Low-phase-transformation-temperature titanium-zirconium-niobium-tantalum shape memory alloy, a preparation method and application thereof

A memory alloy and phase transition temperature technology, applied in the field of shape memory alloys, can solve problems such as the inability to meet the requirements of phase transition characteristics, and achieve the effects of solving the problem of Ni ion toxicity, good biological safety, and good shape memory effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

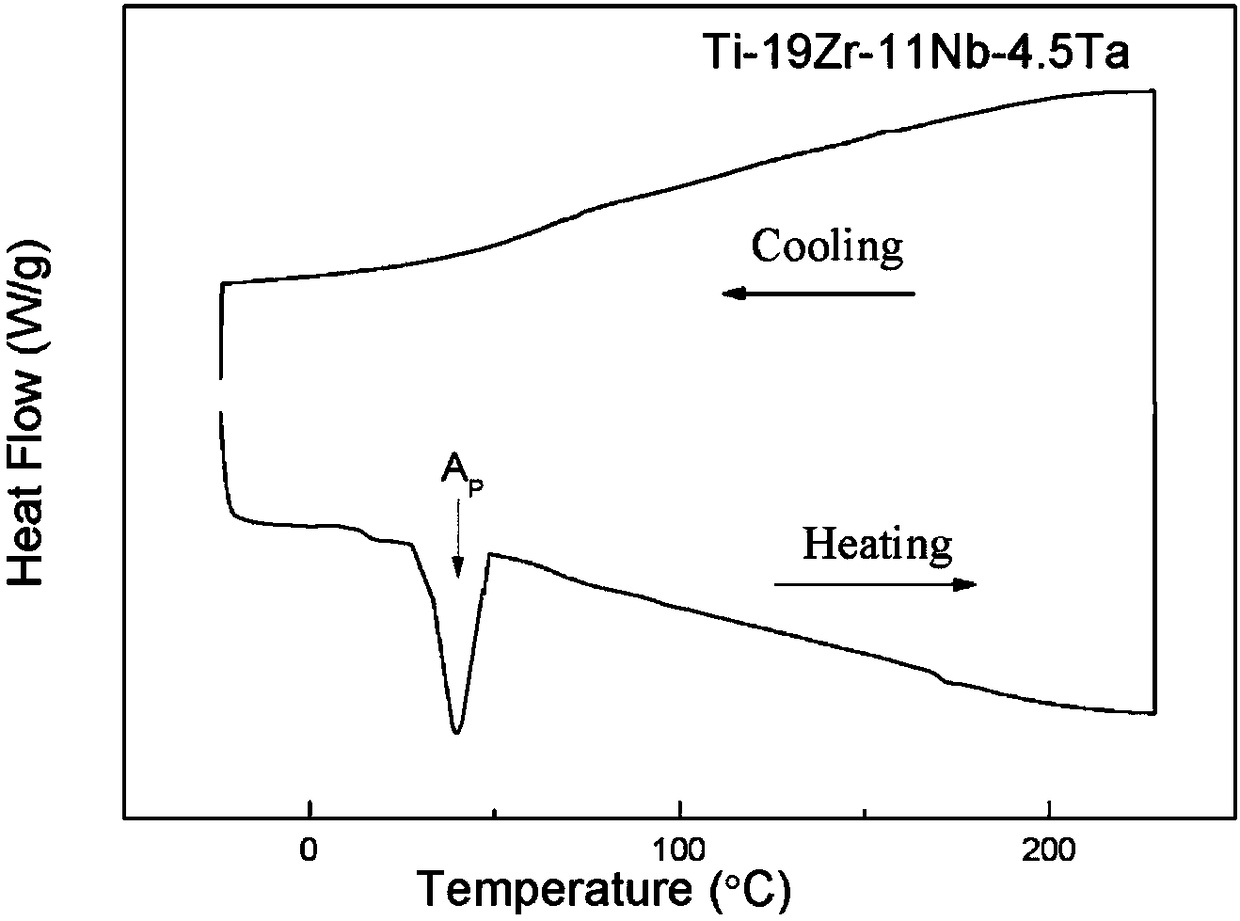

[0036] Example 1: Preparation of low phase transition temperature Ti-19Zr-11Nb-4.5Ta composition shape memory alloy material

[0037] The first step: use titanium block (purity ≥99.99%), zirconium block (purity ≥99.99%), niobium sheet (purity ≥99.98%) and tantalum block (purity ≥99.98%) for vacuum consumable arc melting, for Ensure the homogeneity of the composition and smelt more than 5 times to prepare alloy ingots of 1-5 kg level.

