Glue control device

A technology of supporting device and extruding rubber roller, which is applied in the field of glue control device, can solve the problems of inability to guarantee the uniformity of dipping effect, insufficient glue control of a single set of rollers, and increased viscosity of reflow glue, so as to improve the utilization of glue Efficiency, easy regulation, and the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

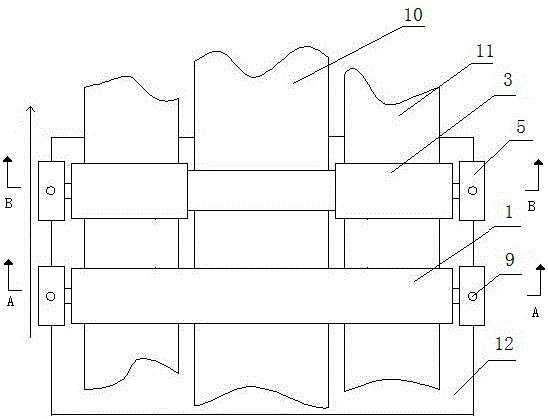

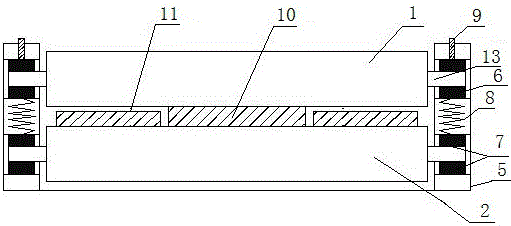

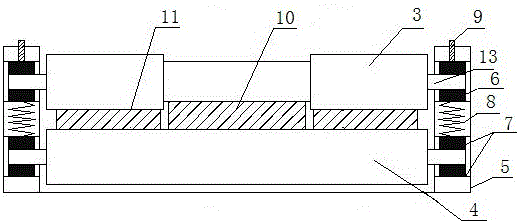

[0023] A glue control device, comprising a first group of extruding rubber rollers, a second group of extruding rubber rollers, and a supporting device 5, such as figure 1 , figure 2 , image 3 , the first group of extruding rollers includes equal-section cylindrical extruding rollers 1 and 2, such as figure 2 , Extruding rubber roller one 1 and extruding rubber roller two 2 are arranged in parallel, and the ends on the same side of extruding rubber roller one 1 and extruding rubber roller two 2 are jointly arranged in a supporting device 5 .

[0024] The second group of extruding rollers includes extruding roller three 3 with variable cross-section cylindrical and extruding roller four 4 with equal cross-section cylindrical, and extruding roller three 3 adopts a dumbbell-shaped roller body. Such as image 3 , Extruding rubber roller three 3 and extruding rubber roller four 4 are arranged in parallel, and the ends of the same side of extruding rubber roller three 3 and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com