Preparation method of Ti-matrix insoluble anode

A soluble anode and titanium-based technology, which is applied in the fields of electrode material preparation, comprehensive utilization of waste lead storage batteries, and material preparation, can solve the problems of lack of anode materials and the failure of industrialization in the organic electrochemical synthesis process, so as to optimize the preparation process and improve Electrochemical performance and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

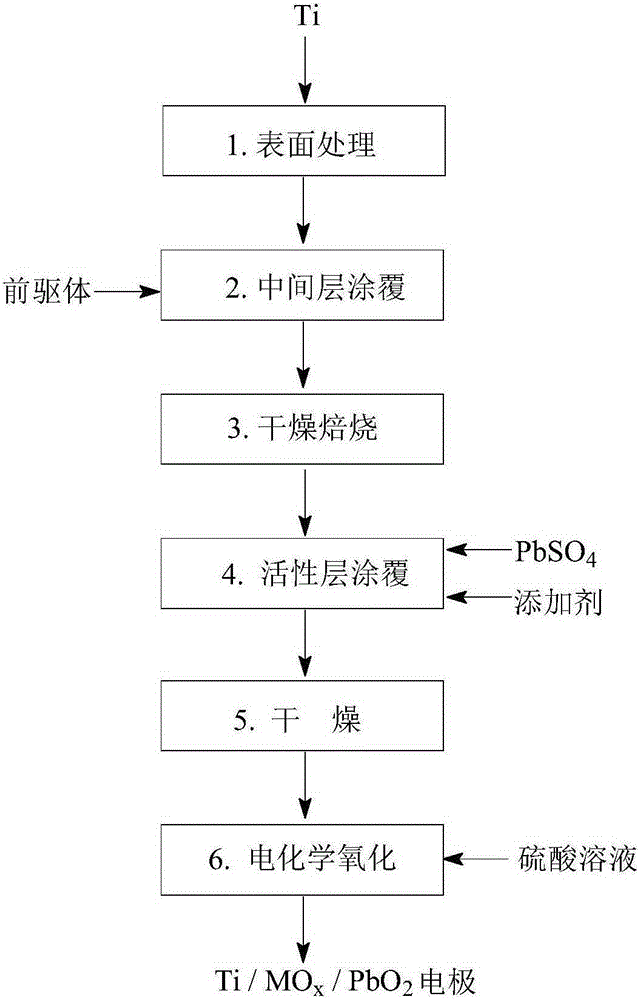

[0041] A method for preparing a titanium-based insoluble anode, in particular, a method that uses metal titanium as the electrode matrix, uses lead paste of waste lead storage batteries as raw material, and uses NH 3 .H 2 O-(NH 4 ) SO 4 Leach PbSO 4 , PbSO obtained through separation and purification 4 As the raw material, the thermal decomposition of the polymeric precursor-electrochemical oxidation of lead sulfate coupling technology, PbSO 4 PbO was prepared by anodic oxidation 2 , to get PbO 2 Directly used as an electrocatalytic electrode material to obtain a titanium-based insoluble anode, the process is as follows figure 1 ,Specific steps are as follows:

[0042] (1) Surface treatment: mechanically grind the plate-shaped titanium metal substrate, degrease the surface in an aqueous hydroxide solution, etch in an oxalic acid solution, and wash with water to obtain a surface-treated titanium substrate, and the substrate material enters the next step;

[0043] (2) In...

Embodiment 2

[0049] A kind of preparation method of titanium-based insoluble anode, with PbSO 4 As the raw material, the thermal decomposition of the polymeric precursor-electrochemical oxidation of lead sulfate coupling technology, PbSO 4 PbO was prepared by anodic oxidation 2 , to get PbO 2 Directly used as an electrocatalytic electrode material to obtain a titanium-based insoluble anode, the steps are as follows:

[0050] (1) Surface treatment: mechanically grind the netted metal titanium substrate, degrease the surface in an aqueous solution of hydroxide and carbonate, etch in an oxalic acid solution, and wash with water to obtain a surface-treated titanium substrate. The base material enters the next step;

[0051] (2) Intermediate layer coating: the metal titanium substrate obtained in the previous step is used as the electrode substrate, and the precursor is made of SnCl 4 , SbCl 3 , PbCl 2 , citric acid and ethylene glycol, the molar ratio of citric acid to ethylene glycol is...

Embodiment 3

[0057] A kind of preparation method of titanium-based insoluble anode, with PbSO 4 As the raw material, the thermal decomposition of the polymeric precursor-electrochemical oxidation of lead sulfate coupling technology, PbSO 4 PbO was prepared by anodic oxidation 2 , to get PbO 2 Directly used as an electrocatalytic electrode material to obtain a titanium-based insoluble anode, characterized in that the method steps are as follows:

[0058] (1) Surface treatment: grinding the rod-shaped metal titanium substrate, degreasing the surface in an aqueous solution of hydroxide, carbonate and bicarbonate, etching in an oxalic acid solution, and washing with water to obtain a surface-treated titanium substrate, The matrix material enters the next step;

[0059] (2) Intermediate layer coating: the metal titanium substrate obtained in the previous step is used as the electrode substrate, and the precursor is made of SnCl 4 , SbCl 3 、LaCl 3 , citric acid and ethylene glycol, the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com