[0038] Step 2: Homogenize the ingot in a vacuum heat treatment furnace at 1000°C for more than 6-10 hours to further eliminate component segregation.

[0039] Step 3: Carry out billet forging treatment on the alloy ingot, the billet temperature is 1000-1100°C, the annealing temperature is 850-1000°C, after 3-5 passes of forging, the size is about 30mm×50mm×80mm. material.

[0040] Step 4: Cut the ingot into thin slices with a thickness of 4-6mm along the cross-section of the block by means of wire-cutting mechanical treatment, and perform co...

Embodiment 2

[0048] Embodiment 2: Preparation of Ti-18Zr-13Nb-6Ta composition shape memory alloy material with low phase transition temperature;

[0049] According to the preparation method described in Example 1, a martensitic Ti-18Zr-13Nb-6Ta composition alloy plate was obtained.

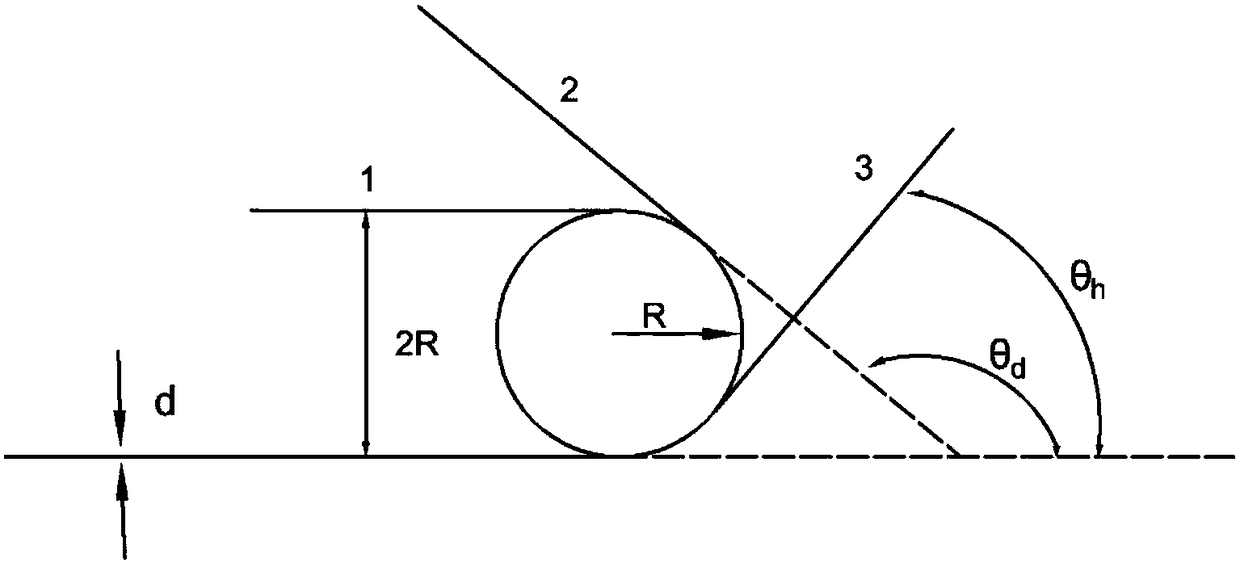

[0050] Cut a sheet sample with a size of 5mm×50mm×0.5mm and pass figure 1 The bending method shown performs the shape memory effect measurement. The maximum shape memory effect of the Ti-18Zr-13Nb-6Ta composition alloy is 3.8%, which is equivalent to that of the existing Ti-Zr-based alloys, indicating that the composition alloy has excellent shape memory performance.

