Method for preparing porous ceramic by using tertiary butanol-based freezing sublimation method

A technology of porous ceramics and tert-butanol, applied in the field of porous ceramics, can solve the problems of difficulty in increasing porosity and insufficient application range, and achieve the effects of controllable porosity, strong applicability and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

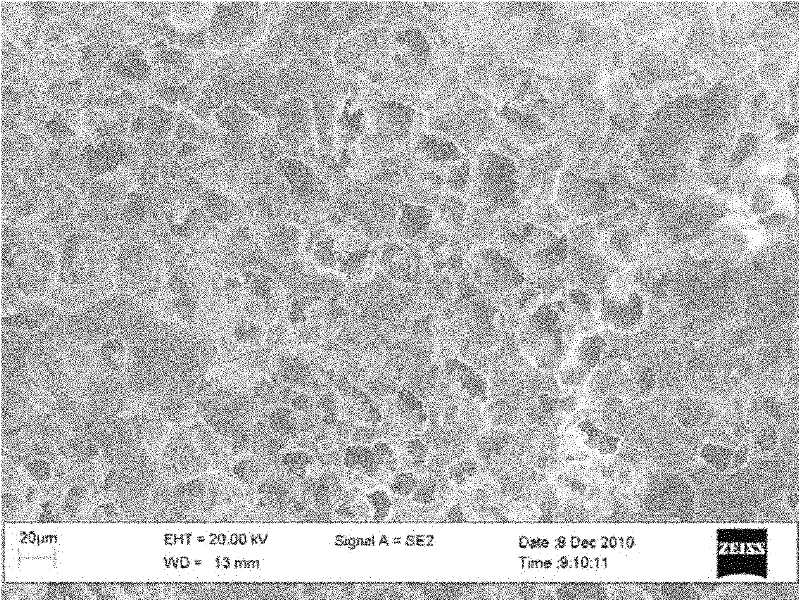

[0028] The raw material is Al with a particle size of about 400 mesh 2 o 3 39.7 grams of powder, 31.6 grams of tert-butanol, 0.397 grams of citric acid and 0.200 grams of polyvinyl butyral, ball milled for 10 hours, poured the dispersed slurry into a polyethylene mold, the temperature at the bottom of the mold was minus 5 ° C, and The temperature at the top is room temperature (20-30°C), the freezing time is 10 minutes, demolded, sublimated for 24 hours under the condition of water circulation pump suction and filtration (pressure is about 0.098MPa), and then kept at 1500°C in an air furnace for 1 hour. The porous ceramic material is synthesized, and the obtained porous ceramic pores are in the shape of straight pores, with a diameter of 20-60 μm and a porosity of 66%. The corresponding scanned photos are listed in the attached figure 1 superior.

