Preparation for high vibration high density lithium iron phosphate

A technology of lithium iron phosphate and tap density, which is applied in chemical instruments and methods, spraying manufacturing, electrode manufacturing, etc., can solve the problems of unsatisfactory tap density and low volume specific capacity of lithium iron phosphate, and achieve superior material processing performance , low cost, simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

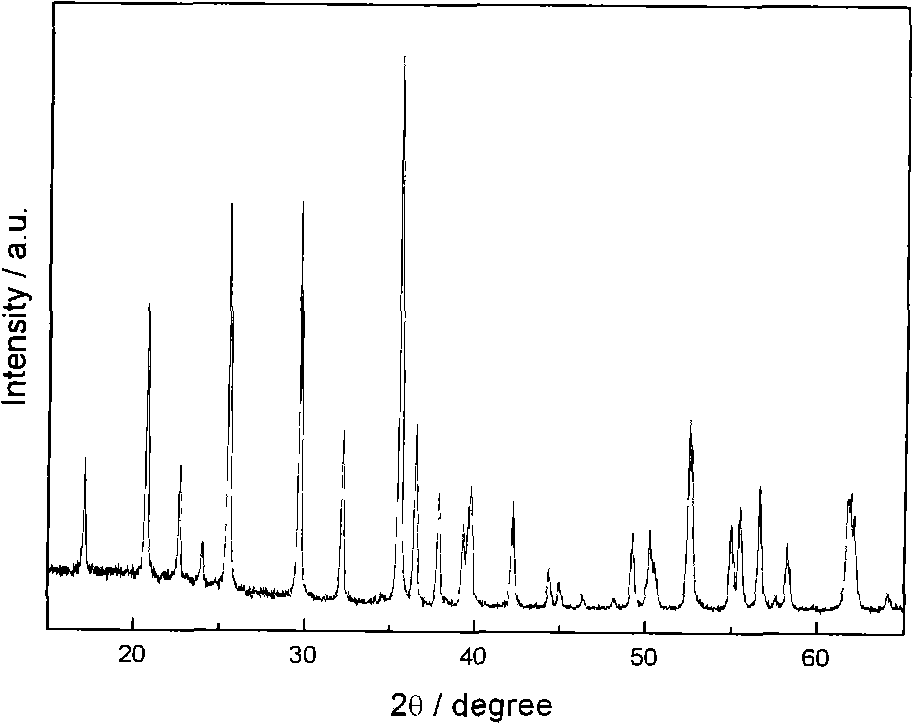

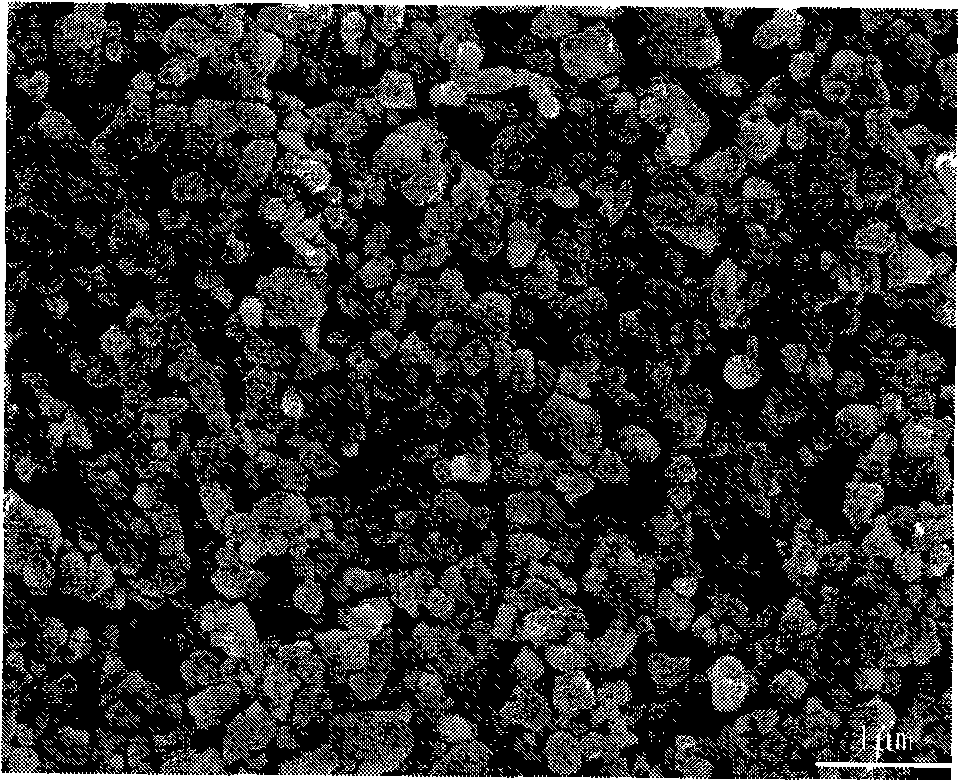

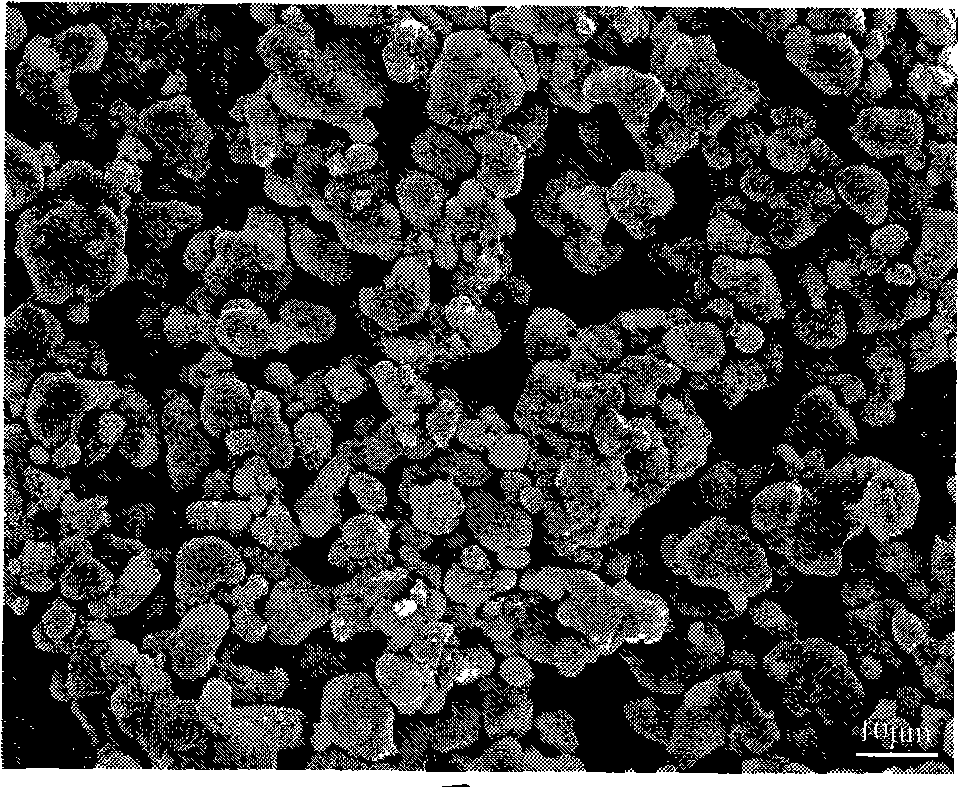

Image

Examples

Embodiment 1

[0044] Take 0.05 mole of ferrous chloride and 0.05 mole of phosphoric acid (calculated according to the effective content of 85% phosphoric acid solution), dissolve them in 200ml deionized water, add 0.005 mole of complexing agent, stir continuously, slowly add The aqueous solution of lithium (calculated by the effective content of 5% concentration lithium hydroxide aqueous solution); Stir for 10 minutes, the solution produces green precipitate, green precipitate is washed repeatedly with deionized water, then green precipitate is carried out centrifugation with high-speed centrifuge; The separated solid was dried in a vacuum drying oven at 50° C. for 8 hours to obtain a precursor.

[0045] Add 1% acetylene black with a high specific surface area to the dried precursor, mix evenly in a vacuum mixer, then place the mixture in an inert gas protection furnace, and raise the temperature to 600°C at a heating rate of 5°C / min. After heat treatment for 10 hours, a uniformly dispersed...

Embodiment 2

