Method of fabricating polyurethane foam with micro pores and polishing pad therefrom

A technology of polyurethane foam and polishing pad, applied in the field of polishing pad, can solve the problems of high production cost, damaged processing allowance, performance change, etc., and achieve the effects of reducing processing cost, increasing processing allowance, and increasing selection possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

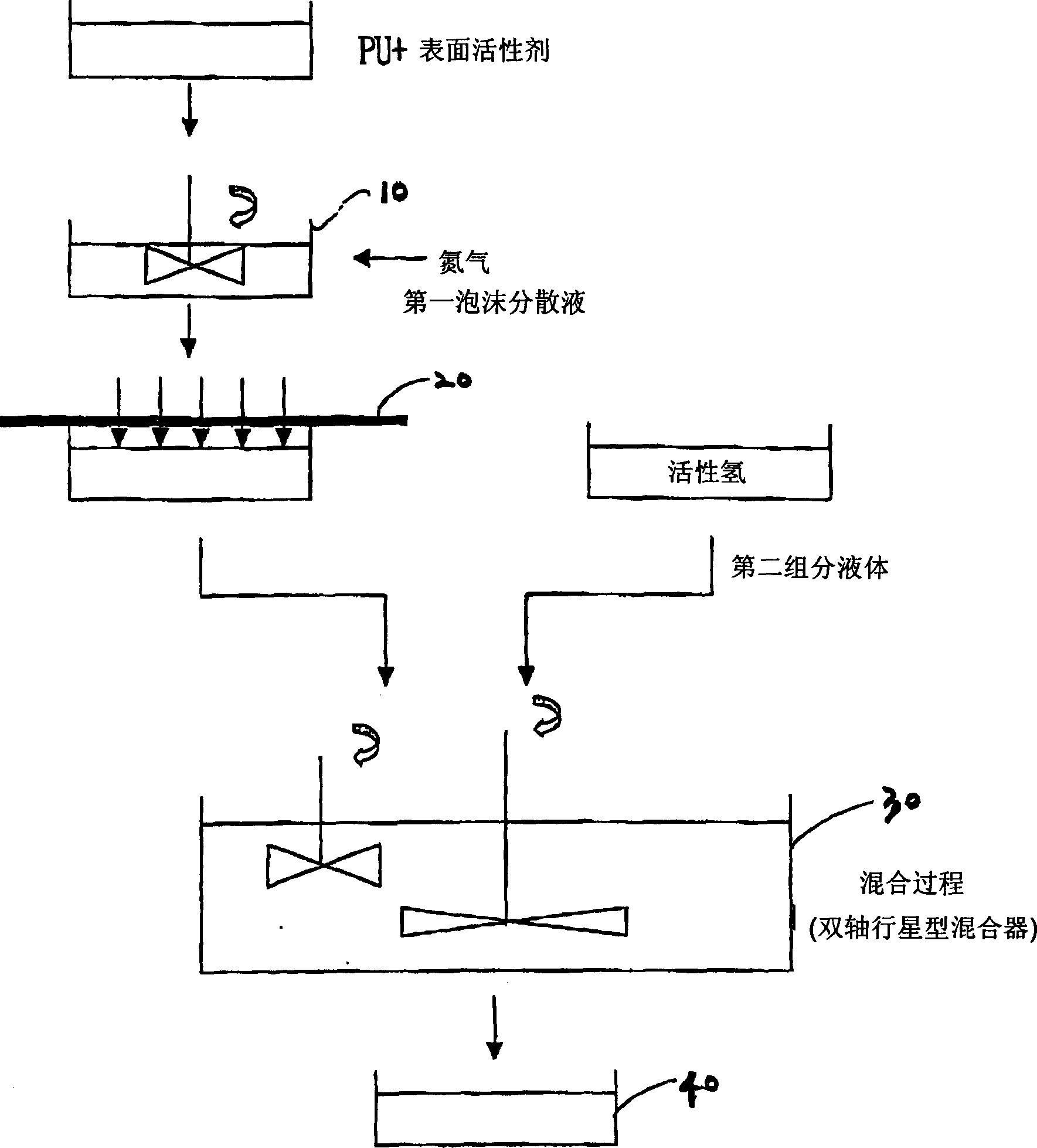

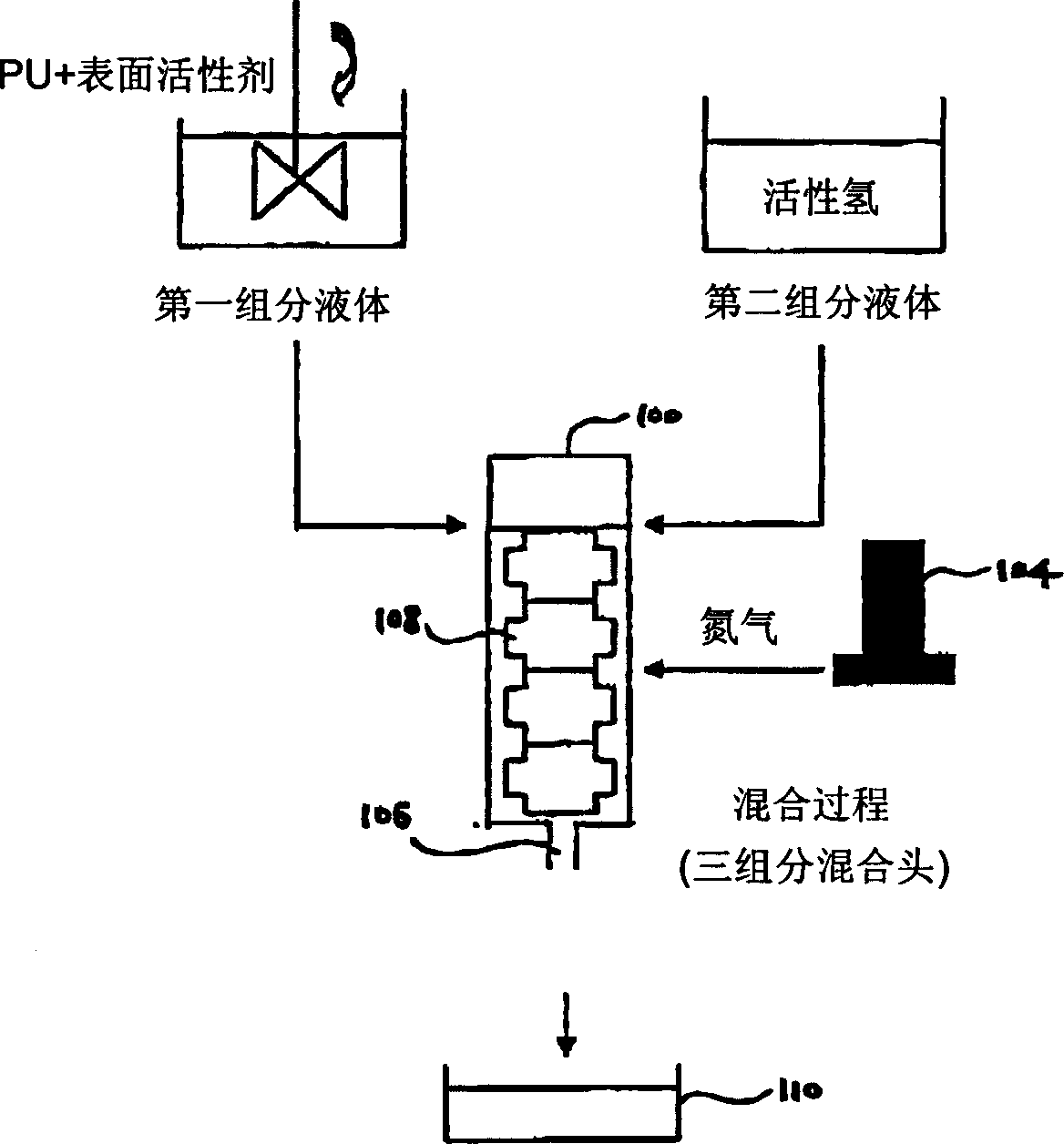

[0075] Such as figure 2 As shown in the schematic diagram of , 1 part by weight of a hydroxyl-containing silicone-based surfactant (trade name: DC-193, DOW CORNING Co., Ltd.) and 100 parts by weight of an isocyanate-terminated urethane prepolymer Adiprene L-325 were mixed and then reacted with each other at a temperature of 60°C for 2 hours. As a result, the hydroxyl group of the polysiloxane-based surfactant is deactivated and a uniform and stable urethane prepolymer reaction liquid (first component liquid) is obtained. This first component liquid is transferred to an air nucleation type molding machine 100, and then, a non-reactive gas N is injected thereinto using a mass flow meter 104. 2 , while injecting 24 parts by weight of MBCA (relative to 100 parts by weight of isocyanate-terminated urethane prepolymer Adiprene L-325) dissolved at a temperature of 120° C. as a second component liquid therein. Next, the mixture is mixed and stirred by the rotating paddle 108, and p...

