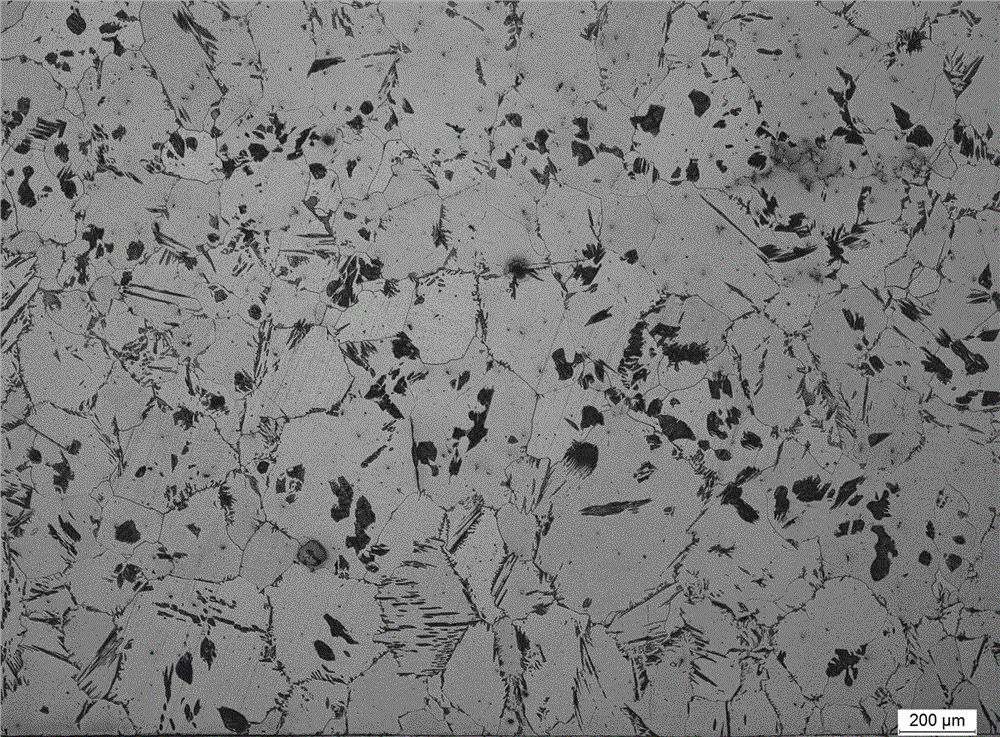

Double-roll thin-belt continuous casting fine crystal grain orientated silicon steel thin strip stock and manufacturing method of thin strip stock

The invention provides a double-roll thin-strip continuous casting fine crystal grain orientated silicon steel thin strip stock and a manufacturing method of the thin strip stock. The thin strip stock consists of the following ingredients in percentage by mass: 0.01 to 0.08 percent of C, 2.8 to 3.4 percent of Si, 0.05 to 0.30 percent of Mn, 0.015 to 0.04 percent of S, 0.005 to 0.05 percent of Als, 0.003 to 0.010 percent of N, 0.01 to 0.5 percent of Ti, 0 to 0.6 percent of Cu, 0 to 0.2 percent of Sn, at most 0.004 percent of O, at most 0.01 percent of P and the balance Fe, wherein the average crystal grain dimension is 20 to 45mm. The method comprises the following steps of (1) melting molten steel; (2) adopting a double-roll thin-strip continuous casting device, and casting molten steel into a cavity to form a melting bath, wherein the overheat degree of the upper surface of the melting pool is 10 to 70 DEG C, and the molten steel is guided out at a speed being 20 to 80m / min. The thin strip stock and the manufacturing method have the advantages that the manufacturing process is simple and effective; the fine crystal grain structure is favorable for improving the toughness and plastic performance of an orientated silicon steel plate, and is favorable for the subsequent texture regulation and control.

Owner:NORTHEASTERN UNIV

Preparation process of UPE filter membrane

ActiveCN113351033AImprove the capture effectHigh filtration precisionSemi-permeable membranesNon solventPolymer science

The invention provides a preparation process of a UPE filter membrane. The process comprises the following steps: preparing a mixed material, wherein the mixed material comprises polyethylene resin and a solvent system, the polyethylene resin at least comprises ultra-high molecular weight polyethylene with a mass average molecular weight of more than 3 million, and the solvent system comprises a solvent compound A and a non-solvent compound B; then heating, melting and mixing the mixed material to form a membrane casting solution; extruding through a die head to form a liquid membrane, wherein along with the reduction of the environment temperature, the liquid membrane is subjected to split-phase curing to form two raw membranes with holes in the outer surfaces different in aperture size; and carrying out synchronous stretching, first heat setting, extraction and second heat setting on the raw membrane to obtain the UPE filter membrane with the required membrane structure. According to the invention, the UPE filter membrane is an asymmetric membrane, has excellent trapping performance on impurity particles with the particle size of 1-30 nm, and is high in interception efficiency; the filtering speed is high, the time required for fluid to pass through the filter membrane is short, and the time cost is low; and the UPE filter membrane is especially suitable for the field of photoresist.