Embodiment 2

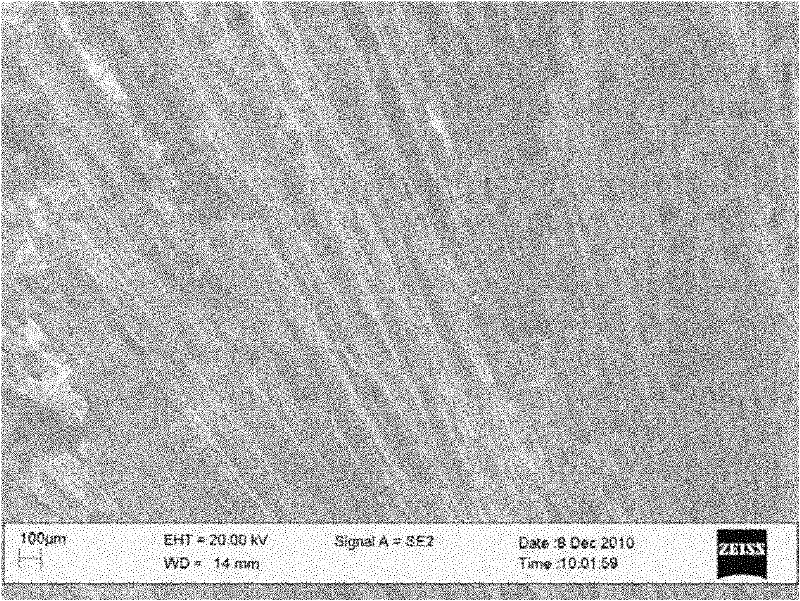

[0030] The raw material is Al with a particle size of about 400 mesh 2 o 3 29.9 grams of powder, 33.6 grams of tert-butanol, 0.297 grams of citric acid and 0.161 grams of polyvinyl butyral, ball milled for 15 hours, poured the dispersed slurry into a polyethylene mold, the temperature at the bottom of the mold was minus 3 ° C, and The top temperature is room temperature (20-30°C), the freezing time is 10 minutes, demolded, sublimated under the condition of water circulation pump suction and filtration (pressure is about 0.098MPa) for 48 hours, and then kept at 1400°C in an air furnace for 1 hour. The porous ceramic material is synthesized, and the obtained porous ceramic pores are in the shape of straight pores, the pore diameter is 50-80 μm, and the porosity can reach 72%. The corresponding scanned photos are listed in the attached figure 2 superior.

Embodiment 3

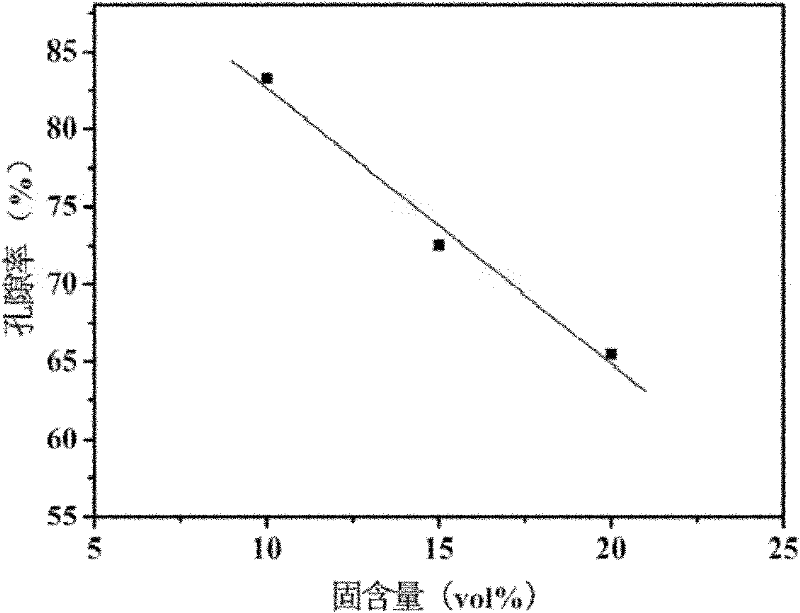

[0032] The raw material is Al with a particle size of about 400 mesh 2 o 3 Powder 19.85 grams, tert-butanol 35.55 grams, citric acid. 0.199 grams and 0.101 grams of polyvinyl butyral, ball milled for 12 hours, pour the dispersed slurry into a polyethylene mold, the temperature at the bottom of the mold is minus 6°C, and the temperature at the top is room temperature (20-30°C). Freeze for 10 minutes, remove the mold, sublimate for 64 hours under the condition of water circulation pump suction and filtration (pressure is about 0.098MPa), and then keep warm at 1500°C for 1 hour in an air furnace to synthesize porous ceramic materials. The obtained porous ceramic pores are straight Pore morphology, the pore diameter ranges from 50 to 100 μm, and the porosity is as high as 84.9%. The relationship between solid content and porosity is shown in the appendix image 3 On the other hand, the porosity increases with the decrease of solid content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com