Aerated concrete block and production method thereof

A technology of aerated concrete and blocks, which is applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc. It can solve the problems of complex configuration process and high production cost, reduce thermal conductivity, reduce mold consumption, and shorten turnaround cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

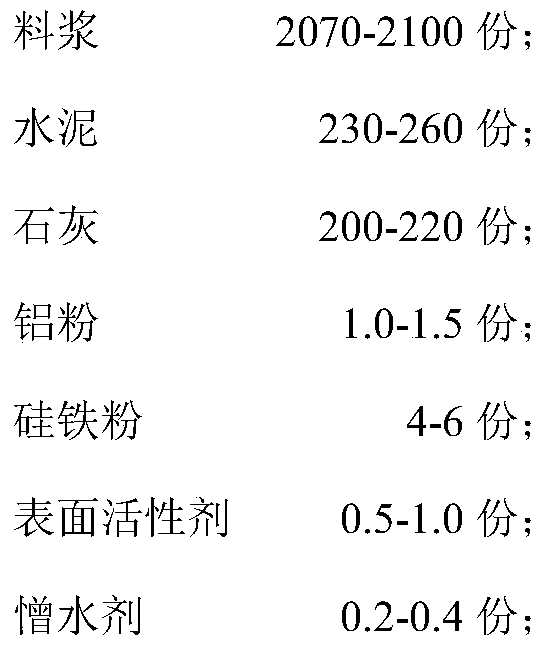

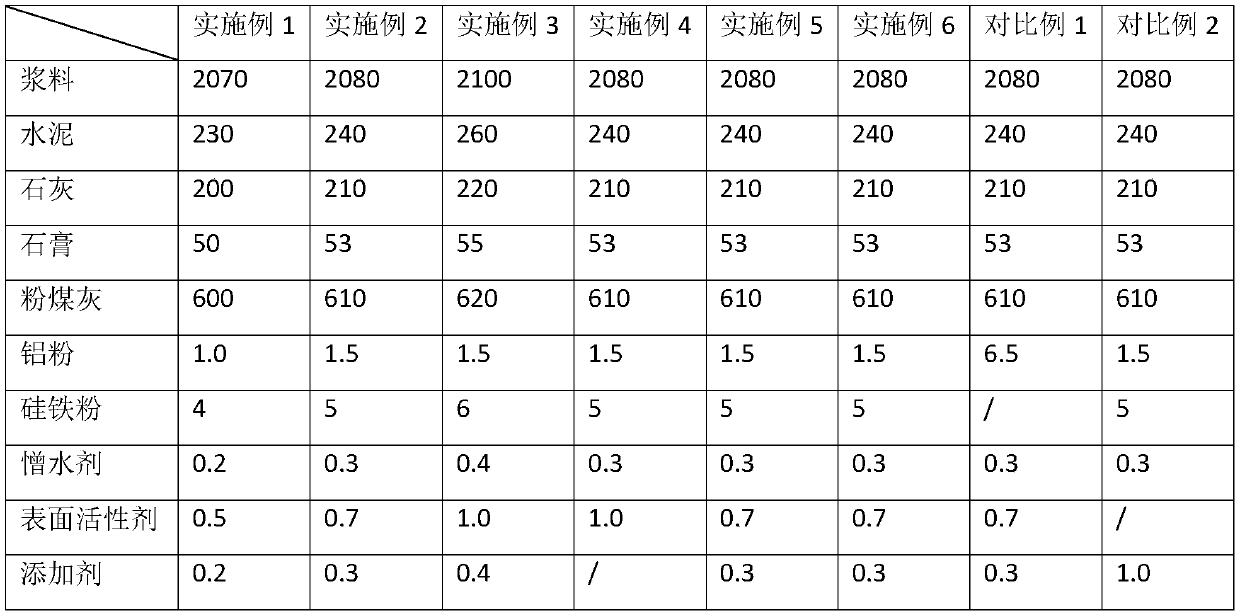

[0042] An air-entrained concrete block, the raw material components are shown in Table 1 in parts by weight.

[0043] The slurry is a mixture of sand and water, the proportion of sand in the slurry is 55%, sodium methyl siliconate is used as a hydrophobic agent, tea saponin is used as a surfactant, and cocamidopropyl betaine is used as an additive. Among them, the calcium oxide content in the lime is greater than 75%.