Owner:HANGZHOU COBETTER TECH CO LTD

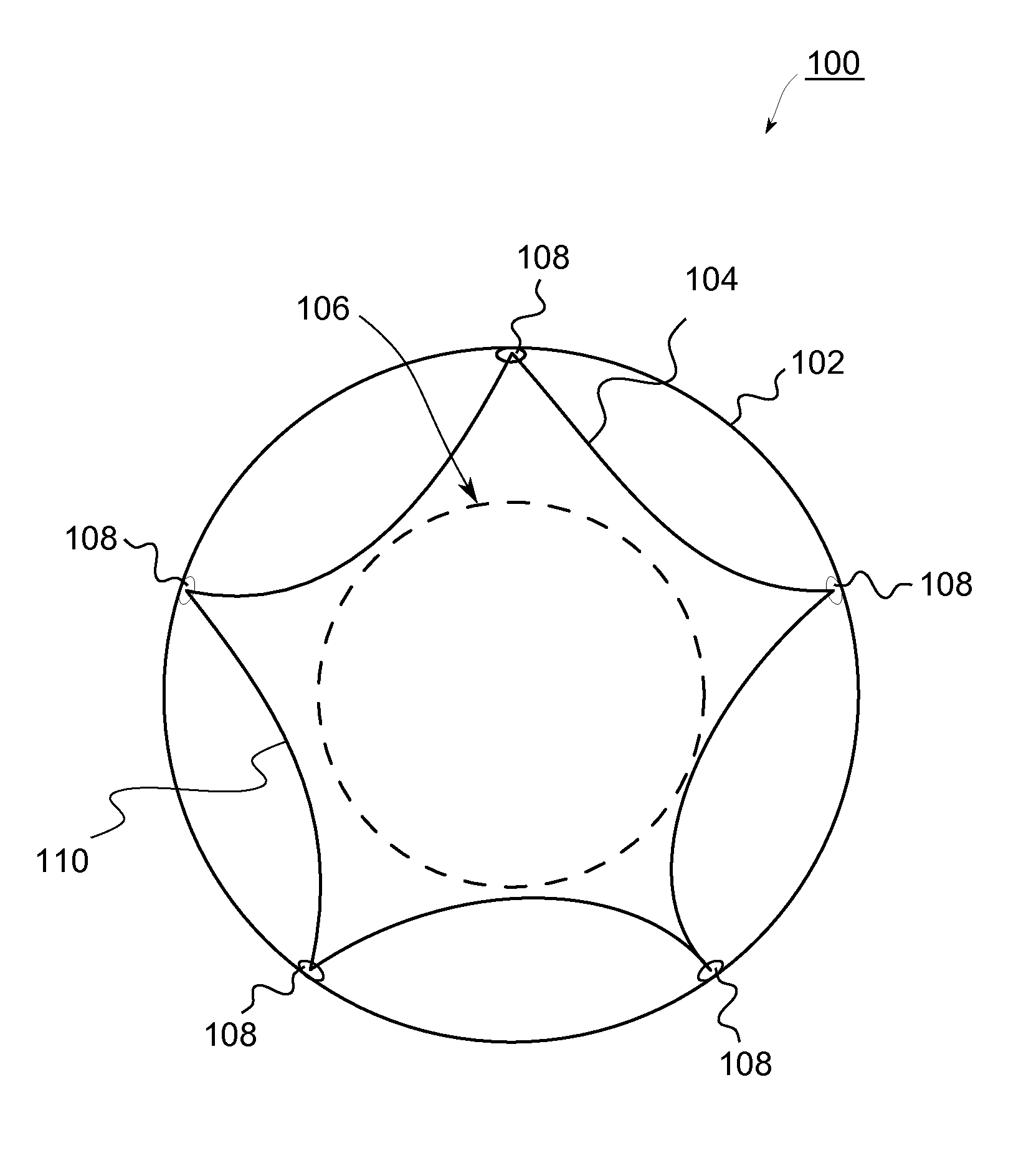

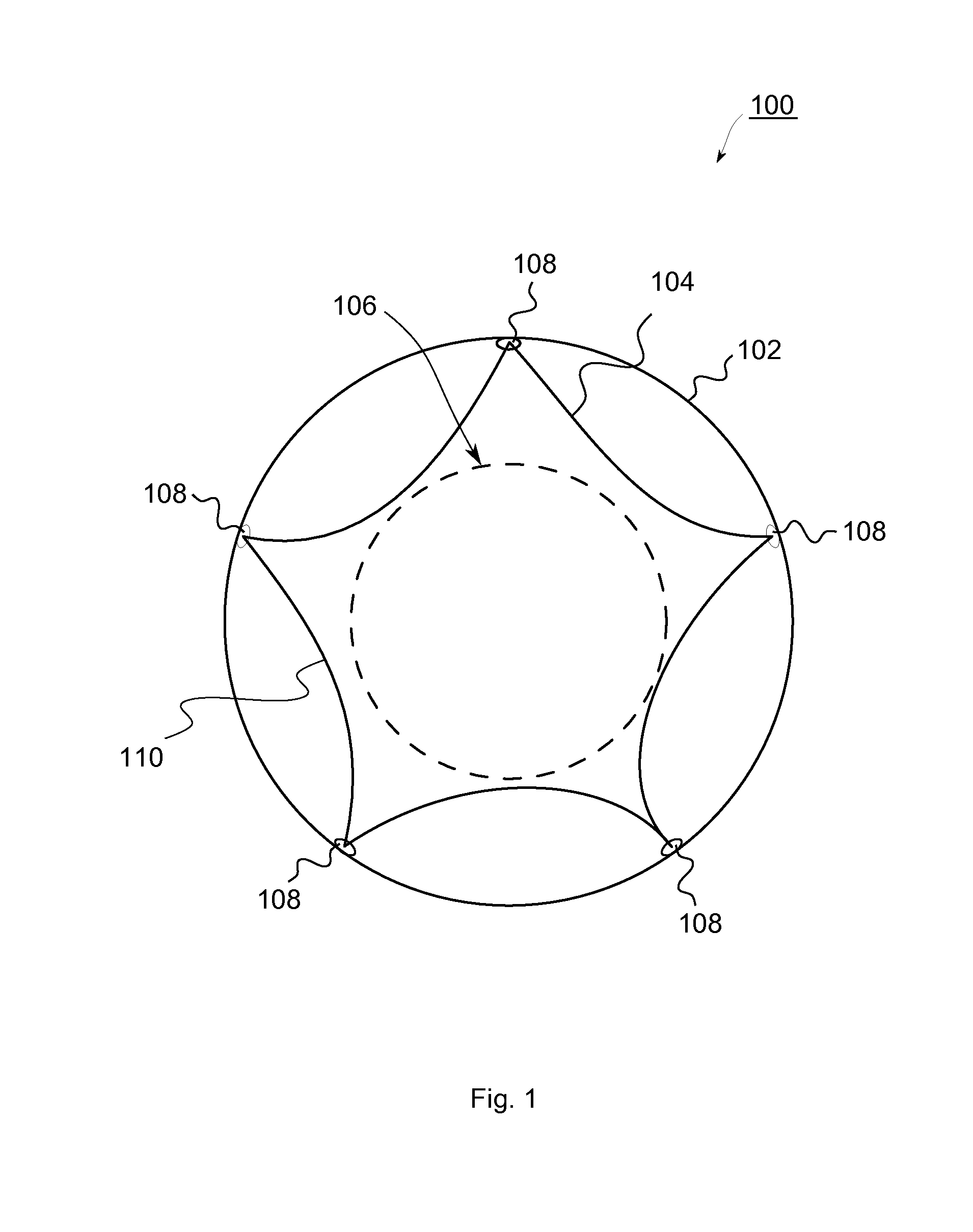

