Vacuum heat insulator and heat insulating box using the insulator

An insulating material and vacuum heat technology, which can be applied to heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc. It can solve the problems of increasing the weight and production cost of vacuum heat insulating materials, achieve good thermal insulation performance, and solve the problem of excessive compressors. Effects of Operational Efficiency Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

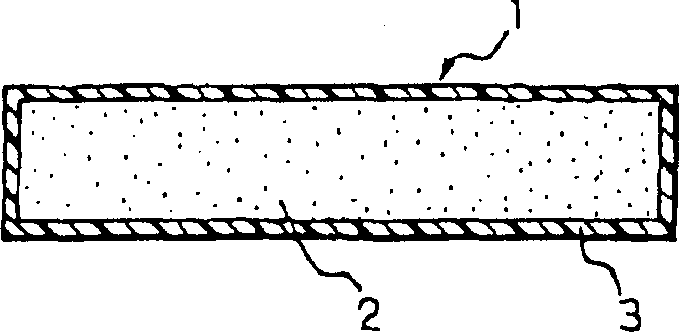

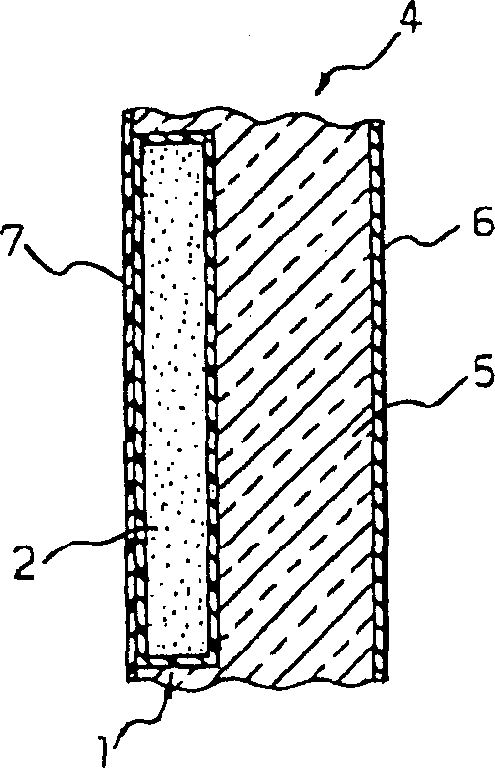

[0051] use figure 1 and 2 Embodiment 1 of the present invention will be described. figure 1 It is a cross-sectional view of the vacuum thermal insulation material according to Embodiment 1 of the present invention; figure 2 It is a sectional view of a heat insulating case using a heat insulating material according to Embodiment 1 of the present invention.

[0052] refer to figure 1 The vacuum heat insulating material 1 comprises a powder mixture obtained by stirring pulverized polyurethane foam powder having an average particle diameter of 150 μm and synthetic silica powder with a stirring mill at high speed (3600 rpm). The grinding powder of the polyurethane foam is obtained by grinding the polyurethane foam on a 150 μm abrasive cloth.

[0053]The prepared powder mixture is filled into a gas-permeable nonwoven fabric to form a core material 2 . The core 2 is placed in an outer part 3 consisting of a metal-plastic film laminate. The gas in the inner space surrounded by ...

Embodiment approach 2

[0068] Described below are the vacuum heat insulating material 1 and the heat insulating box 4 using the vacuum heat insulating material in Embodiment 2 of the present invention. The structure and figure 1 and 2 The embodiment 1 described in is the same and will not be specifically described here.

[0069] The vacuum heat in Embodiment 2 can be prepared by filling the mixture of ground polyurethane foam and synthetic silica powder into the outer layer member 3 made of a metal-plastic film laminate, and then sealing the outer layer member 3 under reduced pressure. Insulation Materials.

[0070] Polyurethane

Specific surface area (m 2 / g)

5

10

15

20

22

25

27

29

31

33

35

37

powder explosion

-

-

-

-

+

+

+

+

+

+

+

+

[0071] Polyurethane

Specific surface area (m ...

Embodiment approach 3

[0089] Described below are the vacuum thermal insulating material 1 and the thermal insulating case 4 using the vacuum thermal insulating material in Embodiment 3 of the present invention. The structure of the vacuum thermal insulation material 1 and thermal insulation box 4 of embodiment 3 figure 1 and 2 The embodiment 1 described in is the same and will not be specifically described here. In Embodiment 3, seven examples are discussed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com