Reaction film formation inorganic dry powder coating material and production method thereof

A technology of reaction film formation and inorganic dry powder, applied in the direction of coating, etc., can solve the problems of short-term storage and poor construction performance, and achieve the effect of low cost, excellent construction performance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

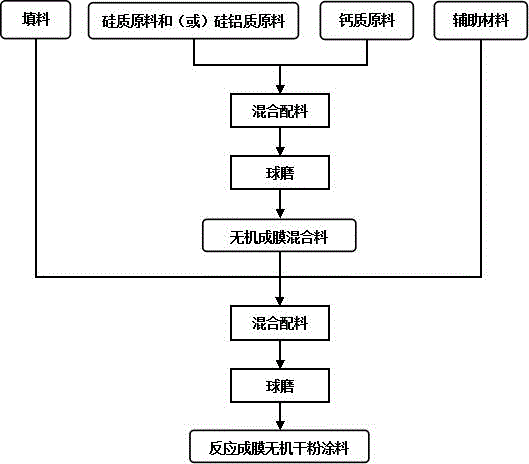

Image

Examples

Embodiment 1

[0027] The components and contents of the reaction film-forming inorganic dry powder coating of this example are: white carbon black 15%, lime calcium powder 30%, double fly powder 33%, talcum powder 14%, titanium dioxide 3.8%, water glass 0.2%, diatom Soil 2.8%, water reducing agent 0.5%, defoamer 0.7%, inorganic pigment 0.

Embodiment 2

[0029] The components and contents of the reactive film-forming inorganic dry powder coating of this example are: white carbon black 22%, lime calcium powder 10%, double fly powder 44%, talcum powder 5%, titanium dioxide 2.5%, water glass 0.5%, diatom Soil 6%, water reducer 1.4%, defoamer 1.5%, iron oxide red 7.1%.

Embodiment 3

[0031] The components and contents of the reactive film-forming inorganic dry powder coating of this example are: white carbon black 4%, lime calcium powder 26%, double fly powder 45%, talcum powder 16%, titanium dioxide 2%, water glass 0.7%, diatom Soil 2.8%, water reducing agent 0.8%, defoamer 1.8%, iron oxide red 0.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com