Dyeing pretreatment agent of cotton fabrics and treatment method

A technology of pre-dyeing treatment and treatment method, which is applied in the pre-dyeing treatment of cotton products and the field of fabric printing and dyeing. It can solve the problems of fast speed and uneven dyeing, and achieve the effects of simple preparation, simple treatment process, and green and environmentally friendly treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A treatment method using a treatment agent, the steps comprising:

[0045] S1, prepare the aqueous solution according to the ratio of bath ratio 1:15;

[0046] S2, with a stirring speed of 200 rpm, add sodium hydroxide to make its concentration 1g / L;

[0047] S3, at a stirring speed of 200 rpm, add TO-7 to make the concentration 0.1g / L;

[0048] S4, with a stirring speed of 200 rpm, add hydrogen peroxide stabilizer to make the concentration 0.1g / L;

[0049] S5, add hydrogen peroxide at a stirring speed of 200 rpm to make the concentration 1g / L;

[0050] S6, with a stirring speed of 200 rpm, add sodium dodecylbenzenesulfonate to make its concentration 0.1g / L;

[0051] S7, put the cotton fabric into the treatment solution, the stirring speed is 100 rpm, the temperature is raised to 60°C, and the temperature is kept for 20min;

[0052] S8, taking out the cotton fabric, fully washing and drying it, and then putting it into a constant temperature and humidity room for 12...

Embodiment 2

[0054] A treatment method using a treatment agent, the steps comprising:

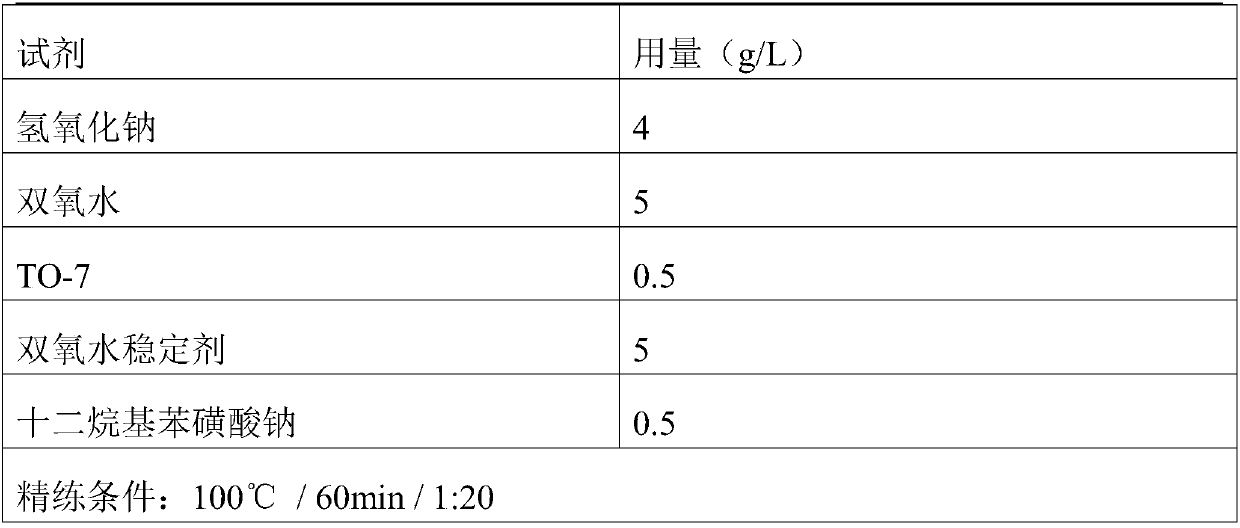

[0055] S1, prepare the aqueous solution according to the ratio of bath ratio 1:20;

[0056] S2, with a stirring speed of 600 rev / min, add sodium hydroxide to make its concentration 10g / L;

[0057]S3, at a stirring speed of 600 rpm, add TO-7 to make the concentration 0.5g / L;

