Construction element for heat insulation

A technology of structural elements, structural components, applied in the field of structural elements for thermal insulation, to achieve optimal orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

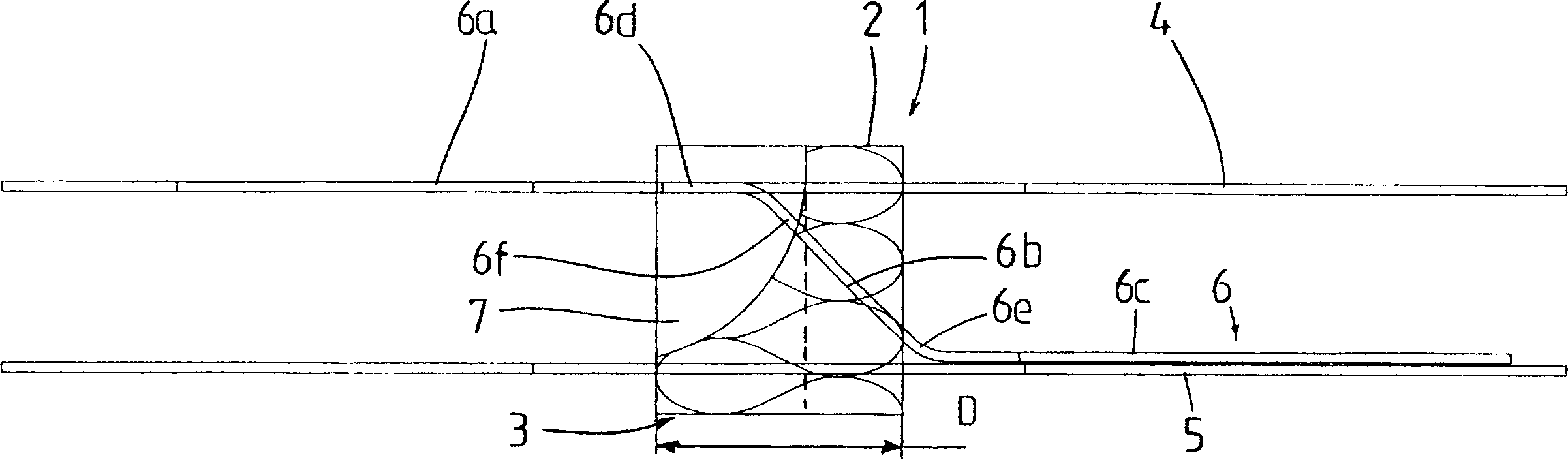

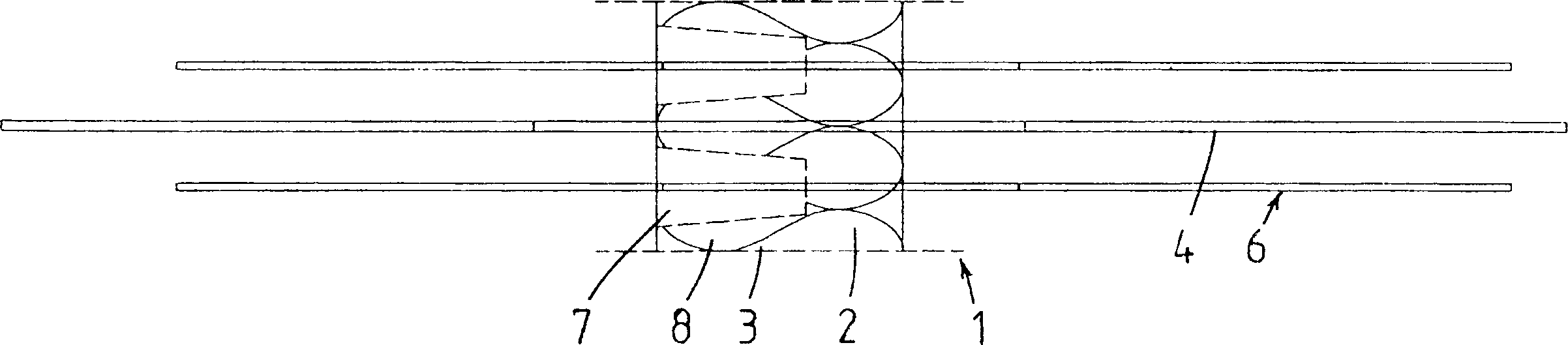

[0012] figure 1 with figure 2 The structural element 1 for thermal insulation shown in includes an insulator 2 with integral protrusions 3 made of the same insulator material and a number of reinforcing bars traversing the insulator - i.e. in the upper Tie bars 4 extending horizontally in the insulation area, compression bars 5 and shear bars 6 extending horizontally in the lower insulation area, wherein the shear bars are in vertical planes parallel to each other inside the insulation has a distinctly inclined distribution section 6b and is bent in areas 6d, 6e at the upper distribution section 6a and at the lower distribution section 6c for connection to two adjoining concrete structural parts, so that said distribution section Protruding horizontally from the insulation at different heights in the vertical plane, the upper distribution section 6 a is assigned to the supporting structural part and the lower distribution section 6 c is assigned to the supported structural p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com