Method for preparing zirconia-alumina composite material by way of zirconia-alumina-carbon oxidation

A technology of zirconia and carbon oxidation, which is applied in the field of preparation of high-performance composite ceramic materials, and can solve the problems of impracticality of nanocrystalline or ultrafine-crystalline composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

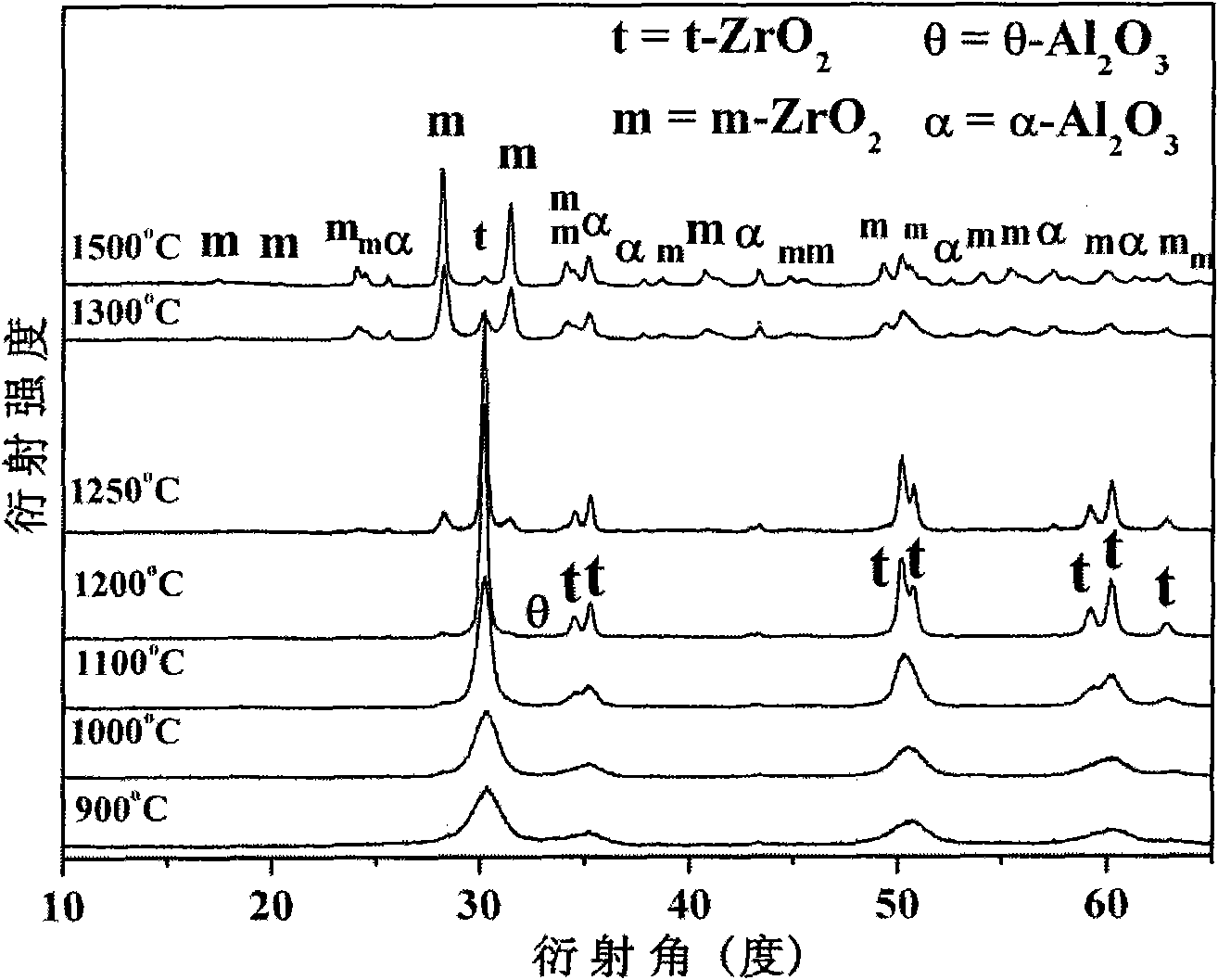

[0022] The raw material is Zr with a particle size of about 200 mesh 3 Al 3 C 5 10 grams of powder, ball milled for 5 hours, in-situ oxidation reaction in an air furnace at a heating rate of 10°C / min to 900°C-1500°C for 5 minutes to prepare ZrO 2 -Al 2 o 3 Composite powder, powder particle size 0.1-10μm, ZrO 2 and Al 2 o 3 Homogeneous mixing at the nanoscale. ZrO in the resulting composite nanopowder 2 and Al 2 o 3 The stoichiometric ratio is ZrO 2 :Al 2 o 3 =2:1. The corresponding X-ray diffraction pattern is attached figure 1 given in.

