Method for producing jet fuel or jet fuel blending component

A technology of jet fuel and blending components, which is applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems of low smoke point, high smoke point, unsatisfactory density, etc., to reduce operating costs, react The effect of easing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

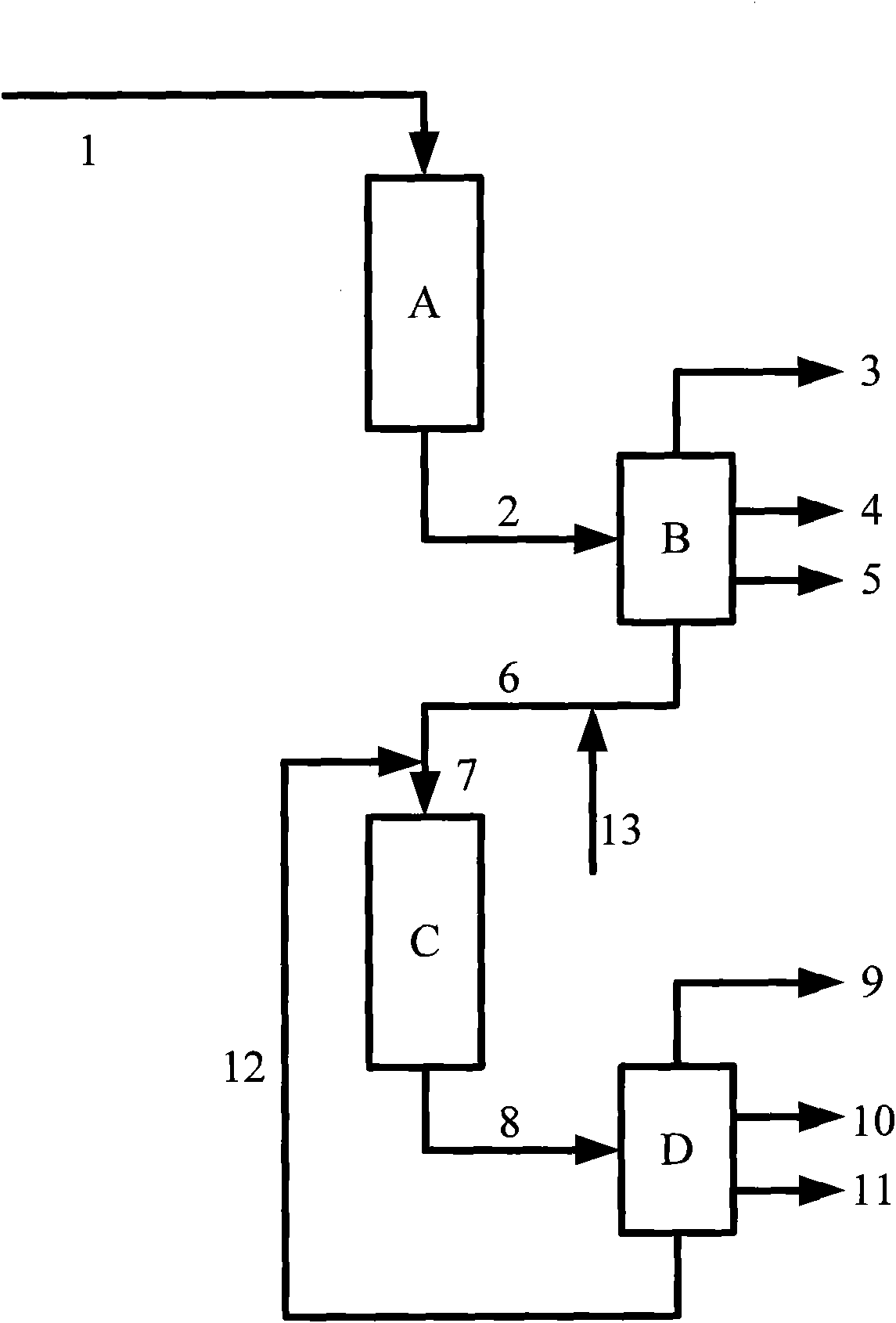

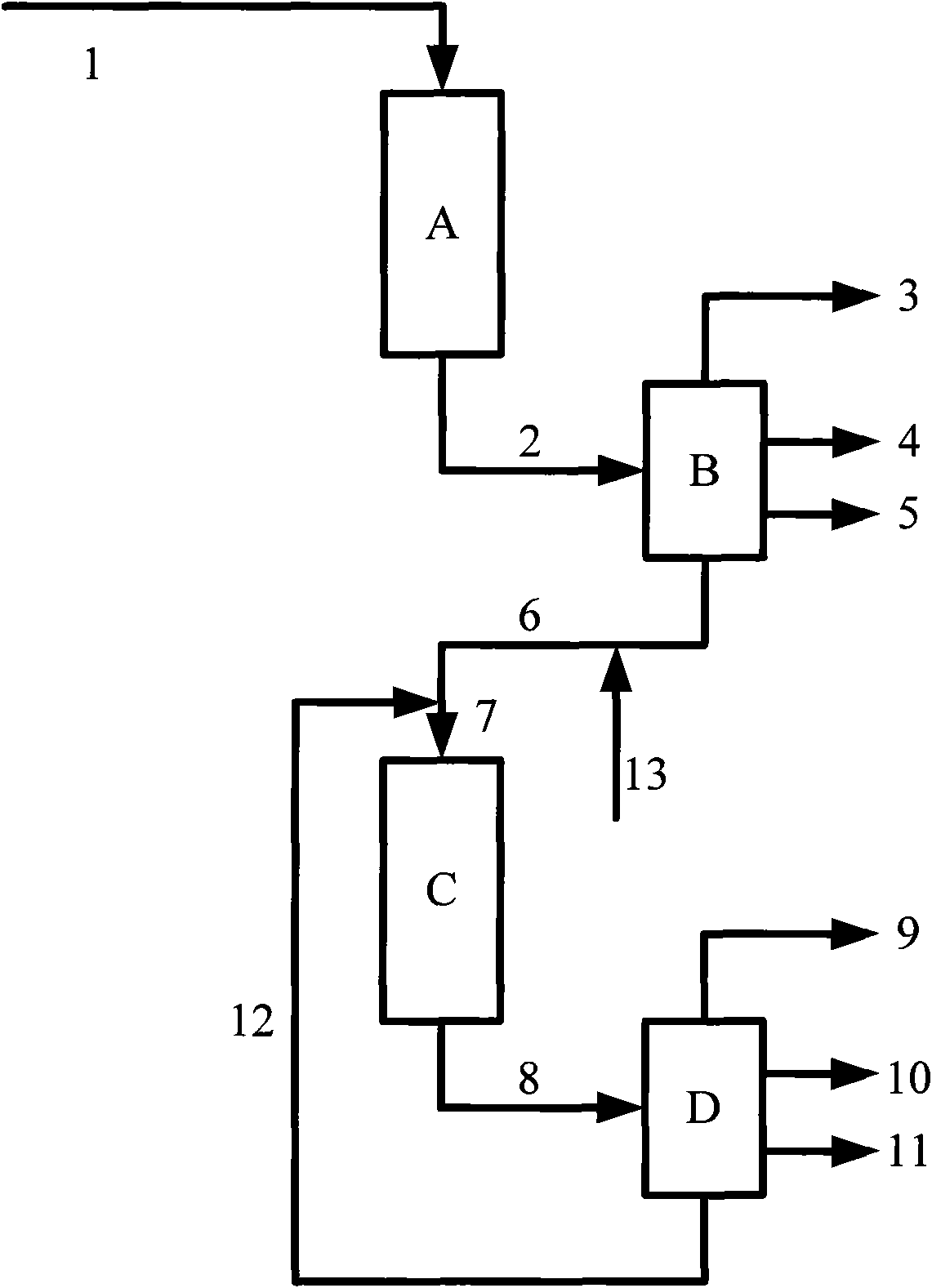

Method used

Image

Examples

Embodiment 1

[0036] Fischer-Tropsch synthetic oil and direct coal liquefied oil are mixed according to the ratio of 30:70 to obtain raw oil A, whose properties are shown in Table 2, and the hydrogenation and upgrading of the mixed oil is carried out according to the aforementioned process flow, and the feed amount of the mixed oil is 123g / h.

[0037] The operating conditions of the hydrofining reaction zone are: temperature 320°C, hydrogen partial pressure 11.0MPa, hydrogen to oil volume ratio 450.

[0038] The operating conditions of the hydroisomerization cracking reaction zone are: temperature 365°C, hydrogen partial pressure 11.0MPa, hydrogen to oil volume ratio 800.

[0039] The temperature range of fractionation tower B cutting distillate oil is: naphtha fraction I is 350°C.

[0040] The temperature range of fractionation tower D cutting distillate oil is: naphtha fraction II is 350°C.