[0058] S4, with a stirring speed of 600 rev / min, add hydrogen peroxide stabilizer to make its concentration 5g / L;

[0059] S5, add hydrogen peroxide at a stirring speed of 600 rpm to make the concentration 5g / L;

[0060] S6, add sodium dodecylbenzenesulfonate at a stirring speed of 600 rpm to make the concentration 1g / L;

[0061] S7, put the cotton fabric into the treatment solution, the stirring speed is 150 rpm, the temperature is raised to 80°C, and the temperature is kept for 60min;

[0062] S8, taking out the cotton fabric, fully washing and drying it, and then putting it into a constant temperature and humidity room for 2...

Embodiment 3

[0064] A treatment method using a treatment agent, the steps comprising:

[0065] S1, prepare the aqueous solution according to the ratio of bath ratio 1:45;

[0066] S2, with a stirring speed of 1000 rev / min, add sodium hydroxide to make its concentration 20g / L;

[0067] S3, at a stirring speed of 1000 rpm, add TO-7 to make the concentration 1g / L;

[0068] S4, with a stirring speed of 1000 rev / min, add hydrogen peroxide stabilizer to make its concentration 10g / L;

[0069] S5, with a stirring speed of 1000 rev / min, add hydrogen peroxide to make its concentration 10g / L;

[0070] S6, with a stirring speed of 1000 rev / min, add sodium dodecylbenzenesulfonate to make its concentration 1.5 g / L;

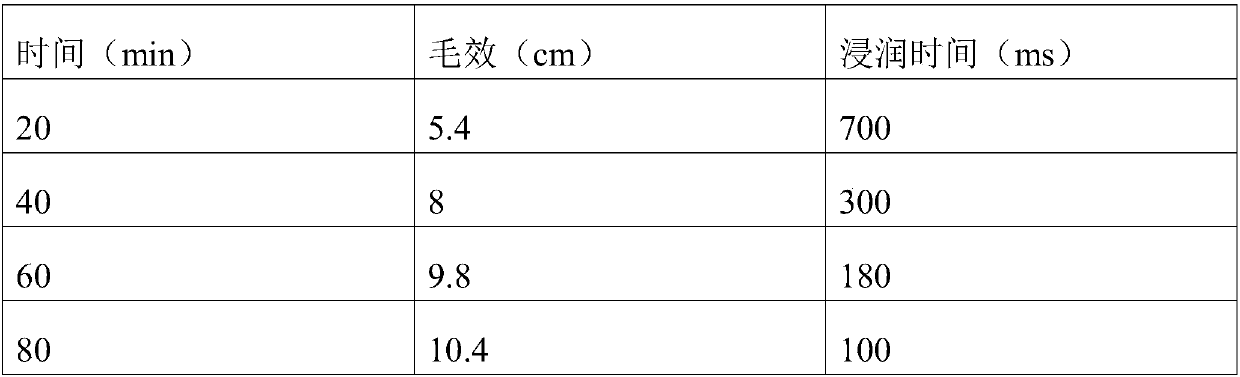

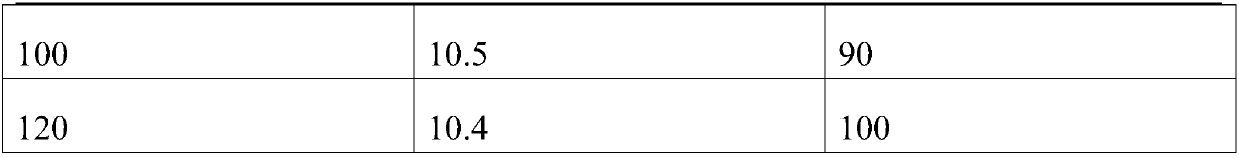

[0071] S7, put the cotton fabric into the treatment solution, the stirring speed is 200 rpm, the temperature is raised to 100° C., and the temperature is kept for 120 minutes;

[0072] S8, taking out the cotton fabric, fully washing and drying it, and then putting it into a constant tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com