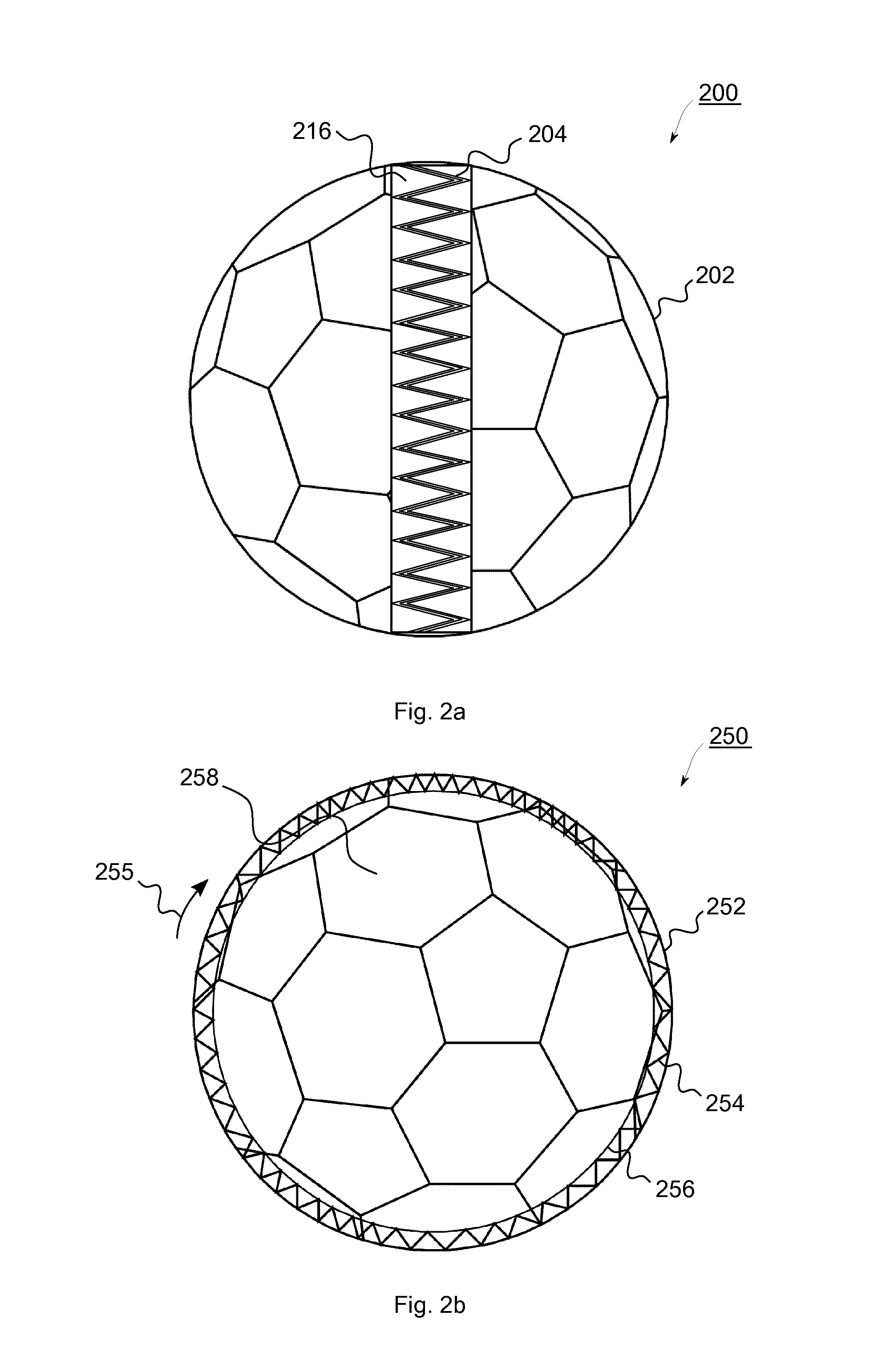

Elastically Deformable Item of Sports Equipment Comprising a Deformable Electromagnetic Coil Structure

