High-sensitivity pressure sensor based on graphene with pointed cone structure and manufacturing method thereof

A pressure sensor and high-sensitivity technology, which is applied in the field of high-sensitivity pressure sensors and its preparation, can solve the problems of inconvenient integration of pressure sensors, and achieve the effects of simple method, strong controllability and uniform distribution density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

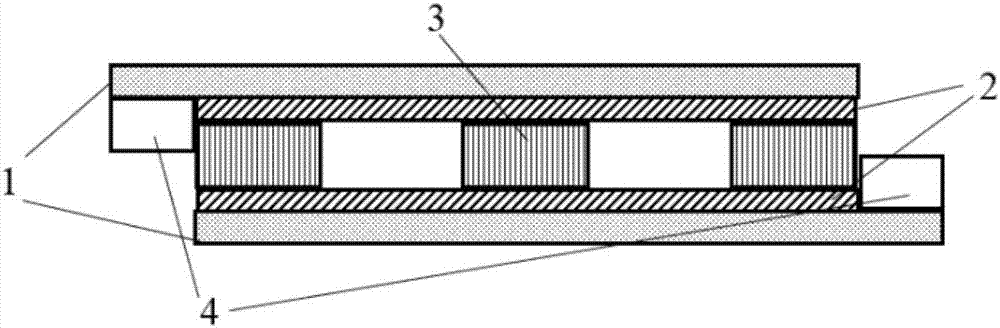

[0040] A preparation method based on a high-sensitivity pressure sensor with pointed cone structure graphene, comprising the following steps:

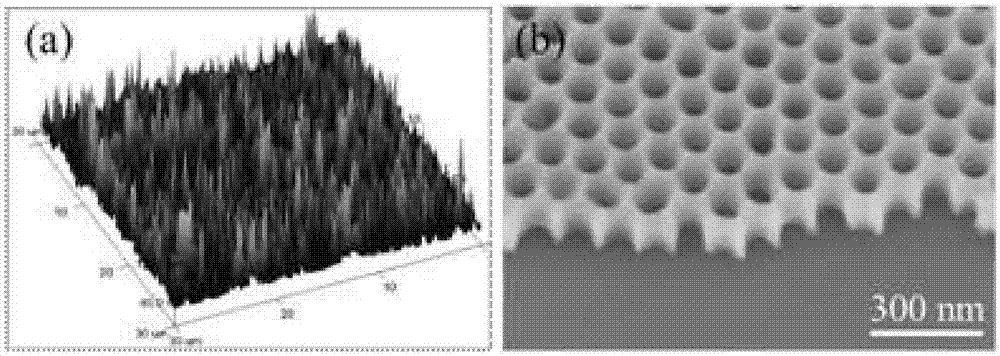

[0041] 1) Transfer two pieces of graphene with a pointed cone structure with a height of about 80 nm on the surface to a flexible PDMS substrate, and then plate a silver electrode with a diameter of 60 μm on one end of the graphene with silver glue.

[0042]2) the AAO with 200nm thickness and 80nm pore size with PMMA support layer is closely attached on the graphene with pointed cone structure on one of the obtained PDMS substrates, then soaked in pure acetone solution for 15min to remove PMMA layer, and obtained graphene and AAO with pointed cone-like structures on PDMS substrates.

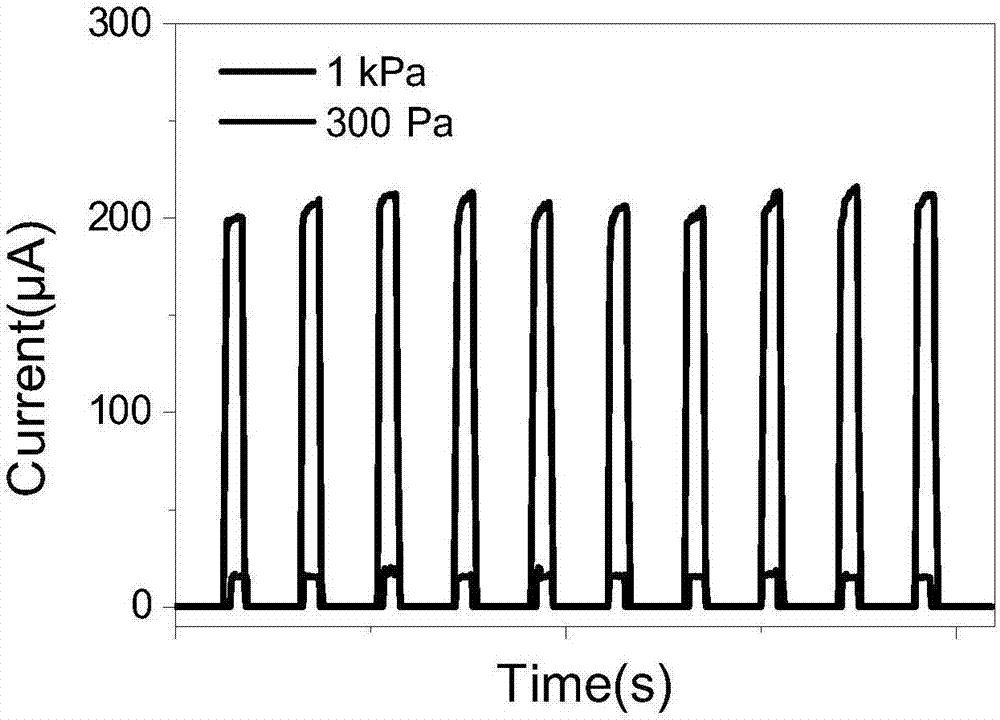

[0043] 3) Another piece of graphene with a pointed cone structure on the PDMS substrate is placed face-to-face on the AAO to obtain a high-sensitivity pressure sensor, which has different current responses under different pressure conditions.

[0044] f...

Embodiment 2

[0047] A preparation method based on a high-sensitivity pressure sensor with pointed cone structure graphene, comprising the following steps:

[0048] 1) Transfer two pieces of graphene with a pointed cone structure with a height of about 80 nm on the surface to a flexible PDMS substrate, and then plate a silver electrode with a diameter of 60 μm on one end of the graphene with silver glue.

[0049] 2) AAO with 250nm thickness and 85nm pore size with PMMA support layer is closely attached on the graphene with pointed cone structure on one of the PDMS substrates obtained, then soaked in pure acetone solution for 15min to remove PMMA layer, and obtained graphene and AAO with pointed cone-like structures on PDMS substrates.

[0050] 3) Another piece of graphene with a pointed cone structure on the PDMS substrate is placed face-to-face on the AAO to obtain a high-sensitivity pressure sensor, which has different current responses under different pressure conditions.

[0051] Fig...

Embodiment 3

[0054] A preparation method based on a high-sensitivity pressure sensor with pointed cone structure graphene, comprising the following steps:

[0055] 1) Transfer two pieces of graphene with a pointed cone structure with a height of about 80 nm on the surface to a flexible PDMS substrate, and then plate a silver electrode with a diameter of 60 μm on one end of the graphene with silver glue.

[0056] 2) AAO with 300nm thickness and 85nm aperture with PMMA support layer is closely attached on the graphene with pointed cone structure on one of the PDMS substrates obtained, then soaked in pure acetone solution for 15min to remove PMMA layer, and obtained graphene and AAO with pointed cone-like structures on PDMS substrates.

[0057] 3) Another piece of graphene with a pointed cone structure on the PDMS substrate is placed face-to-face on the AAO to obtain a high-sensitivity pressure sensor, which has different current responses under different pressure conditions.

[0058] Imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com