Method for preparing tantalum-aluminium-carbon ceramic by in-situ heat-pressing/solid-liquid phase reaction

A liquid phase reaction, solid-liquid phase technology, applied in the field of preparation of machinable layered ceramics, can solve the problems of no research performance, no bulk materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

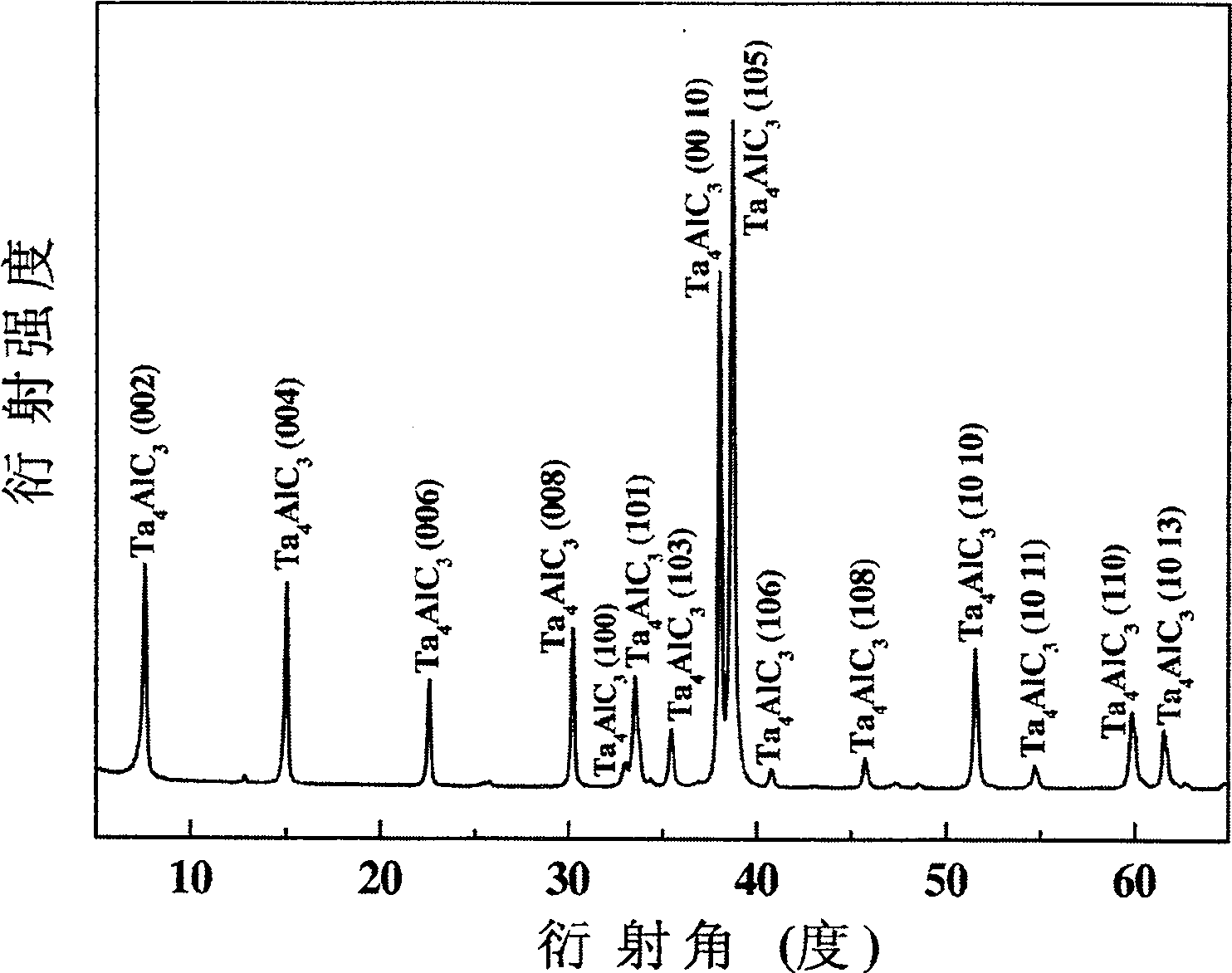

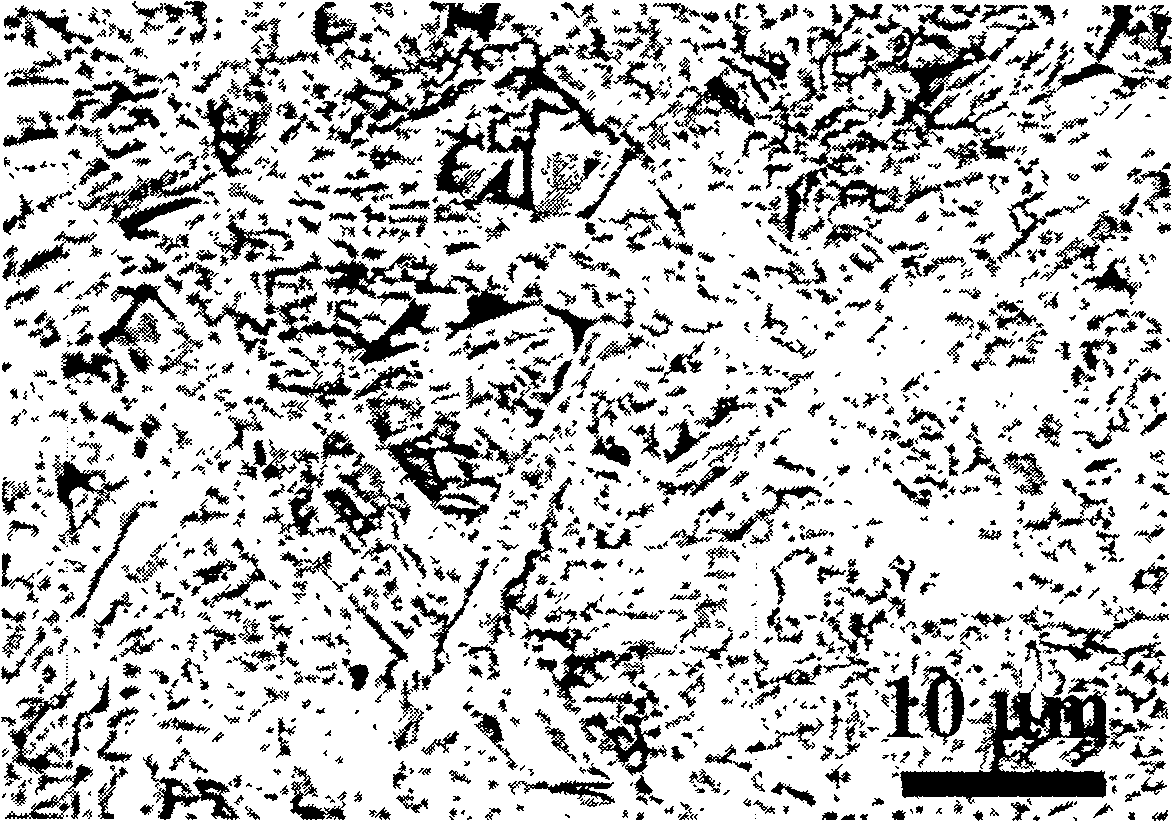

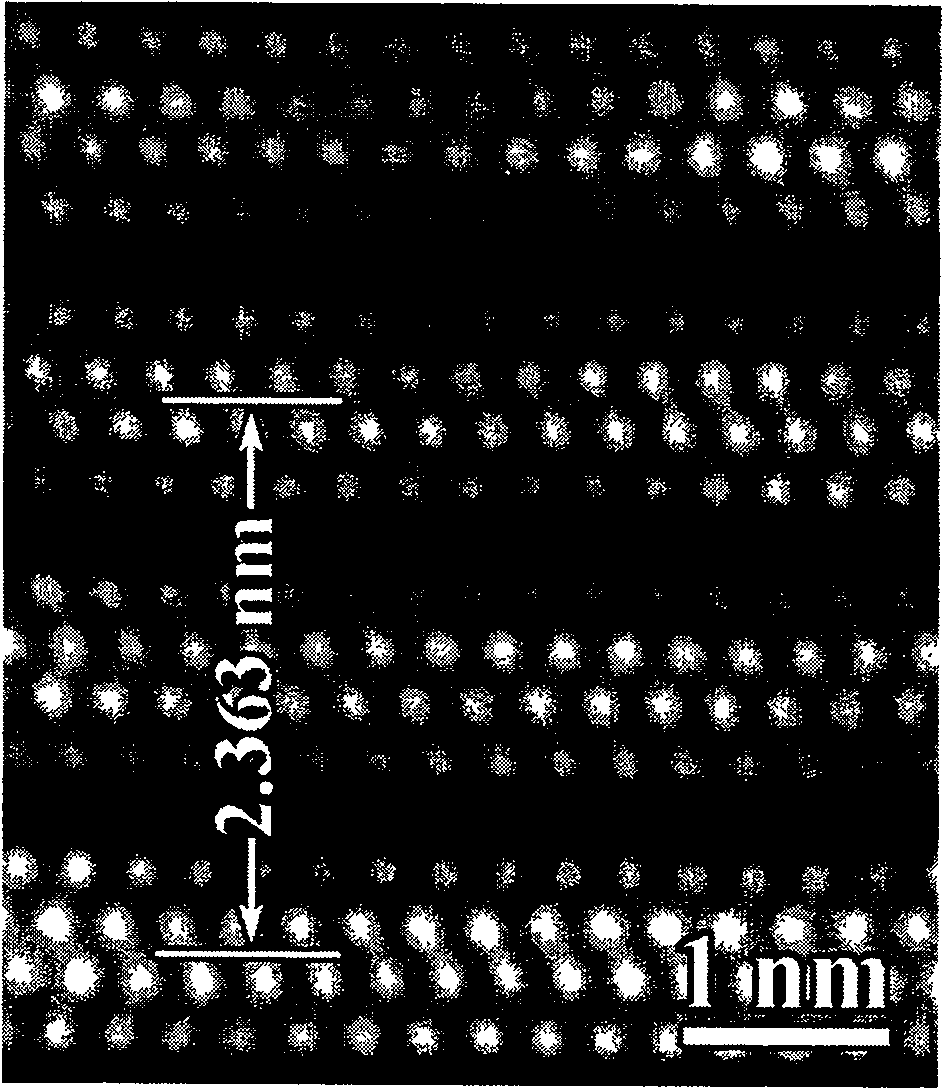

[0022] 180.95 grams of Ta powder, 13.49 grams of Al powder and 9.00 grams of C powder were ball-milled for 8 hours, cold-pressed into a cake under a pressure of 15 MPa, packed into a graphite mould, and passed through an inert gas (argon) as a heat shielding gas. In the press furnace, the temperature was raised to 1530°C at a rate of 10°C / min