High-performance fireproof plate and preparation method thereof

A high-performance, fire-resistant board technology, applied in fire prevention, building components, buildings, etc., can solve the problems of the filling that is difficult to continuously resist flame burning, the alloy has low fire resistance, and escape time, etc., and achieves tight structure and good sealing. , the effect of improving fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

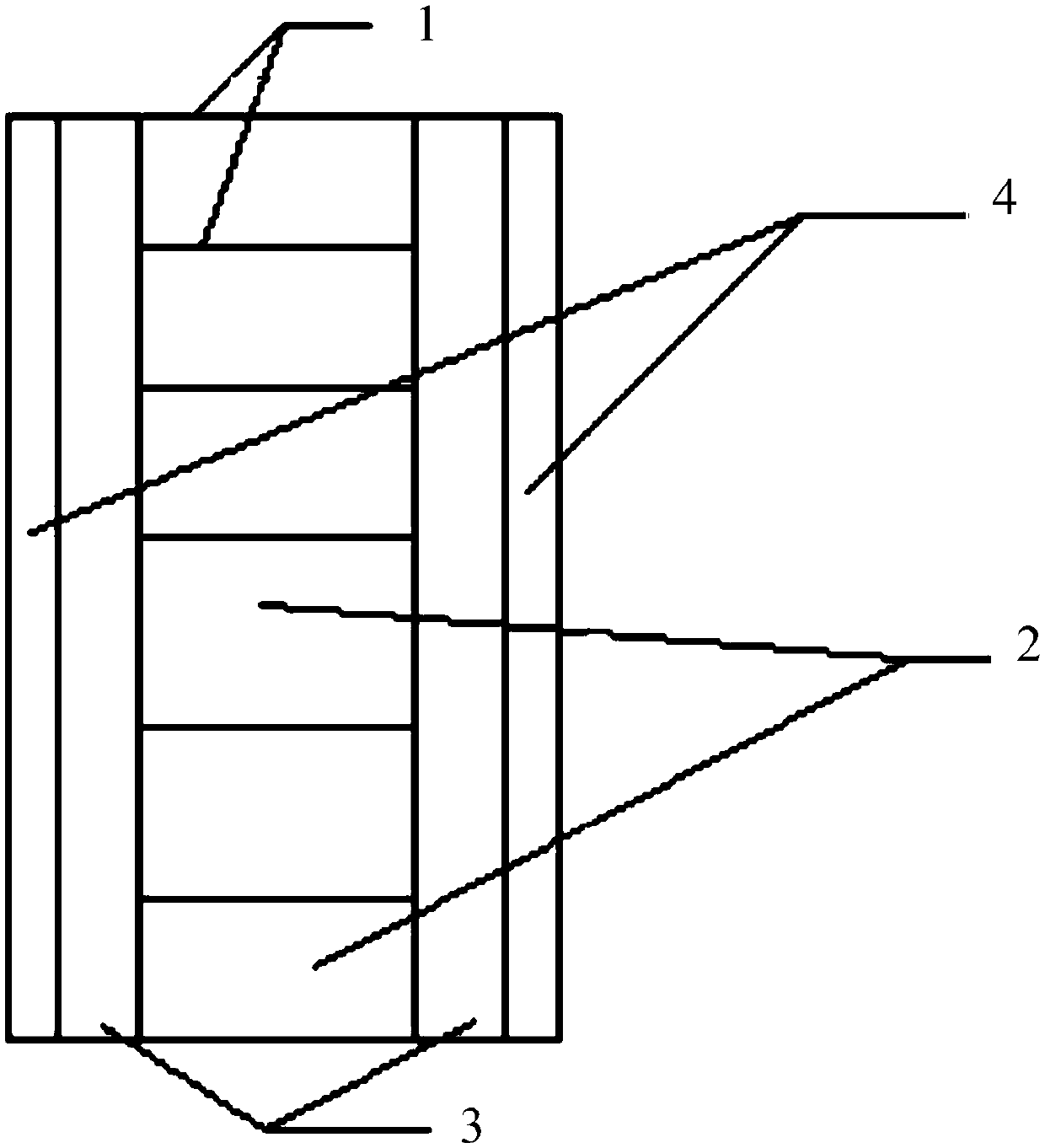

Image

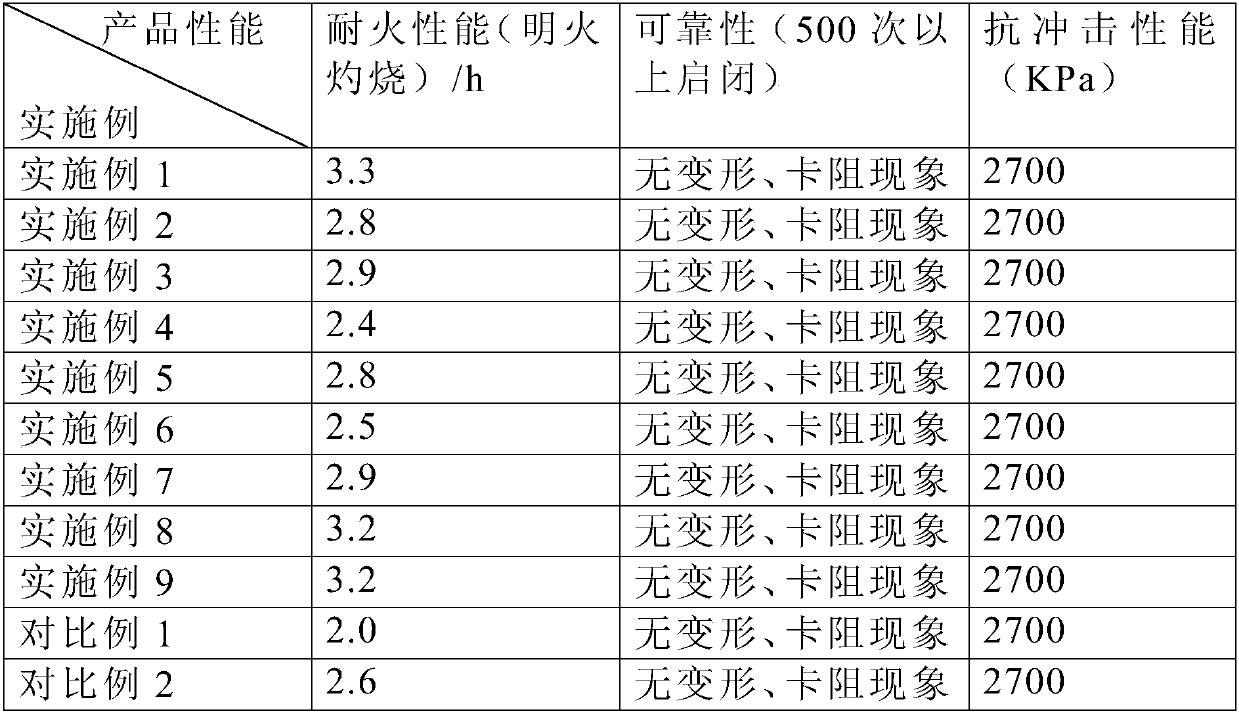

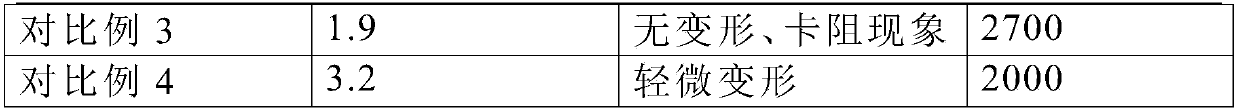

Examples

Embodiment 1

[0036] Prepare the skeleton: select high-quality pine wood, dry it and process it into a standard material, place the standard material in a vacuum environment, control the vacuum degree to be less than 0.01Pa, and evenly spread a layer of magnesium hydroxide and silicon dioxide on the standard material mixed powder, the amount of mixed powder is 130kg / m 3 , and then slowly apply the pressure to 75MPa, keep it for 5h, then carry out secondary drying, and assemble it into a fireproof board skeleton after trimming.

[0037] Putty ash preparation: putty ash is selected according to its composition and weight parts: 100 parts of shale brick ash, 30 parts of kaolin, 40 parts of straw ash, 15 parts of slaked lime, 20 parts of tung oil, 40 parts of starch glue, and 150 parts of water. The specific preparation process is as follows: first burn the straw into ashes in the stove, then grind shale bricks and kaolin into powder, then mix the straw ash, brick ash, kaolin and slaked lime, p...

Embodiment 2

