Technology for deodorizing vegetable oil with high content of unsaturated acid

An acid content, unsaturated technology, applied in the field of food oil refining, can solve the problems of high acid value, low smoke point, and unsatisfactory deodorization effect of finished oil, and achieve high comprehensive benefits, reduced deodorization load, and good deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

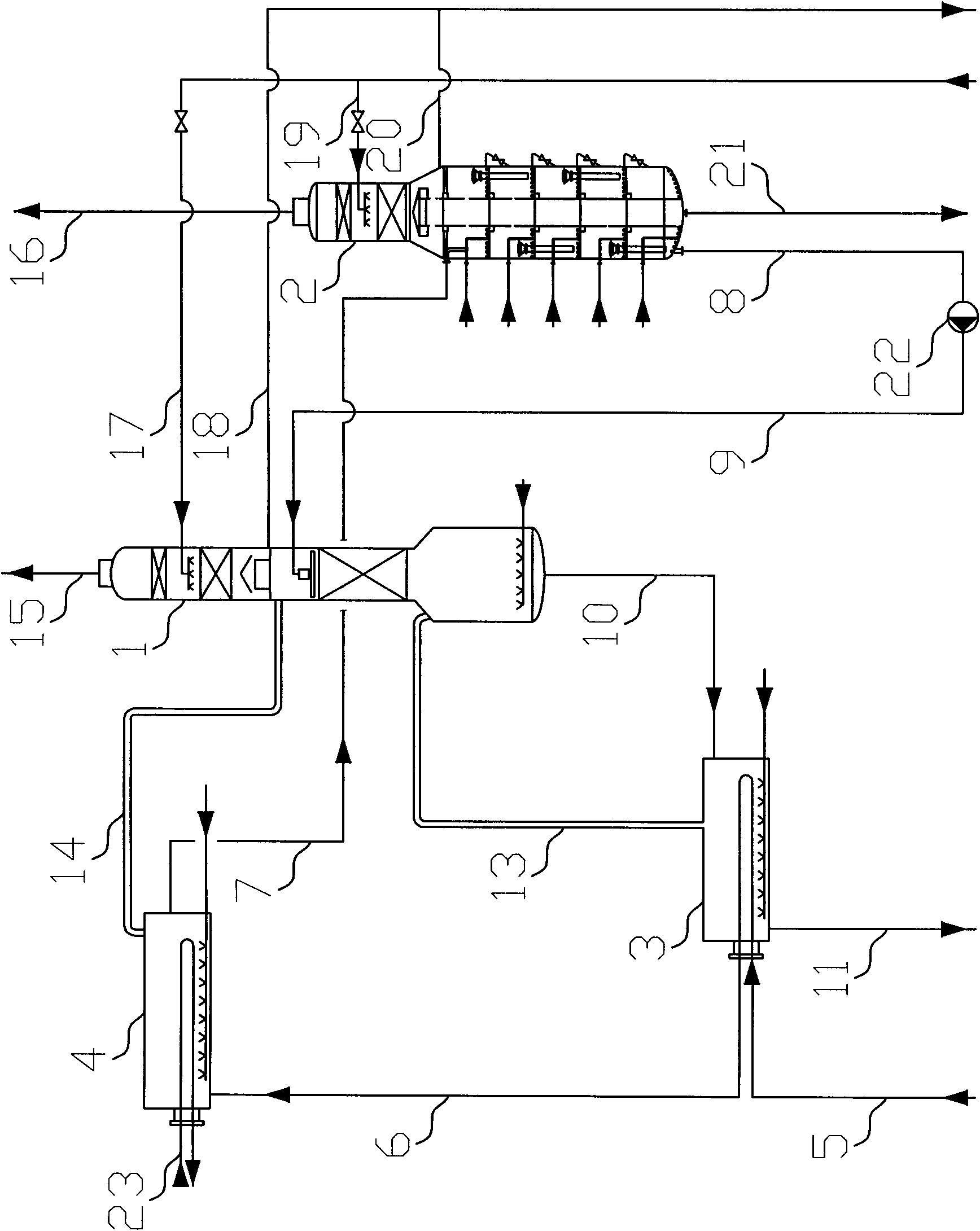

[0011] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as shown in Figure 1, oil before deodorization enters vacuum heat exchanger 3 through oil delivery pipeline 5 among the present invention, and the heat after deodorization that enters vacuum heat exchanger 3 through pipeline 10 transports Oil heat exchange. During heat exchange, the cold oil goes through the tube side before deodorization, and the hot oil goes through the shell side after deodorization. The shell side is composed of multiple flow channels composed of multiple partitions and deflectors, and is equipped with a direct steam stirring device. , to improve heat transfer efficiency. When the cold oil before deodorization is heat-exchanged to 180-190°C, it enters the vacuum heat exchanger 4 connected to high-pressure steam through the oil pipeline 6 to be heated. The 50Bar high-pressure steam used for heating goes through the tube side, and the heated oil before deo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com