for in-situ hot pressing / solid-liquid phase reaction for 0.5 hours, and the hot pressing pressure was 30MPa. The main reaction product obtained was analyzed by X-ray diffraction as Ta 4 AlC 3 . The corresponding X-ray diffraction patterns, scanning electron micrographs, and transmission electron micrographs are listed in the attached Figure 1-3 superior.

Embodiment 2

[0024] 180.95 grams of Ta powder, 14.84 grams of Al powder and 6.00 grams of C powder were ball milled for 12 hours, cold-pressed into a cake under a pressure of 10 MPa, packed into a graphite mold, and heated in a hot-press furnace with argon as a protective gas. The heating rate of 20°C / min was increased to 1450°C in situ hot pressing / solid-liquid phase reaction for 1 hour, and the hot pressing pressure was 35MPa. The main reaction product obtained was analyzed by X-ray diffraction as Ta 4 AlC 3 and Ta 2 Two-phase composites of AlC. The corresponding X-ray diffraction patterns are listed in the attached Figure 4 superior.

Embodiment 3

[0026] 180.95 grams of Ta powder, 20.24 grams of Al powder and 6.00 grams of C powder were ball-milled for 12 hours, cold-pressed into a cake under a pressure of 20 MPa, packed into a graphite mould, and vacuumed (vacuum degree is 10 -2 Pa) in a hot-press furnace at a rate of 10°C / min to 1350°C in situ hot-pressing / solid-liquid phase reaction for 2 hours, and the hot-pressing pressure is 40MPa. The main reaction product obtained was analyzed by X-ray diffraction as Ta 2 AlC. The corresponding transmission electron microscope pictures are attached Figure 5 superior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com