Electrode and battery

A battery and electrode technology, applied in the field of electrodes of the battery, can solve the problems of reduced other characteristics, inability to form sufficient coatings, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

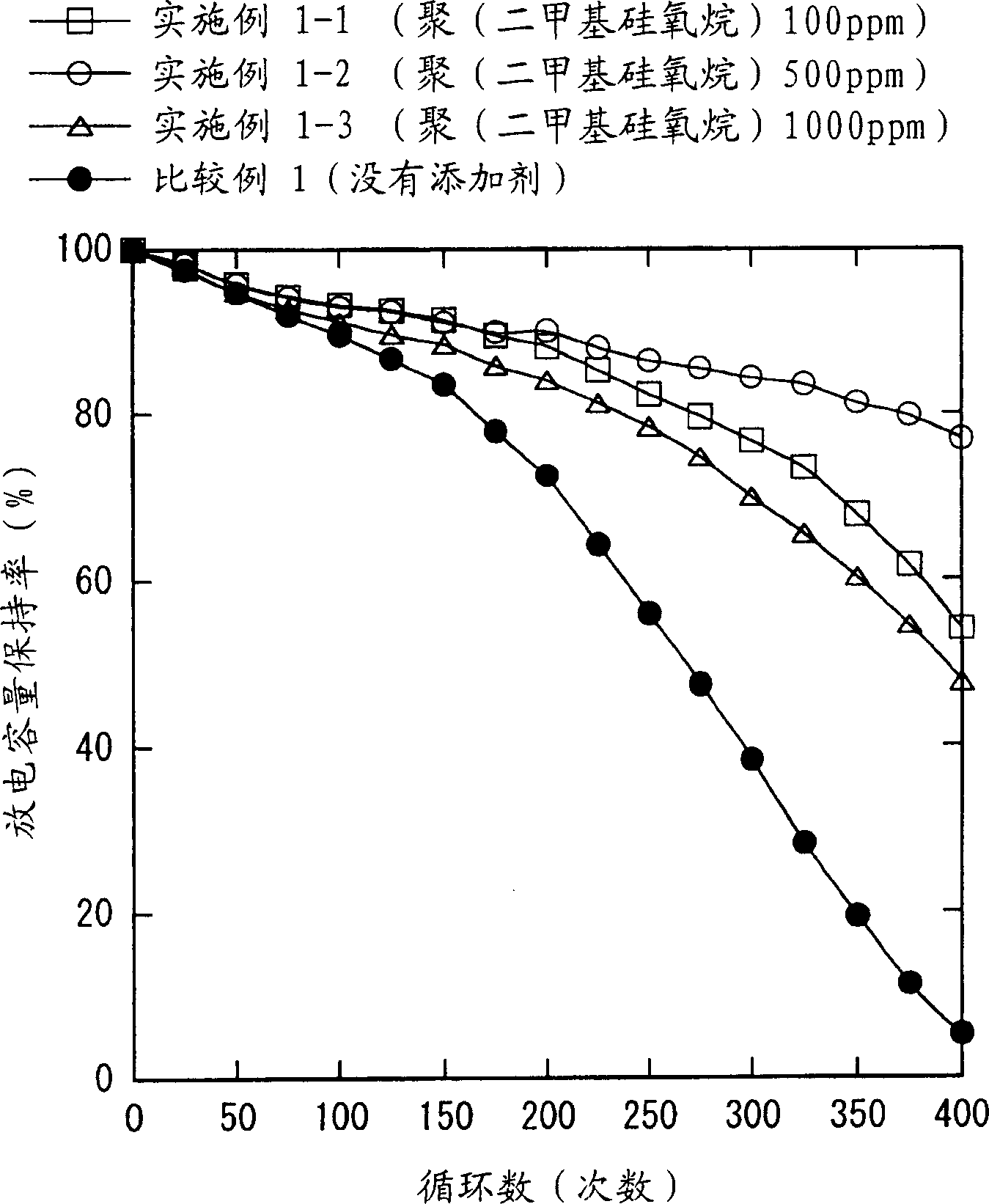

Embodiment 1-1 to 1-3

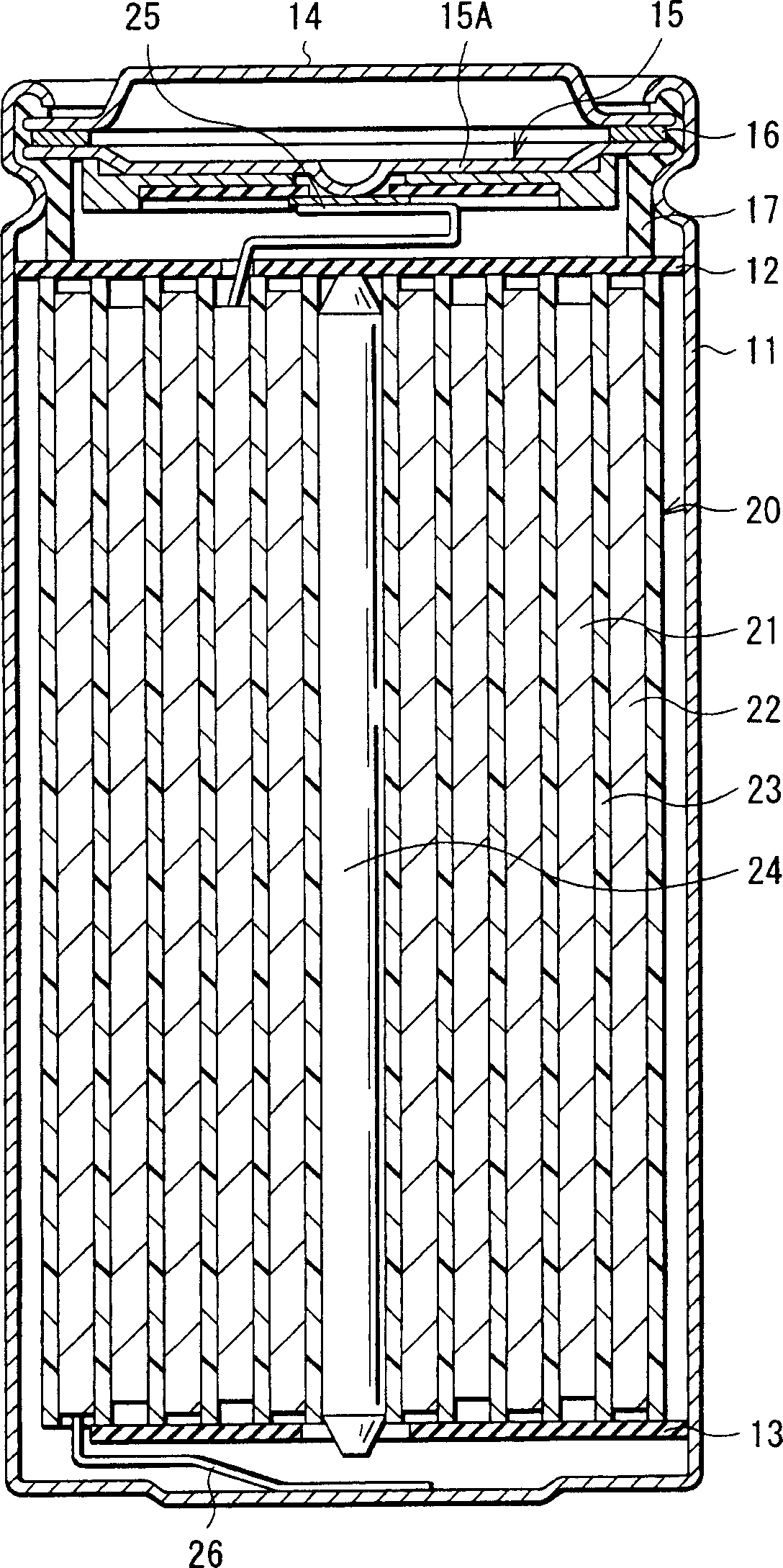

[0050] First, 64 parts by mass of lithium cobalt oxide (LiCoO 2 ), 3 parts by mass of graphite as a conductive agent, and 3 parts by mass of polyvinylidene fluoride as a binder were uniformly mixed. After that, N-methylpyrrolidone was added to the mixture to obtain a positive electrode mixture coating liquid. Next, the positive electrode current collector made of aluminum foil with a width of 56 mm, a length of 550 mm, and a thickness of 20 μm is evenly coated with the obtained positive electrode mixture coating liquid, and the coating liquid is dried to form a 70 μm thick layer on both sides of the positive electrode current collector. positive electrode mixture layer. Thus, the positive electrode 21 was manufactured. Subsequently, a cathode lead 25 made of aluminum was attached to one end of the cathode current collector.

[0051] In addition, 94 parts by mass of graphite as a negative electrode active material and 6 parts by mass of polyvinylidene fluoride as a binder we...

