Method for preparing organic/inorganic composite magnetic microcapsules

A technology of inorganic compounding and microcapsules, applied in the directions of microcapsule preparation, microsphere preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

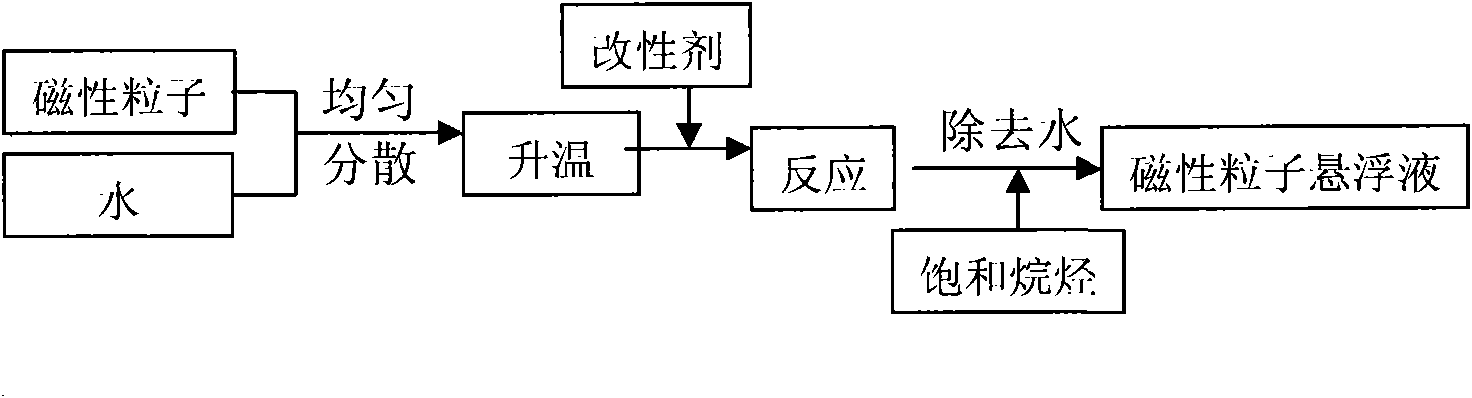

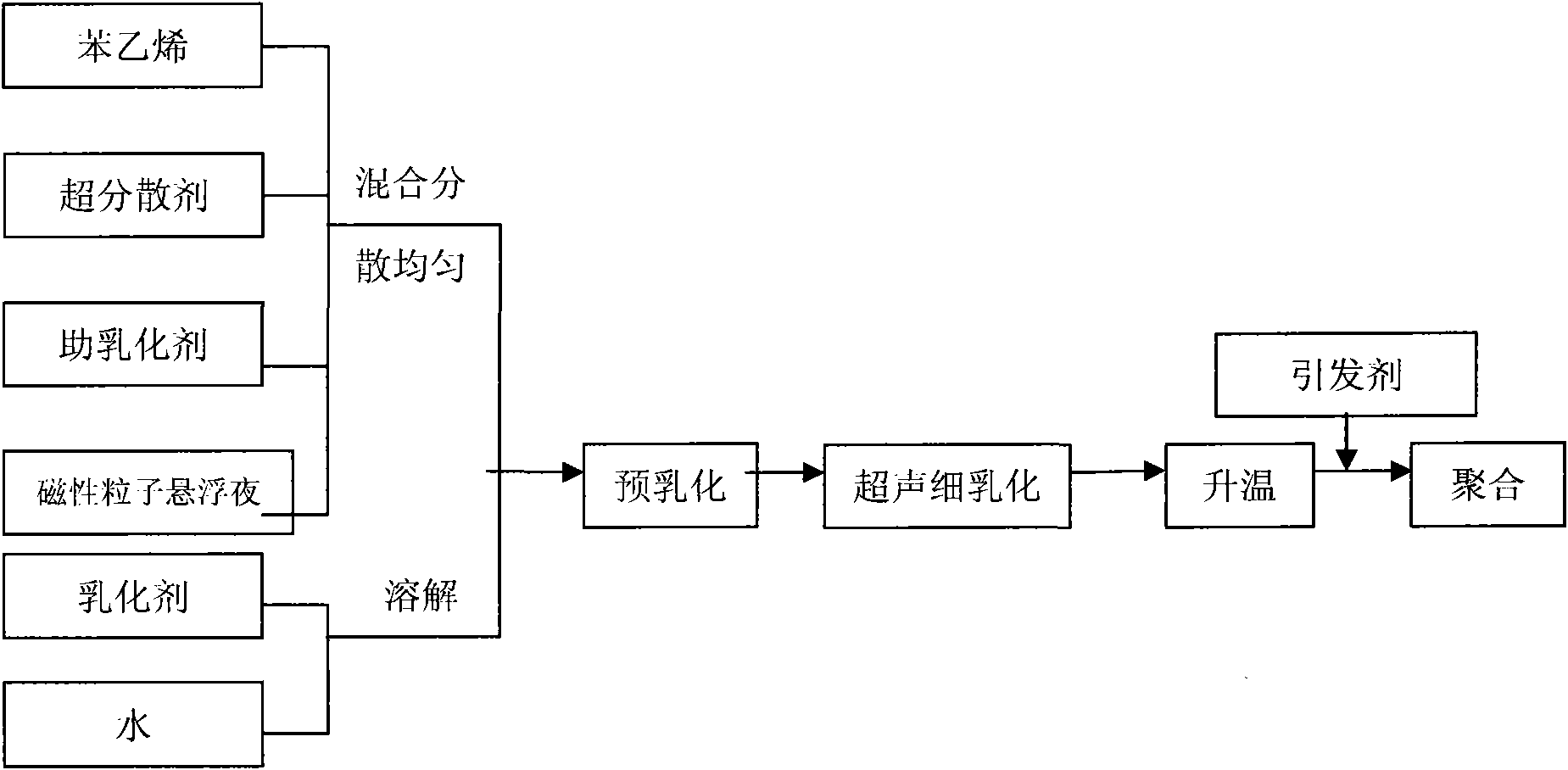

Method used

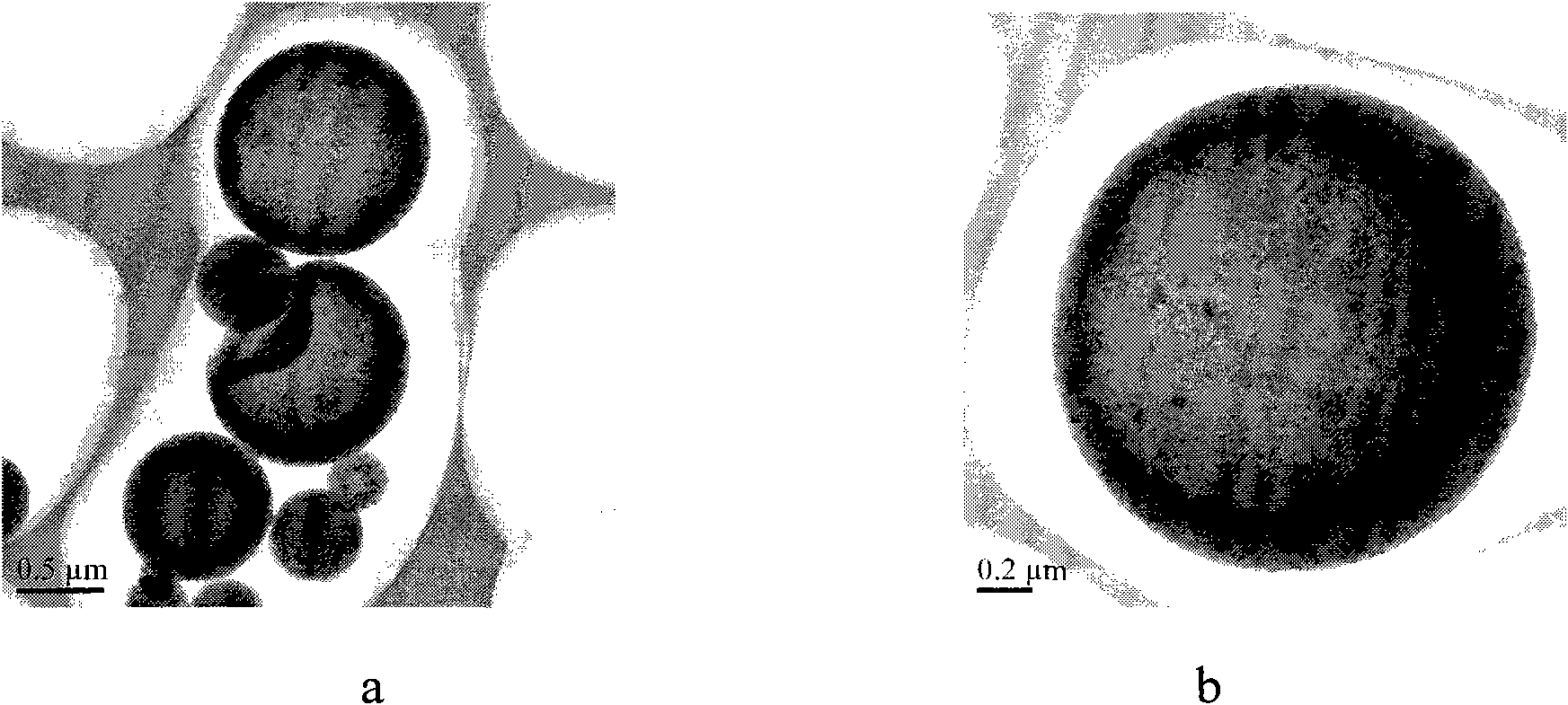

Image

Examples

Embodiment 1

[0029] Embodiment 1: miniemulsion polymerization prepares magnetic microcapsule

[0030] Mix and disperse 5g of ferric oxide and 50g of distilled water, put it into a container equipped with an electric stirrer, a condenser tube and a thermometer, stir and raise the temperature of the system; when the temperature rises to 70°C, add 2g of oleic acid and keep it warm for 40 minutes After pouring out the water, use n-heptane as a dispersant to disperse, and prepare a suspension with a magnetic particle content of 10%; add monomer styrene, Disperbyk-106 and paraffin to the suspension, and then ultrasonically dissolve the The magnetic particles are evenly dispersed in the monomer styrene to form an oil phase, wherein the ratio of