Heat pipe and processing method thereof

A processing method and heat pipe technology, applied in the field of heat conduction, can solve the problems of heat source concentration and component heat generation, and achieve the effect of increasing the capillary pressure difference and increasing the maximum heat transfer capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

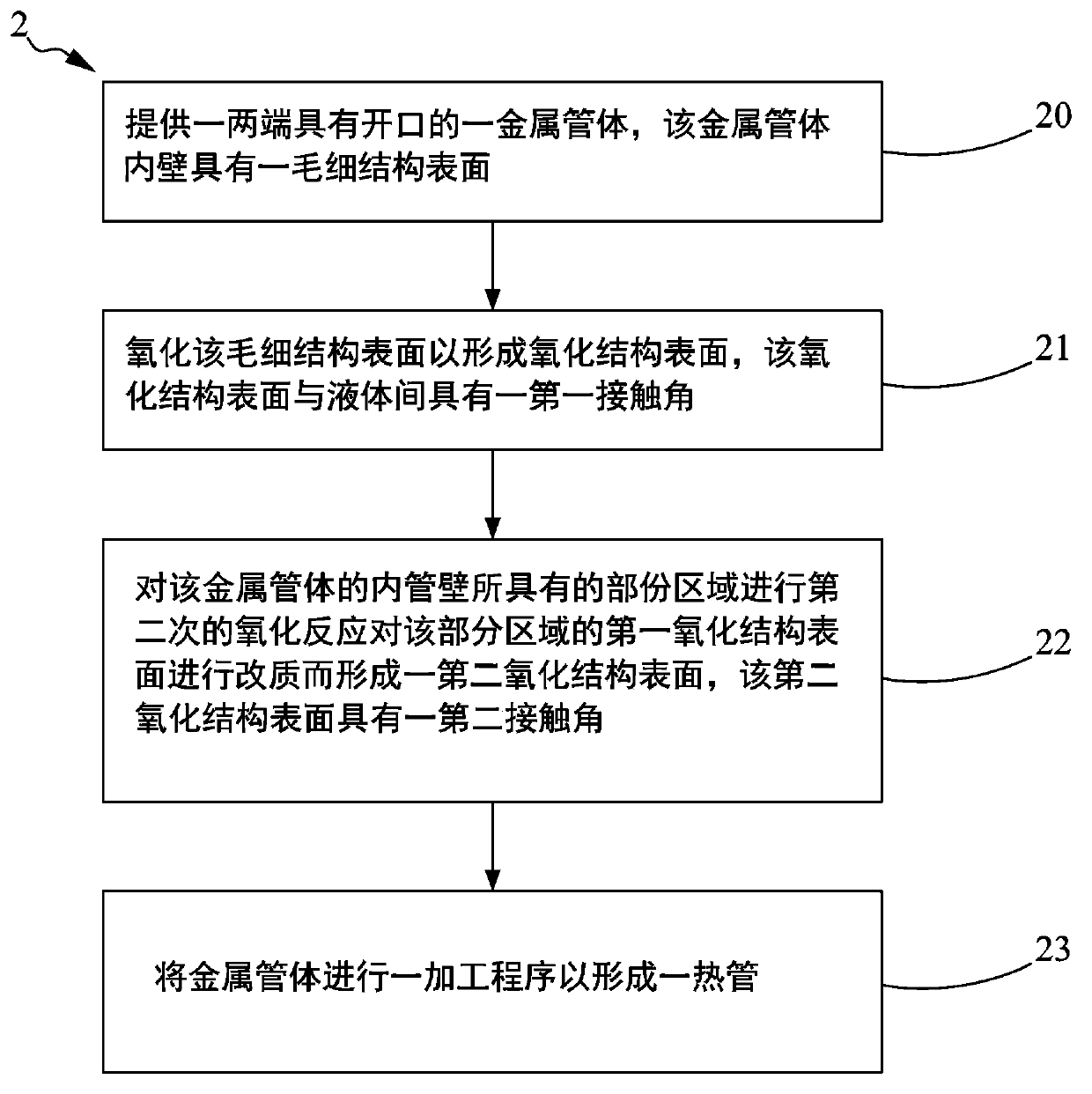

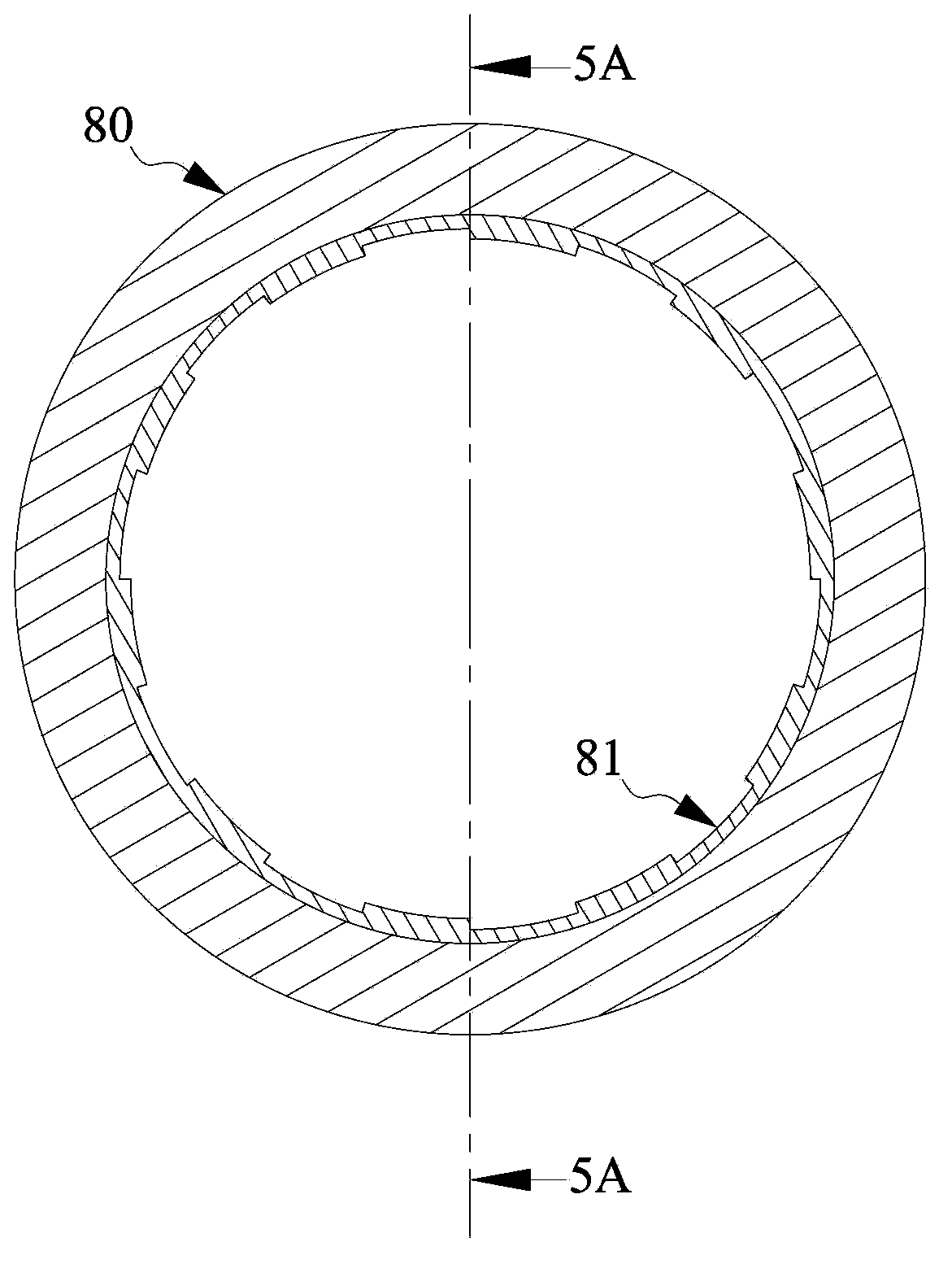

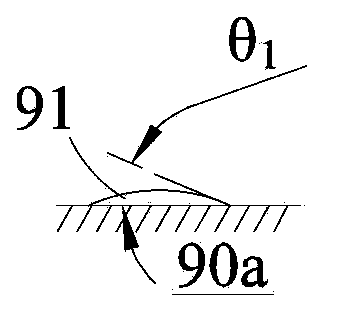

[0051] see figure 1 As shown, this figure is a schematic flow chart of the first embodiment of the heat pipe processing method of the present invention. In this embodiment, the method 2 includes step 20 of providing a metal pipe with openings at both ends. Such as figure 2 As shown, this figure is a schematic side view of one end section of the metal pipe body of the present invention. The metal tube body 80 is a cylindrical hollow tube body with a length, and a capillary structure surface 81 on the inner wall. In this embodiment, the capillary structure surface 81 is a groove structure formed on the inner wall of the metal tube. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com