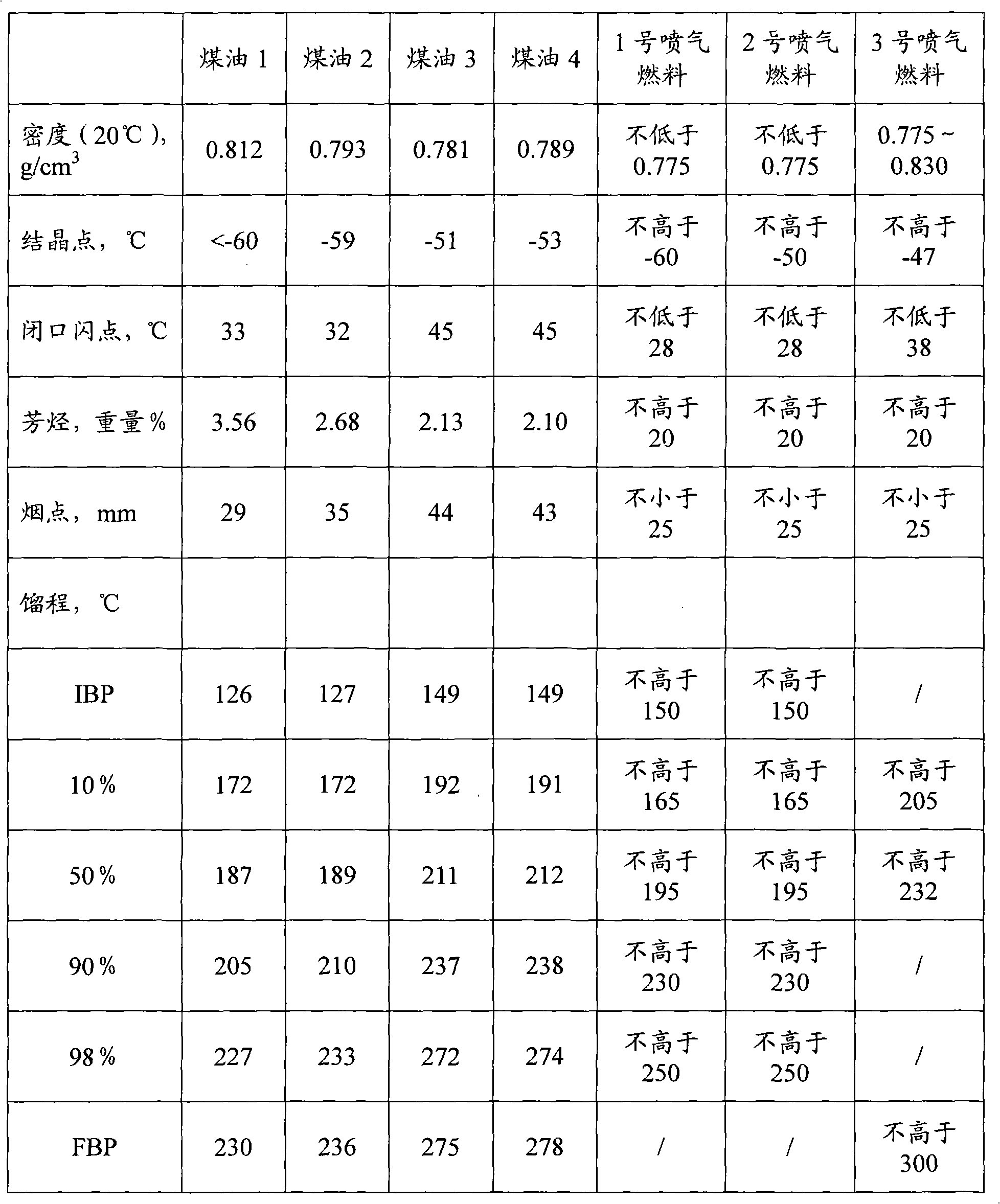

[0041] The properties of kerosene 1 obtained by mixing kerosene fraction I and kerosene fracti...

Embodiment 2

[0043] Fischer-Tropsch synthetic oil and direct coal liquefaction oil were mixed according to the ratio of 50:50 to obtain raw material oil B, whose properties are shown in Table 2. Hydrogenation and upgrading of the mixed oil was carried out according to the aforementioned process flow, and the feed amount of the mixed oil was 138g / h.

[0044] The operating conditions of the hydrofining reaction zone are: temperature 315°C, hydrogen partial pressure 9.5MPa, hydrogen-to-oil volume ratio 400.

[0045] The operating conditions of the hydroisomerization cracking reaction zone are: temperature 365°C, hydrogen partial pressure 9.5MPa, hydrogen to oil volume ratio 800.

[0046] The temperature range of fractionation tower B cutting distillate oil is: naphtha fraction I is 350°C.

[0047] The temperature range of fractionation tower D cutting distillate oil is: naphtha fraction II is 350°C.

[0048] The properties of the kerosene 2 obtained by mixing the kerosene fraction I and th...

Embodiment 3

[0050] Fischer-Tropsch synthetic oil and direct coal liquefaction oil were mixed according to the ratio of 80:20 to obtain raw oil C, whose properties are shown in Table 2, and the hydrogenation and upgrading of the mixed oil was carried out according to the aforementioned process flow, and the feed amount of the mixed oil was 150g / h.

[0051] The operating conditions of the hydrofining reaction zone are: temperature 310°C, hydrogen partial pressure 9.0MPa, hydrogen-to-oil volume ratio 400.

[0052] The operating conditions of the hydroisomerization cracking reaction zone are: temperature 365°C, hydrogen partial pressure 9.0MPa, hydrogen to oil volume ratio 800.

[0053] The temperature range of fractionation tower B cutting distillate oil is: naphtha fraction I is 350°C.

[0054] The temperature range of fractionation tower D cutting distillate oil is: naphtha fraction II is 350°C.

[0055] The properties of the kerosene 3 obtained by mixing the kerosene fraction I and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com