High vacuum heat insulation low temperature liquefied gas storage tank

A low-temperature liquefied gas and high-vacuum technology, used in low-temperature liquefied gas storage and transportation equipment, high-vacuum adiabatic low-temperature liquefied gas storage tanks, tank trucks or tank containers, can solve the problem of large distance between inner and outer heads, difficulty in manufacturing, and increased contact gap. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

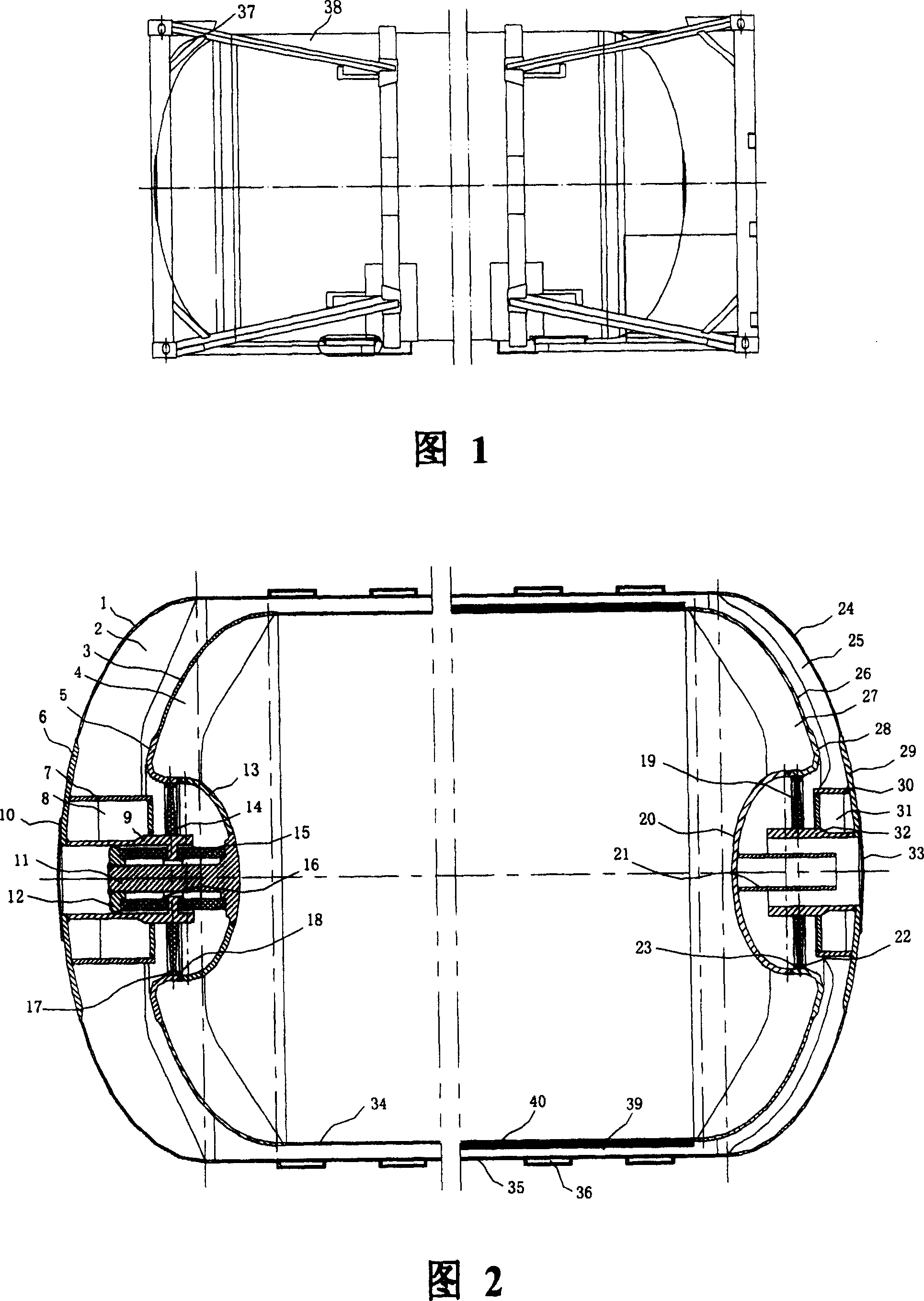

[0024] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. As shown in Figure 1, the present invention comprises a frame 37 and a tank body 38 welded together in an appropriate manner. As shown in Figure 2, the tank body includes the left shell head 1, the left shell head reinforcement plate 2, the inner tank left head head 3, the inner tank left head reinforcement plate 4, the left transition tube 5, and the left reinforcement plate 6 , left reinforcing tube 7, left reinforcing plate 8, left supporting tube 9, left sealing plate 10, stainless steel shaft 11, lock nut 12, left reversed small head 13, left radial supporting plate 14, second spacer 15. The first spacer 16, the left radial support plate left fixed ring 17, the left radial support plate right fixed ring 18, the right radial support plate 19, the right reversed small head 20, the process tube 21, the right radial Support plate right fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com