ActiveUS20150180127A1Efficient manufacturing processGood propertyHollow inflatable ballsAntenna supports/mountingsEngineeringElectromagnetic coil

Embodiments relate to an elastically deformable item of sports equipment (100; 200; 250; 300; 500), comprising at least one deformable electromagnetic coil structure (104; 204; 254; 304; 504) arranged around a curved surface (102; 106; 202; 206; 252; 256; 302; 306; 502; 506) within the item of sports equipment, wherein the at least one deformable electromagnetic coil structure has an elongation reserve corresponding to a maximum elastic deformation of the item of sports equipment.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

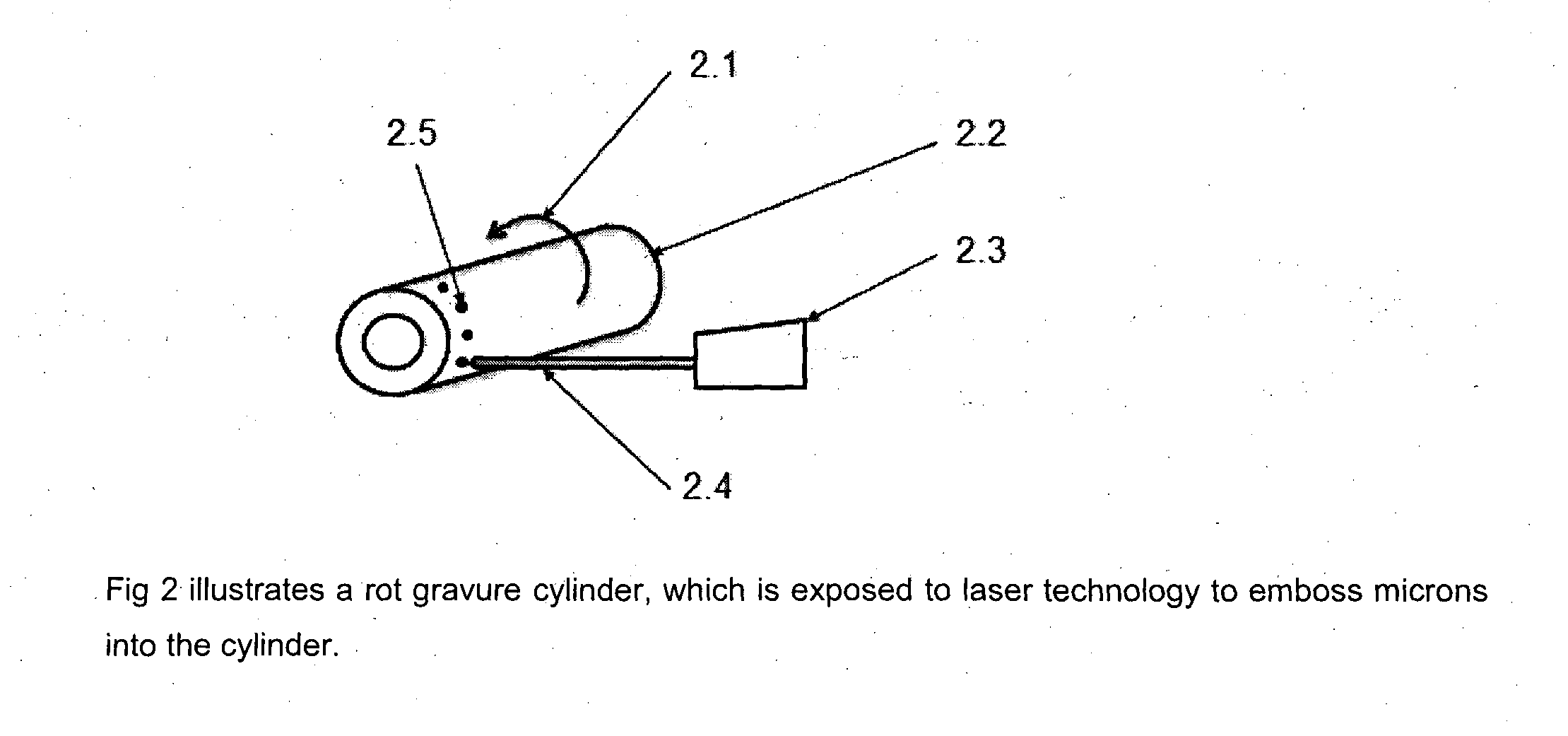

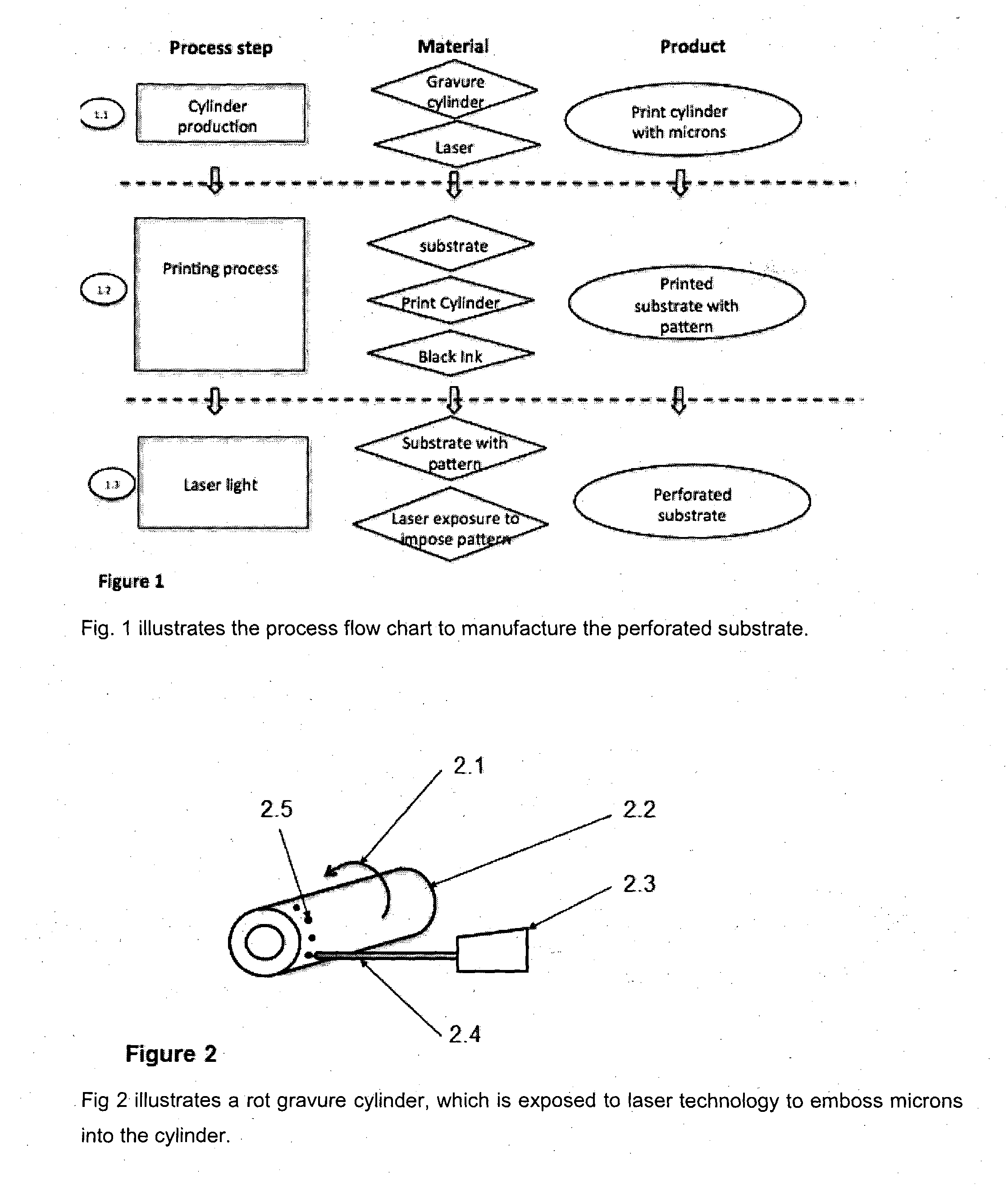

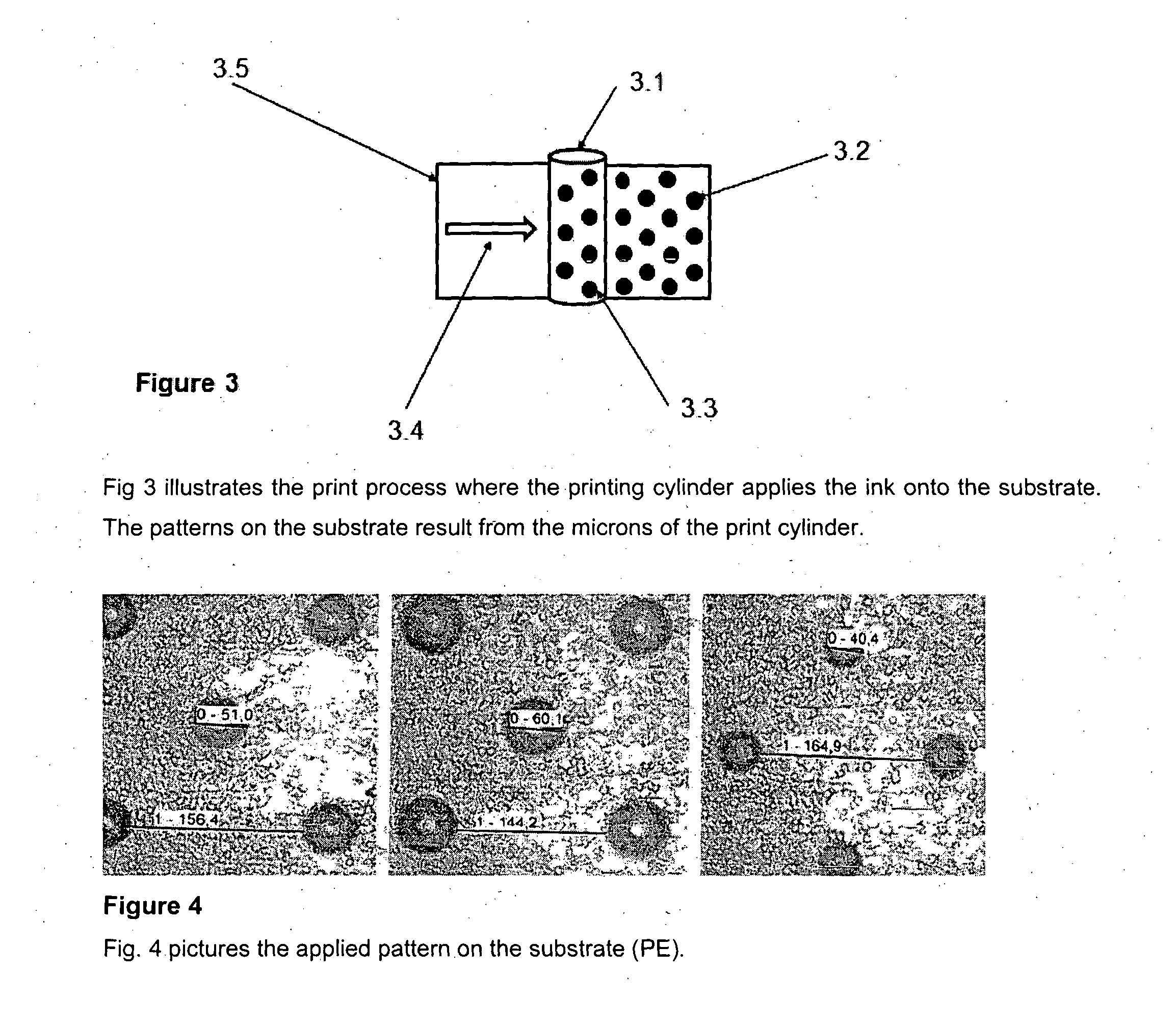

Perforated substrate and a method of manufacture

InactiveUS20170028511A1Improve accuracyEfficient preparationHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLaser technologySupercapacitor