Embodiment 2

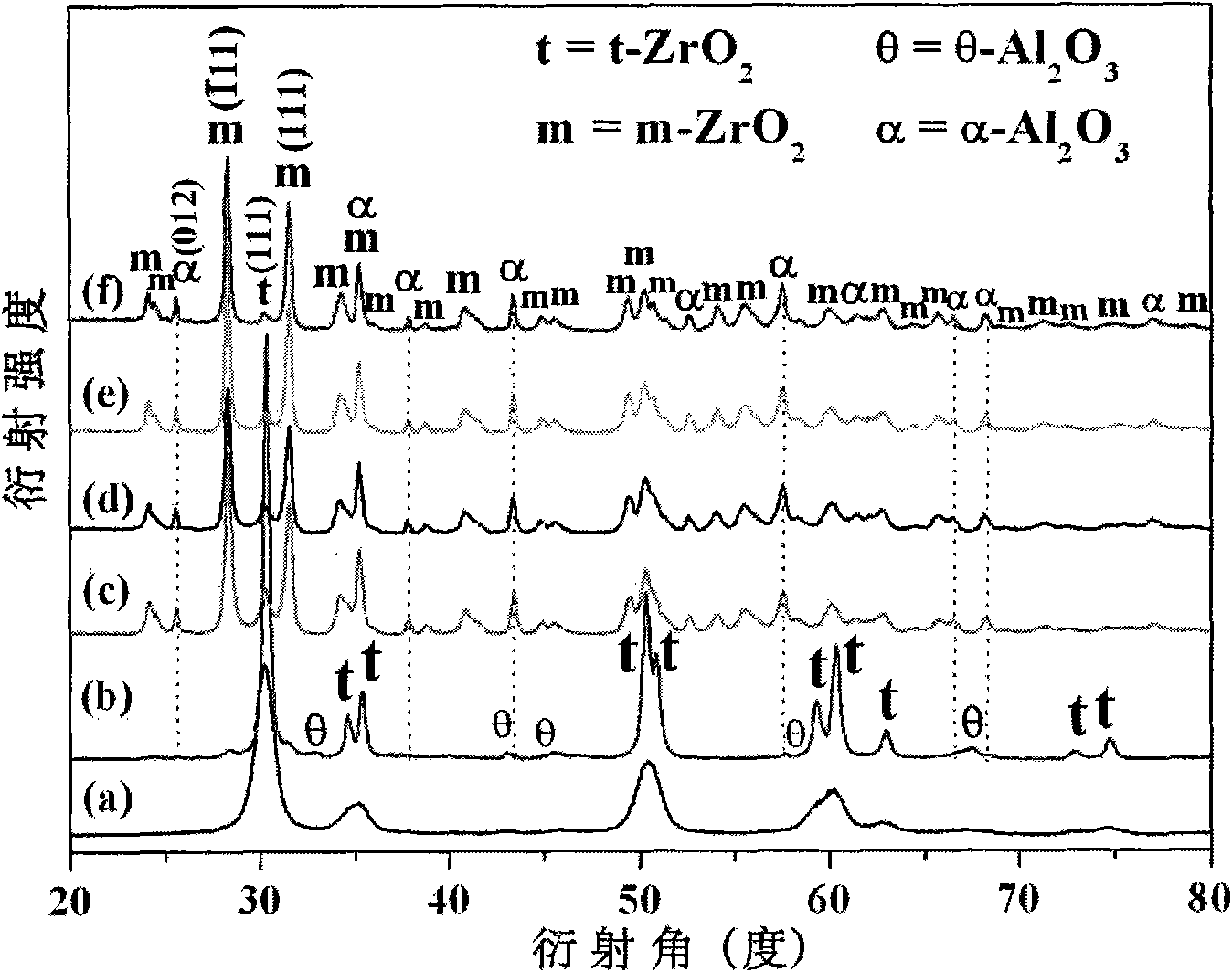

[0024]The raw material is Zr with a particle size of about 400 mesh 2 Al 3 C 4 Powder 20 grams, ball milled for 20 hours, in-situ oxidation reaction in an air furnace at a heating rate of 2°C / min to 1000°C for 20 hours to prepare ZrO 2 -Al 2 o 3 Composite powder, powder particle size 0.1-10μm, ZrO 2 and Al 2 o 3 Homogeneous mixing at the nanoscale. ZrO in the resulting composite nanopowder 2 and Al 2 o 3 The stoichiometric ratio is ZrO 2 : Al 2 o 3 =2:1.5. The corresponding X-ray diffraction patterns are listed in the attached figure 2 (a) on.

