Rectangular materials transporting and fastening system

A material and elongated technology, which is applied to the vehicles used to carry elongated goods, transport buses, transportation and packaging, etc., can solve the problems of low utilization rate of vehicles, non-reusable reinforcement equipment, complicated operation procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

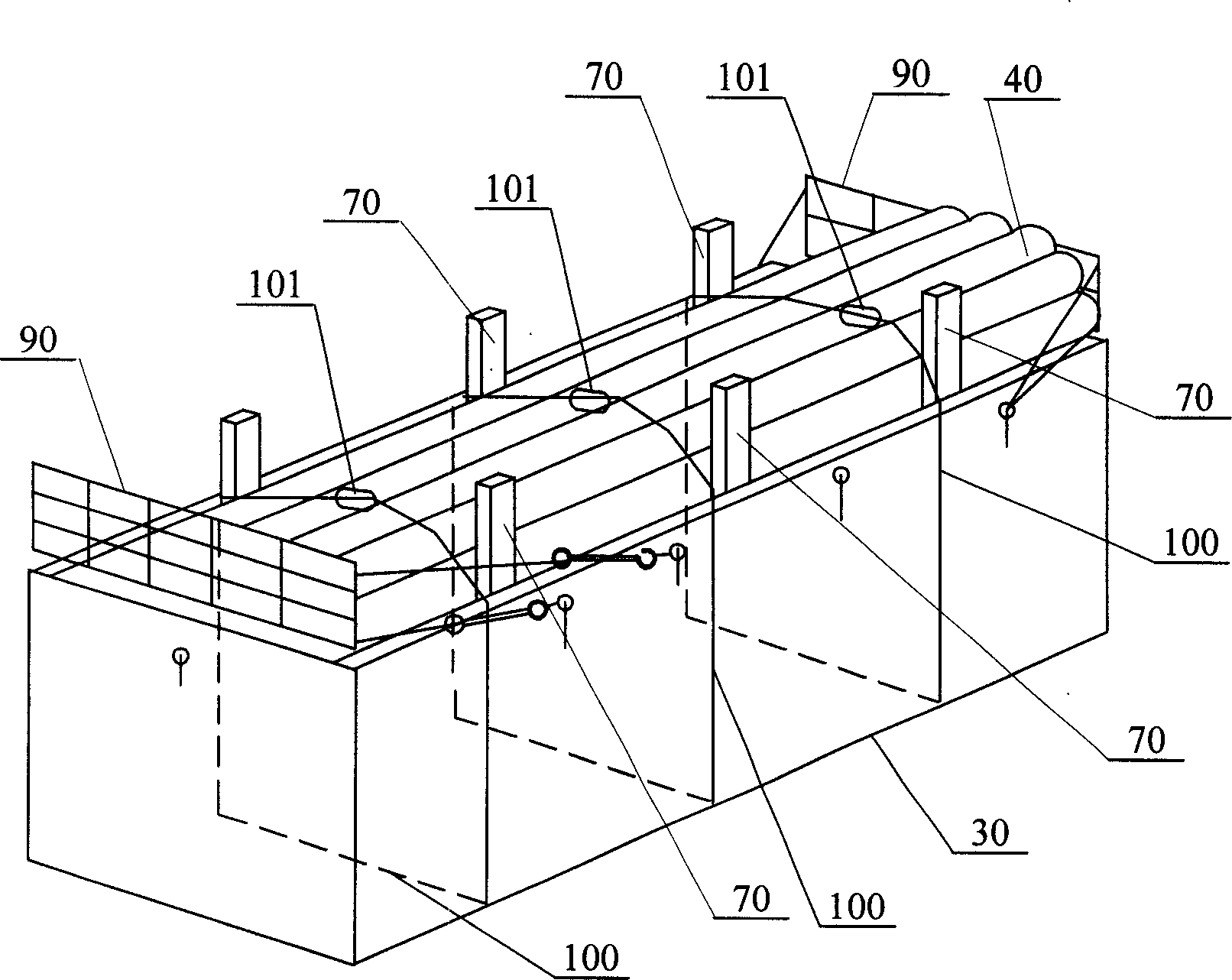

[0005] Specific implementation mode one: (see figure 1 ) This embodiment is composed of a carriage 30, elongated materials 40, steel wire rope 100, wire rope clamp 101, car column 70 and end net 90; On the inner side of the compartment plate, two end nets 90 are respectively arranged on the ends of the elongated material 40 at the front and rear ends of the compartment 30, and the two ends of each end net 90 are fixed on the left and right sides of the compartment 30, and the left and right sides of the compartment 30 Steel wire ropes 100 are respectively fixed around the compartment 30 and the elongated material 40 between the two car columns 70 of lateral symmetry, and the two ends of the steel wire rope 100 are fixedly connected by a wire rope clamp 101 .

