Method for preparing porous insulation material by microwave heating alkali metal silicate

An alkali metal silicate, thermal insulation material technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of large toxic waste gas emission, low energy utilization rate, complex process production, etc., and achieve uniform pore distribution. , The price of raw materials is cheap, and the process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

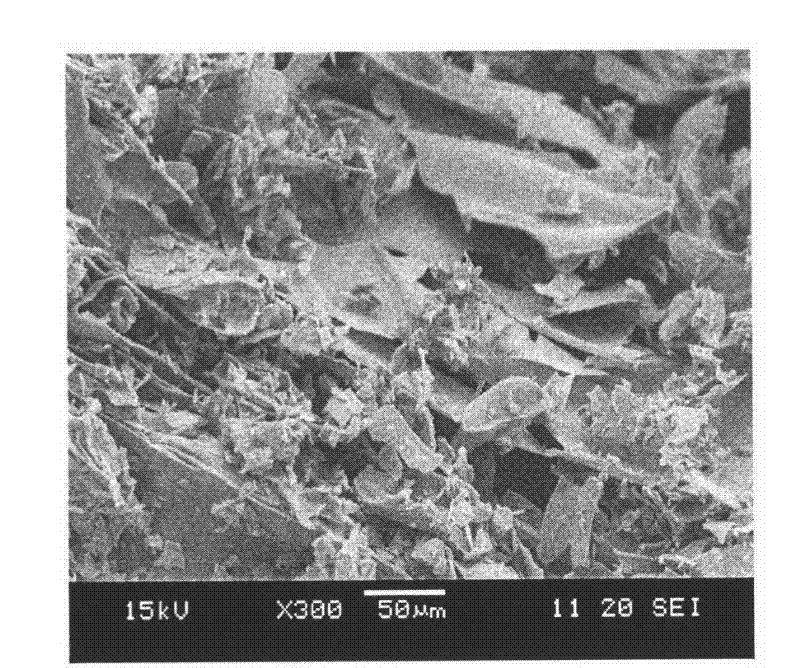

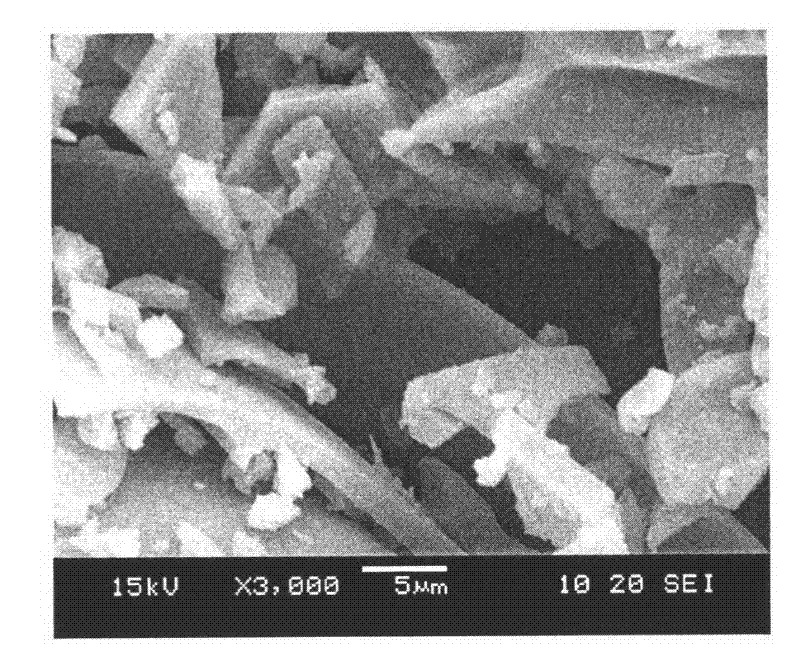

Image

Examples

Embodiment 1

[0032] (1) Preparation of raw materials: with the modulus as n=2.2, Na 2 O mass fraction 10.85%, SiO 2 100ml of water glass with a mass fraction of 24.15% is a raw material;

[0033] (2) Forming: directly add the above raw materials into the cylindrical ceramic mould;

[0034] (3) Heating method: use a frequency of 2450MHz, a power of 800W, and heat for 12 minutes;

[0035] (4) Demoulding step: take out the ceramic mold and demould.

[0036] The sample density is ρ=45kg / m 3 , the thermal conductivity is 0.041W / m·K, the compressive strength is 0.38MPa, and it has good heat insulation performance.

Embodiment 2

[0038] (1) Preparation of raw materials:

[0039] ——with modulus n=3.2, Na 2 O mass fraction 9.3%, SiO 2 The water glass 100ml of mass fraction 20.8% is raw material,

[0040] ——Take 2 g of aluminum silicate fiber (2-5 mm in length) sheared by a machine, add water glass and stir rapidly;

[0041] (2) molding: the raw material of step (1) is directly added in the cylindrical ceramic mould;

[0042] (3) Heating method: microwave heating with a frequency of 2450MHz and a power of 680W for 10 minutes;

[0043] (4) Demoulding step: take out the ceramic mold and perform demoulding.

[0044] The sample density is ρ=80kg / m 3, when the temperature is 200°C, the thermal conductivity λ=0.045W / m·K, has good heat insulation performance; the compressive strength reaches 0.72MPa; after sintering at 400°C, the linear shrinkage rate is 1.85×10 -6 m / °C.

Embodiment 3

[0046] (1) Preparation of raw materials:

[0047] Take 20g of anhydrous sodium metasilicate, add 50ml of water glass (the modulus is n=3.2, the mass percentage of alkali metal silicate is 30%), 0.38g of opacifying agent carbon powder, and stir evenly.

[0048] (2) molding: the raw material of step (1) is directly added in the cylindrical ceramic mould;

[0049] (3) Heating method: Put it in a microwave oven with a frequency of 2450 MHz and a power of 800W, and heat for 7 minutes;

[0050] (4) Demoulding step: take out the ceramic mold and perform demoulding.

[0051] The sample is gray-black, with a density of ρ=67.9kg / m 3 , Thermal conductivity λ=0.055W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com