Preparation method of large-particle-size and high-density spherical cobalt oxide

A technology of cobalt tetroxide and high density, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of cracking, breaking and slowing of growth rate of product particles, and achieve the effect of uniform particle size distribution and preventing particle cracking or breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

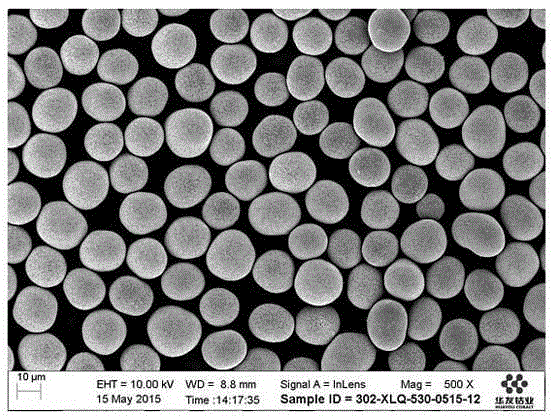

Image

Examples

Embodiment 1

[0024] ①Inject a certain amount of ammonium bicarbonate solution into the reaction kettle as the bottom liquid and submerge the stirring paddle;

[0025] ②Raise the temperature to 50°C, add cobalt chloride solution with a concentration of 80g / L and ammonium bicarbonate solution with a concentration of 180g / L into the reaction kettle at the same time under stirring, and a precipitation reaction occurs. The pH value of the reaction solution is controlled during the feeding process to be 7.0, Until the material is filled to the top of the reactor; after the feeding is completed, stop stirring, and after the solid-liquid layer is separated, the supernatant is pumped away to make room for further feeding, so that the crystals continue to grow;

[0026] ③ Repeat the cycle process of feeding, standing for stratification, pumping supernatant, and continuing feeding for 9 times. At this time, the crystal grows until the seed crystal particle size reaches 9.4 μm;

[0027] ④Separate the ...

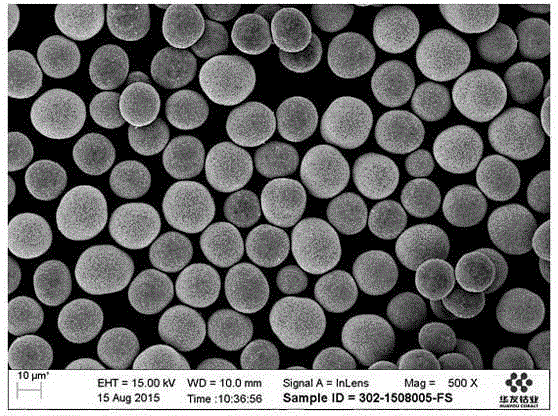

Embodiment 2

[0032] ①Inject a certain amount of ammonium carbonate solution into the reaction kettle as the bottom liquid and submerge the stirring paddle;

[0033] ②Raise the temperature to 70°C, add the cobalt sulfate solution with a concentration of 125g / L and the ammonium carbonate solution with a concentration of 210g / L into the reaction kettle at the same time under stirring, and a precipitation reaction occurs. During the feeding process, the pH of the reaction solution is controlled to be 8.2 until the material Fill up the reactor; after feeding, stop stirring, and after the solid-liquid layer is separated, remove the supernatant to make room for further feeding, so that the crystals continue to grow;

[0034] ③ Repeat the cycle process of feeding, standing for stratification, pumping supernatant, and continuing feeding for 12 times. At this time, the crystal grows until the seed crystal particle size reaches 11.8 μm;

[0035] ④Separate the reactor materials for the first time, tha...

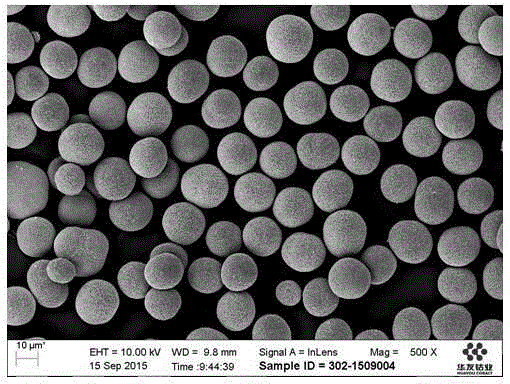

Embodiment 3

[0040] ①Inject a certain amount of ammonium bicarbonate solution into the reaction kettle as the bottom liquid and submerge the stirring paddle;

[0041] ②Raise the temperature to 80°C, add cobalt nitrate solution with a concentration of 160g / L and ammonium carbonate solution with a concentration of 230g / L into the reaction kettle at the same time under stirring, and a precipitation reaction occurs. The pH of the reaction solution is controlled to be 6.7 during the feeding process until the material Fill up the reactor; after feeding, stop stirring, and after the solid-liquid layer is separated, remove the supernatant to make room for further feeding, so that the crystals continue to grow;

[0042] ③ Repeat the cycle process of feeding, standing for stratification, pumping supernatant, and continuing feeding for 10 times. At this time, the crystal grows until the seed crystal particle size reaches 10.3 μm;

[0043] ④Separate the reactor materials for the first time, that is, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com