Elastic composite smoke-proof strip

A smoke-proof rod and elastic technology, applied in fire doors, sealing devices, etc., can solve the problems that the material can only be used once, it is inconvenient to deal with residues, and the two planes cannot be completely closely attached, so as to increase the interface bonding area. , good thermal insulation and sealing effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

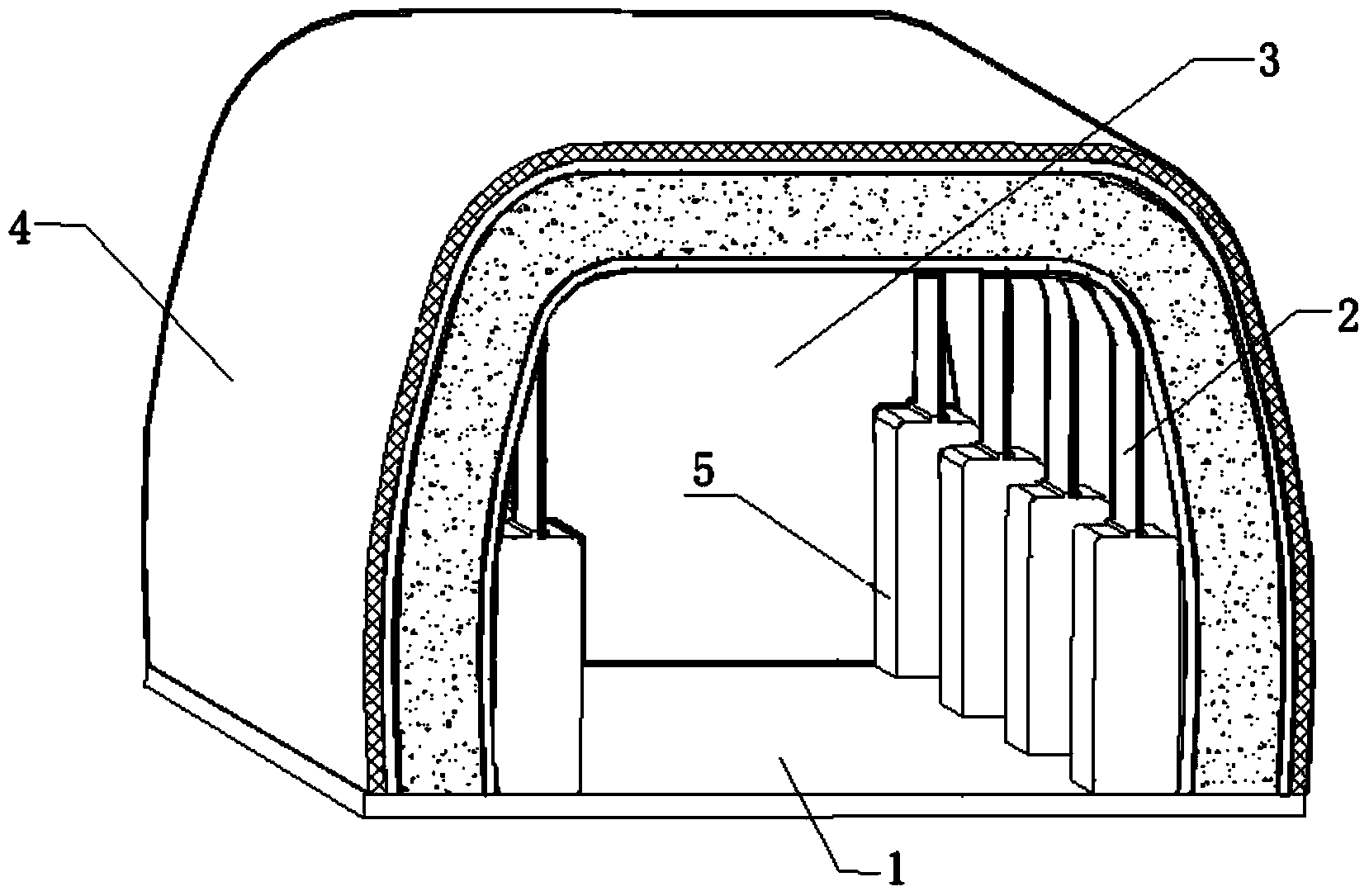

Examples

Embodiment 2

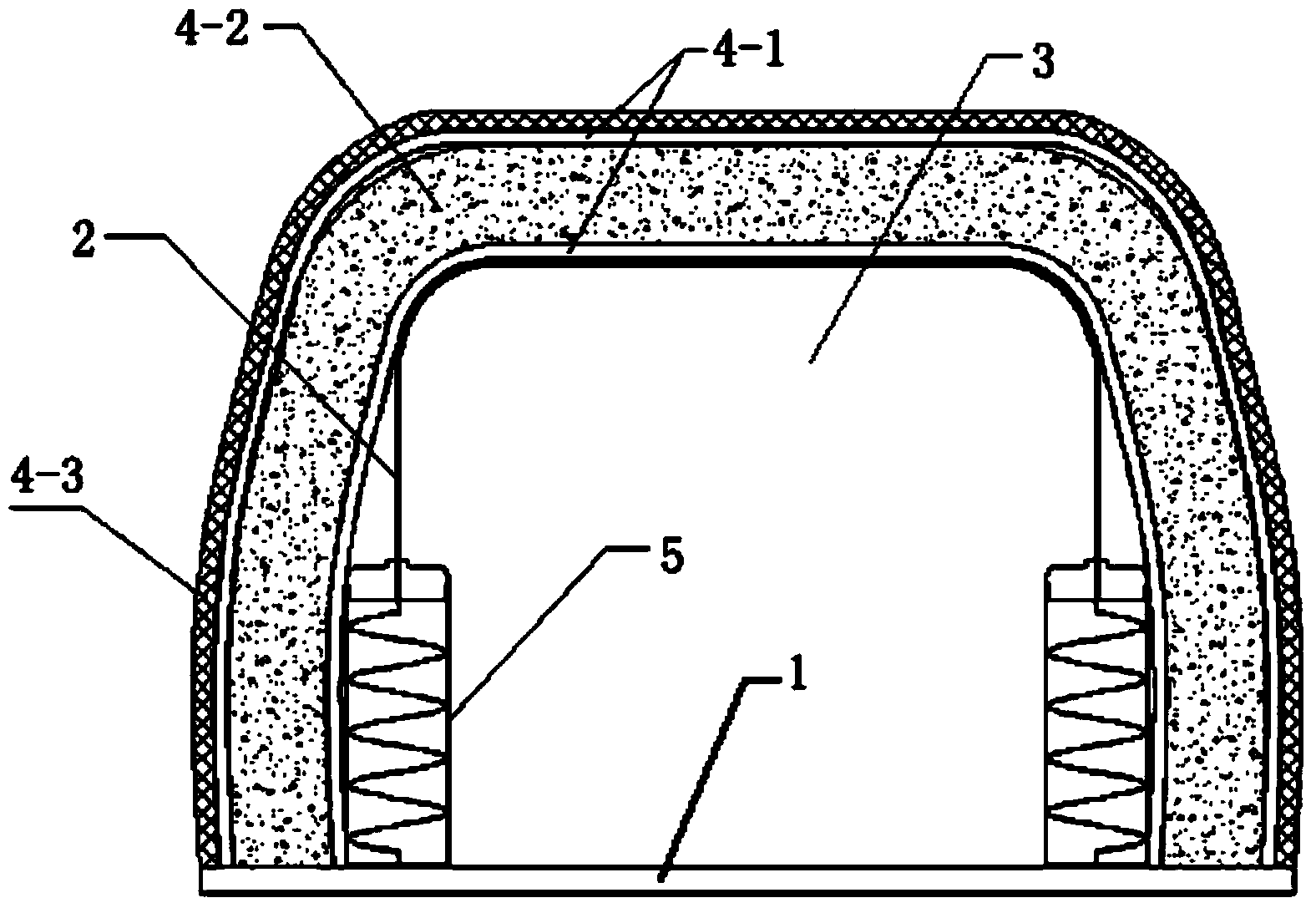

