Aromatic polyamide compound diaphragm, preparation method thereof and secondary battery

A technology of aromatic polyamide and composite diaphragm, which is applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., and can solve the problems of lithium secondary batteries such as reduced safety, combustion or explosion, and limited temperature resistance. Achieve good thermal stability and chemical stability, increase safety, and have strong solvency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

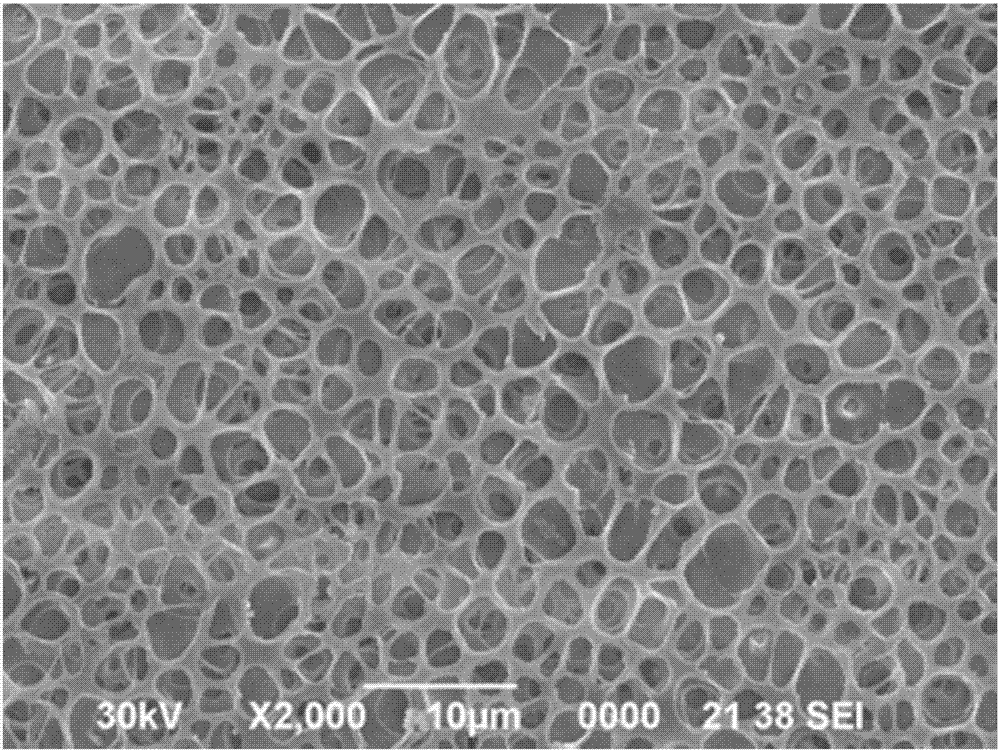

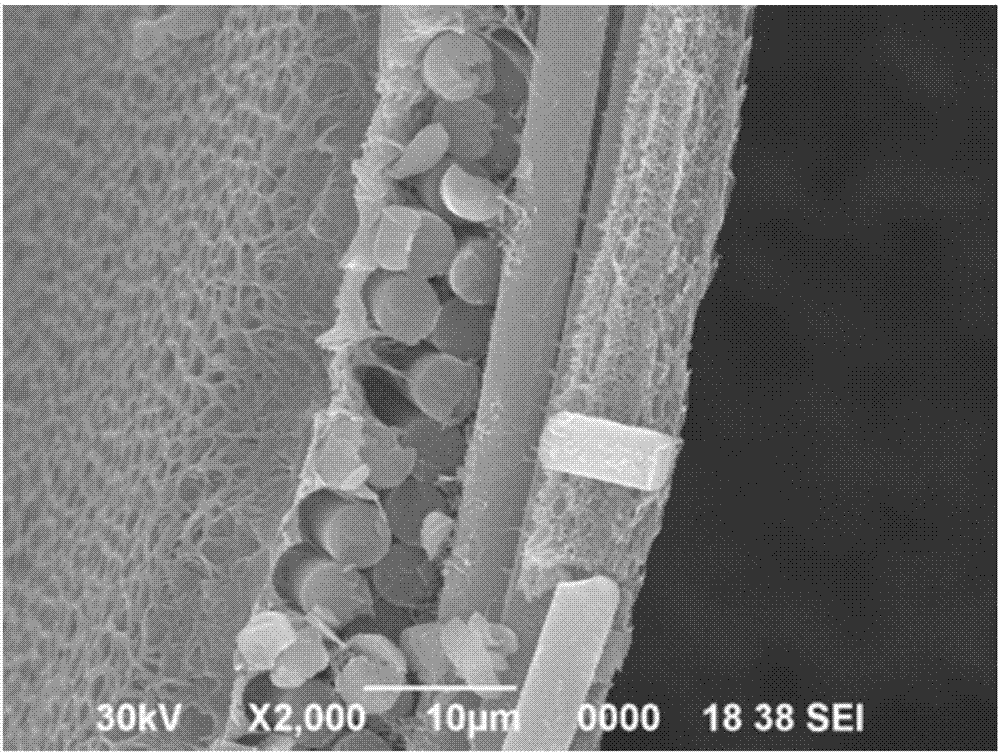

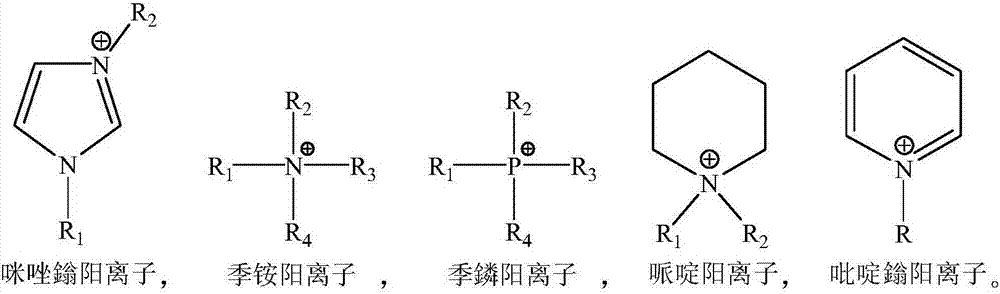

Embodiment 1

[0060]Polymerize in a reaction kettle to obtain 4500 g of polym-phenylene isophthalamide solution, the solvent is DMAC, and the mass percent concentration of the polymer is 9%. 2300 g of N-methyl-N-propylpyrrolium tetrafluoroborate and 700 g of absolute ethanol were mixed in a stirred tank to obtain an ionic liquid solution. The ionic liquid solution and the polym-phenylene isophthalamide solution prepared in the previous stage were respectively injected into the stirring tank and mixed evenly, and then injected into the coating tank. Immerse the glass fiber cloth with a thickness of 12 μm and a single filament diameter of 4.5 μm into the mixed solution in the coating tank, take it out from the mixed solution and then squeeze it through a pressure roller to ensure a uniform thickness of the membrane. The coated film enters the gel bath, the gel bath is a mixed solvent of water and DMAC, wherein the mass percentage of water is 50%, the temperature of the gel bath is 60° C., and...

Embodiment 2

[0064] Same as Example 1, the difference is that 2300 g of N-methyl-N-propylpyrrolium tetrafluoroborate and 230 g of deionized water were mixed in a stirred tank to obtain an ionic liquid solution.

Embodiment 3

[0066] Same as Example 2, the difference is that the gel bath is water, the gel bath temperature is 80°C, the gel time is 10 seconds, and the drying temperature is 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com