A kind of high-strength crack-resistant foam concrete and its preparation method

A technology of foam concrete and crack resistance, which is applied in the field of foam concrete to achieve the effects of reducing bulk density, broadening application fields, and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

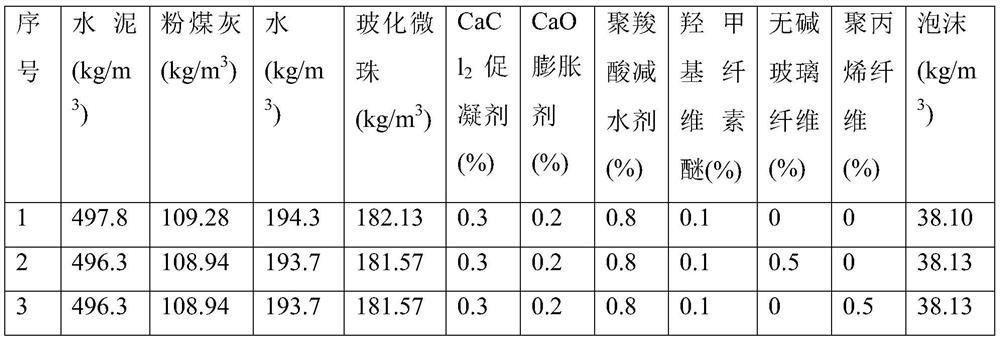

Embodiment 1

[0038] A high-strength crack-resistant foam concrete, according to the target bulk density of 800kg / m 3 The components and their mass percentages are designed as follows: cement 48.19%, fly ash 10.58%, water 18.81%, vitrified microbeads 17.63%, foam 3.67%, expansion agent 0.12%, coagulant 0.18%, water reducing Agent 0.47%, cellulose ether (hydroxymethyl cellulose ether) 0.06%, composite fiber 0.29% (6mm alkali-resistant glass fiber and 12mm polypropylene fiber are mixed in a mass ratio of 1:2); its preparation method Including the following steps:

[0039] 1) Weigh each raw material according to the above ratio; stir the weighed cement, fly ash, vitrified microbeads, expansion agent, coagulant, and cellulose ether evenly, then add water and water reducer and stir evenly, and finally Sprinkle the composite fiber evenly into the mixing pot (first add the shorter glass fiber into the slurry and then add the longer polypropylene fiber and stir evenly), then add the foam produced ...

Embodiment 2

[0043] A high-strength crack-resistant foam concrete, according to the target bulk density of 750kg / m 3 The components and their mass percentages are designed as follows: cement 50.60%, fly ash 10.36%, water 18.29%, vitrified microbeads 15.25%, foam 3.98%, expansion agent 0.18%, coagulant 0.24%, water reducing Agent 0.61%, cellulose ether 0.12%, composite fiber 0.37% (the alkali-resistant glass fiber of 6mm and the polypropylene fiber of 12mm are mixed by the mass ratio of 1:2); Its preparation method comprises the following steps:

[0044] 1) Weigh each raw material according to the above ratio; stir the weighed cement, fly ash, vitrified microbeads, expansion agent, coagulant, and cellulose ether evenly, then add water and water reducer and stir evenly, and finally Sprinkle the composite fiber evenly into the mixing pot (first add the short alkali-resistant glass fiber into the slurry and then add the longer polypropylene fiber and stir evenly), then add the foam produced by...

Embodiment 3

[0048] A high-strength crack-resistant foam concrete, according to the target bulk density of 850kg / m 3 The components and their mass percentages are designed as follows: cement 45.07%, fly ash 11.28%, water 19.72%, vitrified microbeads 19.71%, foam 3.42%, expansion agent 0.06%, coagulant 0.11%, water reducing 0.34% of cellulose ether, 0.06% of cellulose ether (hydroxymethyl cellulose), 0.23% of composite fiber (6mm alkali-resistant glass fiber and 12mm polypropylene fiber are mixed in a mass ratio of 1:2); its preparation method includes Follow the steps below:

[0049] 1) Weigh each raw material according to the above ratio; stir the weighed cement, fly ash, vitrified microbeads, expansion agent, coagulant, and cellulose ether evenly, then add water and water reducer and stir evenly, and finally Sprinkle the composite fiber evenly into the mixing pot (first add the short alkali-resistant glass fiber into the slurry and then add the longer polypropylene fiber and stir evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com