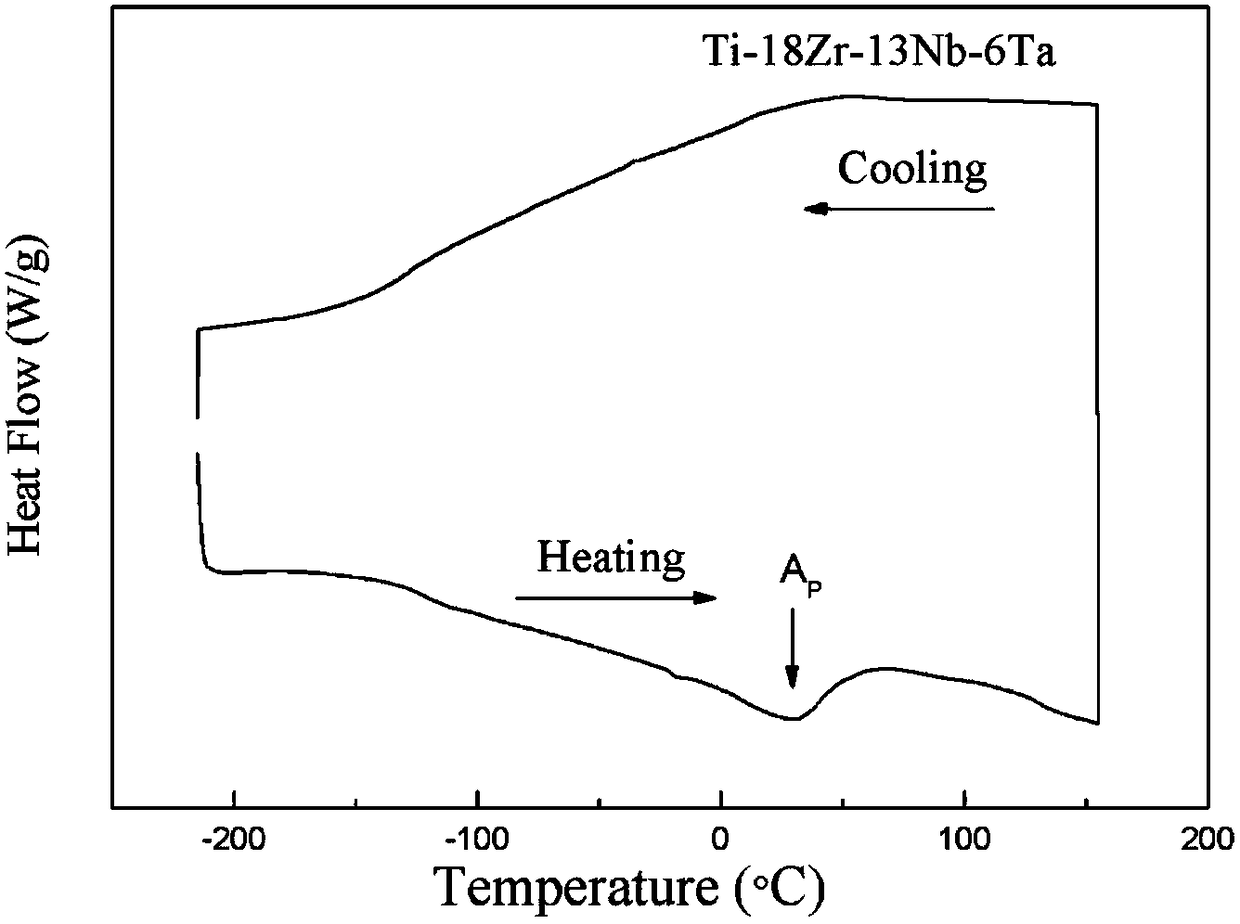

[0051] A sample with a size of 1 mm × 1 mm × 0.5 mm was cut from the alloy plate by slow wire cutting, and the phase transition temperature was measured by a NETZSCHSTA449 differential scanning calorimeter. use image 3 From the DSC curve shown, it can be observed that the reverse martensitic transformation temperature of the composition allo...

Embodiment 3

[0053] Example 3: Preparation of Ti-23Zr-12Nb-4.5Ta composition shape memory alloy material with low phase transition temperature;

[0054] According to the preparation method described in Example 1, a martensitic Ti-23Zr-12Nb-4.5Ta composition alloy plate was obtained.

[0055] Cut a sheet sample with a size of 5mm×50mm×0.5mm and pass figure 1 The bending method shown performs the shape memory effect measurement. The maximum shape memory effect of the Ti-23Zr-12Nb-4.5Ta composition alloy is 3.5%, which is equivalent to that of the existing Ti-Zr-based alloys, indicating that the composition alloy has excellent shape memory performance.

[0056] A sample with a size of 1 mm × 1 mm × 0.5 mm was cut from the alloy plate by slow wire cutting, and the phase transition temperature was measured by a NETZSCHSTA449 differential scanning calorimeter. use Figure 4 From the DSC curve shown, it can be observed that the reverse martensitic transformation temperature of the composition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition peak temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com