Method for preparing Hf3AIN ceramic material through in-situ reaction

A ceramic material and in-situ reaction technology, which is applied in the field of preparation of high-temperature structural ceramics, can solve the problems of impractical hafnium-aluminum-nitrogen ceramic materials and achieve good damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

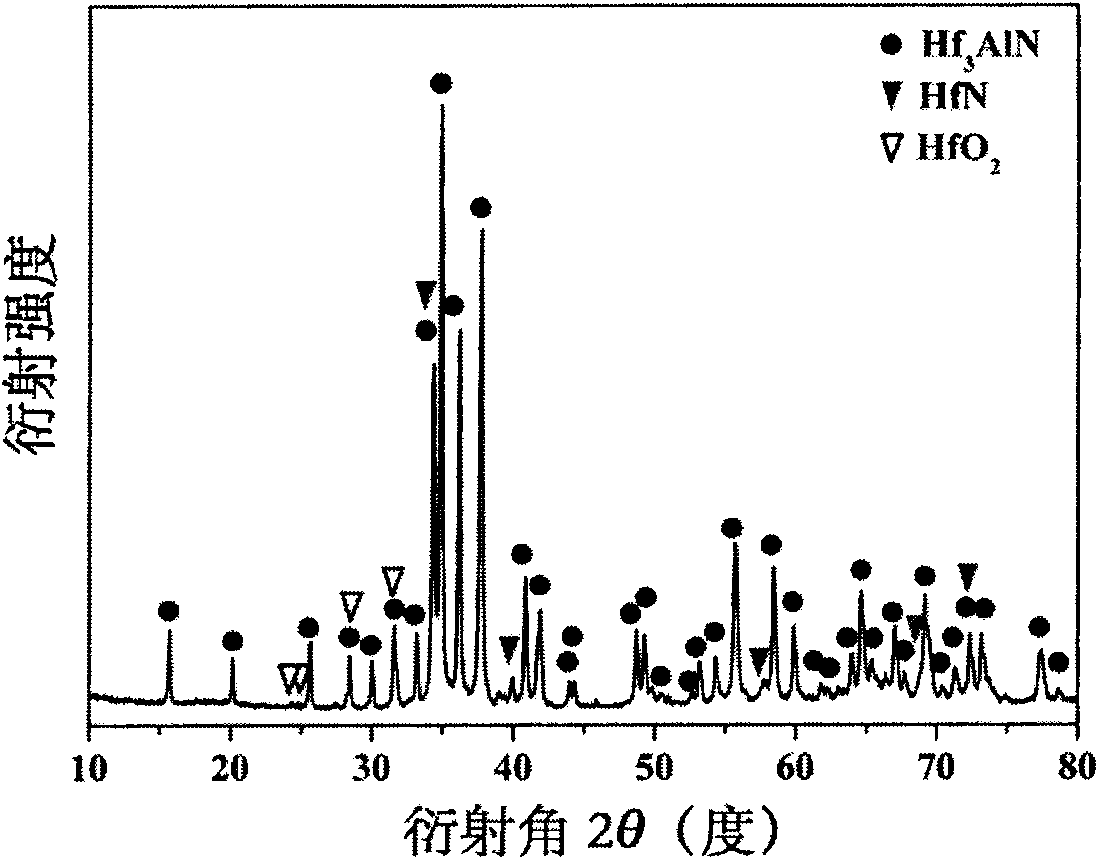

[0020] The raw materials are 100.0 grams of Hf powder, 0.5 grams of Al powder, and 7.2 grams of AlN powder with a particle size of about 400 meshes. They are ball milled for 10 hours, cold-pressed into a cake shape under a pressure of 5 MPa for 10 minutes, and put into graphite molds. , in a hot-press furnace with an inert gas (argon) as a protective gas at a rate of 10°C / min to 1400°C for 1 hour in-situ reaction to synthesize a powder ceramic material, the particle size of the obtained synthetic powder ceramic material is 10 μm. The reaction product is mainly Hf by X-ray diffraction analysis 3 AlN, in addition to small amounts of HfN and HfO 2 Impurities are present. The corresponding X-ray diffraction patterns are listed in the attached figure 1 superior.