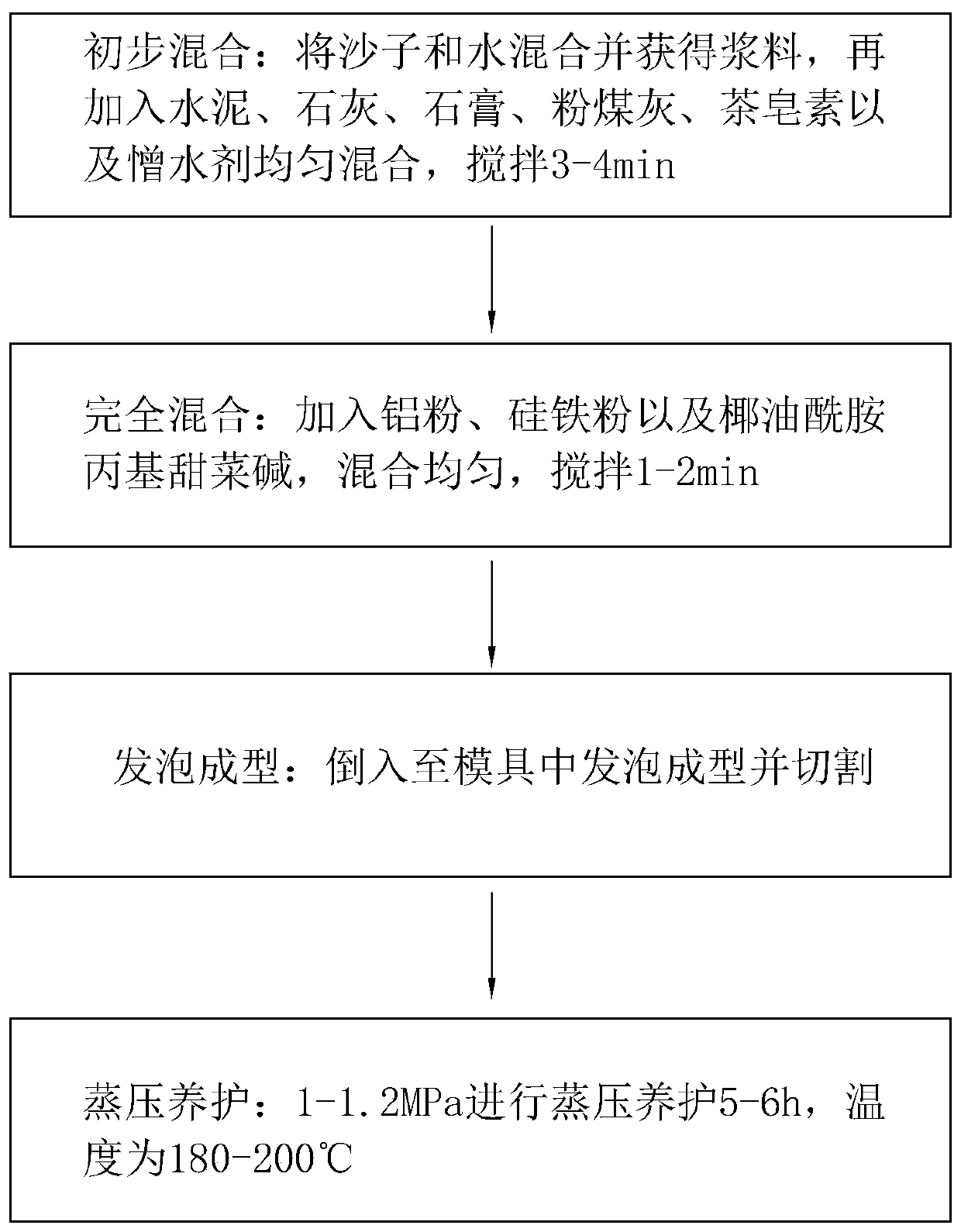

[0044] Such as figure 1 Shown, the preparation method of this air-entrained concrete block comprises the following steps:

[0045] S1, preliminary mixing: mix sand and water to obtain a slurry, then add cement, lime, gypsum, fly ash, tea saponin and water repellent and mix evenly, and stir for 3 minutes;

[0046] S2, complete mixing: add aluminum powder, ferrosilicon powder and additives, mix evenly, and stir for 2 minutes;

[0047] S3, foam molding: pour into the mold for foam molding and cutting;

[0048] S4, autoclaving curing: autoclaving at 1 MPa for 5...

Embodiment 2

[0050] An air-entrained concrete block, the raw material components are shown in Table 1 in parts by weight.

[0051] The slurry is a mixture of sand and water, the proportion of sand in the slurry is 60%, sodium methyl siliconate is used as a hydrophobic agent, tea saponin is used as a surfactant, and cocamidopropyl betaine is used as an additive. Among them, the calcium oxide content in the lime is greater than 75%.

[0052] The preparation method of the air-entrained concrete block comprises the following steps:

[0053] S1, preliminary mixing: mix sand and water to obtain a slurry, then add cement, lime, gypsum, fly ash, tea saponin and water repellent and mix evenly, and stir for 4 minutes;

[0054] S2, complete mixing: add aluminum powder, ferrosilicon powder and additives, mix well, and stir for 1 min;

[0055] S3, foam molding: pour into the mold for foam molding and cutting;

[0056] S4, autoclaved curing: 1.1 MPa autoclaved curing for 6 hours, the temperature is 1...

Embodiment 3

[0058] An air-entrained concrete block, the raw material components are shown in Table 1 in parts by weight.

[0059] The slurry is a mixture of sand and water, the proportion of sand in the slurry is 60%, sodium methyl siliconate is used as a hydrophobic agent, tea saponin is used as a surfactant, and cocamidopropyl betaine is used as an additive. Among them, the calcium oxide content in the lime is greater than 75%.

[0060] The preparation method of the air-entrained concrete block comprises the following steps:

[0061] S1, preliminary mixing: mix sand and water to obtain a slurry, then add cement, lime, gypsum, fly ash, tea saponin and water repellent and mix evenly, and stir for 4 minutes;

[0062] S2, complete mixing: add aluminum powder, ferrosilicon powder and additives, mix well, and stir for 1 min;

[0063] S3, foam molding: pour into the mold for foam molding and cutting;

[0064] S4, autoclaved curing: 1.2MPa autoclaved curing 6h, the temperature is 200 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com