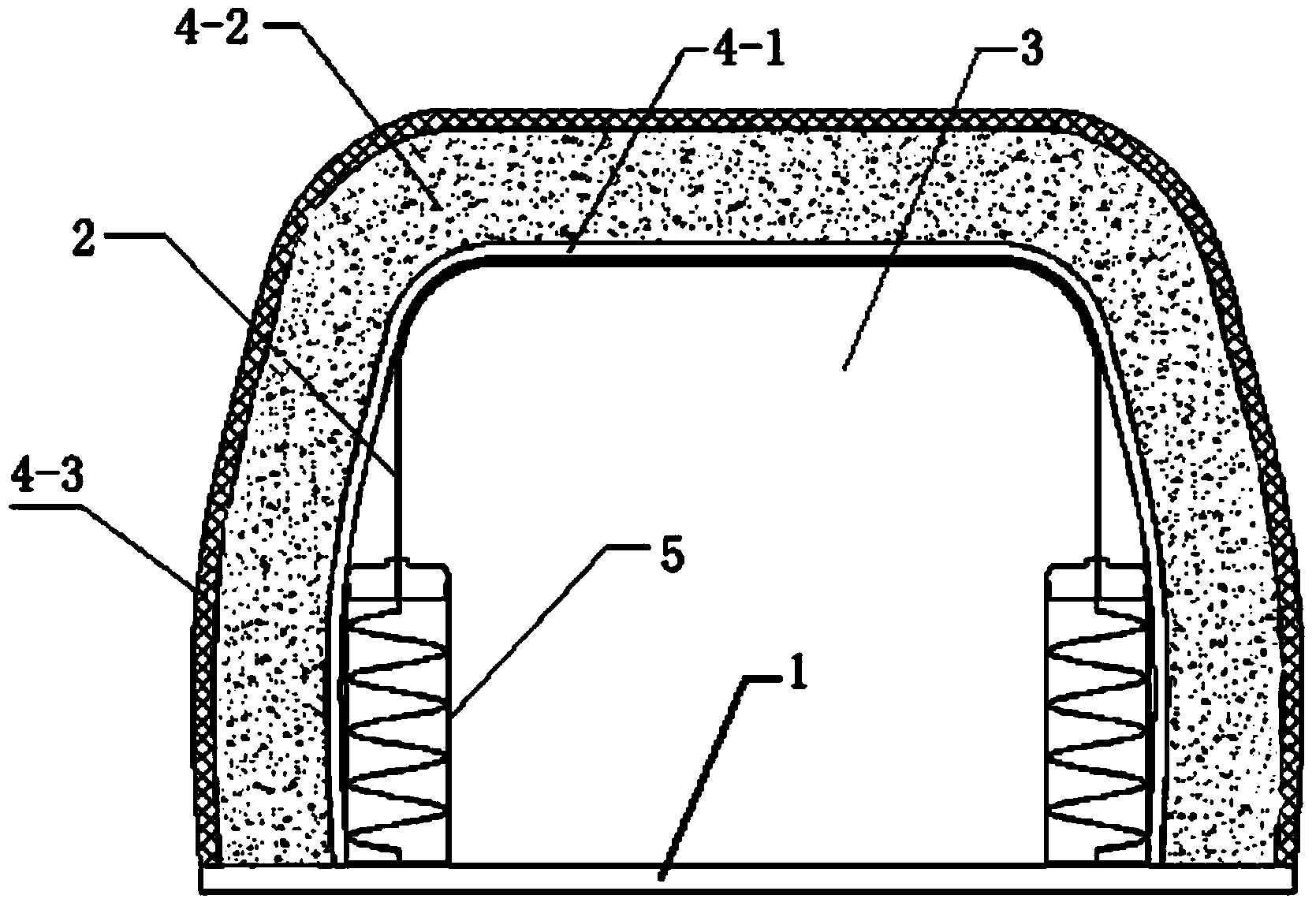

[0032] Example 2, such as image 3 As shown, the smoke-proof strip includes a fire-resistant base 1 made of steel plates, and the metal and non-metal composite layer 4 is sequentially composed of a metal foil layer 4-1, a non-metal filling layer 4-2 and a refractory fiber cloth layer 4-3 from the inside to the outside. The metal foil layer 4-1 is made of copper foil, the non-metal filling layer 4-2 is made of glass fiber cotton layer, and the refractory fiber cloth layer 4-3 is made of glass fiber cloth.

[0033] The smoke-proof strips in Embodiment 1 and Embodiment 2 are used in fire-proof and smoke-proof roller shutters to seal the gap between the fire-proof curtain surface and the guide rail, and between the curtain surface and the door lintel. When the fireproof curtain surface is lowered to the predetermined position, the mechanism drives the curtain surface to approach the guide rail wall where the smoke-proof strip is installed. During the approaching process, the curta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com