[0050] Take 0.1 mole of ferrous sulfate and 0.1 mole of ammonium phosphate, dissolve them in 200ml of deionized water, add 0.01 mole of complexing agent, stir constantly, slowly add 0.1 mole of lithium chloride aqueous solution; stir for 60 minutes, the solution produces green precipitation, The green precipitate was repeatedly washed with deionized water, and then the green precipitate was centrifuged with a high-speed centrifuge; the separated solid was dried in a vacuum oven and dried at 80°C for 1 hour to obtain a precursor.

[0051] Add 5% carbon black with a high specific surface area to the dried precursor, mix evenly in a vacuum mixer, then place the mixture in an inert gas protection furnace, and raise the temperature to 800°C at a heating rate of 5°C / min , heat treatment for 1 hour to obtain a uniformly dispersed primary lithium iron phosphate material with a particle size of 100 nanometers.

[0052] Place the initial lithium iron phosphate material in a closed vacuu...

Embodiment 3

[0055] Take 0.08 mol of ferric ammonium sulfate and 0.08 mol of ammonium hydrogen phosphate, dissolve them in 200ml deionized water, add 0.007 mol of complexing agent, keep stirring, slowly add 0.15 mol of lithium sulfate aqueous solution; stir for 30 minutes, the solution produces green precipitate, The green precipitate was repeatedly washed with deionized water, and then the green precipitate was centrifuged with a high-speed centrifuge; the separated solid was dried in a vacuum oven and dried at 60°C for 4 hours to obtain a precursor.

[0056] Add 3% acetylene black with a high specific surface area to the dried precursor, mix evenly in a vacuum mixer, then place the mixture in a weakly reducing gas protection furnace, and heat up to Heat treatment at 600°C for 8 hours to obtain a uniformly dispersed initial lithium iron phosphate material with a particle size of 350 nm.

[0057] Place the initial lithium iron phosphate material in a closed vacuum container and stir it at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com