specific Embodiment approach 2

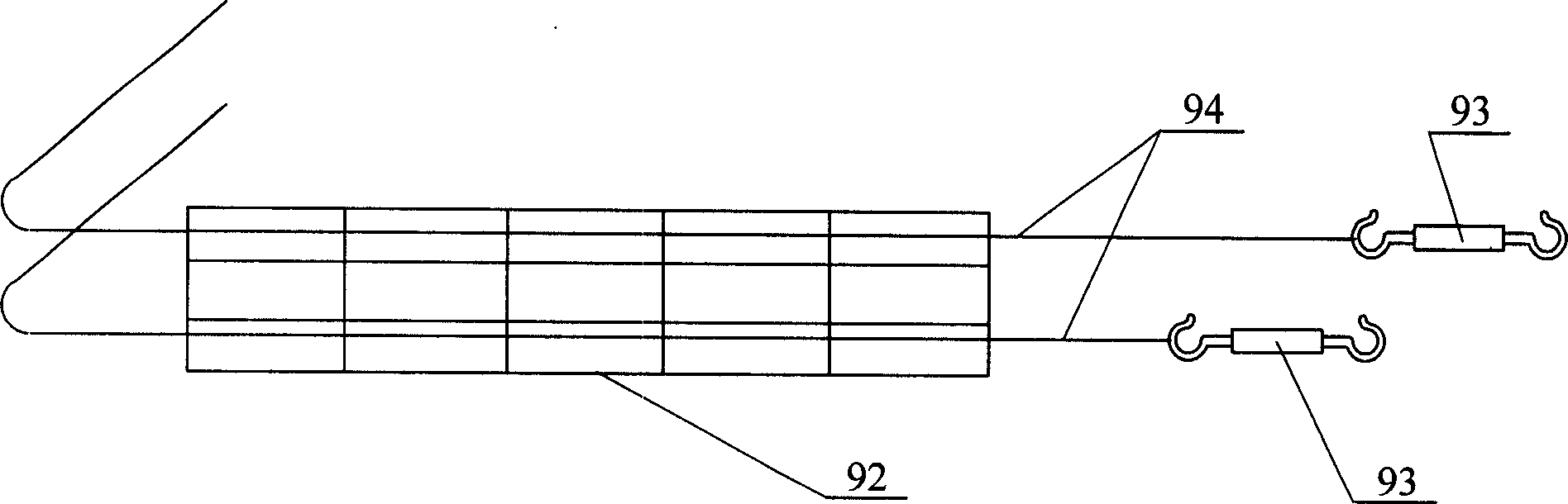

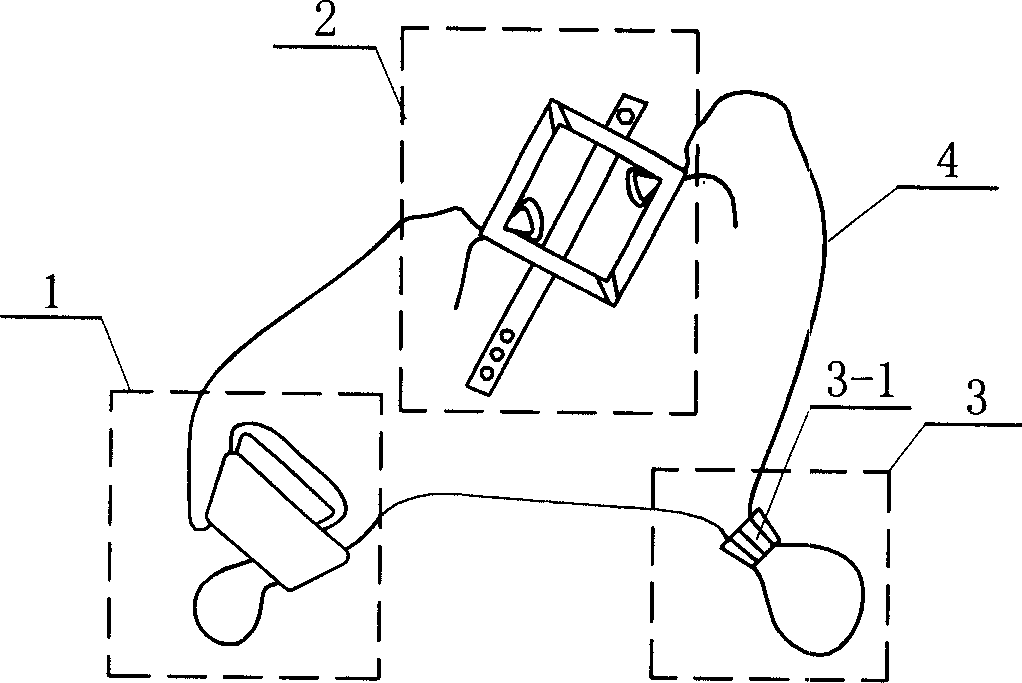

[0006] Specific implementation mode two: (see Figure 2-6 , Figure 8-12, Figure 14-1 7. Figure 26 ) The difference between this embodiment and the first embodiment is that the wire rope 100 and the wire rope clip 101 are replaced by an interlocking fastener 60 . The interlocking fastener 60 of this embodiment replaces the wire rope 100 and the wire rope clip 101, and is used for binding and fixing elongated goods on the vehicle when the vehicle transports the elongated goods. When the height of the goods transported by the vehicle exceeds the height of the compartment, it is often necessary to insert several car pillars 70 inside the compartment of the vehicle to prevent the goods from sliding out of the vehicle. It works together with the car column 70 inserted on it. The structure of the interlocking fastener 60 refers to Figure 2-6 , Figure 8-12, Figure 14-1 7. It includes the non-adjustable locking part 3, the adjustable locking part 1, the fastening part 2 and th...

specific Embodiment approach 3

[0011] Specific implementation mode three: the difference between this implementation mode and specific implementation mode two is that, referring to Figure 3 ~ Figure 14 , the wedge-shaped through hole 2-3 and the hole 2-4 for the twisted rod 2-2 to pass are both arranged at the corner of the fastening body. When in use, the two wedge blocks 2-1 are respectively arranged at two corners on the diagonal of the fastening body, and the twist rod 2-2 is arranged at two corners on the other diagonal of the fastening body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com