Blending of dewaxed biofuels and synthesized paraffinic kerosines with mineral-based kero(JET) distillate cuts to provide on-spec jet fuels

a technology of jet fuel and paraffinic kerosines, which is applied in the direction of biofuels, lubricant compositions, fuels, etc., can solve the problems of decreasing desirable and/or successful approaches, and the difficulty of finding mineral-based additives/blendstocks with the appropriate compositional and physical properties, etc., to improve the other properties of jet-type blends, reduce aromatics, and reduce naphthalenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

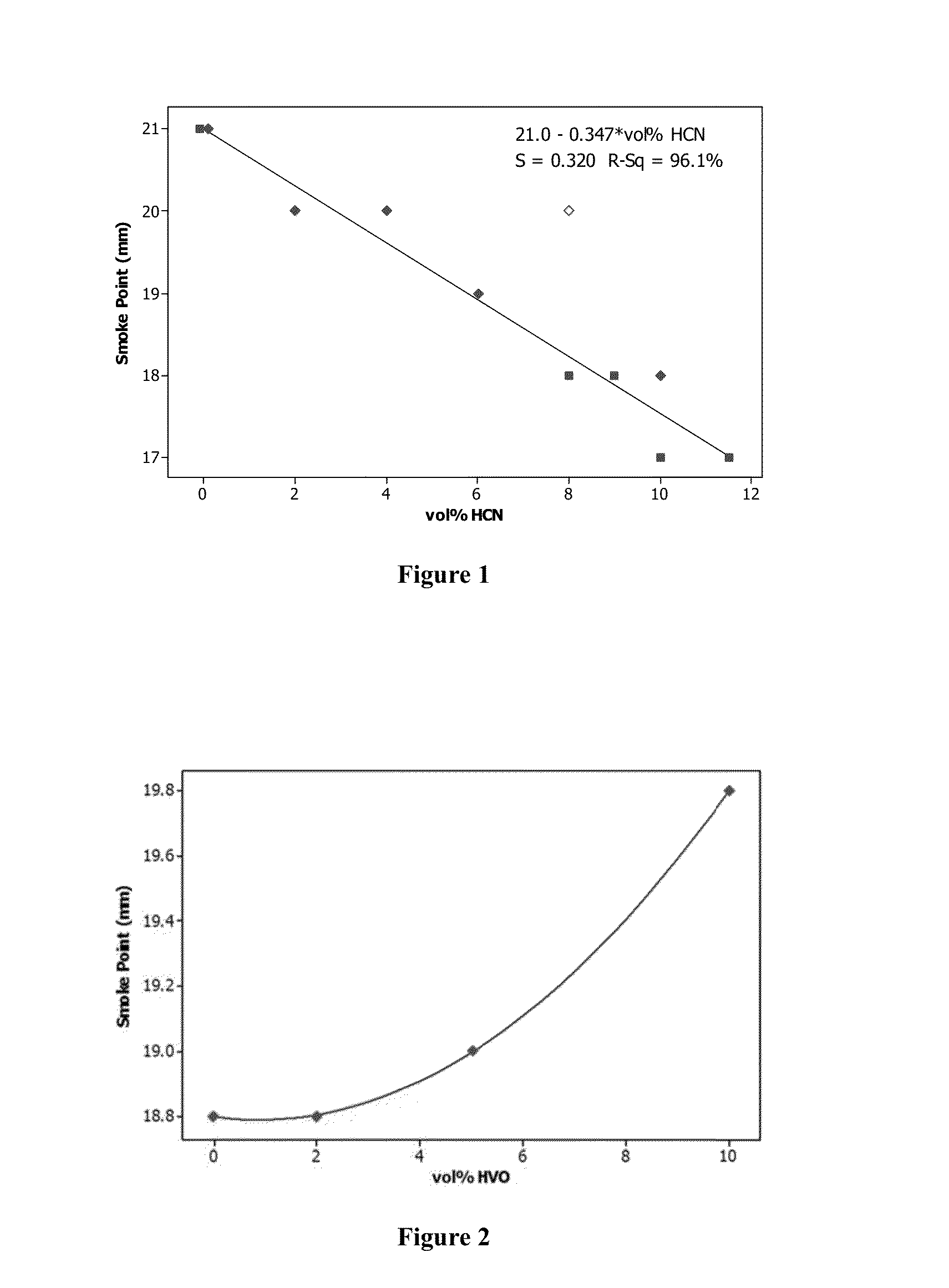

[0063]The cracked blendstock heavy cat naphtha (HCN) was produced during fluid catalytic cracking and had a boiling-point range falling within ˜50° C. to ˜250° C. A combination of plant-scale and lab-scale tests provided data for the relationship between smoke point and vol % HCN in non-cracked jet-boiling-range distillate shown in FIG. 1, which was based on two sets of data (squares and diamonds) with one outlier excluded (unfilled diamond). This relationship indicated that, for every surplus millimeter of smoke point, approximately 3 vol % of HCN can be added to the non-cracked jet-boiling-range distillate.

[0064]Assuming the refinery runs close to the smoke-point specification of 18 mm for its jet-type blends, it can be unable to capture a benefit. A relationship between smoke point and volume percent hydrotreated vegetable oil (HVO), however, was generated for a jet fuel containing ˜8 vol % HCN using the automated smoke-point measurement procedure. This relationship, shown in FIG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| initial boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com