Exterior wall environmental-friendly thermal insulation material

A thermal insulation material and environmental protection technology, applied in the field of building materials, can solve problems such as low structural strength, and achieve the effects of reducing penetration pores, improving structural stability, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

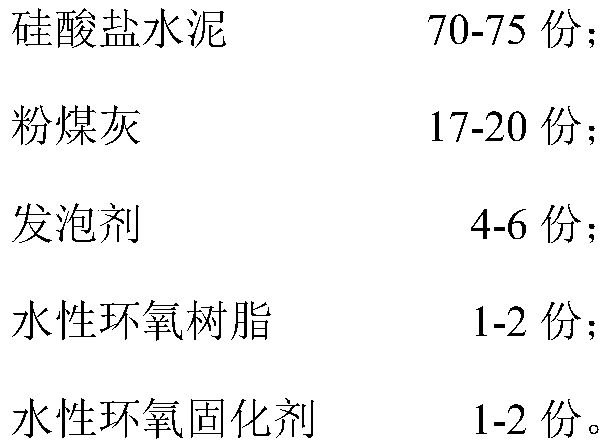

[0035] An environmentally-friendly thermal insulation material for exterior walls, calculated in parts by weight, with raw material components as shown in Table 1.

[0036] Among them, the foaming agent is a protein foaming agent (refer to "Fine Chemicals" Volume 28, Issue 1, January 2011 "Preparation and Performance of Rapeseed Meal Protein Concrete Foaming Agent" homemade).