[0041]Prepare the skeleton: select high-quality pine wood, dry it and process it into a standard material, place the standard material in a vacuum environment, control the vacuum degree to be less than 0.01Pa, and evenly spread a layer of magnesium hydroxide and silicon dioxide on the standard material mixed powder, the amount of mixed powder is 110kg / m 3 , and then slowly apply pressure to 50MPa, hold for 3 hours and then perform secondary drying, and then assemble into a fireproof board skeleton after trimming.

[0042] Putty ash preparation: putty ash is selected according to its composition and weight parts: 100 parts of shale brick ash, 30 parts of kaolin, 40 parts of straw ash, 15 parts of slaked lime, 20 parts of tung oil, 40 parts of starch glue, and 150 parts of water. The specific preparation process is as follows: first burn the straw into ashes in the stove, then grind shale bricks and kaolin into powder, then mix the straw ash, brick ash, kaolin and slaked lime, p...

Embodiment 3

[0046] Prepare the skeleton: select high-quality pine wood, dry it and process it into a standard material, place the standard material in a vacuum environment, control the vacuum degree to be less than 0.01Pa, and evenly spread a layer of magnesium hydroxide and silicon dioxide on the standard material mixed powder, the amount of mixed powder is 150kg / m 3 , and then slowly apply the pressure to 100MPa, keep it for 7 hours and then carry out secondary drying, and assemble it into a fireproof board skeleton after trimming.

[0047] Putty ash preparation: putty ash is selected according to its composition and weight parts: 100 parts of shale brick ash, 30 parts of kaolin, 40 parts of straw ash, 15 parts of slaked lime, 20 parts of tung oil, 40 parts of starch glue, and 150 parts of water. The specific preparation process is as follows: first burn the straw into ashes in the stove, then grind shale bricks and kaolin into powder, then mix the straw ash, brick ash, kaolin and slake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com