Embodiment approach 2-9

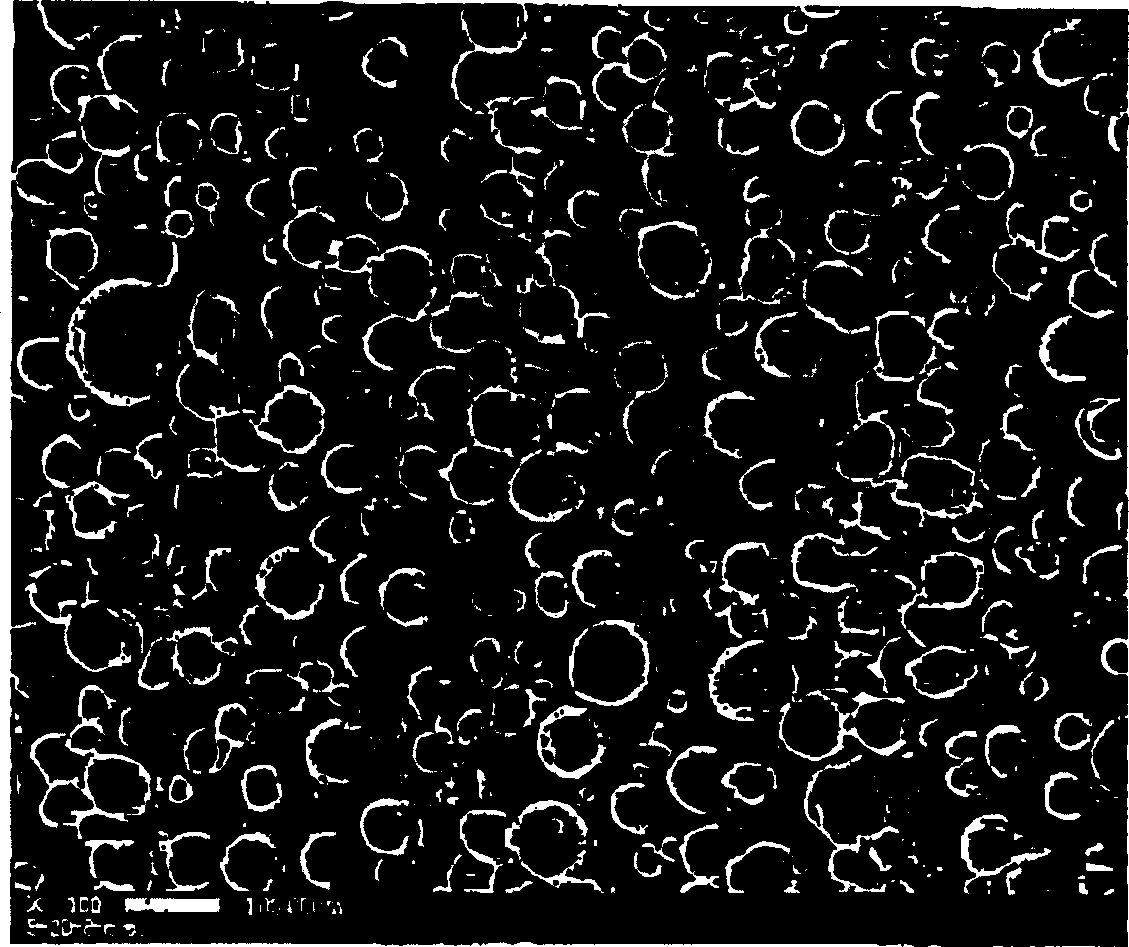

[0079] By the same method as Comparative Example 1, by changing the content of surfactant, the amount of poured mixture and the injection amount of non-reactive gas, etc., wherein the composition ratio is shown in Table 1 below, polishing pads were prepared, and these polishing pads were evaluated. The polishing properties of the pad. The evaluation results are shown in Table 2. The polishing pad prepared by Embodiment 2 was inspected by SEM, and it was found that the pores formed thereon were very uniform and fine. (see Figure 4 )

[0080] carbamic acid

Ethyl prepolymerized

matter (parts by weight)

hollow ball

(parts by weight)

Surfactant

(parts by weight)

active hydrogenation

compound (weight

share)

Mass Flow

meter control water

flat;

responsive injection

Quantity >; (L /

minute)

mix

the solution

row of

put

(kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com