Correction method of equivalent load of axial film oil cylinder of bearing tester

An axial load and bearing test technology, applied in the field of payload correction, can solve problems such as affecting the accuracy of test data, unreported, and difficult to measure bearing performance indicators for test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

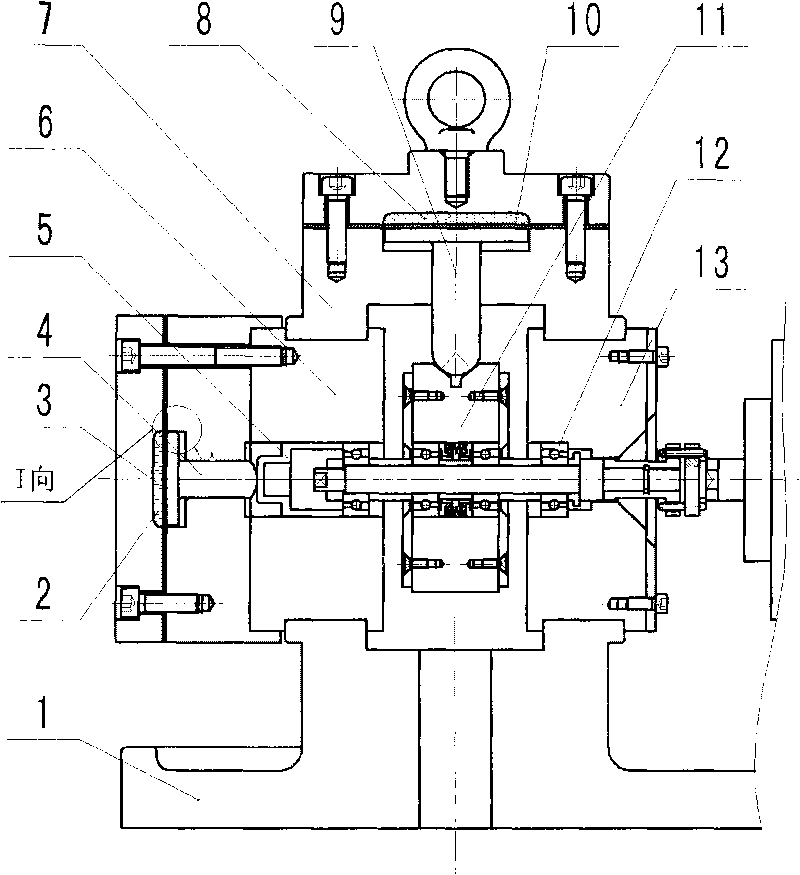

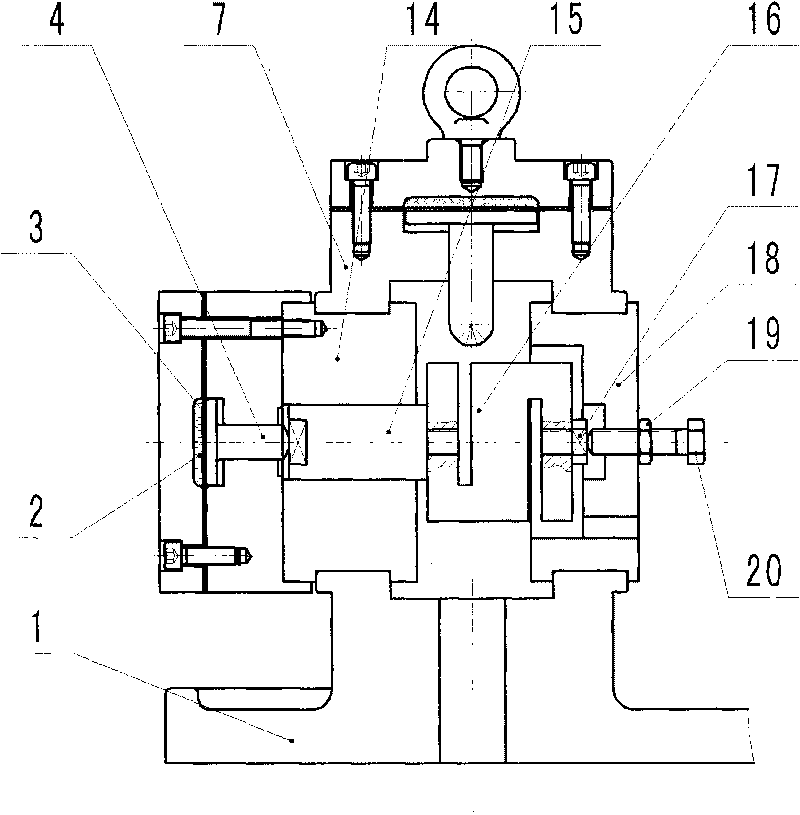

[0027] combine Figure 1-3 , the method for correcting the equivalent load of the axial film loaded oil cylinder of the bearing testing machine of the present invention includes a set of axial load testing device, which consists of a left fixed bushing 14, a left positioning mandrel 15, a test pressure sensor 16 , flat head bolt 17, right fixed bushing 18, nut 19 and ball stud 20. A test pressure sensor 16 is set in the middle of the axial load test device. The test pressure sensor 16 adopts an "S" beam structure strain type pressure sensor. The test accuracy is 0.2% FS of the full-scale steady-state error. The right end of the test pressure sensor 16 is connected to the grub bolt 17, and the left end of the test pressure sensor 16 is connected to the left positioning mandrel 15, and the left positioning mandrel 15 is installed in the left fixed bushing 14. The left end of the left fixed bushing 14 is connected to the axial thin film oil cylinder 2 of the bearing testing machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com