The present invention relates to an optimization of a perforated substrate and a method of manufacturing the substrate using a printing process. The method of manufacturing the perforated substrate involves a substrate which is printed with ink into black patterns via a printing cylinder. The ink is applied to the substrate with small microns inside the cylinder. The microns are fabricated using laser technology. These black patterns on the substrate are exposed to an infrared light, which creates holes within the substrate. The printed features control the flow of change through the substrate. The substrate can be used in different applications such as filters, membranes of electrical separators. Examples of applications of the material include lithium ion battery separator, capacitors, super capacitors, electrical components, Packaging for the F&B industry in the field of breathable packaging or perishable groceries, filter, micro filter, membranes, energy storage devices, and sailcloth.

Owner:LISIT

Non-celluloid sheet material for environment-friendly table tennis

InactiveCN104844834AAvoid security issuesAvoid emissionsSport apparatusLiquid wasteProcess equipment

The invention relates to a non-celluloid sheet material for an environment-friendly table tennis. The non-celluloid sheet material comprises components of cellulose acetate, camphor powder, dimethyl phthalate, zinc oxide whisker, liquid nylon, acetone ester, a pigment, and a solvent. The non-celluloid sheet material prepared by the formula is free of nitrocellulose and not prone to flame and combust, and therefore has excellent safety performance. The safety problem of the table tennis (including raw materials) in production, storage, transportation, and use processes is fundamentally solved. No liquid waste is discharged, and the non-celluloid sheet material has a good environmental protection property. Furthermore, the preparation technology is simple and has a short period. The prepared table tennis is high in hardness and excellent in elastic modulus. The non-celluloid sheet material not only has a mechanical property quite approximate to that of celluloid, thereby guaranteeing the kinetic characteristic of the table tennis, but also has a processing property satisfying requirements of an existing technical device for the table tennis, thereby guaranteeing a high-speed and high-efficiency manufacturing process.