Embodiment 3

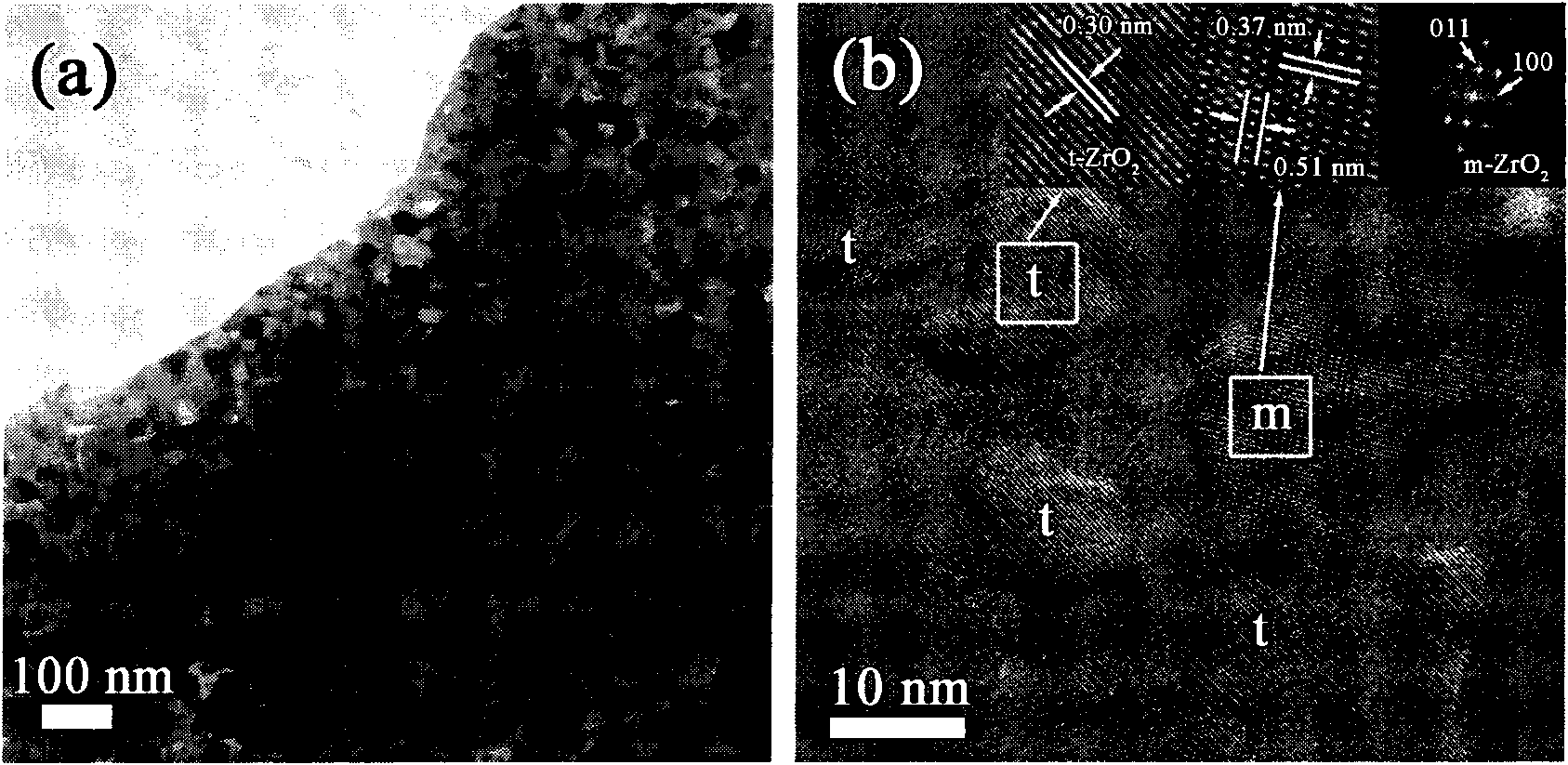

[0026] The multi-phase powder obtained in Example 2 was cold-pressed into a cake under a pressure of 10 MPa, and the cold-pressing time was 5 minutes. / min heating rate increased to 1100 ℃ in situ reaction hot pressing for 1 hour, the hot pressing pressure was 40MPa, the obtained ZrO 2 -Al 2 o 3 Nano-composite materials, the size of the composite ceramic bulk material is Φ25mm×10mm, and the average grain size of the material is 30nm. The corresponding X-ray diffraction patterns are listed in the attached figure 2 (b), the TEM pictures are listed in the attached image 3 above, the density and hardness values are listed in the attached Figure 5 superior.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com