Method for improving high-temperature mechanical property and high-temperature oxidation resistance of titanium silicon carbon

A technology of high temperature oxidation resistance and high temperature mechanics, applied in chemical instruments and methods, layered products, ceramic layered products, etc., can solve the problems of poor oxidation resistance, no improvement in high temperature mechanical properties, and reduced mechanical properties. , to achieve the effect of maintaining high temperature strength, increasing the temperature, improving high temperature mechanical properties and high temperature oxidation resistance, and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

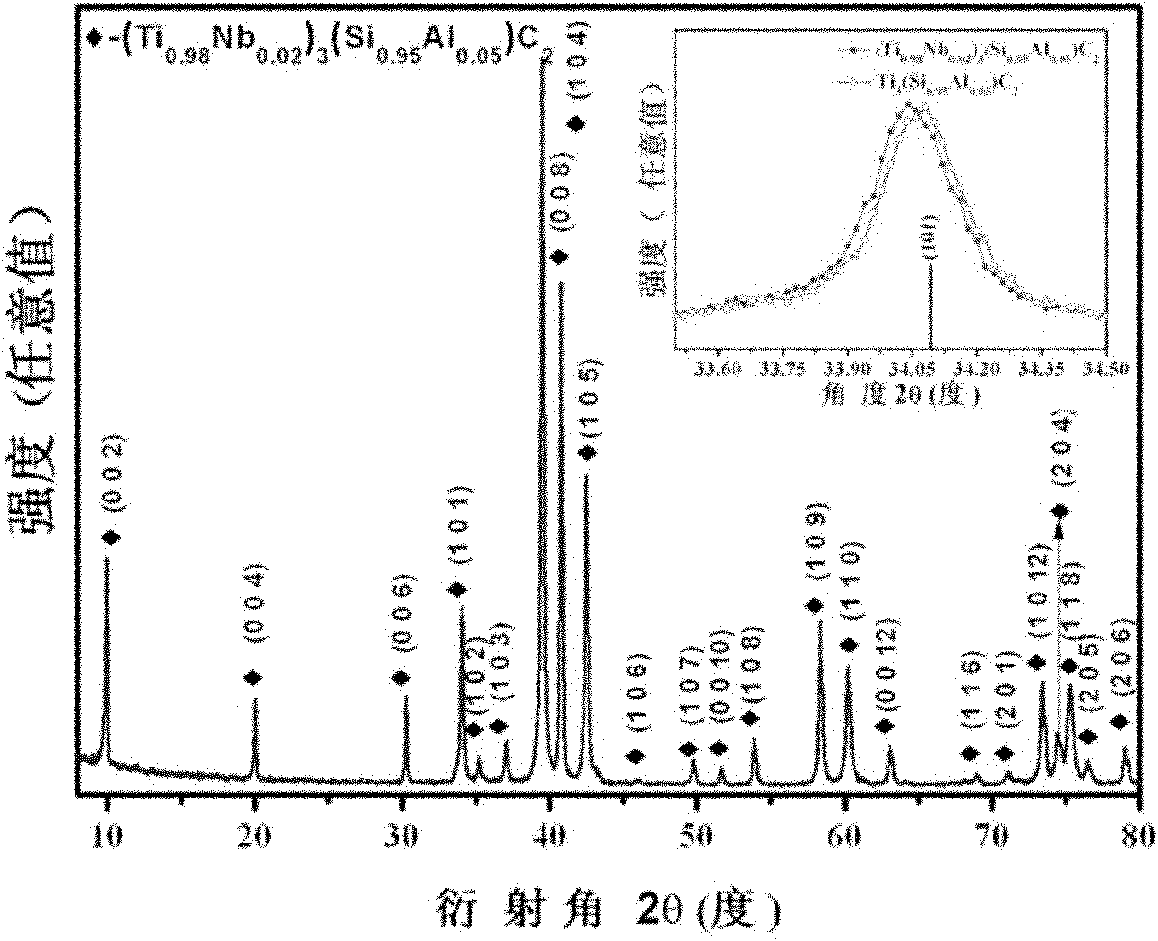

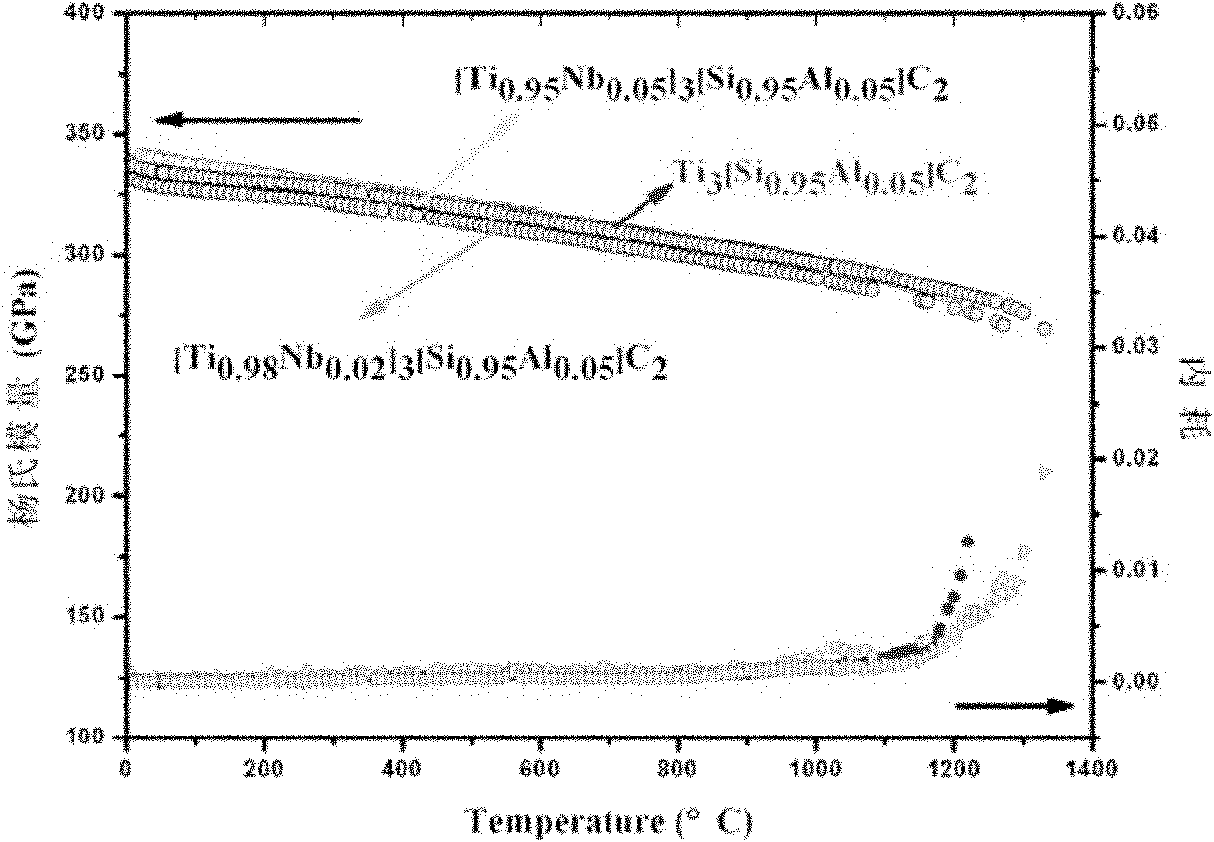

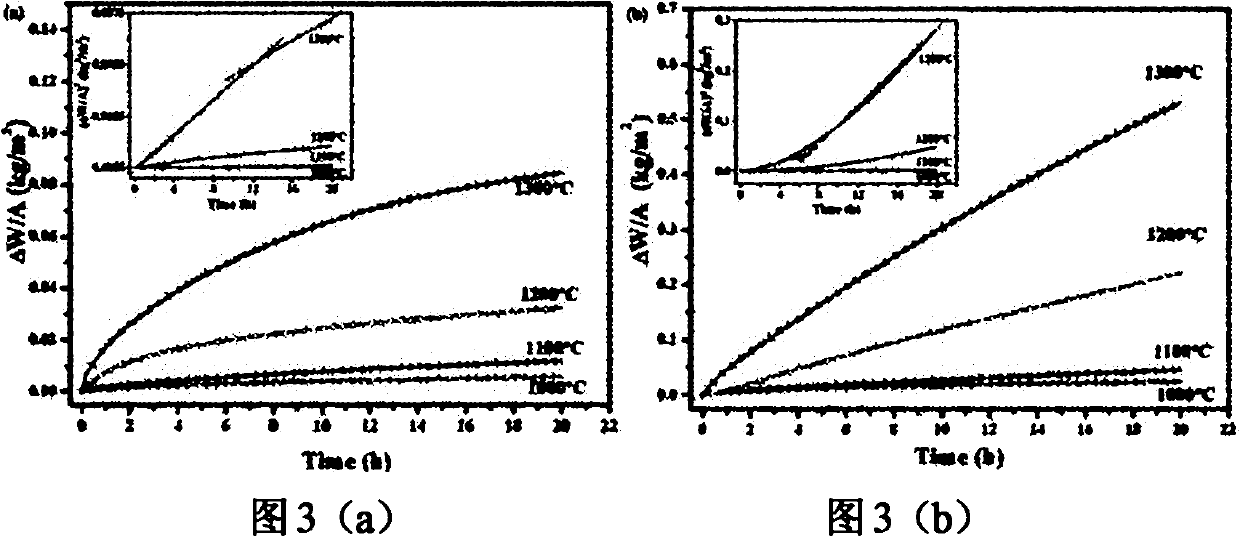

[0031] Select ternary layered ceramic titanium silicon carbon solid solution material (Ti 0.98 Nb 0.02 ) 3 (Si 0.95 al 0.05 )C 2 As the experimental material, its preparation process is as follows:

[0032] Use Ti powder, Nb powder, Si powder, Al powder and graphite powder as synthetic materials, configure the raw material powder according to the stoichiometric ratio of the materials, put the prepared raw material powder into the mixing tank, ball mill for 15 