Spinning riveting assembly and manufacturing method of automobile hub bearing unit

A technology of an automobile wheel hub and a manufacturing method, which is applied in the field of spinning riveting assembly manufacturing of automobile wheel hub bearing units, can solve the problems of large fluctuation of preload, decrease of optimal value bearing life, failure, etc., so as to improve assembly efficiency, Eliminate hidden dangers of unloading and improve the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

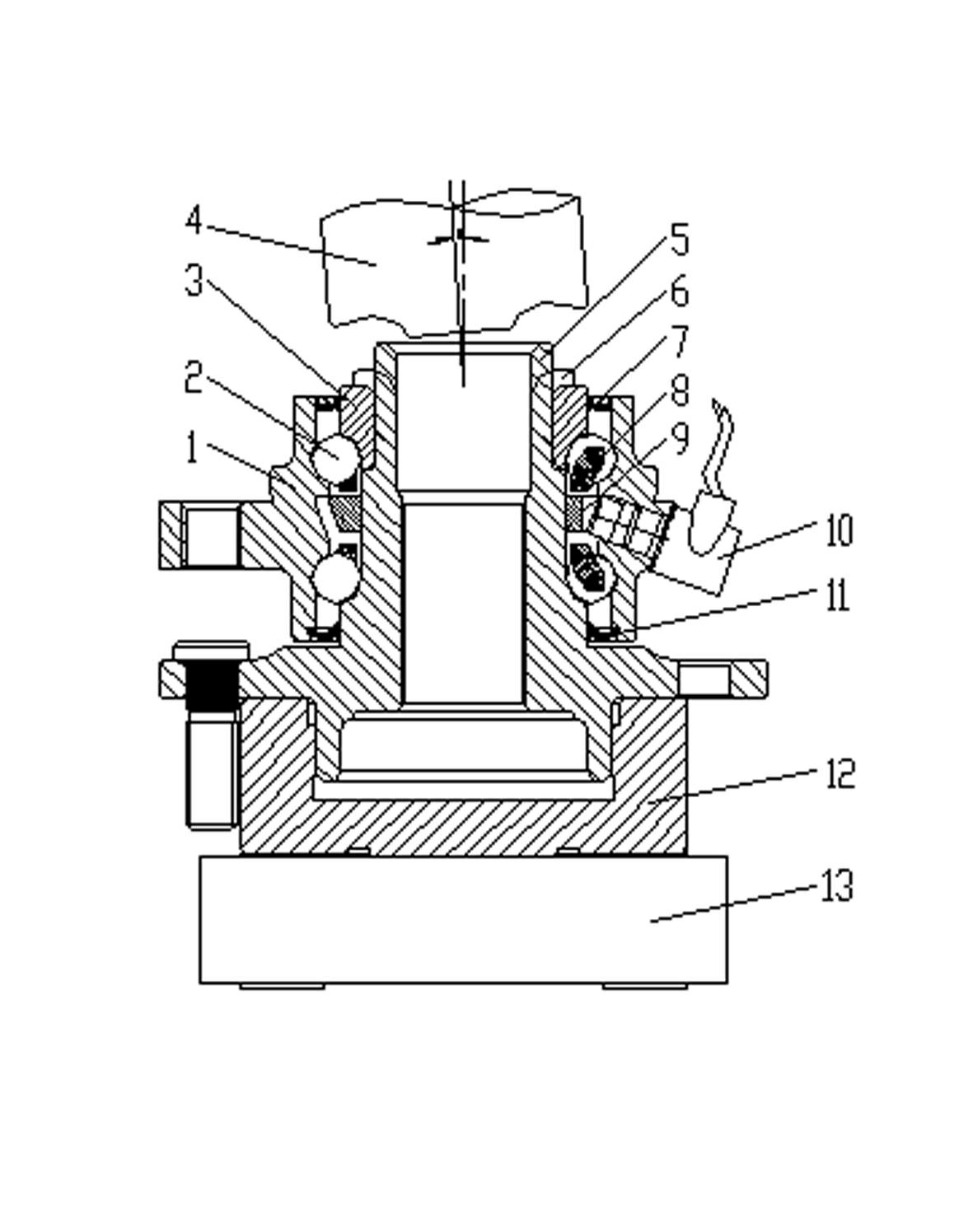

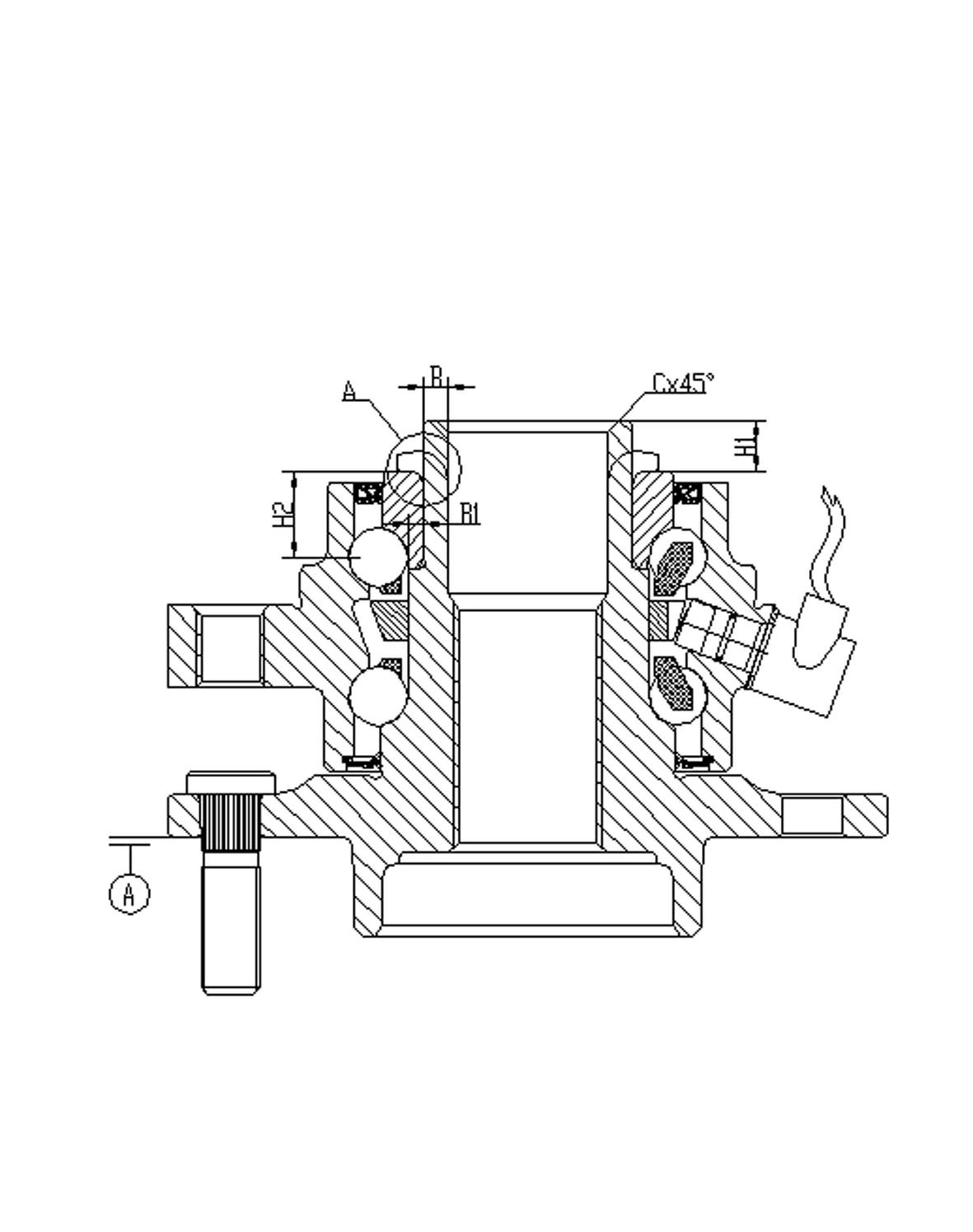

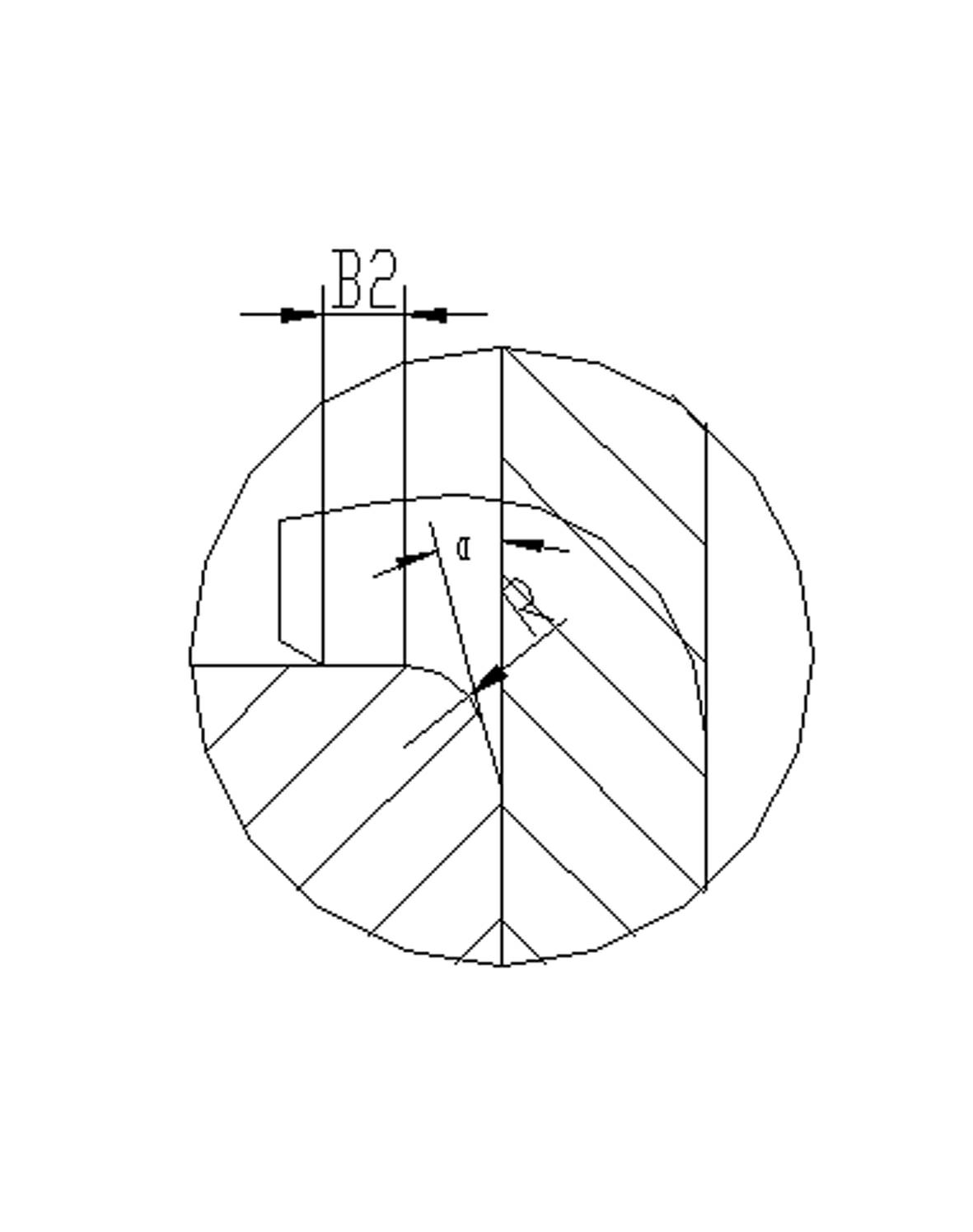

[0021] see figure 1 , figure 2 and image 3 , a spinning type riveting assembly manufacturing method for an automobile hub bearing unit, the riveted hub bearing unit includes a flange outer ring 1, a hub shaft 5 including a riveted shaft end flange, a steel ball 2, a cage 8, Combined sealing ring and dust cover 7, small inner ring 3, two rows of raceways are arranged on the flange outer ring 1, a raceway and a journal for installing the small inner ring 3 are arranged on the hub shaft 5, The small inner ring 3 is pressed into the journal of the hub shaft 5 with an interference fit. The shaft end of the hub shaft 5 is higher than the large end face of the small inner ring 3 by a certain value. A raceway, the flange surface of the flange outer ring 1 has a wall hole through the inside and outside, the cutting sensor 10 is installed in the hole, the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com