Preparation method for controllable growth of heterogeneous seed meso-porous monocrystalline rutile titanium dioxide

A technology of rutile titanium dioxide and silicon dioxide balls, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of ineffective separation of photogenerated carriers and poor contact quality of co-catalyst interface, etc. Achieve uniform shape and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

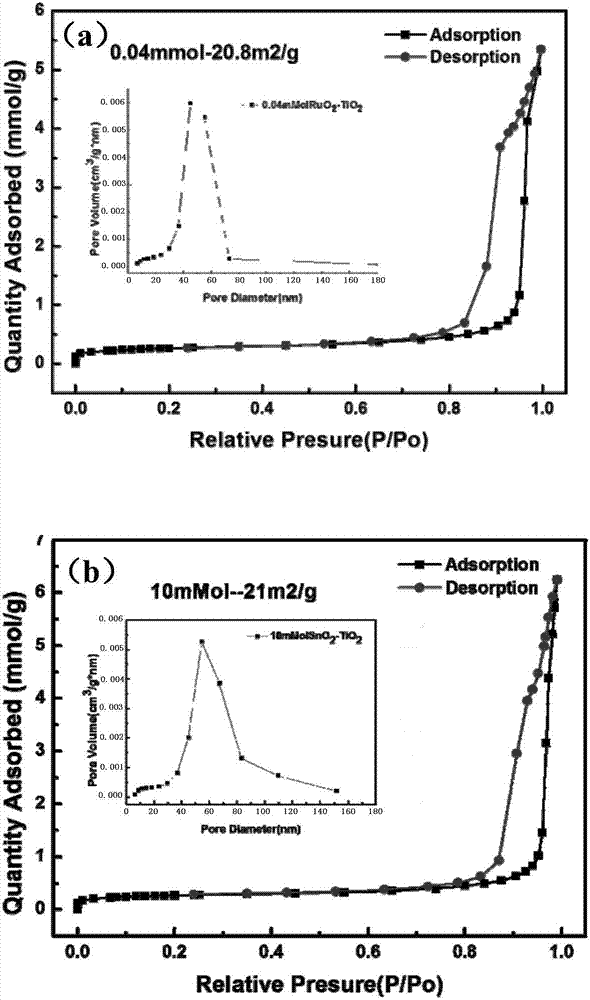

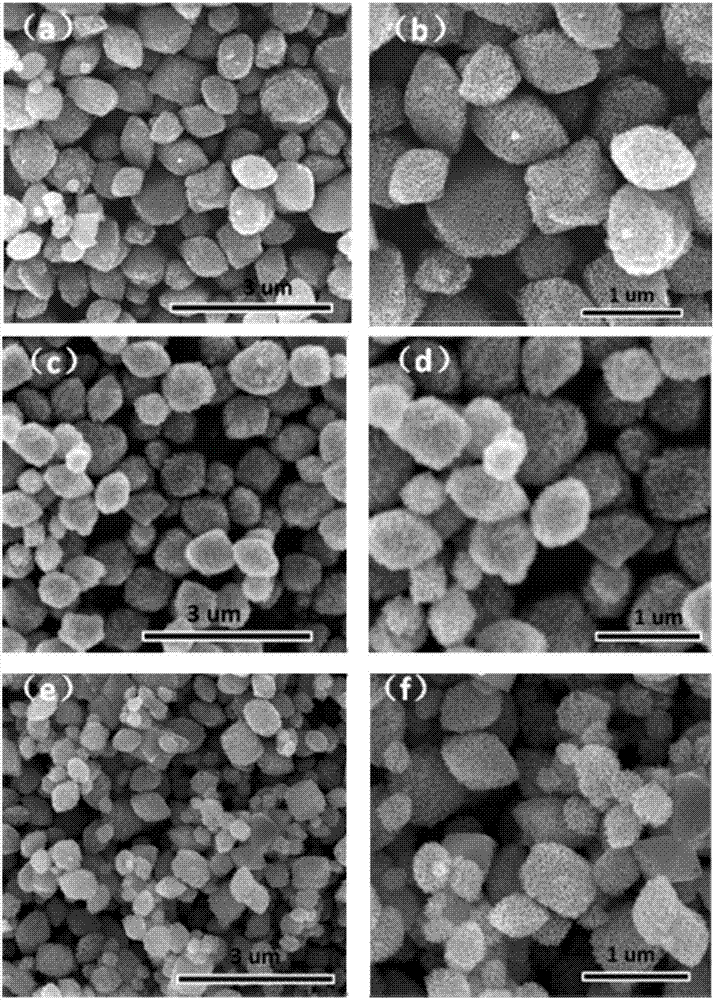

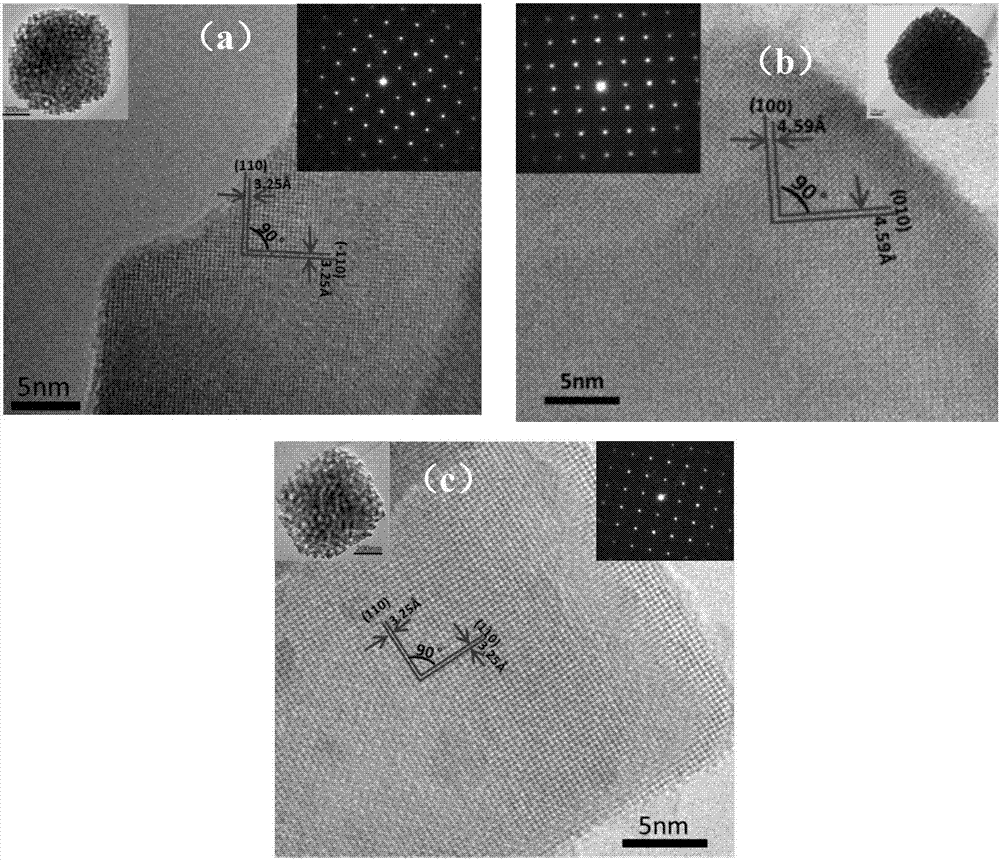

[0038] In this example, RuO 2 Preparation of mesoporous single-crystal rutile TiO as heterogeneous seeds 2 For example:

[0039] Seed template preparation process: take 3g close-packed SiO 2 Put the ball template into 50mL RuCl with a molar concentration of 0.04mM 3 In the aqueous solution, the water bath is at 70°C for 1h, then the silica ball seed template is taken out, rinsed with a large amount of deionized water, and dried in a heating mantle at 80°C; after that, it is placed in a muffle furnace at 500°C for 30min to obtain heterogeneous seeds. Silica ball seed template.

[0040] Prepare TiCl 4 Precursor: 1.64 mL of TiCl 4 Slowly drop into 292mL of concentrated hydrochloric acid with a concentration of 37wt% (ice-water bath), then add deionized water to 1L, and mix well.

[0041] Preparation of mesoporous samples: Take 40 mL of the above precursor solution, put it into a polytetrafluoroethylene liner, add 80 mg of NaF as a shape control agent, add 500 mg of silica b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com