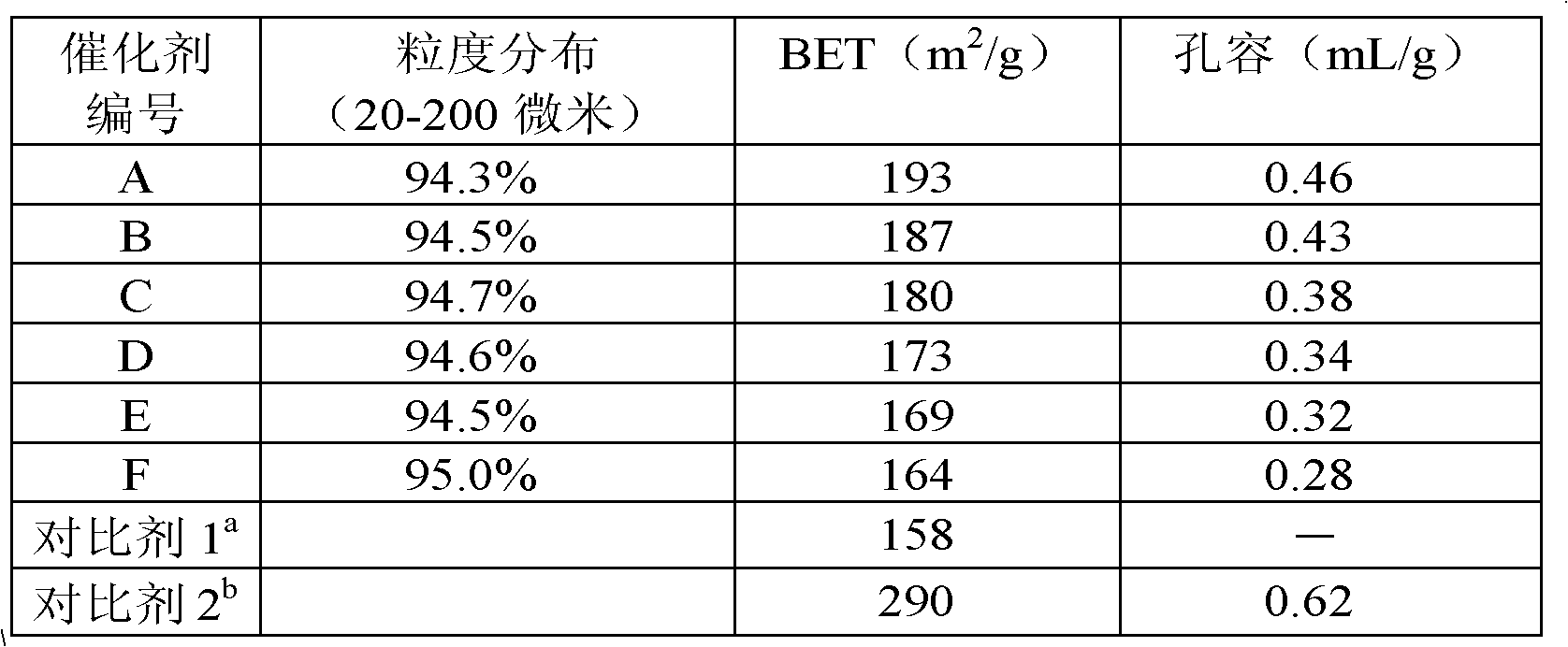

High-abrasion resistance lithium-containing iron series Fischer-Tropsch synthetic catalyst, catalyst bonding agent containing blending silica sol and preparation method and application thereof

A high-wear, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc., can solve problems such as increasing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] In another specific embodiment of the present invention, there is provided a method for preparing a catalyst binder containing lithium and potassium silica sol, comprising: under the condition of 30-90°C, the required composition by catalyst weight ratio It is prepared after mixing lithium hydroxide and / or lithium silicate, potassium hydroxide and / or potassium silicate, and silica sol for 0.3-6 hours.

[0065] In a preferred embodiment, the catalyst binder of the silica sol containing lithium and potassium of the present invention is prepared by the following steps: lithium hydroxide and / or lithium silicate, potassium hydroxide and / or potassium silicate, and silica sol The weight ratio is converted to K, Li and SiO 2 1.5-15:0.1-8:10-60, preferably 1.5-12:0.1-6:10-50, more preferably 2-10:0.1-5:10-40, more preferably 2-10:0.1 -5: 10-30, most preferably 2-8: 0.1-4: 10-25, under the condition of 35-80 ° C, the required lithium hydroxide and / or lithium silicate, hydrogen w...

Embodiment

[0099] Synthesis Example 1

[0100] Step (a): about 76 kilograms of iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), about 0.8 kg copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O) was dissolved in deionized water to make about 2100 liters of solution.

[0101] Step (b): about 43 kilograms of anhydrous sodium carbonate (Na 2 (CO 3 )) was dissolved in deionized water to make about 400 liters of solution. After preheating the mixed solution containing iron and copper metal salts and the sodium carbonate solution to about 50°C respectively, flow the two solutions together into the reactor for co-precipitation within about 40 minutes, and adjust the pH value of the precipitation to about 6 , to carry out precipitation, after the precipitation is completed, let it stand for aging for about 60 minutes, after the aging is completed, filter and wash to obtain a co-precipitation filter cake.

[0102] Step (c): About 11.58 kg of SiO 2 Concentration by weight is that 8% colloidal si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com