A kind of method for producing jet fuel from straight-run diesel oil

A technology for straight-run diesel and jet fuel, which is applied in the production field of producing high-quality jet fuel, can solve the problems of large circulation volume of kerosene fractions, increased equipment investment, complicated operation, etc., and achieves increased yield, improved selectivity, and reduced secondary The effect of the cleavage reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

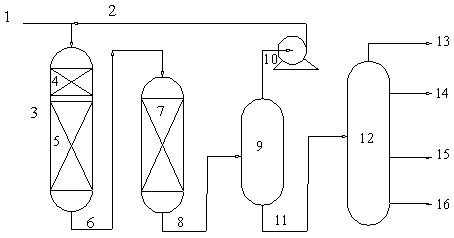

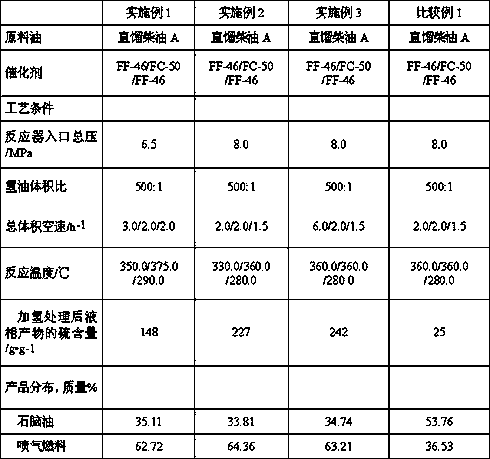

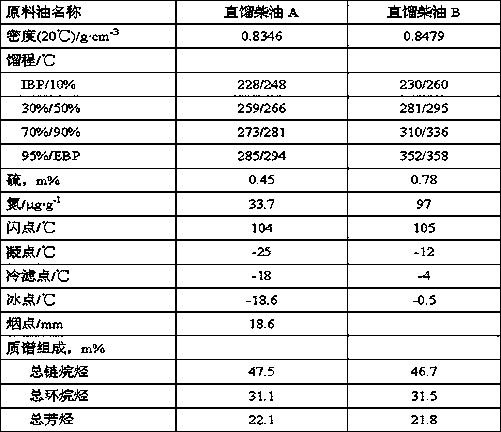

[0032] In this example, two kinds of straight-run diesel oils A and B are used as raw materials, and the catalysts are all commercial catalysts developed by Fushun Petrochemical Research Institute. The hydroprocessing reaction zone and supplementary hydrofining reaction zone are filled with FF-46 hydroprocessing catalyst , The hydrocracking reaction zone is filled with FC-50 catalyst. The specific operation process adopted is shown in the appendix figure 1 . The embodiment adopts the form of two reactors connected in series, and the hydrotreating reaction zone and the hydrocracking reaction zone are in one reactor. The properties of the feedstock oil are shown in Table 1, the basic properties of the catalyst are shown in Table 2, the feedstock oil of Examples 1 to 3 is straight-run diesel oil A, and its process operating conditions and results are shown in Tables 3 to 4; the feedstock oils of Examples 4 to 6 are Straight-run diesel oil B, its process operating conditions and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com