Ni-Mn-Sb alloy material and spark plasma sintering preparation method thereof

A discharge plasma and ni-mn-sb technology, which is applied in metal material coating process, ion implantation plating, polycrystalline material growth, etc., can solve the problems of long sintering time, slow heating rate, and low production efficiency, and achieve The effect of low cost, low synthesis temperature and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

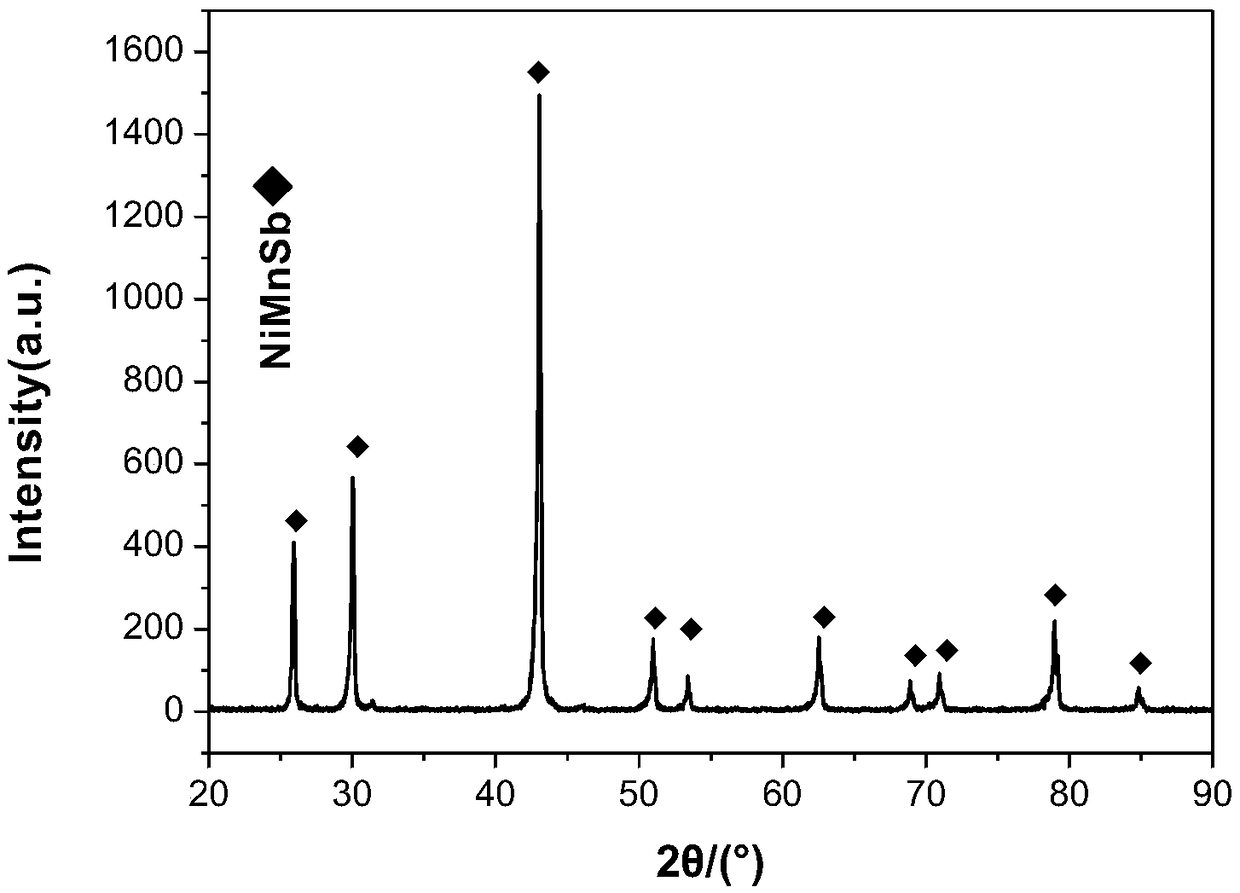

Image

Examples

Embodiment 1

[0029] The sum of atomic ratios of elements in the Ni-Mn-Sb alloy is 100, and the atomic ratio is Ni:Mn:Sb=33.3:33.3:33.3.

[0030] Ni 33.3 mn 33.3 Sb 33.3 A method for preparing an alloy target, comprising the following steps:

[0031] Step 1, the preparation of Ni-Mn-Sb alloy ingot:

[0032] (1) Raw material ratio: according to the chemical formula Ni 33.3 mn 33.3 Sb 33.3 Ingredients;

[0033] (2) Preparation of polycrystalline ingots: the raw materials weighed in step (1) were placed in a water-cooled copper crucible of a vacuum arc melting furnace, and the cavity of the arc melting furnace was evacuated to 3×10 -3 ~5×10 -3 After Pa, pass in an inert protective gas of 0.04-0.05MPa, and repeat the smelting for 4-5 times, and the smelting time is 2-2.5 hours. Arc melting is carried out under electromagnetic stirring to obtain alloy ingots with uniform composition;

[0034] Step 2, preparation of Ni-Mn-Sb alloy target:

[0035] (1) The Ni-Mn-Sb alloy ingot is ground...

Embodiment 2

[0038] The sum of atomic ratios of elements in the Ni-Mn-Sb alloy is 100, and the atomic ratio is Ni:Mn:Sb=33.3:33.3:33.3.

[0039] Ni 33.3 mn 33.3 Sb 33.3 A method for preparing an alloy target, comprising the following steps:

[0040] Step 1, the preparation of Ni-Mn-Sb alloy ingot:

[0041] (1) Raw material ratio: according to the chemical formula Ni 33.3 mn 33.3 Sb 33.3 Ingredients;

[0042] (2) Preparation of polycrystalline ingots: the raw materials weighed in step (1) were placed in a water-cooled copper crucible of a vacuum arc melting furnace, and the cavity of the arc melting furnace was evacuated to 3×10 -3 ~5×10 -3 After Pa, pass in an inert protective gas of 0.04-0.05MPa, and repeat the smelting for 4-5 times, and the smelting time is 2-2.5 hours. Arc melting is carried out under electromagnetic stirring to obtain alloy ingots with uniform composition;

[0043] Step 2, preparation of Ni-Mn-Sb alloy target:

[0044] (1) The Ni-Mn-Sb alloy ingot is ground i...

Embodiment 3

[0047] The sum of the atomic ratios of elements in the Ni-Mn-Sb alloy is 100, and the atomic ratio is n(Ni):n(Mn):n(Sb)=33.3:33.3:33.3.

[0048] Ni 33.3 mn 33.3 Sb 33.3 A method for preparing an alloy target, comprising the following steps:

[0049] Step 1, the preparation of Ni-Mn-Sb alloy ingot:

[0050] (1) Raw material ratio: according to the chemical formula Ni 33.3 mn 33.3 Sb 33.3 Ingredients;

[0051] (2) Preparation of polycrystalline ingots: the raw materials weighed in step (1) were placed in a water-cooled copper crucible of a vacuum arc melting furnace, and the cavity of the arc melting furnace was evacuated to 3×10 -3 ~5×10 -3 After Pa, pass in an inert protective gas of 0.04-0.05MPa, and repeat the smelting for 4-5 times, and the smelting time is 2-2.5 hours. Arc melting is carried out under electromagnetic stirring to obtain alloy ingots with uniform composition;

[0052] Step 2, preparation of Ni-Mn-Sb alloy target:

[0053] (1) The Ni-Mn-Sb alloy in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com