Embodiment 2-1 to 2-4

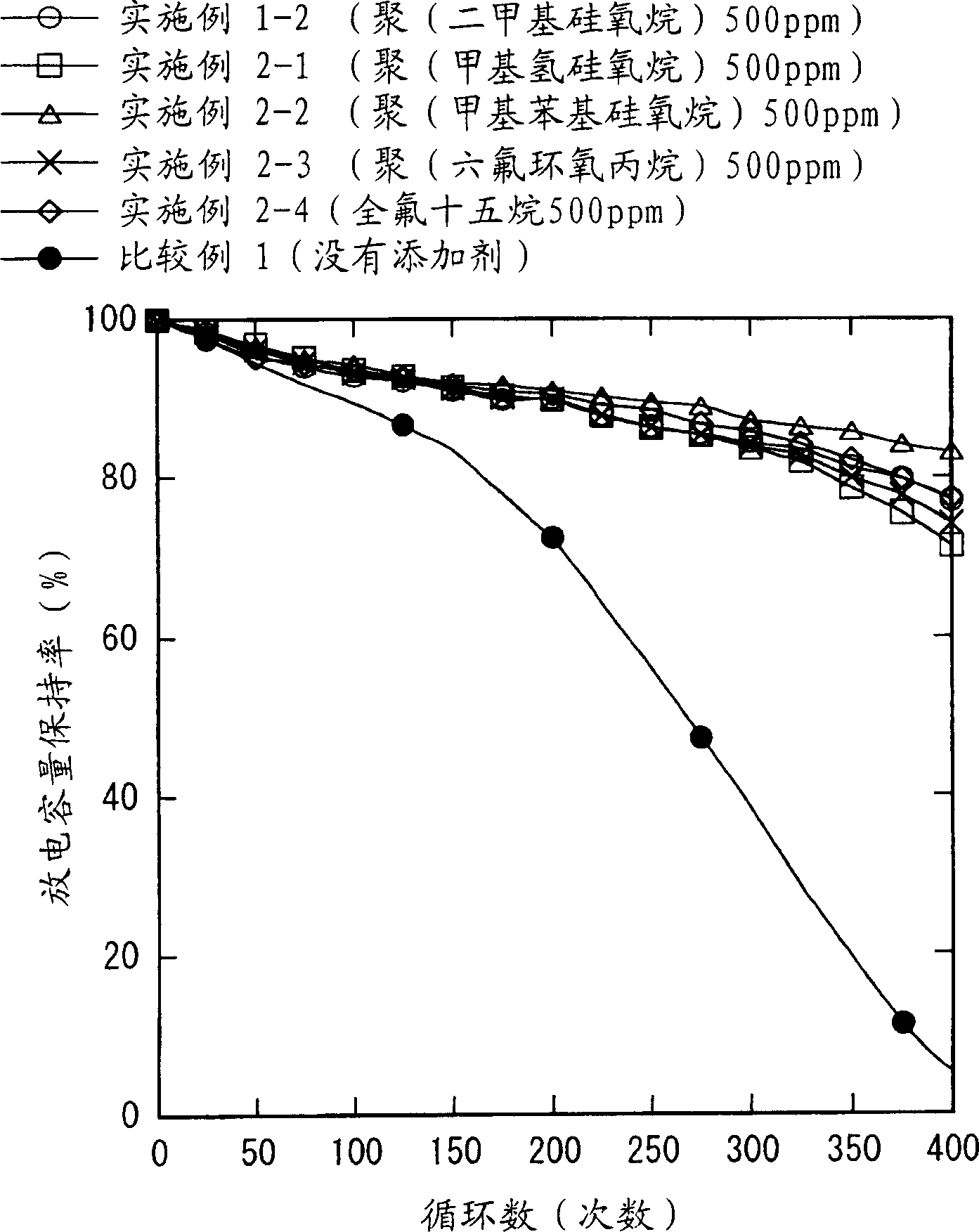

[0060] As Examples 2-1, 2-2, 2-3, and 2-4, secondary batteries were manufactured as in Example 1-2, except that the electrolyte-insoluble and 100 mm 2 Poly(methylhydrogensiloxane), poly(methylphenylsiloxane), poly(hexafluoropropylene oxide), and perfluoropentadecane with a dynamic viscosity of / S and a surface tension of about 20 mN / m Instead of poly(dimethylsiloxane). Like Example 1-2, the secondary batteries of Examples 2-1 to 2-4 were also disassembled and observed. As a result, it was confirmed that poly(methylhydrogensiloxane), poly(methylphenylsiloxane), poly(hexafluoropropylene oxide), or perfluoropentadecane was formed on the surfaces of the positive electrode 21 and the negative electrode 22. coating. In addition, as in Example 1-2, charge and discharge tests were performed to examine cycle characteristics. Its result is shown together with the result of embodiment 1-2 and comparative example 1 in image 3 middle.

[0061] Such as image 3 It was demonstrated th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com