Hydro-cracking method for improving quality of aviation kerosene

A technology for hydrocracking and jet fuel, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of large investment, increase operating cost, increase total airspeed, etc., to improve the quality and operation of jet fuel. Low cost and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

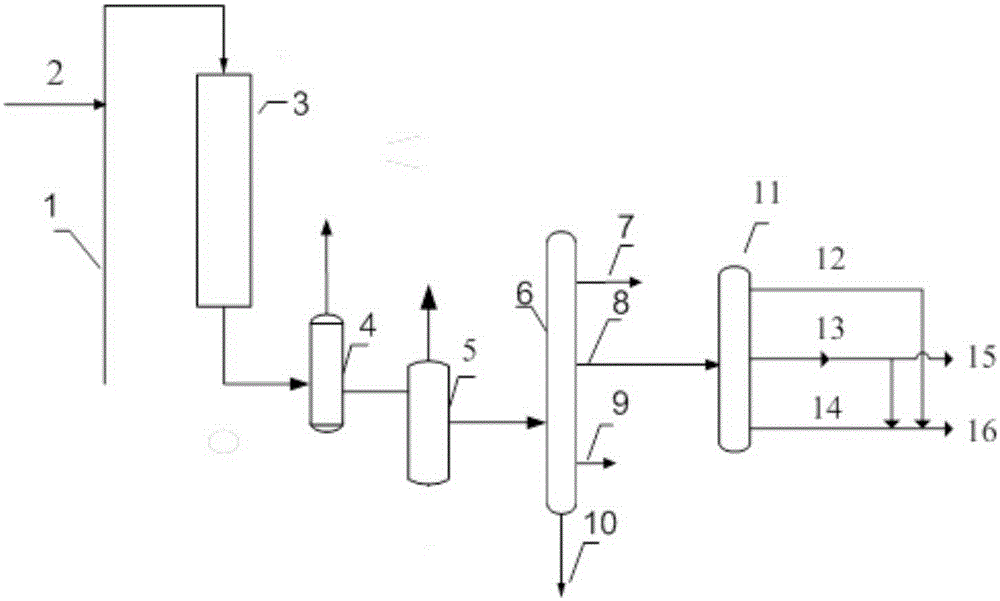

Method used

Image

Examples

Embodiment 1

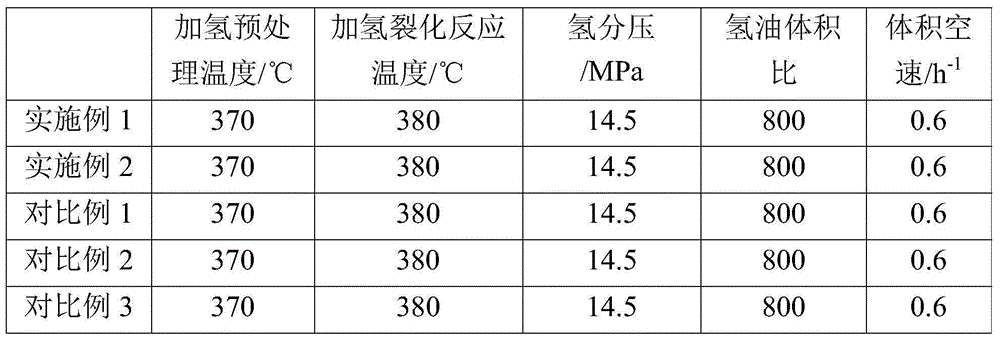

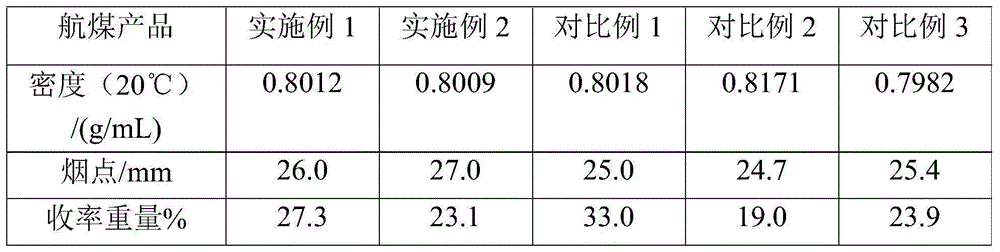

[0072]Feed oil and hydrogen are introduced into the hydrocracking reaction zone containing hydroprocessing pretreatment catalyst, hydrocracking catalyst and post-refining catalyst to react, the reaction conditions are as shown in Table 2; then the reaction flow out of the hydrocracking reactor The product is sequentially introduced into a high-pressure separator and a low-pressure separator for gas-liquid separation to obtain a liquid phase product, and the liquid phase product is introduced into the first fractionation tower for fractionation to obtain naphtha fraction, kerosene fraction, diesel fraction and tail oil fraction (the cut point of the naphtha fraction and the kerosene fraction is 145° C.; the cut point of the kerosene fraction and the diesel fraction is 270° C.; the cut point of the diesel fraction and the tail oil fraction is 320° C. ℃, the same below). The kerosene fraction obtained is introduced into a kerosene fractionation tower for further fractionation to ...

Embodiment 2

[0082] The raw oil and hydrogen are introduced into the hydrocracking reactor containing the hydrocracking catalyst and the post-refining catalyst for reaction, and the reaction conditions are shown in Table 2; then the reaction effluent of the hydrocracking reactor is sequentially introduced into the high-pressure separator Perform gas-liquid separation with a low-pressure separator to obtain liquid phase products, and introduce the liquid phase products into the first fractionation tower for fractionation to obtain naphtha fractions, kerosene fractions, diesel fractions and tail oil fractions. The obtained kerosene fraction is introduced into the kerosene fractionation tower for further fractionation to obtain light jet kerosene fraction, medium jet kerosene fraction and heavy jet kerosene fraction. Jet kerosene fractions are mixed to form jet kerosene products out of the device. Among them, the weight ratio of the extracted medium jet kerosene fraction to the jet kerosene p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com