hours, and then take it out and sieve Standby; after being cold-pressed in a graphite mold with a pressure of 5 MPa for 5 minutes into a cake shape, put it into a hot-press furnace for reaction and hot-press synthesis. The process used for hot-pressing synthesis is: under the pressure of 30MPa, the temperature is raised to the predetermined temperature at 15°C / min, and the temperature is kept at 1550°C for 60 minutes. The reaction is carried out under the flowing Ar gas as the protective gas.

[0033] figure 1 In o...

Embodiment 2

[0044] Select ternary layered ceramic titanium silicon carbon solid solution material (Ti 0.97 Nb 0.03 ) 3 (Si 0.95 al 0.05 )C 2 As the experimental material, its preparation process is as follows:

[0045]Ti powder, Nb powder, Si powder, Al powder and graphite powder are used as synthetic materials, and the raw powder is configured according to the stoichiometric ratio of the materials. The prepared raw material powder is put into the mixing tank, ball milled for 24 hours, and then taken out. Sieve for standby; after cold pressing in graphite mold with a pressure of 8 MPa for 5 minutes into a cake shape, put it into a hot-press furnace for reaction and hot-press synthesis. The process used for hot-pressing synthesis is: under the pressure of 30MPa, the temperature is raised to the predetermined temperature at 10°C / min, kept at 1580°C for 10 minutes, and then kept at 1400°C for 60 minutes. The reaction is carried out under the protective gas of flowing Ar gas of.

[004...

Embodiment 3

[0048] Select ternary layered ceramic titanium silicon carbon solid solution material (Ti 0.95 Nb 0.05 ) 3 (Si 0.95 Al 0.05 )C 2 As the experimental material, its preparation process is as follows:

[0049] Ti powder, Nb powder, Si powder, Al powder and graphite powder are used as synthetic materials, and the raw powder is configured according to the stoichiometric ratio of the materials. The prepared raw material powder is put into the mixing tank, ball milled for 30 hours, and then taken out. Sieve for standby; after cold pressing in a graphite mold with a pressure of 9 MPa for 5 minutes into a cake shape, put it into a hot-press furnace for reaction and hot-press synthesis. The process used for hot-pressing synthesis is: under the pressure of 30MPa, the temperature is raised to the predetermined temperature at 15°C / min, kept at 1600°C for 15 minutes, and then kept at 1400°C for 60 minutes. The reaction is carried out under the protective gas of flowing Ar gas of.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com