Cork-powder-based porous composite material and preparation method and application thereof

A technology of porous composite material and cork powder, which is applied in the field of cork powder-based porous composite material and its preparation, can solve the problems that cork resources cannot be utilized with high value, no high-end cork products, low gross profit rate, etc., and achieve good thermal insulation. Insulation properties, great application potential, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Use "natural cork powder" as raw material to screen out cork particles with a particle size of 0.5mm~1mm;

[0029] (2) Take 200g of the above-mentioned cork particles, spread them in a container and place them in a high-power microwave oven with a power of 1850W, and take them out after 2 minutes of microwave treatment;

[0030] (3) Mechanically mix the microwave-treated cork powder and fumed silica at a mass ratio of 9:1 for 30 minutes to obtain a cork powder / fumed silica composite powder.

[0031] (4) Put the composite powder prepared above into a mold, apply a pressure of 10 tons to it, keep the pressure for 5 minutes, and take it out to obtain a filling core material.

[0032] (5) Put the core material into the packaging material for vacuum packaging to obtain a vacuum heat insulation board. After packaging, the vacuum degree in the vacuum bag is 0.1 mbar. The thermal conductivity of the prepared vacuum insulation panel was tested, and the thermal conductivity ...

Embodiment 2

[0034] (1) Use "expanded cork powder" as raw material to screen out cork particles with a particle size of 0.15mm~0.35mm;

[0035] (2) Take 200g of the above-mentioned cork particles, spread them in a container and place them in a high-power microwave oven with a power of 1850W, and take them out after 2 minutes of microwave treatment;

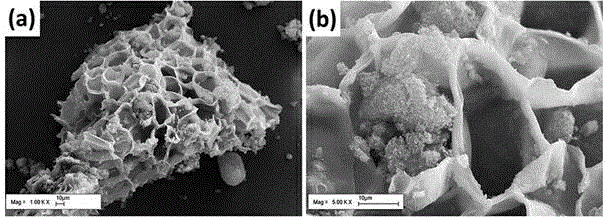

[0036] (3) Mechanically mix the microwave-treated cork powder and fumed silica at a mass ratio of 19:1 for 30 minutes to obtain a cork powder / fumed silica composite powder with a microscopic composite structure Such as figure 1 Shown in the scanning electron microscope photo.

[0037] (4) Put the composite powder prepared above into a mold, apply a pressure of 10 tons to it, keep the pressure for 5 minutes, and take it out to obtain a filling core material.

[0038] (5) Put the core material into the packaging material for vacuum packaging to obtain a vacuum heat insulation board. After packaging, the vacuum degree in the vacuum bag is 0.1 m...

Embodiment 3

[0040] (1) Use "expanded cork powder" as raw material to screen out cork particles with a particle size of 0.5mm~1mm;

[0041] (2) Take 200g of the above-mentioned cork particles, spread them in a container and place them in a high-power microwave oven with a power of 1850W, and take them out after 2 minutes of microwave treatment;

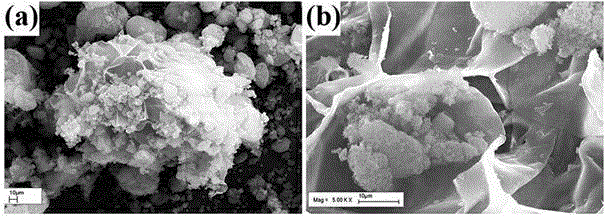

[0042] (3) Mechanically mix the microwave-treated cork powder and fumed silica at a mass ratio of 9:1, and the mixing time is 30 minutes to obtain a cork powder / fumed silica composite powder, whose microscopic composite structure Such as figure 2 Shown in the scanning electron microscope photo.

[0043] (4) Put the composite powder prepared above into a mold, apply a pressure of 10 tons to it, keep the pressure for 5 minutes, and take it out to obtain a filling core material.

[0044] (5) Put the core material into the packaging material for vacuum packaging to obtain a vacuum heat insulation board. After packaging, the vacuum degree in the vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com