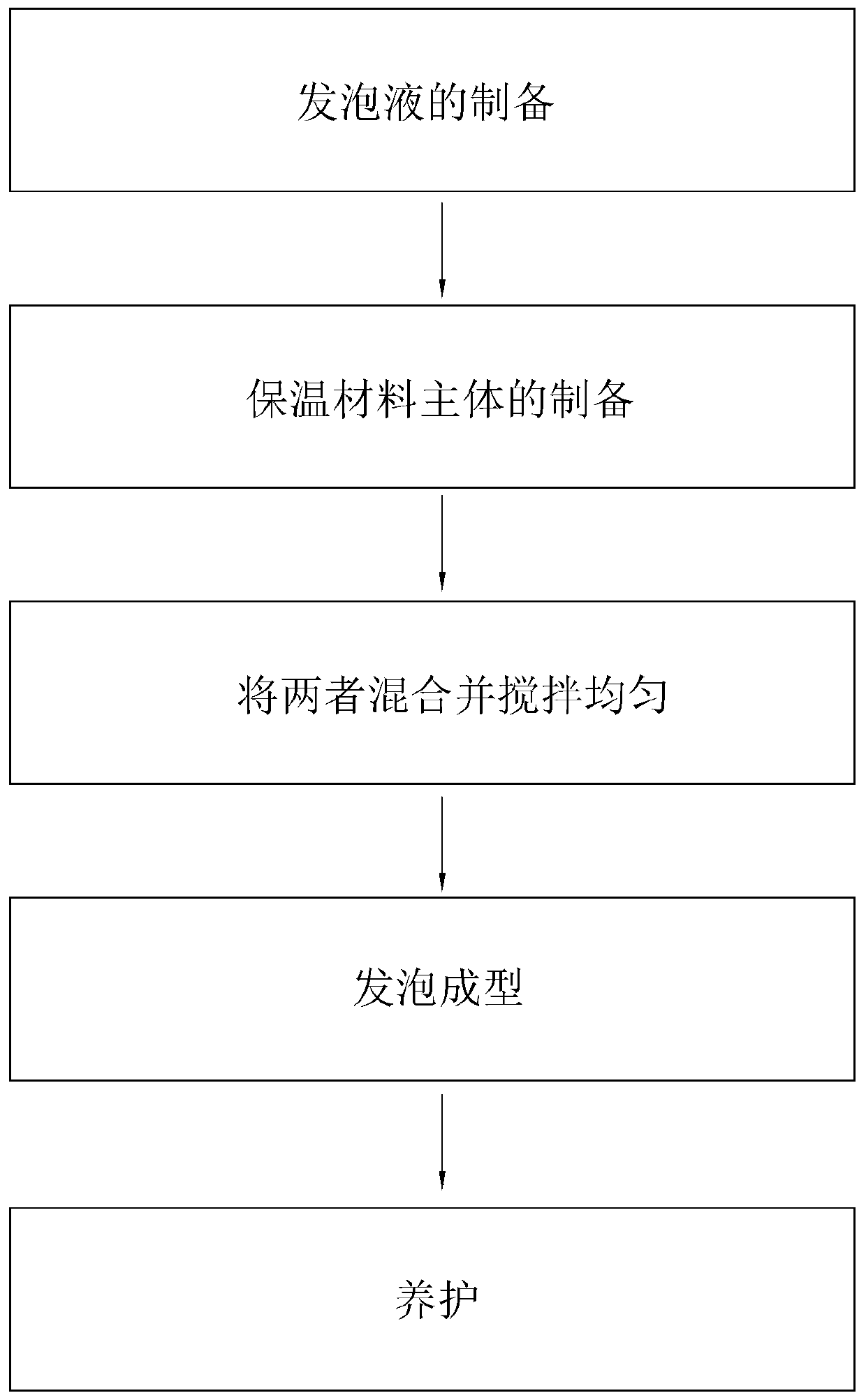

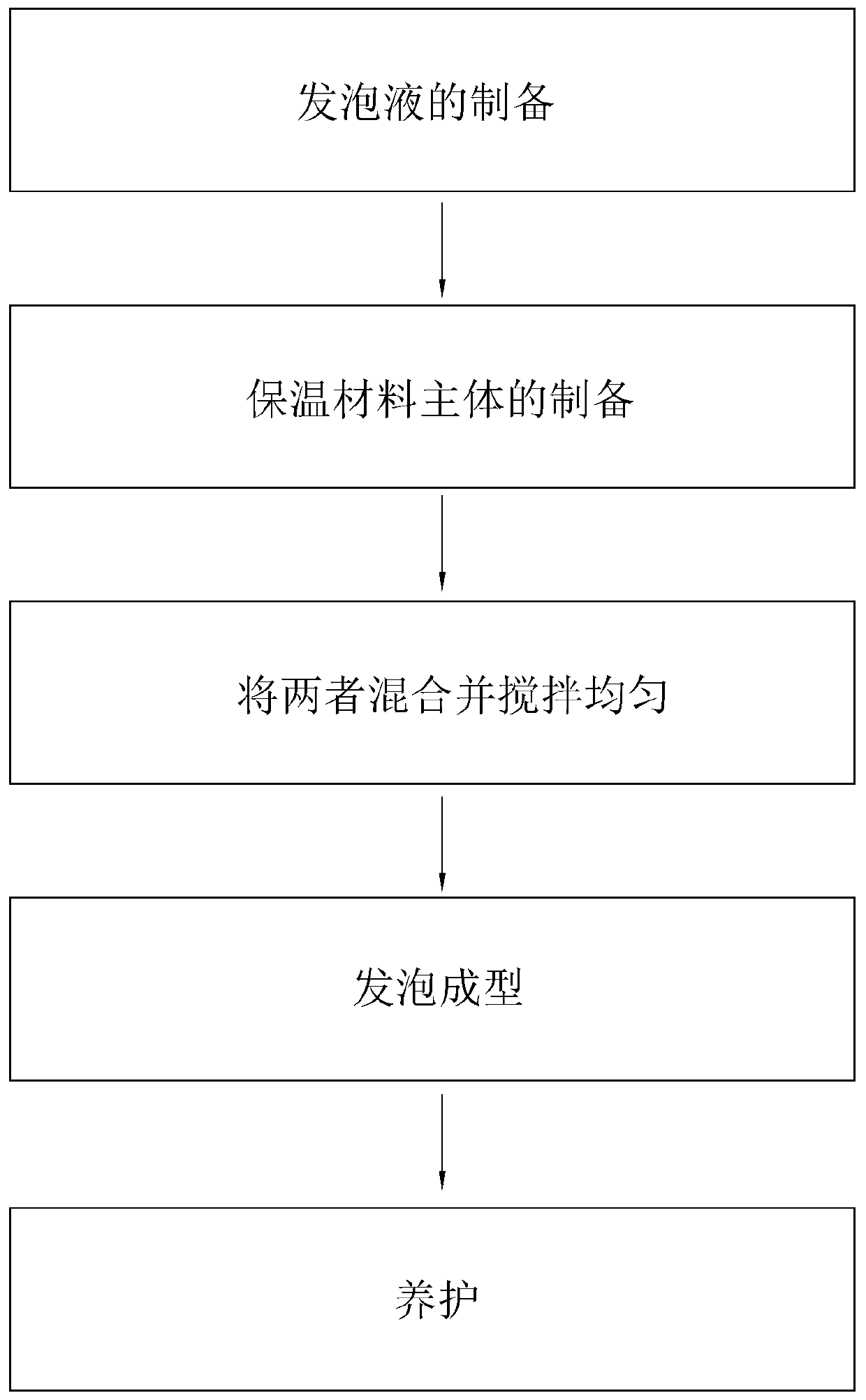

[0037] The preparation method of the external wall environmentally friendly thermal insulation material includes the following steps:

[0038] Step 1. Preparation of foaming liquid: mix protein foaming agent, tea saponin and sucrose, and stir evenly;

[0039] Step 2. Preparation of the main body of the thermal insulation material: Mix Portland cement, fly ash, glass fiber (length 6-8mm) and grapefruit peel fiber (4-6mm) uniformly and fully, add appropriate amount of water and stir to obtain cement slurry , While stirring, add the mixture of water-based epoxy resin (Dow Chemical DER916), water-based epoxy curing...

Embodiment 2

[0043] The difference from Example 1 is that the raw material components are as shown in Table 1 in parts by weight.

Embodiment 3

[0045] The difference from Example 1 is that the raw material components are as shown in Table 1 in parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com