Construction method using modified collapsible loess as roadbed filler

A technology of collapsible loess and roadbed filler, applied in the directions of roads, roads, buildings, etc., to achieve the effect of good elastic-plastic characteristics and large adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

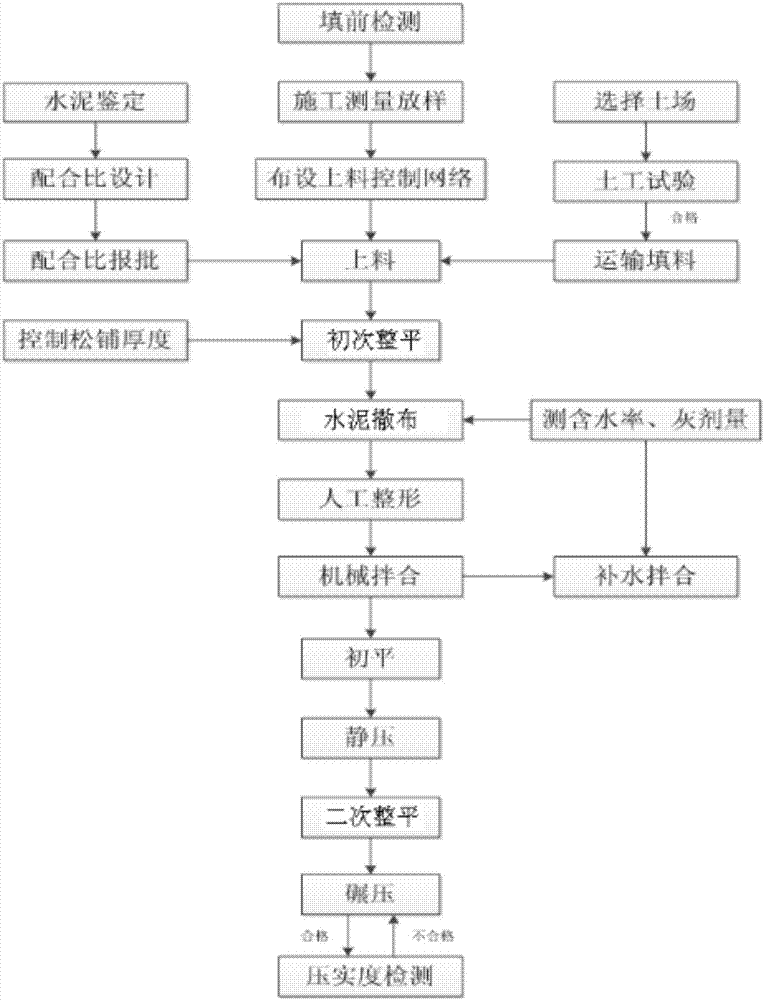

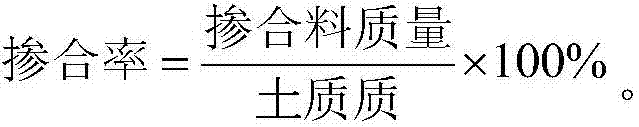

[0059] like figure 1 As shown, the construction method using improved collapsible loess as roadbed filler in this embodiment includes: construction measurement lofting, material loading, primary leveling, cement spreading, mechanical mixing, secondary leveling, rolling, compaction In the test, the filler is loess mixed with cement, and the cement is mixed into the loess by external admixture method, and the amount of admixture is 4%, 5% or 6%. The percentage of soil mass, that is, calculated by mass percentage, see the following formula:

[0060]

[0061] The concrete method of this embodiment:

[0062] Construction measurement and stakeout:

[0063] 1. According to the accuracy required by the design documents and the "Highway Survey Specification", review the original coordinate points, elevation points, encrypted traverse points, and benchmark points according to the construction requirements. Restoring the center line of the route, adding temporary benchmarks, so as ...

Embodiment 2

[0101] This Example In this example, the improved collapsible loess is used as the construction method of the subgrade filler. On the basis of Example 1, the amount of cement is determined through experiments, and the physical properties of the cement-improved loess are tested for liquid-plastic limit, Compaction test, shear strength test, unconfined compressive strength test, CBR test, collapsibility test were done for mechanical properties. Through the analysis of the test data, it is shown that 4%, 5%, 6% cement content is better in improving loess, and it is more economical. The specific test method is as follows:

[0102] 1. The liquid-plastic limit joint tester was used in the test to measure the liquid-plastic limit of cement-improved loess:

[0103] Air-dry the disturbed loess samples in the borrow area, and sieve through a 0.5mm sieve. Take 4 representative soil samples of 200g in each borrow area, and the mixing ratios are 1%, 2%, 3%, and 4% respectively. , 5%, 6%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com