Embodiment 2

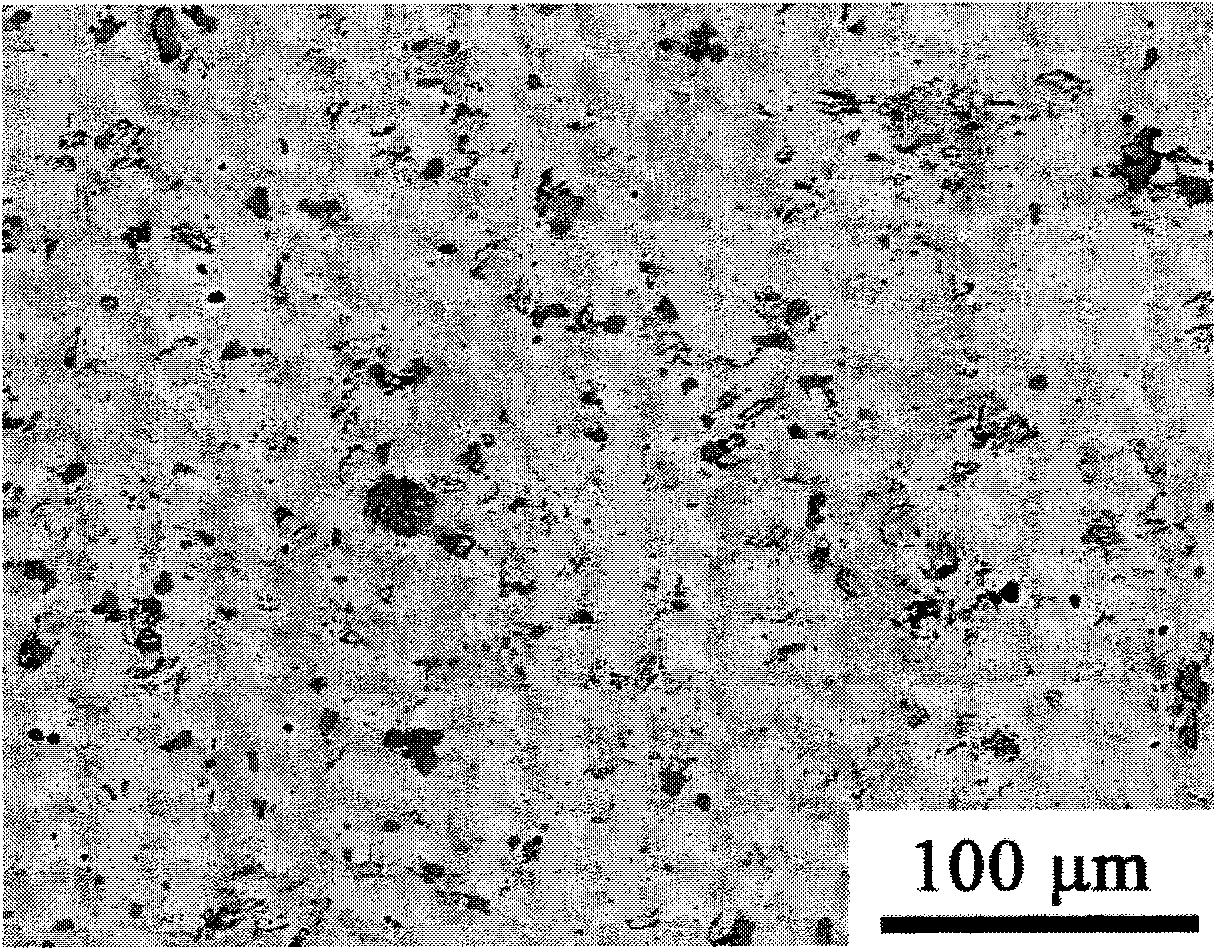

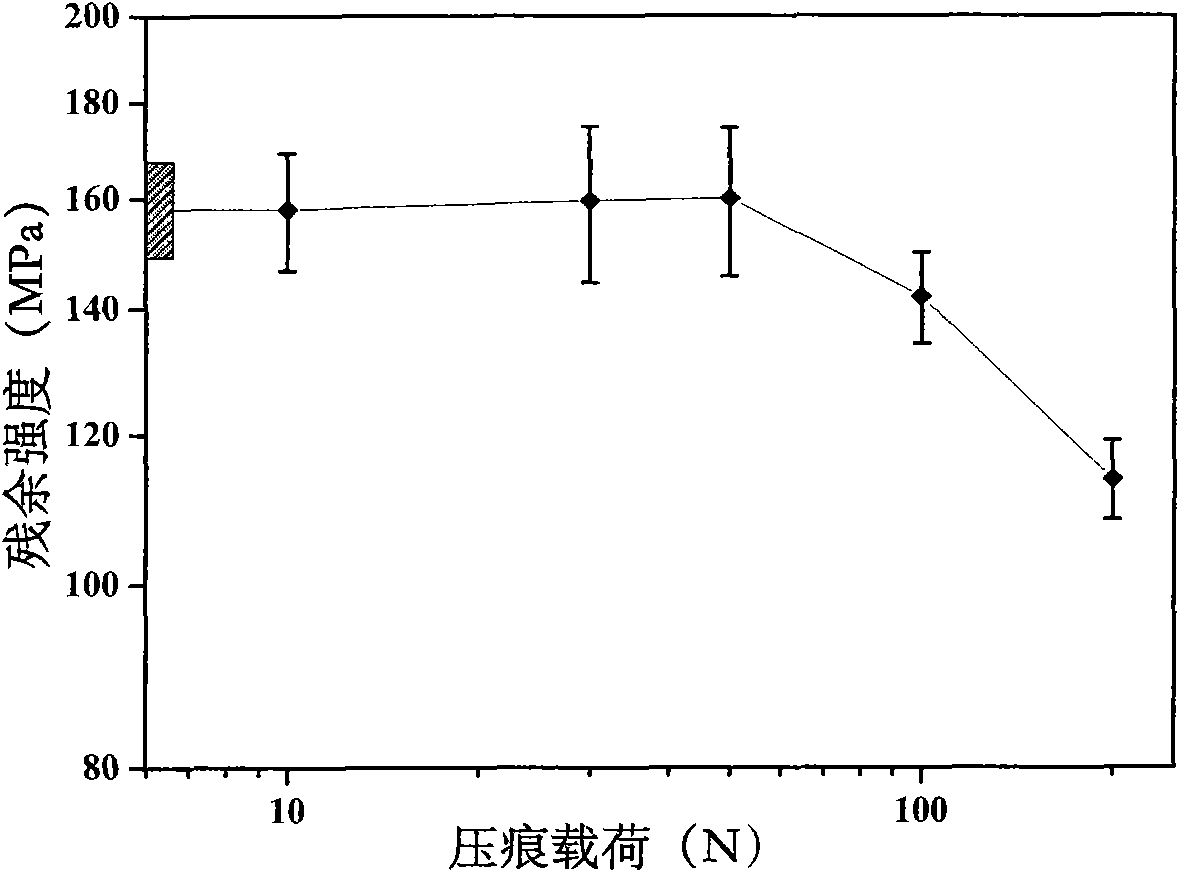

[0022] The raw materials are 100.0 grams of Hf powder, 7.2 grams of Al powder, and 53.9 grams of HfN powder with a particle size of about 400 mesh. They are ball milled for 15 hours and cold pressed into a cake shape under a pressure of 15 MPa. The cold pressing time is 20 minutes and put into a graphite mold. , in a hot-press furnace with inert gas (argon) as a protective gas, the temperature was raised to 1600 °C at a rate of 15 °C / min for 2 hours, and the hot-pressing pressure was 30 MPa to synthesize a bulk ceramic material. The size of the hafnium aluminum nitrogen block material is Φ25mm×5mm. The reaction product is mainly Hf by X-ray diffraction analysis 3 AlN. The corresponding SEM photographs are listed in the attached figure 2 superior. The reaction product has a strong damage tolerance. The corresponding intensity curves are listed in the attached image 3 superior.

Embodiment 3

[0024] The raw materials are 100.0 grams of Hf powder, 1.1 grams of Al powder, and 8.2 grams of AlN powder with a particle size of about 200 meshes. They are ball-milled for 20 hours and cold-pressed into cakes under a pressure of 10 MPa for 5 minutes. Then, they are put into graphite molds. , under vacuum (the degree of vacuum is 10 -2 Pa) in a hot pressing furnace with a heating rate of 20 ° C / min to 1500 ° C in situ reaction hot pressing for 1 hour, and the hot pressing pressure is 40 MPa to synthesize a bulk ceramic material. The obtained hafnium aluminum nitrogen block material has a size of Φ50mm ×10mm. The reaction product is mainly Hf by X-ray diffraction analysis 3 AlN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com