Method for assembling thermo-electric device through printed electronics manufacturing technology

A thermoelectric device and manufacturing process technology, applied in the field of rapid prototyping, to achieve strong controllability, suitable for large-scale production, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] seefigure 1 with figure 2 , in this example, with Te 2 Bi 3 As a thermoelectric material, those skilled in the art can understand that other known thermoelectric materials can replace Te in the following examples. 2 Bi 3 And realize the technical scheme of this embodiment.

[0029] In this embodiment, the method for assembling a thermoelectric device using a printed electronics manufacturing process includes the following steps:

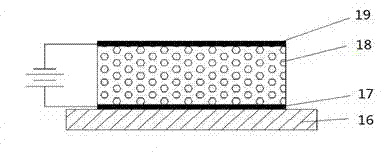

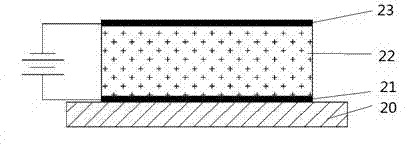

[0030] First, a bottom electrode is plated on the silicon wafer 16 and the silicon wafer 20;

[0031] Among them, the area of silicon wafer 16 and silicon wafer 20 is 20×20mm 2 , the thickness is 0.5~0.7mm;

[0032] Plating a layer of electrode material on the silicon chip, wherein the electrode material can be Au, Ag, Cu, Zn, Fe, Ni, Pt, Ru, Rh, Pd, Mn or Al, select Cu as the bottom electrode 17 and bottom electrode 17 in this example. Electrode 21 material;

[0033] Next, print n-Te 2 Bi 3 18 or P-Te 2 Bi 3 22 Thermoelectric...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, especially in that:

[0039] see image 3 with Figure 4 In this embodiment, the method for assembling thermoelectric devices using a printed electronics manufacturing process includes the following steps:

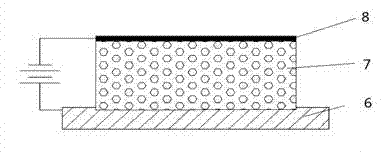

[0040] First, wet etch the aluminum sheet;

[0041] Among them, the thickness of aluminum sheet 6 and aluminum sheet 9 is 1~2mm, and the area is 20×20mm 2 ;

[0042] The etching depth is selected to be 10~20nm, and the etching area is 15×15mm 2 ;

[0043] Secondly, print n-Te on the aluminum sheet 6 and aluminum sheet 9 2 Bi 3 7 or P-Te 2 Bi 3 10 thermoelectric materials assemble a thermocouple;

[0044] The etched aluminum sheet 6 and aluminum sheet 9 can be used as the bottom electrode of the thermoelectric device, and then print n-Te on the aluminum sheet by screen printing. 2 Bi 3 7 or P-Te 2 Bi 3 10, where the pressure is 0.4~0.6MPa;

[0045] After sintering, weld the top electrode on the...

Embodiment 3

[0049] This embodiment is basically the same as the previous embodiment, and the special features are:

[0050] see Figure 5 In this embodiment, the method for assembling thermoelectric devices using a printed electronics manufacturing process includes the following steps:

[0051] First, a bottom electrode is plated on the silicon wafer 24;

[0052] Wherein, the area of the silicon chip 24 is 20×40mm 2 , the thickness is 0.5~0.7mm;

[0053] Plating a layer of electrode material on the silicon chip, wherein the electrode material can be Au, Ag, Cu, Zn, Fe, Ni, Pt, Ru, Rh, Pd, Mn or Al, select Cu as the bottom electrode 25 material in this example;

[0054] Second, print n-Te on the aluminum sheet 2 Bi 3 26 and P-Te 2 Bi 3 27 thermoelectric materials to assemble a U-shaped thermoelectric device;

[0055] The etched aluminum sheet can be used as the bottom electrode of the thermoelectric device, and then the n-Te 2 Bi 3 26 and P-Te 2 Bi 3 27, where the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com