Preparation method of biomass-based nano-silica aerogel

A nano-silica, silicon dioxide technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., to achieve the effect of strong practicability, high thermal performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

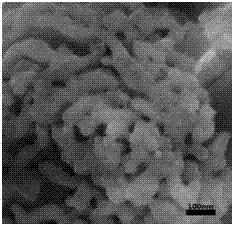

Image

Examples

preparation example Construction

[0014] A preparation method of biomass-based nano-silica airgel, the method comprising the steps of:

[0015] (1) Put the straw into a pulverizer and process it into pieces, then completely soak it in dilute hydrochloric acid and heat it at 60-70°C for 1-2 hours, then wash it with water until neutral, and then dry it in an oven at 105°C until it is absolutely dry;

[0016] (2) Put the dry straw fragments in step (1) into the muffle furnace and calcinate at 570-770°C for 100-300 minutes in the air atmosphere, take out after calcining and quickly cool to obtain silica;

[0017] (3) Mill the silicon dioxide obtained in step (2) by a high-speed vibrating ball mill for 10 to 60 minutes, and then use an ultrasonic disperser to ultrasonically treat it at a power of 200w for 1 to 4 hours to obtain nanometer silicon dioxide;

[0018] (4) adding the nano silicon dioxide obtained in the step (3) to the NaOH solution, heating and reacting the above solution for 2 to 3 hours in a boiling s...

Embodiment 1

[0029] (1) Put 100g of rice straw into a straw grinder to grind, and screen out rice straw fragments that can pass through a 40-mesh sieve but cannot pass through a 60-mesh sieve;

[0030] (2) Take 40g of the screened rice straw fragments and put them into a 500mL beaker, soak them completely in dilute hydrochloric acid with a mass fraction of 6%, and heat them in a 60°C water bath for 1.5 hours. After heating and cooling to room temperature, wash with circulating water vacuum pump and distilled water until neutral;

[0031] (3) After the rice straw scraps are completely filtered and dried, they are put into an oven at 105°C and dried to absolute dryness. Then weigh 30g of dry rice straw and place it in a pre-fired crucible and place it on an electric furnace for carbonization, then move the crucible into a muffle furnace and calcinate at a high temperature of 570°C for 240min. Take out the crucible and let it cool down naturally in the air for 10 minutes, then move it into a...

Embodiment 2

[0039] (1) Put 200g of wheat straw into a straw grinder to crush, and screen out rice straw fragments that can pass through a 40-mesh sieve but cannot pass through a 60-mesh sieve;

[0040] (2) Take 50g of the screened wheat straw scraps and put them into a 500mL beaker with a mass fraction of 6% dilute hydrochloric acid to completely soak them, place them in a 70°C water bath and heat for 1 hour. After heating and cooling to room temperature, wash with circulating water vacuum pump and distilled water until neutral;

[0041] (3) After the wheat straw scraps are completely filtered out of water, they are dried in an oven at 105°C until they are absolutely dry. Then weigh 40g of dry wheat straw scraps and place them in a pre-fired crucible and put them on an electric furnace for carbonization, then move the crucible into a muffle furnace and calcinate at a high temperature of 770°C for 300min. Take out the crucible and let it cool down naturally in the air for 10 minutes, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com