Owner:JIANGSU YAOZHANG SPORTING GOODS

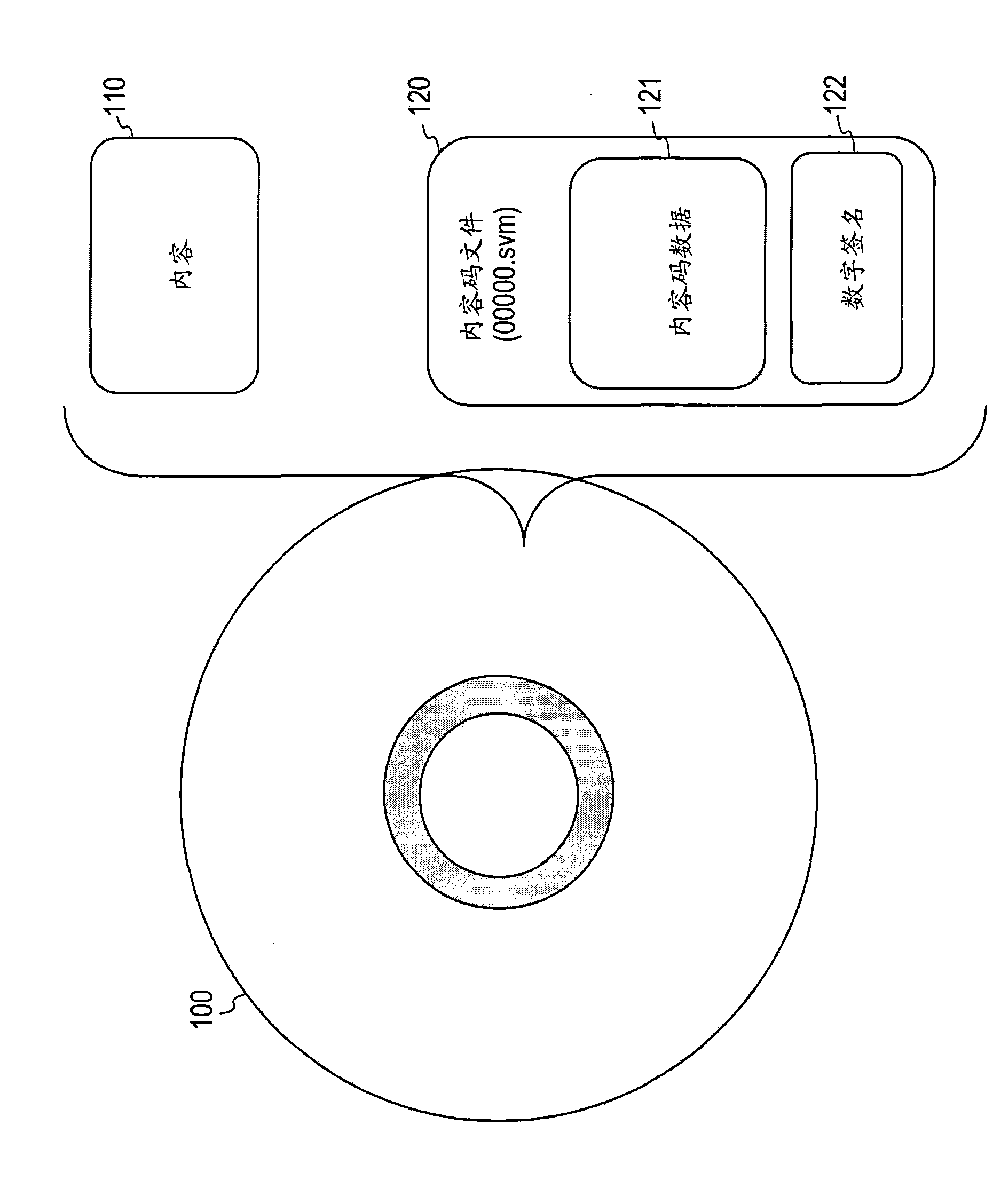

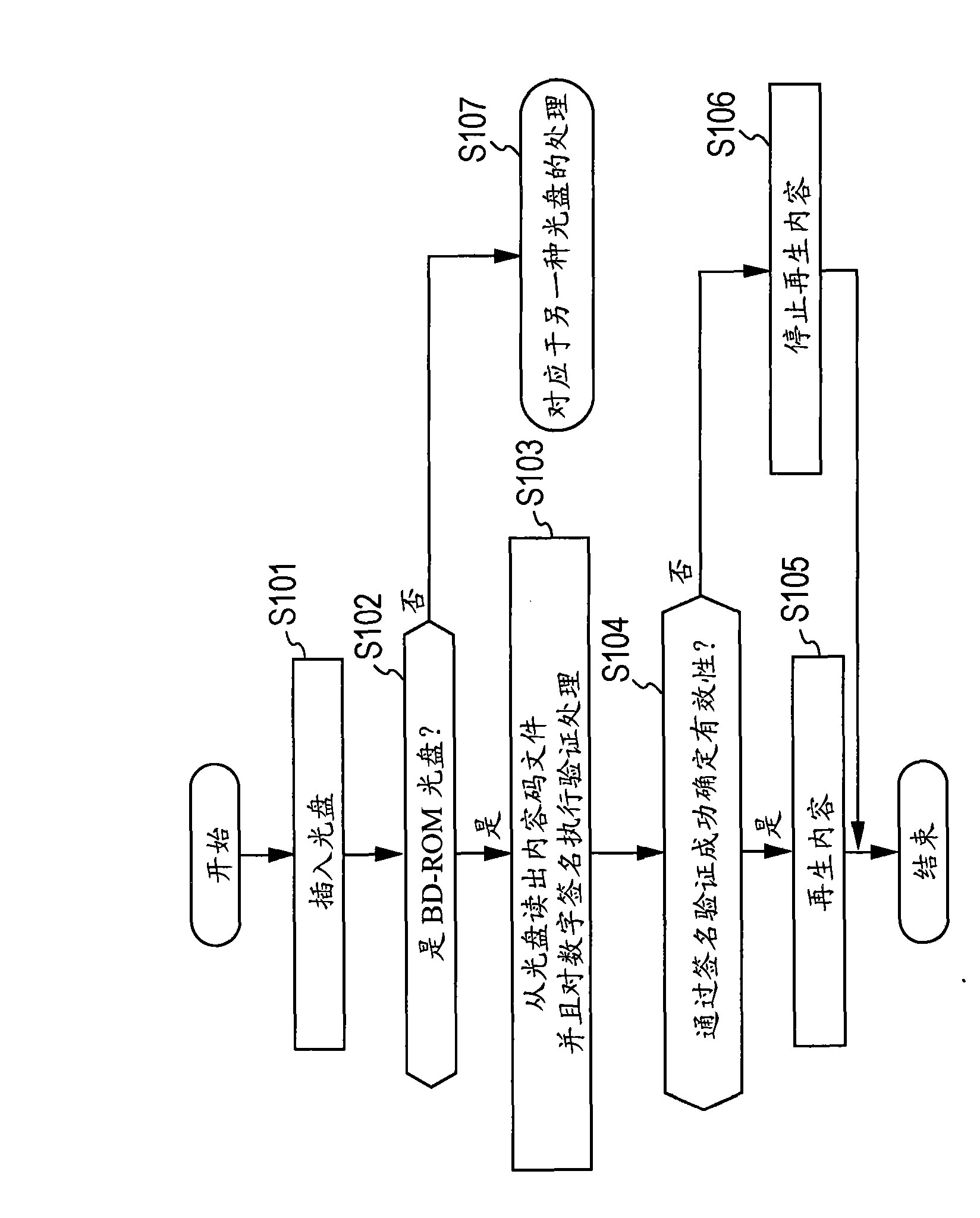

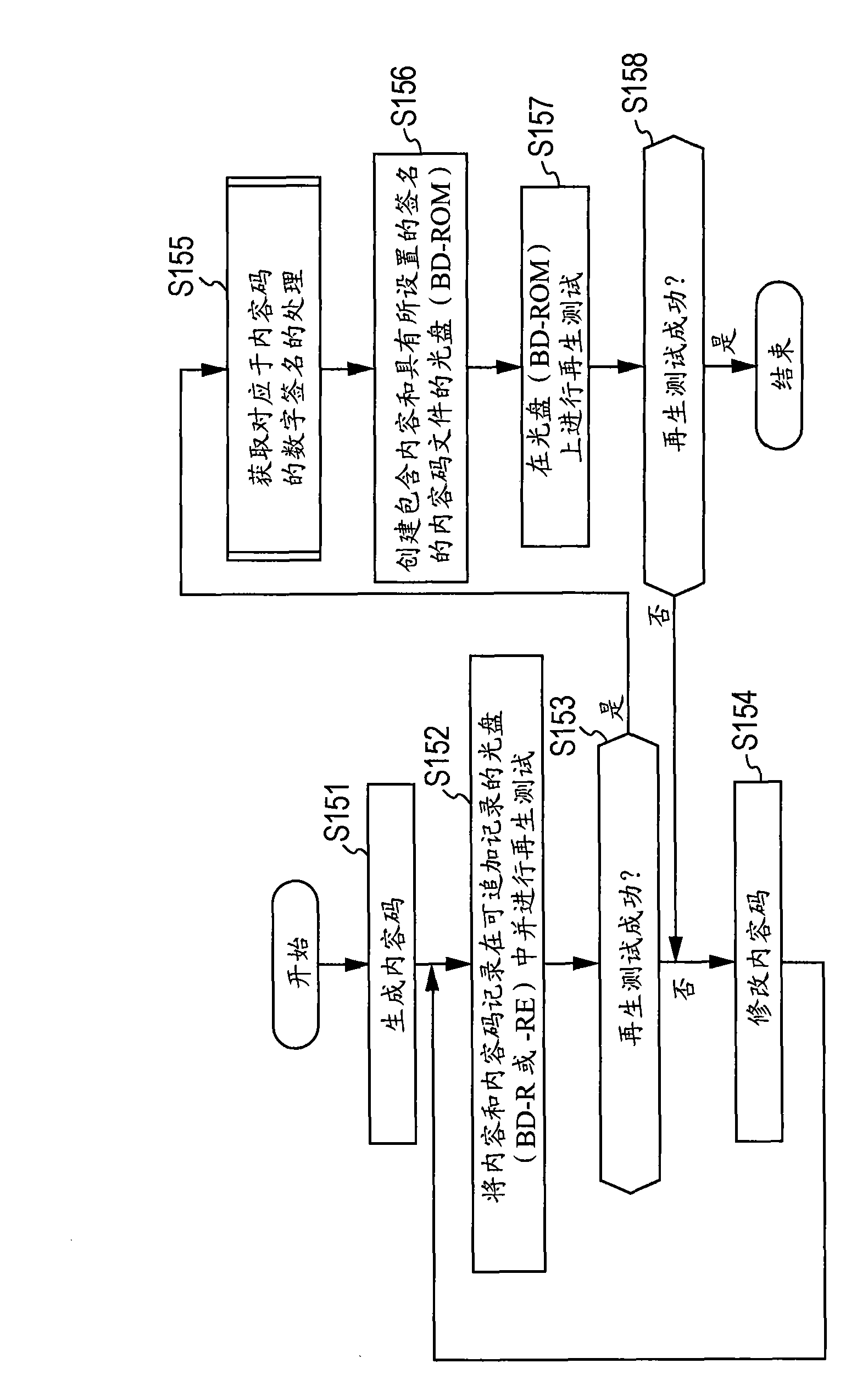

Information processing apparatus, information recording medium, information processing method, and information processing program

InactiveCN101582275AGenerate efficientlyEfficient manufacturing processRecord information storageDigital data protectionInformation processingComputer hardware

The present invention discloses an information processing apparatus, an information recording medium, an information processing method and an information processing program. The information processing apparatus includes: a reproducing unit that reads, from a disc, a content and a content code file storing a content code that includes at least any one of a program or conversion data applied to a content reproducing process, to execute the content reproducing process; and a signature verification unit that verifies a digital signature set for the content code file. The signature verification unit verifies the signature using different pieces of set signature target data between a signature verification process executed in reproducing the content recorded in a ROM disc and a signature verification process executed in reproducing the content recorded in a non-ROM disc other than the ROM disc. The reproducing unit, when signature verification is successfully executed by the signature verification unit, applies the content code stored in the content code file, for which signature verification is successful, to reproduce the content. By means of the invention, it is capable of reducing the cost due to non repeat distribution of the established signature.

Owner:SONY GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com