monomer styrene: suspension: Disperbyk-106: paraffin wax is 10:2:1.5:0.6; the water phase is 1% Aqueous solution of sodium dodecyl sulfonate; mix the oil phase and water phase according to the mass ratio of 1:5, put them into a container with an electric s...

Embodiment 2

[0031] Embodiment 2: miniemulsion polymerization prepares magnetic microcapsule

[0032] Mix and disperse 5g of ferric oxide and 50g of distilled water, put it into a container equipped with an electric stirrer, a condenser and a thermometer, stir and raise the temperature of the system; when the temperature rises to 80°C, add 3g of oleic acid and keep it warm for 40 minutes ; After pouring out the water, use cyclohexane as a dispersant to disperse, and prepare a suspension with a magnetic particle content of 10%; add monomer styrene, Disperbyk-106 and cetyl alcohol to the above suspension, and then ultrasonicate for 5 Minutes uniformly disperse the magnetic particles in the monomer styrene to prepare the oil phase, wherein the monomer styrene:suspension:Disperbyk-106:hexadecanol mass fraction ratio is 10:2:1.0:0.6; the water phase is the concentration It is an aqueous solution of 1% sodium dodecylbenzene sulfonate; mix the oil phase and the water phase according to the mass r...

Embodiment 3

[0033] Embodiment 3: miniemulsion polymerization prepares magnetic microcapsule

[0034] Mix and disperse 5g of barium ferrite with 50g of distilled water, put it into a container equipped with an electric stirrer, a condenser tube and a thermometer, stir and raise the temperature of the system; when the temperature rises to 80°C, add 4g of oleic acid and keep it warm for 40 minutes ; After pouring out the water, use n-hexane as a dispersant to disperse, and prepare a suspension with a magnetic particle content of 10%; add monomer styrene, Disperbyk-108 and hexadecane to the above suspension, and then ultrasonic for 5 minutes The magnetic particles are uniformly dispersed in the monomer styrene to prepare an oil phase, wherein the monomer styrene:suspension:Disperbyk-108:hexadecane mass fraction ratio is 10:3:1.5:0.6; the water phase has a concentration of 0.5% aqueous solution of sodium dodecyl sulfonate; mix the oil phase and the water phase according to the mass ratio of 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com